Beruflich Dokumente

Kultur Dokumente

Concrix - Bi-Component and High Performance

Hochgeladen von

ourebooksOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Concrix - Bi-Component and High Performance

Hochgeladen von

ourebooksCopyright:

Verfügbare Formate

MACROFIBER

Bi-component and

high performance

BINDING.

Trend

Both national and international regulations and requirements for fiber

concrete are constantly changing. These new developments point

clearly in the direction of innovative synthetic fibers featuring perfor-

mance characteristics equal to, or in excess of, steel mesh and steel

fibers and combine that with the benefits (no corrosion, no risk of inju-

ry) of synthetic fiber concrete.

Benefits

Synthetic fiber concrete features a

broad range of applications due to its

high flexural strength, proven post-crack

behaviour, and outstanding processibi-

lity. Optimized fiber dosages serve best

to satisfy quality and economic de-

mands.

Developing Concrix

All demanding requirements have been taken into account in the de-

velopment of Concrix. The result is a polyolefin based, internationally

patented, bi-component macrofiber consisting of a core and a shell.

Concrix displays high tensile strength simultaneously with high bond-

ing strength when added to the concrete matrix. The core material

features excellent tensile strength as a result of its high E-modulus.

Best bonding is achieved by the surrounding shell, featuring a em-

bossed surface and activating additives.

The embossed surface appearance, displaying each individual fiber,

was developed to optimize the bonding to the concrete matrix without

compromising the workability of fiber concrete. A large number of ex-

periments have been carried out to optimize fiber dosages and rheol-

ogy of fiber concrete. Concrix dosages up to 2 vol.% still feature high

concrete fluidity.

Features

Certified according to EN 14889-2

Concrix is compliant with all require-

ments under EN 14889-2 Fibers for

concrete part 2: polymer fibers for

system 1 (for load bearing concrete

structures, mortar and grout [table ZA.

1]) and therefore is suitable to com-

pletely substitute steel fibers (EN

14889-1).

Post-crack behaviour

By adding Concrix, concrete benefits from a significant improvement

in its post-crack behaviour exceeding, that of steel fiber concrete, and

fulfilling international requirements for shotcrete. The excellent values

with respect to the post-crack behaviour of Concrix-Fiber concrete

enable a broad and economic use in the tunnel respectively mining

area and offer a real alternative to high charged steel fiber concrete.

Comparison with other products

Concrix is decisively superior in direct

comparison with other macro synthetic

fibers available on the market. Current-

ly, fiber concretes with a dosage rate of

4,5 kg Concrix per m3 surpass marked-

ly the capacity of 30 kg steel fibers in

the crucial issues.

Further advantages of Concrix

Concrix-Fibers are alkali-resistant, rust resistant, pliable, and unlike

steel fibers, prevent injuries. Concrix is also more cost effective be-

cause it preserves equipment, such as mixers and pumps, from wear

and tear. The low specific weight of Concrix allows for smaller dos-

ages (vol%), yet higher numbers of fibers, resulting in a tighter net-

working and an improved fiber concrete behaviour. The fibers come

bundled to avoid lumps of bristles.

0

5

10

15

20

25

30

35

0 0.5 1 1.5 2 2.5 3 3.5 4

deflection [mm]

l

o

a

d

[

k

N

]

CONCRIX 4.5 kg/m3

Steelfibers 25 kg/m3

Macrofiber Competitor 1 4.5 kg/m3

Macrofiber Competitor 2 4.5 kg/m3

source: Empa, Dbendorf /CH

Benefits Fields of application

No corrosion

No risk of injury

More fibers per kilogram

Reduces wear and tear on machinery

Alkali resistant

Shorter construction time reducing

building costs

Shotcrete (tunnelling, mining etc.)

Prefabrication (tubbing, formed parts etc.)

Industrial floors

Foundation slabs / Basement walls

Traffic areas (streets, airports, port facilities etc.)

