Beruflich Dokumente

Kultur Dokumente

Wire Rope Slings

Hochgeladen von

Er Faiyaz Ahmed0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

339 Ansichten5 SeitenINSPECTION PROCEDURE OF WIRE ROPE SLINGS BY VELOSI QATAR

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenINSPECTION PROCEDURE OF WIRE ROPE SLINGS BY VELOSI QATAR

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

339 Ansichten5 SeitenWire Rope Slings

Hochgeladen von

Er Faiyaz AhmedINSPECTION PROCEDURE OF WIRE ROPE SLINGS BY VELOSI QATAR

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 5

L4-OCP-39.

EXAMINATION OF WIRE ROPE SLINGS

Rev No. 0 Date :20May2009 Page 1 of 5

1.0 Purpose

To define the procedural requirements for Examination of wire rope slings in

accordance with BS EN 13414-1(2003) of Wire Rope Slings

2.0 Scope

Code of Practice for the Safe Use of Lifting Equipment: Wire Rope Slings

3.0 Definition

Nil

4.0 Responsibility

Assurance of Quality Inspection and correct acceptance level of Lifting

Equipment by a qualified Lifting Equipment Inspector

5.0 Procedure

Ensure that the rope diameter, construction and Effective Working Length (EWL),

agrees with that stated on the certificate of Test and Thorough Examination. EWL

is the length the bearing points of the terminal fittings, whether soft eye, thimble,

shackle, link or other.

If the rope has reduced in diameter or increased in length, it can be assumed that it

has been stretched due to overload or partial collapse of the inner core. Partial

collapse of the inner core is indicated by lack of spring in the rope.

Construction of wire rope will be free from broken wires, kinking, bird caging,

distortion etc. refer to section of typical examples of wire rope deterioration for

other mechanical defects, which shall be cause for rejection.

A wire rope sling must be removed from service if any single length (of the

complete length) of ten diameters of the total number of visible broken wires

exceeds 5% of the total number of wires in the rope.

All parts of the wire rope will; be free of any corrosion, wear as shown by flats

on the outer wires, or lack of lubrication.

L4-OCP-39.

EXAMINATION OF WIRE ROPE SLINGS

Rev No. 0 Date :20May2009 Page 2 of 5

Separate the strands with a specially designed tool (i.e. wire rope clamps) to

examine the inner core for wear, broken wires, corrosion and sufficient

lubrication.

Ensure correct ferrule has been fitted for the diameter of the rope.

Ferrules must be secure and thimbles/eyes shall fit correctly with no stretch due

to possible overload, twist, cracks or any other possible damage.

Wire ropes end loops shall not terminate inside the ferrule.

If fitted, examine master link/quad assembly for wear, corrosion, cracks, etc., and

security of fitting

6.0 Associated documents

Engineering Standards and manufacturing literature applicable to this procedure

BS EN 12385 Specification for Steel Wire Ropes.

BS EN 13414 - 1 Wire Rope Slings for General Lifting Purposes

BS 6570 1986 Code of practice for the Selection, Care and

Maintenance of Steel Wire Ropes.

ISO 8792 1986 Wire Rope Slings - safety Criteria and Inspection Procedures

for Use.

Qatar Petroleum Lifting Equipment Regulations

LEEA Handbook 1987, Inspection of Wire Rope Slings for Lifting Purposes

7.0 Records

Record Number Name of the Record Retention Period

L4-OCP-39.

EXAMINATION OF WIRE ROPE SLINGS

Rev No. 0 Date :20May2009 Page 3 of 5

8.0 Revision History

Rev

.

Date Section Outline of Change Authorizati

on

0 First Issue First Issue M Coles

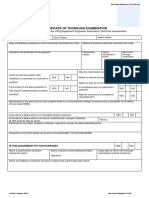

WIRE ROPE SLING - INSPECTION PROCEDURE & CHECK LIST

L4-OCP-39.

EXAMINATION OF WIRE ROPE SLINGS

Rev No. 0 Date :20May2009 Page 4 of 5

EXAMINATION PROCEDURE

Examine each individual leg along its entire length and check for:-

a) Wear

b) Corrosion

c) Abrasion

d) Mechanical damage

e) Broken wires

f) Internal Deterioration

Internal deterioration should be checked for by using two specially designed clamps to open up the

Rope to expose the wire/fibre core

Measure the rope diameter as any reduction from original size could indicate either amount of wear

on outer wires, partial collapse of the core or stretch due to overload.

Examine each ferrule and ensure the correct size of the ferrule has been fitted.

Check that end of the loop does not terminate inside the ferrule is of the longer tapered design

which has an internal step.

