Beruflich Dokumente

Kultur Dokumente

Hydro Forming

Hochgeladen von

Arjun SivaprasadCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Hydro Forming

Hochgeladen von

Arjun SivaprasadCopyright:

Verfügbare Formate

1

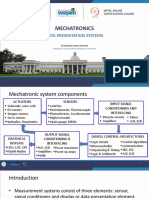

ADVANCES IN HYDROFORMING

TABLE OF CONTENTS

SeminarsTopics.com

LIST OF FIGURES

Fig.1 Hydro formed handle bar ..4

Fig.2 Hydro formed T-junction ............4

Fig.3 Sheet hydro forming 5

Fig.4 Tube hydro forming ............

Fig.5 Stre!!e! in Hydoformed com"onent ..#

Fig. $enefit! of Hydroforming .....11

Fig.# Forming %imit &iagram ....12

Fig.' Schematic &iagram of Tube Hydro forming ( )roce!! *ontrol 14

Fig.+ ,""lication! of Hydroforming .15

Fig.1- )art made u!ing .ariform )roce!! .1+

1

2

ADVANCES IN HYDROFORMING

Fig.11 Setu" for Hammering ..21

Fig.12 Hammering *ycle .22

Fig.13 )art made by Hammering ....24

Fig.14 *on/entional 0ethod of Hydroforming ....2

Fig.15 )re-)re!!uri1ing 0ethod of Hydroforming ....2#

1. INTRODUCTION

Hydro forming i! a high-"re!!ure deformation "roce!! that !ha"e!

metal !heet! or tube! into a "redefined geometry by u!ing a fluid under

high "re!!ure. Hydro forming i! !imilar to the con/entional dee"-

dra2ing techni3ue 2ith a counter-mould. The !"ecific difference from

the con/entional method i! that a fluid i! u!ed in!tead of a die to forming

into final !ha"e. Thi! deformation "roce!! re3uire! a""lication of fluid

"re!!ure! u" to 4--- bar! de"ending on the !i1e of the com"onent.

,! the automobile indu!try !tri/e! to ma4e car lighter5 !tronger

and more fuel efficient5 it 2ill continue to dri/e hydro forming

a""lication!. Some automobile "art! !uch a! !tructural cha!!i!5

in!trument "anel beam5 engine cradle! and radiator clo!ure! are

becoming !tandard hydro formed "art!.

6ecently hydro forming 2a! u!ed for manufacturing of clad "i"e

u!ed in oil and chemical indu!try. The ca"ability of hydro forming can

be more fully u!ed to create com"licated "art!. 7!ing a !ingle hydro

2

3

ADVANCES IN HYDROFORMING

formed item to re"lace !e/eral indi/idual "art! eliminate 2elding5 hole!5

"unching etc... Hydro forming !im"lifie! a!!embly and reduce in/entory.

The "roce!! i! 3uite !im"le - a blan4 2ith a clo!ed-form5 !uch a! a

cylinder5 i! internally "re!!uri1ed u!ing fluid. The fluid i! fre3uently

2ater. The a""lied "re!!ure i! u!ually in the range '--45- 0)a. 8t!

re!ultant "la!tic e9"an!ion i! confined in a die of the de!ired !ha"e.

2. HYDROFORMING

Hydroforming i! a co!t-effecti/e 2ay of !ha"ing malleable metal!

!uch a! aluminum or bra!! into !tructurally !tiff and !trong "iece!. :ne

of the large!t a""lication! of hydro forming i! the automoti/e indu!try5

2hich ma4e! u!e of the com"le9 !ha"e! "o!!ible by hydro forming to

"roduce !tronger5 lighter5 and more rigid body !tructure! for /ehicle!.

Thi! techni3ue i! "articularly "o"ular 2ith the high-end !"ort!

car indu!try and i! al!o fre3uently em"loyed in the !ha"ing of aluminum

tube! for bicycle frame!.

Hydro forming allo2! com"le9 !ha"e! 2ith conca/itie! to be

formed5 2hich 2ould be difficult !tandard !olid die !tam"ing. Hydro

formed "art! can often be made 2ith a higher !tiffne!! to 2eight ratio and

at a lo2er "er unit co!t.

Thi! "roce!! i! ba!ed on the 1+5-! "atent for hydra molding by Fred

%euthe!!er. 8t 2a! originally u!ed in "roducing 4itchen !"out!. Thi! 2a!

3

4

ADVANCES IN HYDROFORMING

done becau!e in addition to the !trengthening of the metal5 hydramolding

al!o "roduced le!! ;grainy; "art!5 allo2ing for ea!ier metal fini!hing.

Fig 1 Hydro formed handle bar Fig 2 Hydro formed T-junction

3. CLASSIFICATION OF HYDOFORMING TECHNIQUES

Hydroforming i! broadly cla!!ified into !heet and tube hydroforming.