Water impermeable concretes

Bibliography:

Empa, Dbendorf / CH

VersuchsStollen Hagerbach AG, Flums / CH

Brugg Contec AG

Aachstrasse 11

CH-8590 Romanshorn

Tel: +41 71 466 12 12

Fax: +41 71 466 12 10

info@bruggcontec.com

www.bruggcontec.com

0

1

/

2

0

1

1

Das könnte Ihnen auch gefallen

- Reinforced Concrete Buildings: Behavior and DesignVon EverandReinforced Concrete Buildings: Behavior and DesignBewertung: 5 von 5 Sternen5/5 (1)

- Studying Flexural Behavior of Reinforced Fibrous Self-Compacted Concrete T - Beams Strengthened With CFRP SheetsDokument11 SeitenStudying Flexural Behavior of Reinforced Fibrous Self-Compacted Concrete T - Beams Strengthened With CFRP SheetsAarohiShirkeNoch keine Bewertungen

- Ceramics Science and Technology, Volume 4: ApplicationsVon EverandCeramics Science and Technology, Volume 4: ApplicationsRalf RiedelNoch keine Bewertungen

- Radtech Man (Fibre Rebar)Dokument48 SeitenRadtech Man (Fibre Rebar)pete0980Noch keine Bewertungen

- Self-healing Ceramic Matrix Composites: A MonographVon EverandSelf-healing Ceramic Matrix Composites: A MonographNoch keine Bewertungen

- Mani Project (Polymer)Dokument50 SeitenMani Project (Polymer)manienggNoch keine Bewertungen

- Advantages and applications of steel fibre reinforced concrete (SFRCDokument213 SeitenAdvantages and applications of steel fibre reinforced concrete (SFRChamsanram100% (3)

- Seminar Report On FRCDokument9 SeitenSeminar Report On FRCRakshith NNoch keine Bewertungen

- SES2DB464C8RGPO0U Use of Steel Fiber Reinforced Sprayed Concrete in The Final Lining of Conventionally ExcavateDokument8 SeitenSES2DB464C8RGPO0U Use of Steel Fiber Reinforced Sprayed Concrete in The Final Lining of Conventionally Excavatemoin4cuetNoch keine Bewertungen

- Highways Feb 2019Dokument4 SeitenHighways Feb 2019Scram PoyuNoch keine Bewertungen

- FRC Concrete FibresDokument8 SeitenFRC Concrete FibresKandasamy AsohanNoch keine Bewertungen

- Low Carbon Lining For Tunnelling Precast Segment - How Dramix® Fibre Reinforced Concrete Could Facilitate This AchievementDokument8 SeitenLow Carbon Lining For Tunnelling Precast Segment - How Dramix® Fibre Reinforced Concrete Could Facilitate This AchievementDeyuan GuoNoch keine Bewertungen

- RCC BendableDokument30 SeitenRCC BendableLak Chauhan50% (2)

- 2004 - Precast SFRC Elements From Material Proprieties To Structural ApplicationsDokument20 Seiten2004 - Precast SFRC Elements From Material Proprieties To Structural ApplicationsLúcio Barboza100% (1)

- Harshad Seminar PPT FRCDokument16 SeitenHarshad Seminar PPT FRCHarsh PuseNoch keine Bewertungen

- Study of High Stength Concrete With Steel Fiber ReinforcementDokument18 SeitenStudy of High Stength Concrete With Steel Fiber Reinforcementmanish kumar thakurNoch keine Bewertungen

- Dramix ShotcreteDokument13 SeitenDramix ShotcreteMiguel Eulufi VillenaNoch keine Bewertungen

- Retrofitting Using FRP LaminateDokument4 SeitenRetrofitting Using FRP LaminateVIVA-TECH IJRINoch keine Bewertungen

- Special Concrete and Concreting TechniquesDokument47 SeitenSpecial Concrete and Concreting TechniquesTesfayeNoch keine Bewertungen

- Datasheet: Product DescriptionDokument2 SeitenDatasheet: Product DescriptionbastopheNoch keine Bewertungen

- Concrete AssignmentDokument24 SeitenConcrete AssignmentPushpesh RanjanNoch keine Bewertungen

- CCC22 - FRC StructuresDokument14 SeitenCCC22 - FRC StructuresAliz JAMNoch keine Bewertungen

- Fibre Reinforce ConcreteDokument26 SeitenFibre Reinforce Concretekamanasish bhowmik100% (8)

- Introducing Fibre Reinforced ConcreteDokument26 SeitenIntroducing Fibre Reinforced ConcretePANKAJ AGNIHOTRINoch keine Bewertungen

- Sifcon ConcreteDokument10 SeitenSifcon ConcreteMostfa Seham0% (1)