The ferrule should be free from cracks or other deformities.

Examine each thimble and check for correct fitting, Snagging damage and elongation. (Stretched

thimbles /eyes could indicate possible overload).

Examine wire rope around thimbles as it is often abraded due to sling being dragged over rough

surfaces.

If fitted, examine master link/quadruple assembly and check for wear, corrosion and cracking.

OWNER: DATE:

L4-OCP-39.

EXAMINATION OF WIRE ROPE SLINGS

Rev No. 0 Date :20May2009 Page 5 of 5

LOCATION SURVEYOR

SERIAL NO: NO OF LEG

ROPE DIA LENGTH

SWL MASTERLINK DIA

ITEM DESCRIPTION OK NOT OK

1 Wire Rope

a) Wear

b) Corrosion

c) Abrasion

d) Mechanical damage

e) Broken wires

2 Thimble Eye

a) Distortion

b) Crack

c) Elongation

3 Master Link/ Quad Assembly

a) Wear

b) Corrosion

c) Elongation

d) Crack

4 Ferrule

a) Mechanical damage

b) Cracks

c) Protrude

OTHERS (to be specified)

REMARKS

Das könnte Ihnen auch gefallen

- FEM - 1.001 - Booklet 1 To 8Dokument277 SeitenFEM - 1.001 - Booklet 1 To 8Er Faiyaz Ahmed100% (6)

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Rf-7800r-Rc Universal Remote Control System Tcm26-12078Dokument2 SeitenRf-7800r-Rc Universal Remote Control System Tcm26-12078Lavanda Focsani50% (2)

- Kondotec Wire Rope CatalogDokument30 SeitenKondotec Wire Rope CatalogAnonymousNoch keine Bewertungen

- LEEA-064 Guidance To CE Marking of Lifting Equipment For Which There Is No Harmonised Standard Version 1 July 2015Dokument9 SeitenLEEA-064 Guidance To CE Marking of Lifting Equipment For Which There Is No Harmonised Standard Version 1 July 2015Deepak RMNoch keine Bewertungen

- Opito Rigger TrainingDokument61 SeitenOpito Rigger TrainingTasia DiNoch keine Bewertungen

- Gin WheelDokument10 SeitenGin WheelBarkat Ullah100% (2)

- Inspection of Wire Rope ProcedureDokument4 SeitenInspection of Wire Rope ProceduremochisitampanNoch keine Bewertungen

- Design of Lifting LugDokument7 SeitenDesign of Lifting Luga_toups100% (1)

- Design of Lifting LugDokument7 SeitenDesign of Lifting Luga_toups100% (1)

- Web SlingsDokument8 SeitenWeb SlingsmadihcoNoch keine Bewertungen

- EN 13000 Situation May 10 Rated Capacity LimiterDokument50 SeitenEN 13000 Situation May 10 Rated Capacity Limiterfabio manente100% (1)

- Crane Sheave - Early FailuresDokument14 SeitenCrane Sheave - Early FailuresMichael WoodNoch keine Bewertungen

- LEEA 059 5 Guidance To Documentation & Marking Part5Dokument23 SeitenLEEA 059 5 Guidance To Documentation & Marking Part5GaniyuNoch keine Bewertungen

- BSEN-16191 Venkatesh Mohan Tunnel Safety Specalist PDFDokument54 SeitenBSEN-16191 Venkatesh Mohan Tunnel Safety Specalist PDFVenkatesh MohanNoch keine Bewertungen

- BS en 13414-2-2003 + A2-2008Dokument26 SeitenBS en 13414-2-2003 + A2-2008Horas CanmanNoch keine Bewertungen

- LEEA ACADEMY STEP NOTES - Foundation - Aug2018 - v1.8 Print PDFDokument72 SeitenLEEA ACADEMY STEP NOTES - Foundation - Aug2018 - v1.8 Print PDFSelva GanapathiNoch keine Bewertungen

- Gin Wheels or Pulley WheelsDokument1 SeiteGin Wheels or Pulley WheelsNanang RizalNoch keine Bewertungen

- Banksman Slinging R2Dokument31 SeitenBanksman Slinging R2Ilyas ZeriNoch keine Bewertungen

- No. 8 - Chain & Chain SlingsDokument11 SeitenNo. 8 - Chain & Chain SlingsAhmed AtefNoch keine Bewertungen

- Lifting Beams and SpreadersDokument2 SeitenLifting Beams and SpreadersNadeem MalikNoch keine Bewertungen

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDokument3 SeitenAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNoch keine Bewertungen

