Beruflich Dokumente

Kultur Dokumente

Casing Design Considerations

Hochgeladen von

Yougchu LuanOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Casing Design Considerations

Hochgeladen von

Yougchu LuanCopyright:

Verfügbare Formate

Casing design considerations

The objective of the casing design is to define a set of casing strings (casing scheme), capable of withstanding a variety of external and internal

pressures, thermal loads and loads related to the self-weight of the casing. These casing strings are subjected to time-dependent corrosion, wear and

possibly fatigue, which downrate their resistance to these loads during their service life.

Objectives of casing design

- protect from sloughing shales or moving salt formations;

- isolate the reservoirsfrom unwanted fluids

- protect fresh-water horizons;

- provide a means to handle kicks;

- conduit for produced fluid;

- conduit for drilling, logging and completion tools;

- provide a smooth conduit for future casing and tubing strings;

- support wellhead equipment and subsequent casing strings;

- provide a means of anchoring the blowout preventers and Xmas tree.

Casing strings are subjected to corrosion, wear and fatigue, which down rate their resistance to these loads during their service life. The interaction

between the casing strings - which may lead to annular pressure build-up or wellhead movement also merits attention.

Casing design information should be available at the wellsite, to ensure that the operating envelope remains within the design criteria.

Casing design steps

- collection of all the relevant data by a multi-disciplinary team

- selection of the casing scheme which is most cost-effective over the entire life cycle of the well (Casing/tubing represents 15% of the drilling

expenditure).

- definition of the various load cases to which each casing string is likely to be subjected.

- evaluation of the casing string to withstand the applied loads.

The interaction between the casing strings - which may lead e.g. to annular pressure build-up or wellhead movement - also merits attention.

Sequence of design criteria considerations

Burst

Collapse

Tension

Couplings

Multi-axial corrections

Cost

For pressure less than 8000 psi, biaxial corrections should always be applied. If pressure is greater than 8000-10000 psi, tri-axial analysis should be

performed.

Sequence for graphical design

Maximise the load

Minimise the backup

Calculate the resultant

Select the design factor

Calculate the design line

Casing catalogue specifications

Nominal diameter

For steel casing, drill pipe and tubing it is the OD of the tube.

For line pipe and fiberglass casing it is the ID of the tube

Grade:

Example: F25, H40, J or K50, L75, L or N 80, C90, C95, C100, C110, P105, P110, Q125, V150

The first letter doesnt mean anything specific except:

C: Corrosion (less strong more expensive but corrosion resistant)

C 100, C110 can also be used for H2S applications

N80 40 lbs/ft 5750 psi is 10 % cheaper than C75 40 lbs/ft 5390 psi

L: H2S application

HRC < 22

Same hardness cross-wall: No stress concentration. The difference between HRC inside and outside the pipe wall is less than 3.

J55 may be welded on the side

K55 seamless

Average Yield Stress = Minimum Yield Stress + 10000

Collapse

Based on D/t ratio, various collapse modes can be considered:

Yield collapse: loading the inside of the pipe to reach yield stress. No deformation

Plastic collapse: empirical

Transition collapse: made up by the API

Elastic collapse: theoretical calculation

Burst

2 equations available:

Barlow: thin wall cylinder

Lam: thick wall cylinder. To be used when D/t correspond to Yield collapse. this will give approx. 5% more strength.

Design factor:

Should account for wear and should not be the same for a vertical well followed by 2 days drilling vs a deviated well with 30 days drilling. Do not use

Spiral hard face stabs accross casings.

Das könnte Ihnen auch gefallen

- Test Procedure For Sand Wash SystemsDokument1 SeiteTest Procedure For Sand Wash SystemsYougchu LuanNoch keine Bewertungen

- Setting Up Drilling OfficesDokument2 SeitenSetting Up Drilling OfficesYougchu LuanNoch keine Bewertungen

- TCP Perforating ProgrammeDokument3 SeitenTCP Perforating ProgrammeYougchu LuanNoch keine Bewertungen

- Reporting Requirements - Drilling OperationsDokument2 SeitenReporting Requirements - Drilling OperationsYougchu Luan100% (1)

- Job Description - Technical AssistantDokument1 SeiteJob Description - Technical AssistantYougchu LuanNoch keine Bewertungen

- Job Description - Senior Drilling SupervisorDokument1 SeiteJob Description - Senior Drilling SupervisorYougchu Luan100% (1)

- Job Description - Technical Assistant DrillingDokument1 SeiteJob Description - Technical Assistant DrillingYougchu LuanNoch keine Bewertungen

- Solids Content - Mud TestingDokument1 SeiteSolids Content - Mud TestingYougchu LuanNoch keine Bewertungen

- Job Description - Drilling SuperintendentDokument1 SeiteJob Description - Drilling SuperintendentYougchu LuanNoch keine Bewertungen

- Job Description - Drilling AssistantDokument1 SeiteJob Description - Drilling AssistantYougchu LuanNoch keine Bewertungen

- 1 Problems Setting The Packer: Contingency ProceduresDokument1 Seite1 Problems Setting The Packer: Contingency ProceduresYougchu LuanNoch keine Bewertungen