- Ingles 01Dokument7 SeitenIngles 01Ruben Santos Nina MamaniNoch keine Bewertungen

- Fibre Reinforced ConcreteDokument19 SeitenFibre Reinforced ConcreteJethalal Champaklal Gada67% (3)

- Experimental Investigation of High Strength Precast Reinforced Concrete Walls Used (Vierendeel Truss Form)Dokument12 SeitenExperimental Investigation of High Strength Precast Reinforced Concrete Walls Used (Vierendeel Truss Form)emad mohamedNoch keine Bewertungen

- 2011 Form Finding Methodology For Force-Modelled Anticlastic Shells in Glass Fibre TRC Composites - Doi Engineering StructuresDokument9 Seiten2011 Form Finding Methodology For Force-Modelled Anticlastic Shells in Glass Fibre TRC Composites - Doi Engineering StructuresNina Iovita GheorghiesNoch keine Bewertungen

- Bendable Concrete: Properties and Applications of Engineered Cementitious Composite (ECCDokument30 SeitenBendable Concrete: Properties and Applications of Engineered Cementitious Composite (ECCNagesh Chitari83% (6)

- Use of Steel Fibre in m20 ConcreteDokument44 SeitenUse of Steel Fibre in m20 ConcretenemsharuNoch keine Bewertungen

- Project 0075Dokument9 SeitenProject 0075krishna reddyNoch keine Bewertungen

- Fiber Reinforced Concrete: Developments and Applications To BuildingsDokument10 SeitenFiber Reinforced Concrete: Developments and Applications To BuildingschkevinlyNoch keine Bewertungen

- Synthetic Fibers For Crack ControlDokument9 SeitenSynthetic Fibers For Crack ControlourebooksNoch keine Bewertungen

- Fibre Reinforced Concrete ThesisDokument6 SeitenFibre Reinforced Concrete ThesisHelpMeWriteMyEssayCambridge100% (2)

- Fiber-Reinforced - Concrete Power Point PresentationDokument27 SeitenFiber-Reinforced - Concrete Power Point Presentationusama anterNoch keine Bewertungen

- Fiberconcrete EnglishDokument9 SeitenFiberconcrete EnglishEdgar DimasNoch keine Bewertungen

- IJSR-Architectural Use of Precast Ultra High Performance ConcreteDokument3 SeitenIJSR-Architectural Use of Precast Ultra High Performance ConcreteAchal GargNoch keine Bewertungen

- Experimental Investigation on Cellular Lightweight Concrete BlocksDokument9 SeitenExperimental Investigation on Cellular Lightweight Concrete Blockss_omeone4usNoch keine Bewertungen

- 1 s2.0 S2352012421002605 MainDokument16 Seiten1 s2.0 S2352012421002605 MainVinkaNoch keine Bewertungen

- Structural Glass Fiber Reinforced Concrete For Slabs On GroundDokument8 SeitenStructural Glass Fiber Reinforced Concrete For Slabs On GroundYusuf TrunkwalaNoch keine Bewertungen

- Fibre Reinforced Concrete Design and ApplicationsDokument42 SeitenFibre Reinforced Concrete Design and ApplicationsSampath N100% (1)

- F INALDokument19 SeitenF INALBhushan JadhavNoch keine Bewertungen

- Fibre Reinforced ConcreteDokument45 SeitenFibre Reinforced Concretetusshaarpatil100% (6)

- 2003 - Biit2 Sri BushingsDokument7 Seiten2003 - Biit2 Sri Bushingsdevraj22Noch keine Bewertungen

- Technical Seminar On Fibre Reinforced Sprayed Concrete For SRMEGDokument42 SeitenTechnical Seminar On Fibre Reinforced Sprayed Concrete For SRMEGPatrick Pereira0% (1)

- Concrete Is The Most Widely Used Structural Material in The World With An AnnualDokument9 SeitenConcrete Is The Most Widely Used Structural Material in The World With An AnnualMisty Odom100% (1)

- Structural Glass Fiber Reinforced Concrete for Slabs on GroundDokument7 SeitenStructural Glass Fiber Reinforced Concrete for Slabs on GroundJayanth RaviNoch keine Bewertungen