- Wire Rope InspectionDokument21 SeitenWire Rope Inspectionrois100% (2)

- Loler AcopDokument71 SeitenLoler AcopMoheb BotrosNoch keine Bewertungen

- LEEA Lifting and Slinging Course OutlineDokument4 SeitenLEEA Lifting and Slinging Course OutlineSankaranarayananNoch keine Bewertungen

- Tips For Heavy Lifting AND Rigging Engineering: Inspection: 1Dokument25 SeitenTips For Heavy Lifting AND Rigging Engineering: Inspection: 1pablodugalNoch keine Bewertungen

- Periodic Inspection Sling GBDokument2 SeitenPeriodic Inspection Sling GBjeanmichelqNoch keine Bewertungen

- Learner Guide - RBDokument61 SeitenLearner Guide - RBEducation 2.0Noch keine Bewertungen

- Banksman SlingerDokument9 SeitenBanksman SlingerPirlo PoloNoch keine Bewertungen

- Slinging Tubulars, Scaffold, BeamsDokument3 SeitenSlinging Tubulars, Scaffold, BeamsAngel AngeleyeNoch keine Bewertungen

- Web-Sling-Recommended-Operating-and-Inspection-GuidelineDokument12 SeitenWeb-Sling-Recommended-Operating-and-Inspection-GuidelineibrahimNoch keine Bewertungen

- Guidance On The Use of U-Bolt Type Wire Rope Grips: Document Reference: LEEA-049Dokument6 SeitenGuidance On The Use of U-Bolt Type Wire Rope Grips: Document Reference: LEEA-049Ganiyu100% (1)

- 03 Wire Rope Strand TerminationsDokument20 Seiten03 Wire Rope Strand Terminationsoluomo1Noch keine Bewertungen

- LEEA - Instruction For Safe Use of Flat Woven Webbing SlingsDokument2 SeitenLEEA - Instruction For Safe Use of Flat Woven Webbing Slingsdonnyars1979Noch keine Bewertungen

- LEEA Think Lifting Portrait A4 4pp v2Dokument4 SeitenLEEA Think Lifting Portrait A4 4pp v2Muhammad KamranNoch keine Bewertungen

- ToolboxTalks D-D Ratio 041315 PDFDokument1 SeiteToolboxTalks D-D Ratio 041315 PDFkaniniuserNoch keine Bewertungen

- 59-1 Man BasketDokument3 Seiten59-1 Man BasketAkhil100% (1)

- Products - Monthly Checklist MCDokument2 SeitenProducts - Monthly Checklist MCDiegoCaicedo1982Noch keine Bewertungen

- BS-7121-11-1998 Offshore CranesDokument23 SeitenBS-7121-11-1998 Offshore CranesAkram DriraNoch keine Bewertungen

- BS 07121-2-4-2013Dokument36 SeitenBS 07121-2-4-2013Abdel Rahman SalahNoch keine Bewertungen

- Web Slings PDFDokument26 SeitenWeb Slings PDFCesar Fernando Via SaldarriagaNoch keine Bewertungen

- LOLERDokument82 SeitenLOLERNguyen Phuc LinhNoch keine Bewertungen

- Hooks and Shackles: Clevis Grab Hook Clevis Slip HookDokument7 SeitenHooks and Shackles: Clevis Grab Hook Clevis Slip HookWade SperryNoch keine Bewertungen

- Chain Pulley Block or Chain Hoist Safety Dos and Don'tsDokument5 SeitenChain Pulley Block or Chain Hoist Safety Dos and Don'tsAkram BadranNoch keine Bewertungen

- Synthetic Webbing & Round Sling Acceptance CriteriaDokument3 SeitenSynthetic Webbing & Round Sling Acceptance CriteriarustamriyadiNoch keine Bewertungen

- Appointed Person: Planning and Regulatory RequirementsDokument6 SeitenAppointed Person: Planning and Regulatory RequirementssamNoch keine Bewertungen

- LEEA Certificate of Thorough ExaminationDokument1 SeiteLEEA Certificate of Thorough Examinationengmuhmud100% (1)

- Wire Rope Sling Tech InfoDokument6 SeitenWire Rope Sling Tech InfoDaud PirriNoch keine Bewertungen

- Riggers Quiz: Name: - DateDokument1 SeiteRiggers Quiz: Name: - Dategunnery02Noch keine Bewertungen

- 2 - DSM Notes Hoisting MechanismDokument13 Seiten2 - DSM Notes Hoisting MechanismsanketNoch keine Bewertungen

- Authorised Examiners Lifting EquipmentDokument13 SeitenAuthorised Examiners Lifting EquipmentdunglxNoch keine Bewertungen