Sheet hydroforming i! further cla!!ified into !heet hydroforming 2ith a

"unch <SHF-)= and !heet hydroforming 2ith a die <SHF-&=5 de"ending

on 2hether a male <"unch= or a female <die= tool 2ill be u!ed to form the

"art. SHF-& i! further cla!!ified into hydroforming of !ingle blan4! and

double blan4!5 de"ending on the number of blan4! being u!ed in the

4

5

ADVANCES IN HYDROFORMING

forming "roce!!

Fig.3 Sheet hydro forming <Source> ?@=

5

ADVANCES IN HYDROFORMING

8n tube hydroforming tube i! loaded into hydoroforming die! and

the "re!! clo!e!. The !ealing rod engage! the "art !ealing the end! and

fill! the tube 2ith 2ater. )re!!ure in!ide the tube increa!e!5 no2 the

!ealing rod i! "u!he! the tube into the die and the internal "re!!ure i!

ram"ed to ma9imum /alue. The hydroformed tube ta4e! the !ha"e of the

mould. Final "art i! remo/ed from the mould.

Fig.4 Tube hydro forming <Source> ?@=

#

ADVANCES IN HYDROFORMING

4. BENEFITS OF HYDRO FORMING

4.1 Better degree ! de!r"#t$% ! t&e !r"ed '#rt

$y a""lying a uniform force to the metal !heet5 the fluid !ha"e! it

into the form of the tool. 8n thi! "roce!!5 a uniform di!tribution of !heet

thic4ne!!e! i! achie/ed5 2hich allo2! for ma9imum degree! of

deformation. ,bru"t change! in !tre!! are a/oided A a factor that en!ure!

high dimen!ional accuracy and reduce! the tendency of the material to

return to it! original !i1e and !ha"e 2hen the a""lied load i! remo/ed.

C%(e%t$%#) dee'*dr#+$%g H,dr!r"ed +$t& t&e FB2-

!trong local thinning of the

material

inhomogeneou! di!tribution of

material thic4ne!!e!

le!! internal !tre!! of the formed

"art

le!! internal !tre!! and le!! tendency

to return to it! original !ha"e

homogeneou! !trength and le!!

amount of 2a!te

high dimen!ional accuracy

Fig.5 Stre!!e! in Hydoformed com"onent

#

'

ADVANCES IN HYDROFORMING

4.2 Gd S.r!#/e F$%$0&

Since the metal !heet i! deformed u!ing a "re!!uri1ed fluid in!tead of

a con/entional dee"-dra2ing die5 the !urface i! not in direct contact 2ith

any tool that may lead to !urface damage. 8n the hydroforming "roce!!5 the

metal !heet only come! into contact 2ith the tool 2hen the ma9imum

re3uired forming "re!!ure i! reached. Thi! re!ult! in e9cellent !urface

fini!h of the formed "art!.

4.3 U0e ! V#r$.0 E%g$%eer$%g M#ter$#)0

The hydroforming "roce!! allo2! you to u!e the com"lete !"ectrum

of all ductile and malleable material!. Bo matter if you are u!ing 0tee)

0&eet01 0t#$%)e00 0tee)1 !"ecial alloy!5 aluminum5 co""er5 bra!! or titan> for

all of them5 o"timum degree! of deformation can be achie/ed. 0etal !heet

thic4ne!!e! range from -.-5 to mm. S"ecifically for /ery thin metal

!heet!5 the "o!!ibilitie! of hydroforming are far !u"erior to tho!e of

con/entional forming techni3ue!

4.4 S#($%g0 $% t)$%g /0t0 .' t 234

%o2 tooling co!t! are a great ad/antage of the hydroforming "roce!!

u!ing the Form $alancer. Tooling co!t! are reduced to 5-C by the fact

alone that only the negati/e molding tool i! needed. Further !a/ing! are

generated by no longer needing hold-do2n de/ice! and guide 2ay !y!tem!.

&ue to the "o!!ibilitie! of forming com"le9 geometrie! 2ith only one tool5

u"!tream machining o"eration! can often be omitted5 2hich in mo!t ca!e!

reduce! tooling co!t! to only 2-C com"ared to tho!e of con/entional dee"-

dra2ing tool!.

'

+

ADVANCES IN HYDROFORMING

4.- Red./t$% $% +e$g&t

,utoma4er! continuou!ly !tri/e to reduce motor /ehicle ma!!5

mainly for efficiency and en/ironmental rea!on! !uch a! im"ro/ing fuel

efficiency and reducing emi!!ion!. Ho2e/er5 a! they reduce /ehicle

2eight5 they mu!t try to a/oid com"romi!ing other im"ortant criteria5 !uch

a! !trength and energy management. They loo4 for technologie!5

techni3ue!5 and "roce!!e! that !ati!fy the!e /ariou! need!5 to 2hich

hydroforming i! the an!2er. ,l!o the "roce!! and functional characteri!tic!

need to be maintained. 8f a de!ign engineer change! a "art5 he ha! to thin4

about ho2 2ill the manufacturing engineer! ma4e the ne2 "artD Ho2 2ill

the line 2or4er! join the /ariou! "art! to ma4e a!!emblie!D Ehen fini!hed5

2ill e/erything 2or4 a! intendedD ,n!2er! to all thi! 3ue!tion! in

Hydroforming.