- CBM Unit1 Part1Dokument26 SeitenCBM Unit1 Part1RajeshNoch keine Bewertungen

- Class Note Concrete Moddified 10 01 2069 PDFDokument63 SeitenClass Note Concrete Moddified 10 01 2069 PDFPratik Babu GhimireNoch keine Bewertungen

- To Investigate How Well Industrial Waste Polymer Fibre Performs Physically and Mechanically When Utilised in Concrete MixturesDokument6 SeitenTo Investigate How Well Industrial Waste Polymer Fibre Performs Physically and Mechanically When Utilised in Concrete MixturesIJRASETPublicationsNoch keine Bewertungen

- Composite Fabrication by Filament WindingDokument26 SeitenComposite Fabrication by Filament WindingAVI_ROHININoch keine Bewertungen

- Fibre Reinforced ConcreteDokument6 SeitenFibre Reinforced ConcreteFranklyn GenoveNoch keine Bewertungen

- Durability of SFRC PDFDokument10 SeitenDurability of SFRC PDFBehzadDastjerdyNoch keine Bewertungen

- 1 s2.0 S0950061822038296 MainDokument12 Seiten1 s2.0 S0950061822038296 MainMuhammad FiqriNoch keine Bewertungen

- Fiber Reinforced Concrete: Properties, Types, and ApplicationsDokument23 SeitenFiber Reinforced Concrete: Properties, Types, and ApplicationsSherif FodaNoch keine Bewertungen

- 2018 - FRC - Opportunities For Synthetic Fibre Reinforcement in Concrete TramlinesDokument10 Seiten2018 - FRC - Opportunities For Synthetic Fibre Reinforcement in Concrete TramlinesJuhász KPNoch keine Bewertungen

- Application of Textile Reinforced Concrete in PrecastDokument7 SeitenApplication of Textile Reinforced Concrete in PrecastShankar NarenNoch keine Bewertungen

- Fosroc Nitowrap Carbon Fibre SheetDokument4 SeitenFosroc Nitowrap Carbon Fibre Sheetalexcus1539Noch keine Bewertungen

- Ijs DR 191415Dokument11 SeitenIjs DR 191415Ricky RickxNoch keine Bewertungen

- History of The Development of Cement and Concrete (Non-HydraulicDokument2 SeitenHistory of The Development of Cement and Concrete (Non-HydraulicourebooksNoch keine Bewertungen

- Introduction To FRCDokument3 SeitenIntroduction To FRCourebooksNoch keine Bewertungen

- Equivalent Load ConceptDokument1 SeiteEquivalent Load ConceptourebooksNoch keine Bewertungen

- Early Age Cracking Tests PDFDokument15 SeitenEarly Age Cracking Tests PDFourebooksNoch keine Bewertungen

- IRC Publications Page 3Dokument1 SeiteIRC Publications Page 3ourebooksNoch keine Bewertungen

- Sky ScapperDokument1 SeiteSky ScapperourebooksNoch keine Bewertungen

- IRC Publications Page 2Dokument1 SeiteIRC Publications Page 2ourebooksNoch keine Bewertungen

- Astm C 1581Dokument1 SeiteAstm C 1581ourebooks0% (1)

- Reinforced Concrete Text BookDokument1 SeiteReinforced Concrete Text BookourebooksNoch keine Bewertungen

- IRC PublicationsDokument1 SeiteIRC PublicationsourebooksNoch keine Bewertungen

- Guyed ChimneyDokument1 SeiteGuyed ChimneyourebooksNoch keine Bewertungen

- Yield Line PatternDokument1 SeiteYield Line PatternourebooksNoch keine Bewertungen

- First Floor DisplacementsDokument1 SeiteFirst Floor DisplacementsourebooksNoch keine Bewertungen

- Rectilinear MotionDokument1 SeiteRectilinear MotionourebooksNoch keine Bewertungen

- Engineering VibrationsDokument1 SeiteEngineering VibrationsourebooksNoch keine Bewertungen

- Mechanical VibrationsDokument1 SeiteMechanical VibrationsourebooksNoch keine Bewertungen

- Ring TestDokument1 SeiteRing TestourebooksNoch keine Bewertungen

- Mathematical Model of Human BeingDokument1 SeiteMathematical Model of Human BeingourebooksNoch keine Bewertungen

- Tall Structure PDFDokument1 SeiteTall Structure PDFourebooksNoch keine Bewertungen