- BS en 1459 Forklift Safety IndustrialtrucksDokument52 SeitenBS en 1459 Forklift Safety IndustrialtrucksIslam ShaheenNoch keine Bewertungen

- PuwerDokument106 SeitenPuwerBenny Salazar BotonesNoch keine Bewertungen

- Edge Protection - Epf-Cop-32-33 PDFDokument37 SeitenEdge Protection - Epf-Cop-32-33 PDFcisyabNoch keine Bewertungen

- BS en 13414-1 2003 PresentationDokument6 SeitenBS en 13414-1 2003 PresentationAlbadeel Inspection & Conformity Co. ltd100% (1)

- Webbing SlingDokument3 SeitenWebbing Slingmoha19841Noch keine Bewertungen

- Crane Rule PresentationDokument44 SeitenCrane Rule PresentationbangladragosNoch keine Bewertungen

- Rigging CourseDokument16 SeitenRigging Coursemianba17100% (1)

- Iso 8792 1986Dokument9 SeitenIso 8792 1986Ather SeemabNoch keine Bewertungen

- 0.1 SI - 11 - Hand - Chain - Block - SI - 11.4Dokument2 Seiten0.1 SI - 11 - Hand - Chain - Block - SI - 11.4Achmad ChusnadiNoch keine Bewertungen

- Foundation Course (FOU) : DescriptionDokument15 SeitenFoundation Course (FOU) : DescriptionVinu VincentNoch keine Bewertungen

- Safe Work Procedure A Complete Guide - 2020 EditionVon EverandSafe Work Procedure A Complete Guide - 2020 EditionNoch keine Bewertungen

- Crane Wire RopeDokument32 SeitenCrane Wire RopeRajmohan Babu100% (3)

- Wire Rope Technical InfoDokument11 SeitenWire Rope Technical Infoأزيزى سودينNoch keine Bewertungen

- AMSADokument84 SeitenAMSAEr Faiyaz AhmedNoch keine Bewertungen

- Mobile CranesDokument7 SeitenMobile CranesEr Faiyaz Ahmed100% (1)

- CSWIP Plant Inspectors 5th Edition, May 2012Dokument13 SeitenCSWIP Plant Inspectors 5th Edition, May 2012Er Faiyaz AhmedNoch keine Bewertungen

- Constitution of India-Complete Full TextDokument471 SeitenConstitution of India-Complete Full TextDaras Bir Singh67% (6)

- Materials Science 2 - DOEDokument112 SeitenMaterials Science 2 - DOEshiv_1987Noch keine Bewertungen

- QP Lifting ProcedureDokument24 SeitenQP Lifting ProcedureEr Faiyaz Ahmed100% (1)

- Die and MoldDokument120 SeitenDie and MoldEr Faiyaz AhmedNoch keine Bewertungen

- DOE Fundamentals Handbook, Mechanical Science, Volume 1 of 2Dokument122 SeitenDOE Fundamentals Handbook, Mechanical Science, Volume 1 of 2Bob VinesNoch keine Bewertungen

- Maintenance and Thorough Examination of Mobile CranesDokument106 SeitenMaintenance and Thorough Examination of Mobile CranesKate Poole100% (2)

- LeadershipDokument156 SeitenLeadershipjames lai96% (26)

- DOE Fundamentals Handbook, Mechanical Science, Volume 1 of 2Dokument122 SeitenDOE Fundamentals Handbook, Mechanical Science, Volume 1 of 2Bob VinesNoch keine Bewertungen

- 2 1Dokument23 Seiten2 1Chockalingam ChidambaramNoch keine Bewertungen

- GATE SyllabusDokument4 SeitenGATE SyllabusEr Faiyaz AhmedNoch keine Bewertungen

- Introduction To Gas Power CyclesDokument3 SeitenIntroduction To Gas Power CyclesJoseph SajanNoch keine Bewertungen

- CNC MachineDokument12 SeitenCNC MachineEr Faiyaz AhmedNoch keine Bewertungen

- Material Selection & DesignDokument122 SeitenMaterial Selection & DesignEr Faiyaz Ahmed100% (1)

- Material Selection & DesignDokument122 SeitenMaterial Selection & DesignEr Faiyaz Ahmed100% (1)

- Lta Gs (Lifting)Dokument11 SeitenLta Gs (Lifting)Chan NaingNoch keine Bewertungen

- Codigos VWDokument5 SeitenCodigos VWLuchito E. CuevaNoch keine Bewertungen

- HRB Hydrostatic Regenerative Braking System TheDokument7 SeitenHRB Hydrostatic Regenerative Braking System ThexxshNoch keine Bewertungen

