Beruflich Dokumente

Kultur Dokumente

Inverter Drive

Hochgeladen von

ejhagunOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Inverter Drive

Hochgeladen von

ejhagunCopyright:

Verfügbare Formate

Easy Start Guide

LS Industrial Systems

Starvert SV-iG5A Frequency Inverter

available from LS.InverterDrive.com

This guide is intended to compliment the user manual provided by the manufacturer.

It is provided as a basic introduction to the product for Inverter Drive Supermarket customers.

It should not be used as a replacement for the manual issued by the manufacturer.

v1.0

20110406

This product is not a safety device. All safety considerations including but not

limited to Emergency Stop provision should be assessed separately and are

outsidethe scope of thisguide.

ENT

SET

RUN

RUN

FWD

REV

STOP

RESET

LS Industrial Systems SV-iG5A Inverter

Easy Start Guide

Page 1

This guide has been produced by The Inverter Drive Supermarket Ltd.

All content, including but not limited to graphics, text and procedures copyright The Inverter

Drive Supermarket and must not be reproduced or altered without prior written permission.

Page 1

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Contents

Power and Motor Connections (Single Phase)

Power and Motor Connections (Three Phase)

Motor Connections - Star and Delta

Parameters - Overview

Parameters to set before use

How to set Motor no-load current - H34

How to Operate the Inverter

How to enable Sensorless Vector Mode

How to connect and configure a Potentiometer

for remote speed control

How to connect and configure a Run/Stop switch

How to reset the Inverter to Factory Defaults

How to set a Parameter value

How to connect and configure a Fwd/Rev switch

Contents

LS Industrial Systems SV-iG5A

Easy Start Guide

1. Power and Motor Connections (Single Phase)

Page 2

This guide has been produced by The Inverter Drive Supermarket Ltd.

All content, including but not limited to graphics, text and procedures copyright The Inverter

Drive Supermarket and must not be reproduced or altered without prior written permission.

Live

Neutral

Earth

Phase

Phase

Phase

Earth

Notes:

The order of the three phases determines the

direction the motor turns.

The smaller green earth terminals are not part

of the main termal block.

Important:

Do not connect any of the Power or Motor

cables tothe terminals markedB1 andB2.

Use screened SY cable between the Inverter

and Motor to minimise electromagnetic

interference.

Ensure the motor cable screen is earthed at

the motor end.

Before commencing, confirmthat the iG5Aand all

cables are completely isolated from the power

supply, have been isolated for at least 5 minutes

andthat the motor isnot turning.

Motor

R T B1 B2

Power

U V W

LS Industrial Systems SV-iG5A

Easy Start Guide

2. Power and Motor Connections (Three Phase)

Before commencing, confirmthat the iG5Aand all

cables are completely isolated from the power

supply, have been isolated for at least 5 minutes

andthat the motor isnot turning.

Page 3

This guide has been produced by The Inverter Drive Supermarket Ltd.

All content, including but not limited to graphics, text and procedures copyright The Inverter

Drive Supermarket and must not be reproduced or altered without prior written permission.

Notes:

The illustration above is based on the 11kW -

22kWsize. The terminal layout for the smaller

sizes (0.37kW- 7.5kW) is slightly different.

The order of the three motor phases

determines the direction the motor turns.

The order of the three power phases is

unimportant.

The smaller green earth terminals are not part

of the main terminal block.

Important:

Do not connect any of the Power or Motor

cables to the terminals marked P1(+), B1,

B2 or N(-).

The terminal marked N does NOT mean

Neutral.

Use screened SY cable between the Inverter

and Motor to minimise electromagnetic

interference and ensure the screen is earthed

at the motor end.

T(L3) P1(+) N(-) B1 B2 U V W

Motor Power

R(L1) S(L2)

Phase

Phase

Phase

Earth

LS Industrial Systems SV-iG5A

Easy Start Guide

3. Motor Connections - Star and Delta

Page 4

This guide has been produced by The Inverter Drive Supermarket Ltd.

All content, including but not limited to graphics, text and procedures copyright The Inverter

Drive Supermarket and must not be reproduced or altered without prior written permission.

3.2 Motor connectedinDELTA:

Delta connectionissuitablefor:-

230Vsupply to230/400Vdual-voltage motor.

400Vsupply to400/660Vdual-voltage motor.

The link configuration is shown in the

illustration opposite and is sometimes referred

toa three-a-breast.

The order of the three phases determines the

direction the motor turns.

Note that the cable screen and earth are

connected together at the earth terminal.

Phase

Phase

Phase

Earth

Screen

3.1 Motor connectedinSTAR(or Wye):

Star connectionissuitablefor:-

400Vsupply to230/400Vdual-voltage motor.

660Vsupply to400/660Vdual-voltage motor.