H,d!r"ed (er0.0 St#"'ed C"'%e%t0

+

1-

ADVANCES IN HYDROFORMING

0uch of a /ehicleF! 2eight i! in the !tructural frame5 and mo!t frame! are

made from !teel. The e9ce"tion i! aluminum52hich i! u!ed in !ome

automobile!.

C%/e't

M#00

56g7

8e)d Le%gt&

5""7

9er!r"#%/e Fre:A!t

L#d$%g

Stam"ed 23.- 45+15

6ed !cale !et to 1.- 9

material !trength

Hydroformed 2-.+ 35+#5

6ed !cale !et to 1.- 9

material !trength

*hange -2.1 -+4-

*om"ared to a traditional !tam"ed automoti/e "art5 a !imilar

tubular com"onent ha! le!! ma!! and re3uire! le!! 2elding. 8n thi!

ca!e5 the reduction! 2ere more than + "ercent ma!! and 1+

"ercent in 2eld length.

4.; Ne#r), .%)$"$ted +#)) T&$/6%e00 (#r$#t$%0

1-

11

ADVANCES IN HYDROFORMING

The 2all thic4ne!! can be adju!ted any2here along the "art bet2een

!ome "redetermined minimum and ma9imum thic4ne!!5 allo2ing a nearly

infinite combination of thic4ne!! 1one!. Thi! le/el of de!ign freedom

enable! de!ign engineer! to fine-tune the "art to achie/e a de!ired load

re!"on!e. .ariable-2all technology i! not limited to round cro!! !ection!G

it can be u!ed to manufacture mo!t !ymmetric !ha"e! 2ithout any

"o!tforming o"eration!. Heat treatment add! e/en more /er!atility to the!e

!tructure!5 im"arting "ro"ertie! that range from tho!e of !tri" to fully cold-

2or4ed !teel. Finally5 it can be beneficial in many nonautomoti/e

a""lication! a! 2ell.

Fig. $enefit! of Hydroforming

-. FORMING LIMIT DIAGRAM

11

12

ADVANCES IN HYDROFORMING

&uring hydro forming "roce!! failure occur! due to thinning5 thi!

i! due to the e9ce!!i/e deformation in a gi/en region. , 3uic4 and

economical analy!i! of deformation in a forged "art i! analy1ed from

forming limit diagram. The !heet i! deformed5 con/erting circle! in to

elli"!e5 and the di!torted "attern i! then mea!ured and e/aluated.

6egion! 2here the area ha! e9"anded are location! of !heet thinning

6egion! 2here area ha! contracted ha/e undergone !heet thic4ening.

7!ing the elli"!e on the deformed grid5 the major <Strain! in the

direction of larger radiu!= and a!!ociated minor !train! <Strain!

"er"endicular to the major= can be determined for /ariety of location!

and /alue! can be "lotted on the forming limit diagram. 8f both major

and minor !train! are "o!iti/e deformation i! 4no2n a! !tretching5 and

thinning 2ill "o!!ible.

Fig.# Forming %imit &iagram

12

13

ADVANCES IN HYDROFORMING

;. HYDROFORMING 9ROCESS CONTROL

, ty"ical hydro forming !y!tem 2ould include a "re!! ca"able of

de/elo"ing nece!!ary force! to clam" the die /al/e! together 2hen

internal "re!!ure act! on fluidH a high "re!!ure 2ater !y!tem to inten!ify

2ater "re!!ure for forming com"onent5 loo4ing including aerial cylinder

and "unche!5 de"ending on com"onent and a control !y!tem for "roce!!

monitoring.

Since the entire "roce!! of o"eration ta4e! "lace in!ide a clo!ed

die5 one cannot !ee 2hat actually ha""en! during forming. Therefore the

controller "lay! a /ital role in di!"laying5 monitoring and controlling the

different "arameter!.

13

14

ADVANCES IN HYDROFORMING

Fig.' Schematic &iagram of Tube Hydro forming and )roce!! *ontrol

14

15

ADVANCES IN HYDROFORMING

<. A99LICATIONS

,lmo!t any indu!try can benefit from the ad/antage! of the

hydroforming "roce!!. ,gain and again com"anie! are faced 2ith the

challenge of !imultaneou!ly achie/ing both lo2er o"erating co!t! and

inno/ati/e !olution! for e/olutionary ad/ance! of their "roduct!. :ur high-

"re!!ure forming technology offer! attracti/e "o!!ibilitie! in term! of "rice-

"erformance ratio and manufacturing time. Hydroforming find! it!

a""lication in follo2ing indu!trie!>

,utomoti/e indu!try

,ero!"ace indu!try

0edicine technology

Ilectronic a""liance!