- Tall StructureDokument1 SeiteTall StructureourebooksNoch keine Bewertungen

- Characterization of The Toughness of FRC Using Load CMOD ResponseDokument14 SeitenCharacterization of The Toughness of FRC Using Load CMOD ResponseourebooksNoch keine Bewertungen

- Mode ShapesDokument1 SeiteMode ShapesourebooksNoch keine Bewertungen

- Full Page PhotoDokument1 SeiteFull Page PhotoourebooksNoch keine Bewertungen

- MDOFDokument1 SeiteMDOFourebooksNoch keine Bewertungen

- FTMDokument1 SeiteFTMourebooksNoch keine Bewertungen

- Ground Floor Slab and BeamsDokument1 SeiteGround Floor Slab and BeamsourebooksNoch keine Bewertungen

- Influence of Bending Test Configuration On Cracking Behavior of FRC FullDokument9 SeitenInfluence of Bending Test Configuration On Cracking Behavior of FRC FullourebooksNoch keine Bewertungen

- Frame AnalysisDokument1 SeiteFrame AnalysisourebooksNoch keine Bewertungen

- 48 M ChomneyDokument1 Seite48 M ChomneyourebooksNoch keine Bewertungen

- 99 M Chimney GermanyDokument1 Seite99 M Chimney GermanyourebooksNoch keine Bewertungen

- Paper IndustryDokument8 SeitenPaper IndustryBasil BabymNoch keine Bewertungen

- Ballou, R. - Transport FundamentalsDokument22 SeitenBallou, R. - Transport FundamentalsGhani RizkyNoch keine Bewertungen

- Chapter 20 - PPT OutlineDokument5 SeitenChapter 20 - PPT OutlineJanice TangNoch keine Bewertungen

- Recycled Aggregates Paper PresentationDokument26 SeitenRecycled Aggregates Paper PresentationManoj Prince100% (2)

- EngDokument12 SeitenEngelangandhiNoch keine Bewertungen

- Mol ReportDokument86 SeitenMol ReportAyesha KhanNoch keine Bewertungen

- Classification of Building OccupanciesDokument24 SeitenClassification of Building OccupanciesMelanie67% (3)

- ADokument2 SeitenAAGNALDOJULIONoch keine Bewertungen

- A+ Woodwork & Design Contact ListDokument15 SeitenA+ Woodwork & Design Contact ListDeepika-deepix AroraNoch keine Bewertungen

- Method of Statment For Welding of Carbon Steel Pipes Dks-mst-c11-001 Rev 1Dokument17 SeitenMethod of Statment For Welding of Carbon Steel Pipes Dks-mst-c11-001 Rev 1Sherief Abd El Baky83% (12)

- TECSYSDokument25 SeitenTECSYSJenny QuachNoch keine Bewertungen

- NW Clayton Livable Centers Initiative UpdateDokument45 SeitenNW Clayton Livable Centers Initiative UpdatecityplannermorganNoch keine Bewertungen

- Special Mission Aircraft Briefing: Air Ambulance Configurations for Hawker and Beechcraft ModelsDokument22 SeitenSpecial Mission Aircraft Briefing: Air Ambulance Configurations for Hawker and Beechcraft ModelsBernardoNoch keine Bewertungen

- DPW Series Profile Wrapping Application HeadDokument2 SeitenDPW Series Profile Wrapping Application HeadNordson Adhesive Dispensing SystemsNoch keine Bewertungen

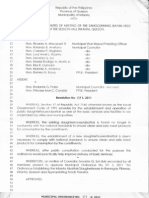

- Municipal Ordinance #7Dokument4 SeitenMunicipal Ordinance #7eabandejas973100% (1)

- Legrand Cable Lighting & Data Trunking TechnicalDokument35 SeitenLegrand Cable Lighting & Data Trunking TechnicalboltgingerkoppyNoch keine Bewertungen

- MRP Vs DDMRPDokument9 SeitenMRP Vs DDMRPWilyMorenoRojas100% (1)

- Cement-Mortar Lined Steel Pipe SpecDokument39 SeitenCement-Mortar Lined Steel Pipe SpecMohamed AhmedNoch keine Bewertungen

- Sport Aviation Abr-1975Dokument92 SeitenSport Aviation Abr-1975laerciofilho100% (1)