For safety purposes, Star (shown opposite) is

the default configuration for newmotors and is

sometimes known as two at one side.

Only two links are required for Star. Double-up

the links if changing from Delta to allow the

motor tobe changed toback in future.

The order of the three phases determines the

direction the motor turns.

Phase

Phase

Phase

Earth

Screen

Dual voltage induction motors typically include

terminal boxes with six points. The points can

be connected together with links in one of two

ways tosuit one of the two rated voltages.

The two ways of connecting the links are

shown below. These are known as Star (the

higher voltage) or Delta (the lower voltage).

Link

The selection of Star or Delta is not optional

and must match the supply voltage.

Dual voltage motor nameplates include

symbols to represent voltage and full load

current in each configuration.

Delta is represented by a triangle and star by a

Y(Wye).

DELTA

STAR

Link

LS Industrial Systems SV-iG5A

Easy Start Guide

Page 5

This guide has been produced by The Inverter Drive Supermarket Ltd.

All content, including but not limited to graphics, text and procedures copyright The Inverter

Drive Supermarket and must not be reproduced or altered without prior written permission.

4. Parameters - overview

Parameter Description How to set

H30 Motor Power in kW Set to match motor nameplate - eg. 0.75 for 0.75kW, 1.5 for 1.5kW etc.

H31 Number of Motor Poles Set to match motor nameplate - eg. 2700-3000RPM = 2, 1350-1500RPM = 4 etc.

H32 Motor Slip in Hz Calculate: (Motor Frequency - ((Motor RPM x Poles) / 120))

H33 Motor Full Load Current in Amps Set to match motor nameplate - eg. 4.7

H34 Motor No-Load Current in Amps See section 6 for details of how to correctly set this value.

Parameter Description How to set

drv Run/Stop Command Source Set to for Run/Stop buttons on the iG5A. 0

Frq Speed Command Source Set to to use internal frequency parameter (can be changed whilst the motor us running). 1

Parameter Description How to set

F21 Max Output Frequency in Hz Default is 60. Change to 50 for 50Hz motor.

F22 Base Frequency Default is 60. Change to 50 for 50Hz motor.

F24 Enable Max/Min Frequency Default is 0 (off). Set to 1 to enable parameters F25 and F26 for future use.

F27 Torque Boost Default is 0 (off). Set to 1 to improve starting Torque.

F50 Thermal Overload Default is 0 (off). Set to 1 to enable Thermal Overload Protection.

The iG5Acontains a number of settings which

can be changed to tailor it for use in a wide

range of applications. These settings are

known as parameters.

Parameters are typically referred to by code or

number (eg. H21 = Max Output Frequency)

with a description available in the manual.

The parameters contain critical information

essential to the correct operation of the iG5A.

Therefore, they should at least be checked by

the user before it is operated for the first time.

The parameters listed in section 5 are intended

to provide a starting point to allow for basic

operation of the iG5AInverter.

5.3 Parameters in Function Group 2 - H

Press left/right to find H0 then up/down to find parameter number

5. Parameters to set before use

See section 7 for an explanation of Parameter Groups

and to learn how to set a parameter value.

Set the following parameters to allow the iG5A

to run in standard mode with Run, Stop and

Speed Control fromthe integral keypad.

If any of the parameters have been changed

previously, follow the procedure in section 13

toreset the iG5AtoFactory Defaults.

5.2 Parameters in Function Group 1 - F

Press left/right to find F0 then up/down to find parameter number

5.1 Parameters in the Drive Group

Press left/right to find 0.00 (or selected frequency) then up/down to find parameter

Easy Start Guide

6. How to set Motor no-load current - H34

LS Industrial Systems SV-iG5A

This guide has been produced by The Inverter Drive Supermarket Ltd.

All content, including but not limited to graphics, text and procedures copyright The Inverter

Drive Supermarket and must not be reproduced or altered without prior written permission.

6.1.1 Set the frequency to50Hz andstart the motor.

Follow the instructions described in section 8 How to

operate the Inverter to set the output frequency to 50Hz

and start the motor.

Once the Inverter has reached 50.00Hz proceed to the step

below.

Motor no-load current can only be determined with the

motor running off-load. Decouple the motor from the

machine before beginning!

6.1.2 Use the navigation pad to locate the CUr

parameter.

Make a note of this value. It is Motor no-load current

inAmps andmust beset inparameter H34.

Whilst the motor is running, press the down arrow on the

navigation pad until CUr is displayed (as shown opposite).

CUr is a read-only parameter which displays output

current inAmps.

Press "ENT" to select Cur. The output current will be

displayed.

Press the red Stop/Reset button tostop the motor.

Skip this section if using the iG5A in a Fan

or Pumpapplication.