Heating ( air conditioning

,griculture indu!try

<a= <b= <c=

Fig.+ ,""lication! of Hydroforming

15

1

ADVANCES IN HYDROFORMING

2. ADVANCES IN HYDROFORMING

8n recent year! hydroforming ha! become a commonly u!ed method

of tube e9"an!ion for many a""lication!5 !uch a! automoti/e cha!!i!

frame!5 e9hau!t manifold "i"ing connector!5 and air-conditioning !y!tem

com"onent!. $ecau!e hydroforming u!e! 2ater under high "re!!ure to

e9"and the tube or "i"e from the in!ide5 and 2ater can ta4e any !ha"e5 itJ!

a /er!atile "roce!! and i! !uitable for forming com"le95 !ingle-"iece

com"onent!.

&uring the la!t decade5 indu!try ha! !een da2n of hydroforming a!

an alternati/e for !tam"ing and /ariou! forming the rea!on for thi! are it!

ad/antage! and the un"recedented re!earch 2or4 done in im"ro/ing the

techni3ue! of hydroforming. Some of the ne2 techni3ue! are>

.ariform "roce!! or )re!!ure !e3uencing

Hammering

)re-)re!!uri1ing

0anufacturing of *lad )i"e!

1

1#

ADVANCES IN HYDROFORMING

2.1 V#r$!r" 'r/e00 r 9re00.re Se=.e%/$%g

)re!!ure Se3uence Hydroforming <)SH= i! a "atented tube

hydroforming "roce!! that utili1e! lo2 internal fluid "re!!ure to !u""ort the

tube 2hile the die clo!e!. :nce clo!ed the majority of the "art "rofile ha!

been formed. ,t thi! "oint the internal "re!!ure i! increa!ed to loc4 in the

form and "ro/ide bac4u" for "unching hole!.

Hole !i1e can range from a! !mall a! 2 time! material thic4ne!! to a!

large a! 5- mm K 2-- mm. Hole! can be e9truded or clean "ierced5 and

"ractically any !ha"e including round5 !lot5 !3uare5 he9agon5 or

rectangular. The re!ulting material !lug i! ty"ically "u!hed bac4 out of the

2ay and left attached in!ide the tube5 though there are techni3ue! a/ailable

to remo/e them 2hen re3uired.

)re!!ure Se3uence Hydroforming <)SH= i! com"atible 2ith mo!t

metal!5 if it can be made into a tube )SH can form it. The "roce!! that

normally e!tabli!he! the re3uired material elongation i! the "rebending

o"eration. )SH ha! "ro/en "roce!! com"atibility 2ith High Strength !teel

u" to +- 0)a 7TS5 &ual )ha!e5 and T68) !teel!. 8n addition to carbon

!teel the )SH "roce!! ha! been u!ed to form both 5--- and --- !erie!

aluminum5 and numerou! grade! of !tainle!! !teel.

1#

1'

ADVANCES IN HYDROFORMING

)re!!ure Se3uence Hydroforming <)SH= re!ha"e! the tube cro!!

!ection into the re3uired "rofile 2ithout !tretching the material. The tube

material thic4ne!! di!tribution found after hydroforming i! the !ame a! that

"re!ent in the bent tube. )re!!ure Se3uence Hydroforming <)SH= re!ha"e!

the tube 2hile the die clo!e!. :nce the die i! com"letely clo!ed the tube

ha! been forced to ta4e the !ha"e of the die ca/ity 2ithout re3uiring the

material to e9"and. High )re!!ure Hydroforming fir!t clo!e! the die on an

under!i1ed tube and then utili1e! high internal fluid "re!!ure to e9"and the

tube to fill the die ca/ity. The "art to "art or floor to floor cycle time for

)re!!ure Se3uence Hydroforming i! in the range of 1# !econd! for a !mall

"art !uch a! an 8n!trument )anel $eam to 24 !econd! for a large "art !uch

a! a roof rail or !tructural member.

The )re!!ure Se3uence Hydroform <)SH= "roce!! u!e! a com"letely

different mechani!m than H)H to form the corner!. 8n the )SH "roce!!5 the

tool !to"! before it i! com"letely clo!ed on the tube5 thi! i! referred to a!

the "refill height. The tool d2ell! at thi! "oint a! the tube i! then filled 2ith

fluid and lightly "re!!uri1ed. The die i! then fully clo!ed 2hile the tube i!

!u""orted by the "re"re!!ure. 7!ing thi! !u""ort )SH form! the cro!!

!ection corner! 2hile the die i! clo!ing under "re"re!!ure.

)re!!ure Se3uence Hydroforming i! a dimen!ionally !table and

robu!t "roce!!. )roduct feature! that are "roduced in the hydroform tool are

ty"ically /ery !table a! the entire "art "rofile and all "iercing i! com"leted

in a !ingle ca/ity.

1'

1+

ADVANCES IN HYDROFORMING

Se3uencing the "re!!ure "re/ent! "inching the material in the die. ,!

"art com"le9ity continue! to increa!e5 in order to minimi1e "art5 containing

the tubular blan4 in!ide the die ca/ity become! more difficult. ,n

im"ro"erly contained blan4 can ea!ily become "inched bet2een the die

hal/e!5 leading to an im"ro"er fill and "erha"! ru"ture. 8t al!o eliminate!

the need for "o!thydroforming "roce!!e! !uch a! annealing and 2a!hing.