- Procurement StandardsDokument13 SeitenProcurement StandardssafrancooolNoch keine Bewertungen

- Holy Name Cathedral Zoning AppDokument119 SeitenHoly Name Cathedral Zoning AppDave MatthewsNoch keine Bewertungen

- ForgingDokument50 SeitenForgingdeepakr93100% (1)

- Compliance Matrix To Repair Station (Normativa)Dokument42 SeitenCompliance Matrix To Repair Station (Normativa)Eduardo ColmeneroNoch keine Bewertungen

- Oil & Gas Pipeline - 1 PDFDokument21 SeitenOil & Gas Pipeline - 1 PDFAshif IqubalNoch keine Bewertungen

- Ekta 12345Dokument12 SeitenEkta 12345Vishal ParasharNoch keine Bewertungen

- Dimensiones Pernos de Anclaje PEIKKO.Dokument6 SeitenDimensiones Pernos de Anclaje PEIKKO.j-balderasNoch keine Bewertungen

- Engineering Materials: (Hi) Wrought IronsDokument1 SeiteEngineering Materials: (Hi) Wrought Ironsyashvirsingh21Noch keine Bewertungen

- STEEL FRAMING SYSTEMSDokument28 SeitenSTEEL FRAMING SYSTEMSSeason Ch'ngNoch keine Bewertungen

- BN Islander BrochureDokument16 SeitenBN Islander BrochureMF84Noch keine Bewertungen

- Tips For Avoiding Crane Runway Problems PDFDokument25 SeitenTips For Avoiding Crane Runway Problems PDFLCSNoch keine Bewertungen

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsVon EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNoch keine Bewertungen

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentVon EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNoch keine Bewertungen

- Guidelines for the Management of Change for Process SafetyVon EverandGuidelines for the Management of Change for Process SafetyNoch keine Bewertungen

- Guidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisVon EverandGuidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisNoch keine Bewertungen

- Produced Water Treatment Field ManualVon EverandProduced Water Treatment Field ManualBewertung: 4.5 von 5 Sternen4.5/5 (5)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationVon EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationBewertung: 4 von 5 Sternen4/5 (18)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationVon EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNoch keine Bewertungen

- Nuclear Energy in the 21st Century: World Nuclear University PressVon EverandNuclear Energy in the 21st Century: World Nuclear University PressBewertung: 4.5 von 5 Sternen4.5/5 (3)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksVon EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksBewertung: 5 von 5 Sternen5/5 (1)

- Chemical Process Safety: Learning from Case HistoriesVon EverandChemical Process Safety: Learning from Case HistoriesBewertung: 4 von 5 Sternen4/5 (14)

- Guidelines for Developing Quantitative Safety Risk CriteriaVon EverandGuidelines for Developing Quantitative Safety Risk CriteriaNoch keine Bewertungen

- Guidelines for Siting and Layout of FacilitiesVon EverandGuidelines for Siting and Layout of FacilitiesNoch keine Bewertungen

- Perfume Engineering: Design, Performance and ClassificationVon EverandPerfume Engineering: Design, Performance and ClassificationBewertung: 4 von 5 Sternen4/5 (5)

- Guidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsVon EverandGuidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsNoch keine Bewertungen

- Bow Ties in Risk Management: A Concept Book for Process SafetyVon EverandBow Ties in Risk Management: A Concept Book for Process SafetyNoch keine Bewertungen

- Well Control for Completions and InterventionsVon EverandWell Control for Completions and InterventionsBewertung: 4 von 5 Sternen4/5 (10)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersVon EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNoch keine Bewertungen

- Robotics: Designing the Mechanisms for Automated MachineryVon EverandRobotics: Designing the Mechanisms for Automated MachineryBewertung: 4.5 von 5 Sternen4.5/5 (8)

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesVon EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNoch keine Bewertungen

- Recognizing and Responding to Normalization of DevianceVon EverandRecognizing and Responding to Normalization of DevianceNoch keine Bewertungen

- Process Plant Equipment: Operation, Control, and ReliabilityVon EverandProcess Plant Equipment: Operation, Control, and ReliabilityBewertung: 5 von 5 Sternen5/5 (1)

- Guidelines for Engineering Design for Process SafetyVon EverandGuidelines for Engineering Design for Process SafetyNoch keine Bewertungen