- Sand Content - Mud TestingDokument1 SeiteSand Content - Mud TestingYougchu Luan100% (2)

- Mud PolicyDokument1 SeiteMud PolicyYougchu LuanNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- PH102Dokument2 SeitenPH102Shobhit ParkiNoch keine Bewertungen

- Rotary Kiln BurnerDokument5 SeitenRotary Kiln BurnerAllen de Guzman100% (1)

- ElecDokument40 SeitenElecakela_life100% (4)

- Smart Energy Coordination of Autonomous ResidentiaDokument13 SeitenSmart Energy Coordination of Autonomous ResidentiaAhmed SabriNoch keine Bewertungen

- Chemistry Practice QuestionsDokument12 SeitenChemistry Practice QuestionsMfanafuthi0% (1)

- Axpert MKS IV Off-Grid Inverter Selection GuideDokument1 SeiteAxpert MKS IV Off-Grid Inverter Selection GuideMax Hernandez RNoch keine Bewertungen

- An Introduction To Light-Front Dynamics For Pedestrians: 1 PreliminariesDokument36 SeitenAn Introduction To Light-Front Dynamics For Pedestrians: 1 PreliminariesBayer MitrovicNoch keine Bewertungen

- Abdul Rasheed (2019-Me-34) Thermodynamic AssignmentDokument6 SeitenAbdul Rasheed (2019-Me-34) Thermodynamic AssignmentAbdul Rasheed GhaziNoch keine Bewertungen

- MM435 - CDP-2 - Corrosion CellsDokument24 SeitenMM435 - CDP-2 - Corrosion CellsAbdul Ahad ShamsNoch keine Bewertungen

- FC45X-X Cummins Leroy GRDokument7 SeitenFC45X-X Cummins Leroy GRIsrael GomezNoch keine Bewertungen

- ME8512 - TE - AU Practical Students Individual QuestionDokument4 SeitenME8512 - TE - AU Practical Students Individual Questionsikkandar faizNoch keine Bewertungen

- TNB Iar 2020Dokument360 SeitenTNB Iar 2020yerio.dwiyantoNoch keine Bewertungen

- Manual Qrod PDFDokument17 SeitenManual Qrod PDFEzequiel GuerreroNoch keine Bewertungen

- Genset DataDokument12 SeitenGenset DatagebreNoch keine Bewertungen

- CombineDokument56 SeitenCombineRajagopal GanapathyNoch keine Bewertungen

- Diagnostic Study For Cement Mill OptimizationDokument9 SeitenDiagnostic Study For Cement Mill OptimizationHilmy MuhammadNoch keine Bewertungen

- New Generation PlanningDokument3 SeitenNew Generation PlanningSyed ArifNoch keine Bewertungen

- Advanced Motion Controls FC1010Dokument7 SeitenAdvanced Motion Controls FC1010Servo2GoNoch keine Bewertungen

- 32 Direct Acting Normally Closed Valve 17 MMDokument2 Seiten32 Direct Acting Normally Closed Valve 17 MMBiswanath LenkaNoch keine Bewertungen

- Gastron BDM Sarawak Summary 16.05.2023Dokument5 SeitenGastron BDM Sarawak Summary 16.05.2023yusuf mohd sallehNoch keine Bewertungen

- Chemistry: Long Exam 1Dokument4 SeitenChemistry: Long Exam 1Barbara BananaNoch keine Bewertungen

- GulfSea Turbine Oil Series PDFDokument2 SeitenGulfSea Turbine Oil Series PDFObydur RahmanNoch keine Bewertungen

- Flow Testing BrochureDokument12 SeitenFlow Testing BrochureImadNoch keine Bewertungen

- High Temperature Primary Batteries For Venus Surface MissionsDokument24 SeitenHigh Temperature Primary Batteries For Venus Surface MissionsEsau Hernandez CalosNoch keine Bewertungen

- Air Leak in Test of Esp ProcedureDokument5 SeitenAir Leak in Test of Esp Procedurenetygen1Noch keine Bewertungen

- 230L2M551 - Cement Mixing EquipmentDokument43 Seiten230L2M551 - Cement Mixing Equipmentyao nestorNoch keine Bewertungen

- Analisis Soalan Fizik Kertas 2 BHG A Trial SPM 2010Dokument3 SeitenAnalisis Soalan Fizik Kertas 2 BHG A Trial SPM 2010Norhazami HashimNoch keine Bewertungen

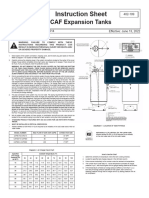

- Taco CAF Expansion Tank Install ManualDokument3 SeitenTaco CAF Expansion Tank Install ManualTEMPNoch keine Bewertungen

- CIAT Podplafonski MJLINEDokument30 SeitenCIAT Podplafonski MJLINEIgor SpasovicNoch keine Bewertungen

- TRIP To RP High Burden RelaysDokument2 SeitenTRIP To RP High Burden RelaysbyjuvcNoch keine Bewertungen