7!ing the )SH "roce!!5 tube corner radii are formed in the bending mode

beyond the yield limit of the ba!e material5 rather than in the ten!ile mode

reached during con/entional high-"re!!ure hydroforming.

Fig.1- )art made u!ing .ariform )roce!!

1+

2-

ADVANCES IN HYDROFORMING

2.2 H#""er$%g

Hammering u!e! t2o alternating "re!!ure!. 8t reduce! the drag force5

2hich i! the friction that de/elo"! bet2een the 2or4 "iece and the die. ,!

the internal "re!!ure increa!e!5 the 2or4 e9"an!ion force increa!e! the drag

force5 or friction5 bet2een the 2or4 "iece and the die. ,l!o5 the internal

"re!!ure become! a force that "u!he! bac4 again!t the hydraulic !y!tem.

The combination of 2or4 e9"an!ion force and internal "re!!ure i! the

reaction force.

,! the reaction force increa!e!5 it become! difficult to force the

material to flo2 into all of the contour! and rece!!e! of the die. The

hammering method cycle! bet2een a high and lo2 "re!!ure. The re"eated

"re!!ure dro"! reduce the drag force5 allo2ing the material to flo2 further

in the die. 8t al!o "re/ent! thinning at the e9"an!ion area! and im"ro/e! the

"roce!! ca"ability.

The hammering "roce!! i! dri/en by a "um" that /arie! the "re!!ure

it de/elo"!5 !uch a! a direct dri/e /olume <&&.= control "um"5 a high-

"re!!ure generator that u!e! a hydraulic !er/o "um". The &&. i! a hybrid

of an ,* !er/omotor and re/er!ible-"i!ton "um". The "ul!ation! are

generated by controlling the for2ard and re/er!e rotation of the ,*

!er/omotor at high !"eed.

2-

21

ADVANCES IN HYDROFORMING

The time from !tart-u" time to !hutdo2n time <including hold time=

i! one cycle. The fre3uency i! the number of cycle! that ela"!e in one

!econd and i! mea!ured in hert1 <H1=. 6e!ult! from hydroforming trial!

ha/e !ho2n that the o"timal hammering fre3uency range i! bet2een 1 and

3 H1. Fre3uencie! higher than 3 H1 ma4e it "hy!ically im"o!!ible for the

"re!!ure to reach the intended high and lo2 "oint!.

8n other 2ord!5 re/er!ing the "re!!ure more than 3 time! "er !econd

doe!nJt gi/e the hydraulic !y!tem enough time to achie/e the "rogrammed

"re!!ure!. The o"timal "re!!ure range i! bet2een #25 and 4535- "ound! "er

!3uare inch <)S8=5 or 5 to 3- 0)a.

Fig.11 Setu" for Hammering <Source> ?#@=

21

22

ADVANCES IN HYDROFORMING

,bo/e figure !ho2! the actual !etu" u!ed for Hammering. The

com"lete !y!tem u!e! three &&. "um"!. :ne generate! the "ul!ating

"re!!ure that form! the tubeH the other! are multi"ur"o!e "um"! u!ed to

rai!e and lo2er the "re!!J! u""er die at high !"eed. Ehen the u""er die i!

com"letely clo!ed5 the &&. !eal! and "re!!e! in both end! of the tube

2or4 "iece. The &&.J! ,* !er/omotor i! regulated by a *B*. Thi!

control! the hammering fre3uency and "re!!ure increa!e rate.

The "ul!e fre3uency and "re!!ure on the !econdary !ide i! controlled

by the re/er!ible ,* !er/omotor of the &&. "um" and "ul!ing the

"rimary !ide of the oil and 2ater boo!ting cylinder at a ratio of 1-to-1-.

The !ha"e that can be formed in one cycle of tube e9"an!ion i! determined

by the ma9imum 2ater ca"acity in the high-"re!!ure cylinder.

Fig.12 Hammering *ycle

22

23

ADVANCES IN HYDROFORMING

The Hammering method cycle! bet2een a high and lo2 "re!!ure5 !o

Hammering ha! more /ariable! than in con/entional hydroforming. 8n!tead

of one "re!!ure5 hammering u!e! t2o alternating "re!!ure!. ,l!o5 in thi!

ca!e5 the la!t t2o cycle! a! can be !een in abo/e figure ha/e a brief hold

time of -.2 !econd at the "oint! of minimum and ma9imum "re!!ure.

Hammering allo2! the u!er to /ary the difference bet2een the high and

lo2 "re!!ure <1-0)a in thi! ca!e=5 the cycle time and al!o the hold time.

The t2o main "roblem! faced 2hile forming are ru"turing and

buc4ling. 6u"turing i! u!ually the re!ult of !etting the internal "re!!ure too

high or the e9"an!ion force too lo2. Thi! cau!e! the material to !tretch and

become too thin in the e9"an!ion area5 ultimately cau!ing a ru"ture. Thi! i!