- Fraunhofer HSF Report Presentation 2018Dokument15 SeitenFraunhofer HSF Report Presentation 2018Taso GegiaNoch keine Bewertungen

- Datasheet HSD123KPW1-A30Dokument23 SeitenDatasheet HSD123KPW1-A30Furkan biçerNoch keine Bewertungen

- Enventory 1Dokument11 SeitenEnventory 1Albert Jay Oring TuicoNoch keine Bewertungen

- Condor PK 17 280 Spec SheetDokument4 SeitenCondor PK 17 280 Spec SheetJulito Santa CruzNoch keine Bewertungen

- FORCE 12 Powered Mixer Operating Manual and User GuideDokument18 SeitenFORCE 12 Powered Mixer Operating Manual and User GuideNicolasAvilaPizarroNoch keine Bewertungen

- N. Tesla.: 46 7, 2-, 4-4 (He/ea& 9a (AuDokument5 SeitenN. Tesla.: 46 7, 2-, 4-4 (He/ea& 9a (Auhix256Noch keine Bewertungen

- Experiment No. 2 Identification of Resistor Color Codes and Verification of Ohm'S LawDokument7 SeitenExperiment No. 2 Identification of Resistor Color Codes and Verification of Ohm'S LawJames Patrick TorresNoch keine Bewertungen

- How To Build A Spark Gap Tesla Coil (SGTC)Dokument27 SeitenHow To Build A Spark Gap Tesla Coil (SGTC)dushmshr1Noch keine Bewertungen

- Hexapod Master Slave CommunicationDokument22 SeitenHexapod Master Slave CommunicationDigvijay MaheshwariNoch keine Bewertungen

- Automation and Controls - Nick DawkinsDokument56 SeitenAutomation and Controls - Nick DawkinsRiky Fitriadi100% (1)

- Eurocomach ES 400 ZT Excavator Operating ManualDokument184 SeitenEurocomach ES 400 ZT Excavator Operating ManualJoe ZhaoNoch keine Bewertungen

- BE3DDokument63 SeitenBE3DLoja De Telemóveis AlfNoch keine Bewertungen

- It2040a It Replacememt Input Output Filter Capacitor Bank MHT 160 250kvaDokument28 SeitenIt2040a It Replacememt Input Output Filter Capacitor Bank MHT 160 250kvaSaid TouhamiNoch keine Bewertungen

- Very Impb Prog PDFDokument284 SeitenVery Impb Prog PDFVishesh ShrivastavaNoch keine Bewertungen

- SHIMANO 105 Caliper Brake: Black / SilverDokument1 SeiteSHIMANO 105 Caliper Brake: Black / SilverGaudencio LingamenNoch keine Bewertungen

- Electrical SystemDokument368 SeitenElectrical SystemAnonymous 28jRu2jNoch keine Bewertungen

- Royal Enfield 350 STD, 4 Speed Gear Box - ExploredDokument15 SeitenRoyal Enfield 350 STD, 4 Speed Gear Box - ExploredantonymariaNoch keine Bewertungen

- Isuzu D Max Owners Manual Combined 17myDokument698 SeitenIsuzu D Max Owners Manual Combined 17myMauricio GonzalezNoch keine Bewertungen

- Taylor Manual de PartesDokument244 SeitenTaylor Manual de PartesAlexander Simanca Candela100% (1)

- Codigo 425 MaxxforceDokument2 SeitenCodigo 425 MaxxforceBulmaro LópezNoch keine Bewertungen

- Powerpress ANDRITZDokument4 SeitenPowerpress ANDRITZCesar LapaNoch keine Bewertungen

- Manlift Inspection ReviewDokument3 SeitenManlift Inspection Reviewjose corrosionNoch keine Bewertungen

- Otis Door Drive User ManualDokument34 SeitenOtis Door Drive User ManualRoyal Akash100% (8)

- VSX-1015 RRV3113 PDFDokument140 SeitenVSX-1015 RRV3113 PDFAlver TuizaNoch keine Bewertungen

- Installation Guide: Layer 2 Ethernet SwitchDokument48 SeitenInstallation Guide: Layer 2 Ethernet SwitchAngel Simo MoralesNoch keine Bewertungen

- Model: Frequency: Fuel Type: C2250 D5 50 Diesel: Generator Set Data SheetDokument3 SeitenModel: Frequency: Fuel Type: C2250 D5 50 Diesel: Generator Set Data SheetLizbeth TrujilloNoch keine Bewertungen