Motor no load current is an important

parameter to set to get the best possible motor

performance.

Correctly set, it allows the Inverter to maintain

the precise output current to suit the motor and

significantly improves torque at lower speeds.

The procedure involves running the motor off-

load at its rated speed and making a note of

output current. This value is then set in

parameter H34.

Once set, this can be confirmed by running the

motor off-load at 50Hz and 5Hz and noting that

the output current is the same in both cases.

6.1 How to determine Motor no-load current by operating the iG5A.

Page 6

LS Industrial Systems SV-iG5A

Easy Start Guide

7. How to set a Parameter value

Page 7

This guide has been produced by The Inverter Drive Supermarket Ltd.

All content, including but not limited to graphics, text and procedures copyright The Inverter

Drive Supermarket and must not be reproduced or altered without prior written permission.

7.1 Use the left and right arrows on the navigation pad

tomove betweenparameter groups.

From the initial screen (shown opposite), press the right

arrow on the navigation pad to move between each of the

four parameter groups. Select H0".

7.2 Use the up and down arrows on the navigation pad

to move between parameters within the selected

parameter group.

7.3 Press "ENT" toedit a parameter.

Once the desired parameter is shown on the display, in this

case H33, press "ENT" toselect it.

Drive

Group

Function

Group 1 F

Function

Group 2 H

I/O

Group

In this example, we will set

Parameter H33 (Function Group 2

H, Parameter number 33) which

is motor rated current.

Press the up arrow on the

navigation pad repeatedly to move

fromH0 to H1, H2, H3 etc. until you

reach H33.

Page 8

This guide has been produced by The Inverter Drive Supermarket Ltd.

All content, including but not limited to graphics, text and procedures copyright The Inverter

Drive Supermarket and must not be reproduced or altered without prior written permission.

7.4 Use the left and right arrows on the navigation pad

to move between digits. Use the up and down arrows to

increase or decrease the digit value.

In this example, the motor nameplate states 4.7A at 230V

so we will change the default value from5.0 to4.7.

LS Industrial Systems SV-iG5A

Easy Start Guide

7.5 Press "ENT" to save changes. Press "ENT" again to

confirm.

Once the value of H33 has been changed to 4.7 press

"ENT" tosave changes.

The display will then flash indicating that the change needs

tobe confirmed.

Press "ENT" again to confirm the change or wait to cancel

the change and return to the edit screen in the previous

step.

Press up to

change to 0 to 7

Press down to

change 5 to to 4

Press left to

change digit

7.6 Parameter value isset.

Now H33 has been successfully set. The screen will return

tothe parameter list.

Repeat the steps above to set the value of other

parameters. See section 5 for recommended settings.

Press the left or right keys on the navigation pad to return to

the Drive Group (ie. the group which does not start with F, H

or I).

Easy Start Guide

8. How to operate the Inverter

Page 9

This guide has been produced by The Inverter Drive Supermarket Ltd.

All content, including but not limited to graphics, text and procedures copyright The Inverter

Drive Supermarket and must not be reproduced or altered without prior written permission.

8.1 Set the requiredspeed.

Use the right navigation key to cycle through the F, H and I

parameter groups until you reach the Drive group - the

display will show0.50 or your selected frequency.

Press ENT to edit this value and use the navigation keys

to change the value as required (eg. to 50.00). Press ENT

tosave changes.

Note: If the motor is running, changes to the frequency

value will take effect immediately (ie. no need tosave).

8.2 Press the greenRun buttontostart the motor.

The green Run button will start the motor. The motor will

accelerate to the speed set in step 1 (above) in the time

defined by the ACC parameter found in the Drive

parameter group.

Motor speed can be changed whilst the motor is running by

modifying the frequency value as described in 8.1 above.

When the motor is running, the RUN light will be

displayed. The FWD or REV light will also be displayed

depending on the direction of rotation.

8.3 Press the redStop/Rst buttontostopthe motor.

The red Stop/Rst button will stop the motor.

The time taken (in seconds) to stop the motor is determined

by the dEC parameter which can be found in the Drive

parameter group.

LS Industrial Systems SV-iG5A

Easy Start Guide

9. How to enable Sensorless Vector Mode

LS Industrial Systems SV-iG5A

Page 10

This guide has been produced by The Inverter Drive Supermarket Ltd.

All content, including but not limited to graphics, text and procedures copyright The Inverter

Drive Supermarket and must not be reproduced or altered without prior written permission.

The standard operating mode of the iG5A

Inverter is VxF. This is the simplest form of

operation and controls Volts and Frequency to

vary the speed of a standard Induction Motor.

The iG5A can also operate in Sensorless

Vector mode. This can improve motor

performance without requiring a separate

feedback device.