2hy it i! critical to balance the internal "re!!ure and initial e9"an!ion

force. 7!ing an initial "re!!ure that i! too high al!o can cau!e the "i"e to

e9"and too 3uic4ly5 cau!ing the material at the a9i! !ealing area to "ull

a2ay. Thi!5 in turn5 cau!e! the fluid to lea45 !o the "re!!ure doe! not ri!e to

the !et /alue and the "roce!!ing canJt !tart.

$uc4ling u!ually i! cau!ed by !etting the internal "re!!ure too lo2 or

the e9"an!ion force too high. 7!ing a "roce!!ing time that i! too fa!t al!o

may contribute to buc4ling.

Hammering eliminate! the!e "roblem! a! it u!e! t2o alternating

"re!!ure! 2hich balance! initial "re!!ure ( e9"an!ion force. ,! 2e can !ee

the "art made by con/entional hydroforming "roce!! !ho2n in the diagram

belo2 i! ru"tured5 2herea! the "art at the bottom made by Hammering did

not get ru"tured.

23

24

ADVANCES IN HYDROFORMING

Fig.13 )art made by Hammering

2.3 9re*'re00.r$>$%g

24

25

ADVANCES IN HYDROFORMING

8n "re-"re!!uri1ing method a metal tube i! "laced in lo2er mold

2ith the end! !tic4ing out from it and inject! a "re!!uri1ing fluid into the

metal tube through the in!ide of a !eal "unch and gradually "re!!e! the

!eal "unche! again!t the tube end!5 in the !tate 2ith internal "re!!ure and

"re!!ing force a""lied the u""er mold i! lo2ered !o a! to deform the

tube and end the "roce!!ing 2ith the tube end! !tic4ing out from the

mold and further boo!ting the internal "re!!ure in metal tube after

clo!ing the mold and ending the forming o"eration and a hydroformed

"roduct ha/ing a flange acro!! the entire length in longitudinal !ection i!

formed.

,! !ho2n in Fig.14 the con/entional hydroforming method relate!

to "lacing a metal tube !horter in length than the mold in a mold !o that

the tube end! of the metal tube are "o!itioned in!ide the end face! of

mold5 then u""er mold i! lo2ered to clo!e the mold and clam" the tube

bet2een u""er and lo2er mold!. ,fter that !eal "unche! ad/ance and

2ater i! in!erted a! a "re!!uri1ing fluid from one of the !eal!5 the

"re!!ure in!ide the tube i! rai!ed to obtain "redetermined !ha"e.

8n thi! ne2 techni3ue of "re-"re!!uri1ation a metal tube i! "laced

in the lo2er mold 2ith it! tube end! !tic4ing out of the mold5 injecting

"re!!uri1ed fluid into the metal tube through an in!ide of a !eal "unch

2hile "re!!ing !eal "unche! again!t the tube end!5 filling the in!ide of

metal tube 2ith a "re!!uri1ed fluid to a""ly internal "re!!ure5 then the

u""er mold i! lo2ered !o a! to clo!e the mold5 deforming the tube to the

"redetermined !ha"e 2ith the tube end! !tic4ing out of the mold. The

"roce!! i! !ho2n in Fig.15.

25

2

ADVANCES IN HYDROFORMING

Fig.14 *on/entional 0ethod of Hydroforming

2

2#

ADVANCES IN HYDROFORMING

Fig.15 )re-)re!!uri1ing 0ethod of Hydroforming <Source> ?3@=

2#

2'

ADVANCES IN HYDROFORMING

2.4 M#%.!#/t.r$%g ! C)#d '$'e0

The energy !ector i! hot right no25 and !o i! "i"e "roduction. )i"e

for tran!"orting crude oil and crude ga! mu!t meet !e/eral criteria. The

material mu!t ha/e !ufficient durability5 corro!ion re!i!tance5 and

!trength5 and the !i1e mu!t be large enough to tran!"ort the de!ired

/olume. *orro!ion re!i!tance i! nece!!ary to "re/ent ero!ion damage

from "ollutant! in the oil or ga!5 2hich include hydrogen !ulfide5

chloride!5 and 2ater. Finding the o"timum material for ma4ing "i"e for

thi! indu!try i! tric4y. %o2-alloy carbon !teel! tend to be !trong5 but lac4

corro!ion re!i!tance. Stainle!! !teel! re!i!t corro!ion but lac4 !trength.

*ladding lo2-alloy carbon !teel 2ith a thin layer of a corro!ion-re!i!tant

alloy i! a !uitable "roce!!.

,n alternati/e i! to "roduce clad "i"e that ma4e! the be!t u!e of

corro!ion-re!i!tant alloy! and lo2-alloy !teel!. Such "i"e ty"ically i!

made from !trong5 lo2-alloy carbon !teel and lined 2ith a !lee/e made

from a corro!ion-re!i!tant material a""ro9imately -.1+ inch thic4. The

!im"le!t mechanically clad "i"e con!i!t! of a corro!ion-re!i!tant liner

in!erted into a lo2-alloy e9ternal carbon !teel "i"e. , more !o"hi!ticated

mechanically clad "i"e i! "roduced by !hrin4ing the e9ternal "i"e or

rolling one "i"e in!ide the other. The nature of the mechanical bond

de"end! on the "roce!!. 6egardle!! of the method5 the bond i! "urely

mechanical. The t2o di!tinct material! remain t2o di!tinct material!

they do not fu!e together to become a !ingle ma!! a! metallurgically

bonded "i"e! do.

2'

2+

ADVANCES IN HYDROFORMING

, "roce!! 2a! de/i!ed 2hich u!ed hydraulic "re!!ure on the inner

"i"e and induction heating on the outer "i"e. The hydraulic "re!!ure cau!ed

the inner "i"e to e9"andH remo/ing the heat cau!ed the outer "i"e to !hrin4

a! it cooled.

, modern im"ro/ement to thi! "roce!! u!e! a hydraulic "i"e

calibration and lining machine e3ui""ed 2ith an additional 2ater !y!tem a!

2ell a! !o"hi!ticated control!. 8t u!e! a "roce!! !imilar to automoti/e "art!

hydroforming machine! to attain a high degree of com"re!!i/e contact

bet2een the t2o "i"e!. The corro!ion-re!i!tant "i"e i! in!erted into the

outer lo2-alloy carbon !teel "i"e in a !emi automated o"eration and i! then

"laced into the calibration machineF! o"en tool form. The tool clo!e! and

a9ial cylinder! !eal each of the "i"e end!. Hydraulic fluid under high

"re!!ure e9"and! the inner tube. , firm com"re!!i/e contact i! achie/ed by

the ela!tic and "la!tic beha/ior! of the outer "i"e and the inner "i"e. The

ela!tic !"ring bac4 of the outer "i"e i! greater than the "la!tic e9"an!ion of

the inner "i"eH the re!ulting re!idual "re!!ure !tre!! of the inner "i"e i! in

the region of #525- to 1455-- "ound! "er !3uare inch <)S8=.

Thi! "ro/ide! a homogenou! contact along the "i"eF! entire length.

:ne of the chief ad/antage! of u!ing a hydroforming "roce!! to

manufacture mechanically clad "i"e i! !im"le economic!. *om"ared to

"roducing a non-clad or a metallurgically clad "i"e5 manufacturing clad

"i"e 2ith thi! method re"re!ent! a !ignificant co!t reduction. )otential co!t

reduction i! in 2elding5 becau!e clad "i"e ha! thinner 2all! than

homogenou! "i"e5 and !o re3uire! le!! 2elding time. 8n thi! !cenario5 the

clad "i"e! are -.3+ in. thic45 2herea! the homogenou! "i"e i! -.5+ in.

thic45 a 13 "ercent difference.

2+

3-

ADVANCES IN HYDROFORMING

?. CONCLUSION

8n thi! !eminar re"ort recent de/elo"ment! in hydroforming are

di!cu!!ed !y!tematically. ,fter di!cu!!ing the!e 2e conclude that>

1. Hydroforming ha! 2ide a""lication in many indu!trie! li4e

automobile5 aero!"ace5 electronic good!5 !anitary fitting!5 etc.

0any benefit! offered A Lood !urface fini!h5 7!e of almo!t all

ductile and malleable material5 $etter deformation5 High

dimen!ional accuracy5 Sa/ing! u" to '-C in "o!t forming

"roce!!e! <6efer "age '=. $ecau!e of !o many benefit! offered

Hydroforming i! con!idered a! an effecti/e method to meet the

demand! of e/er e/ol/ing manufacturing !ector.

2. &ue to introduction of hydroforming it i! no2 "o!!ible to u!e light

2eight aluminum !tructural frame in!tead of the con/entional

hea/y 2eight !teel frame in automobile!. 6e!ulting in reduction of

2eight by more than + "ercent and 2eld length by 1+C

<6efer "age 1-=.

3-

31

ADVANCES IN HYDROFORMING

3. Hydroforming facilitate! manufacturing of a !ingle large com"le9

com"onent in!tead of many !mall com"onent!5 reducing the

tooling co!t! by 5-C. For e9am"le> o"eration! li4e "iercing can be

done during hydroforming it!elf. There i! no need of fini!hing the

!urface after hydroforming a! hydrofomred com"onent ha! a high

grade of !urface fini!h.

4. :f the abo/e di!cu!!ed recent techni3ue! )re!!ure !e3uencing and

Hammering are the mo!t u!eful method!. 7!ing the!e method! 2e

can hydroform any malleable metal ranging from co""er to high

grade !tainle!! !teel. $y reducing the drag force Hammering

eliminate! the t2o major "roblem! faced in forming namely

ru"turing and buc4ling.

Thu! ado"ting the!e ne2 techni3ue! there i! better utili1ation

of material. The day 2ill not be far a2ay 2hen hydroforming 2ill

com"letely re"lace the con/entional !tam"ing and forming

"roce!!e!.

31

32

ADVANCES IN HYDROFORMING

13. REFERENCES

1= 6e!earch "a"er> M&e/elo"ment! in HydroformingN A S.H.Oang

2= 7.S. )atent 25#135314

3= 7.S. )atent 2-1---1'4#3

4= $oo4> MHydroforming for ad/anced manufacturingN5 $y 05 PoQ5

2--+ Eoodhead )ubli!hing %imited.

5= $oo4> MHydroforming technology> ,d/anced 0aterial! ( )roce!!e!N

<6efereed=> 0ay5 1++#> ,S0 8nternational.

= $oo4> MFundamental! of HydroformingN by Harjinder Singh.

#= htt">RR222.thefabricator.comRtechcellRhydroforming

'= htt">RR222.americanhydroformer!.com

+= htt">RR222.!ciencedirect.com

32

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Quantitative Analysis For Business Midterm - SolutionDokument6 SeitenQuantitative Analysis For Business Midterm - SolutionYiPingHungNoch keine Bewertungen

- COMDokument17 SeitenCOMmarcy ginez peña garciaNoch keine Bewertungen

- Manual Elipz Rev MDokument4 SeitenManual Elipz Rev MoyoveraNoch keine Bewertungen

- Module 1 Local History and GovernanceDokument71 SeitenModule 1 Local History and GovernanceEamacir UlopganisNoch keine Bewertungen

- 15 - Data Presentation System - NewDokument35 Seiten15 - Data Presentation System - NewKARTHIK S SNoch keine Bewertungen

- Endocrine SeminarDokument58 SeitenEndocrine SeminarShahirah ShuhaimiNoch keine Bewertungen

- PAN EDU 231 CourseDokument3 SeitenPAN EDU 231 CourseGeorge JaneNoch keine Bewertungen

- PUMA Promotions PDFDokument13 SeitenPUMA Promotions PDFtharunNoch keine Bewertungen

- Ecological Design, A New CritiqueDokument12 SeitenEcological Design, A New CritiqueBerrak Kırbaş Akyürek0% (1)

- Today's Topics: Procedures More Examples MARS Intro Number SystemsDokument43 SeitenToday's Topics: Procedures More Examples MARS Intro Number SystemsUlas GulerNoch keine Bewertungen

- Cleaning Park for Community ServiceDokument6 SeitenCleaning Park for Community ServiceSri AnishNoch keine Bewertungen

- ACTIVITY-SHEET HANDICRAFT7 FinalDokument9 SeitenACTIVITY-SHEET HANDICRAFT7 FinalJohn Nelson PiconesNoch keine Bewertungen

- Physics Blue Print I Puc 2023-24 PDFDokument2 SeitenPhysics Blue Print I Puc 2023-24 PDFPrakash ReddyNoch keine Bewertungen

- Desain LRT PDFDokument754 SeitenDesain LRT PDFWahyu SaputraNoch keine Bewertungen

- Ventilation Ceilings GBDokument7 SeitenVentilation Ceilings GBMujtabaNoch keine Bewertungen

- 01-Introductin Data ModelingDokument23 Seiten01-Introductin Data ModelingGOHAR GHAFFARNoch keine Bewertungen

- Finding Hamiltonian Neutrosophic Cycles in Classes of Neutrosophic GraphsDokument48 SeitenFinding Hamiltonian Neutrosophic Cycles in Classes of Neutrosophic GraphsHenry GarrettNoch keine Bewertungen

- Editable Periodic Table MS WORDDokument8 SeitenEditable Periodic Table MS WORDYasir50% (2)

- Last Duchess Download in PDFDokument3 SeitenLast Duchess Download in PDFKali RajNoch keine Bewertungen

- Astero E0201E-20 991063Dokument186 SeitenAstero E0201E-20 991063Thinh Nguyen100% (1)

- Experiment No 1 Preparation of CheeseDokument5 SeitenExperiment No 1 Preparation of CheeseArmiee InfiniteNoch keine Bewertungen

- TI Ếng Anh Thầy Tùng Vocabulary And Grammar Level B2; Multiple Choice QuestionsDokument6 SeitenTI Ếng Anh Thầy Tùng Vocabulary And Grammar Level B2; Multiple Choice QuestionsQuỳnh AnhNoch keine Bewertungen

- Operator Manual FurunoDokument40 SeitenOperator Manual FurunoJan JbaNoch keine Bewertungen

- Cap 18 Raices Sist SensorialDokument2 SeitenCap 18 Raices Sist SensorialSandra OrtizNoch keine Bewertungen

- Matlab Signal ProcessingDokument418 SeitenMatlab Signal ProcessingNguyễn Kiến Long91% (11)

- Multi Level Practice Test 5Dokument5 SeitenMulti Level Practice Test 5Erkin SadikovNoch keine Bewertungen

- Registration Card Sample 4Dokument5 SeitenRegistration Card Sample 4Ben CruzNoch keine Bewertungen

- Light of Consciousness - J. BhattacharjeeDokument257 SeitenLight of Consciousness - J. BhattacharjeeGeetika CnNoch keine Bewertungen

- Safety Can Chemical Compatibility ChartDokument1 SeiteSafety Can Chemical Compatibility ChartMan NamNoch keine Bewertungen

- Statistical Hydrology PDFDokument41 SeitenStatistical Hydrology PDFAlexandre HesslerNoch keine Bewertungen