Sensorless Vector mode operates in the same

way as VxF but performs a number of

calculations to improve lowspeed torque.

This requires an ID run during which the

Inverter runs the motor for approx. 1 minute at

various speeds togather the necessary data.

Decouple the motor from the machine

before startinganIDrun.

Parameter Description How to set

H40 Control Mode Default is 0. Change to 3 to enable Sensorless Vector Mode.

H41 Auto-tuning Default is 0. Ensure motor is off-load before changing to 1 to begin ID run.

9.1 Parameters in Function Group 2 - H

Press left/right to find H0 then up/down to find parameter number

ENT

SET

RUN

RUN

FWD

REV

STOP

RESET

The display will show tun whilst

the iG5A performs its ID run.

Easy Start Guide

10. How to connect and configure a Potentiometer

for remote speed control

LS Industrial Systems SV-iG5A

Page 11

This guide has been produced by The Inverter Drive Supermarket Ltd.

All content, including but not limited to graphics, text and procedures copyright The Inverter

Drive Supermarket and must not be reproduced or altered without prior written permission.

VR V1 CM

Parameter Description How to set

Frq Speed Command Source Set to to enable 0-10V via 10kOhm Potentiometer 3

10.1 Parameters to change in the Drive Group

Press left/right to find 0.00 (or selected frequency) then up/down to find parameter

If the iG5A speed control parameter is

unsuitable for the application, a remote

Potentiometer can be used instead.

This provides the benefit of allowing motor

speed to be controlled froma more convenient

location such as a cabinet door (if the iG5A is

cabinet-mounted) or on the machine itself.

A Potentiometer of rating should be

used.

The number of turns depends on the

application but both single turn and ten turn

Potentiometers are available fromThe Inverter

Drive Supermarket at InverterDrive.com.

10kOhm

10.2 Connectingthe Potentiometer

A wiring diagram is shown in the illustration

opposite. The most important connection at

the Potentiometer end is the centre terminal or

wiper.

The wiper will output a variable voltage

between 0 and 10 volts and should be

connected to the V1 terminal at the Inverter

end. It is this voltage which provides the speed

signal with 0Vbeing slowest and 10Vfastest.

The default output frequency at 0Vis 0.5Hz. To

change this, edit Parameter F25.

The default output frequency at 10V is 50Hz.

To change this, edit Parameter F26.

If the rotation of the Potentiometer is the

opposite to that required (ie. turn anti-

clockwise to increase speed instead of

clockwise) reverse connections VRand CM.

Use shielded SYcable between Potentiometer

and Inverter and ensure that the cable screen

is earthed at the green earth terminal on the

Inverter.

iG5A I/O

Terminal

Blocks

2

1

3

Screen to

Earth Terminal

10kOhm

Potentiometer

SY Cable

2 1 3

CM

Screen to

Earth Terminal

iG5A I/O

Terminal

Blocks

Switch

SY Cable

Easy Start Guide

11. How to connect and configure a Run/Stop switch

LS Industrial Systems SV-iG5A

Page 12

This guide has been produced by The Inverter Drive Supermarket Ltd.

All content, including but not limited to graphics, text and procedures copyright The Inverter

Drive Supermarket and must not be reproduced or altered without prior written permission.

2

P1

Parameter Description How to set

drv Run/Stop Command Source Set to for Programmable Input 1 P1". 1

11.1 Parameters to change in the Drive Group

Press left/right to find 0.00 (or selected frequency) then up/down to find parameter

The parameters described in Section 5 enable

Run/Stop operation via the red and green

buttons on the Inverter.

If this is unsuitable for the application, a remote

Run/Stop switch can be used instead.

Note that once this procedure is complete, the

Run/Stop buttons on the Inverter can no longer

be used.

1

11.2 Connectingthe Switch

Digital Input

A wiring diagram is shown in the illustration

opposite.

The CM terminal output is 24V DC when the

Inverter is connected to a power supply. This is

provided as a 24Voutput only and has no other

function.

When the P1 terminal receives 24V (ie. when

the circuit with CM is complete), Run is

enabled and motor will turn. Conversely, when

it receives 0V (ie. when the circuit with CM is

broken), Run is disabled and the motor will

stop.

This behaviour is known as a .

Any 24V DC signal connected to P1 will cause

the Inverter to run. This can be useful if an

external source such as a PLC is controlling

the Inverter. If the 24V DC signal is external, a

connection toCMis not required.

Use shielded SYcable between the switch and

Inverter and ensure that the cable screen is

earthed at the green earth terminal on the

Inverter.

Note that although 2 core SYcable is shown in

the illustration opposite, multi-core SY cable

can be used if several digital inputs are to be

used.

1 2

Easy Start Guide

12. How to connect and configure a Fwd/Rev switch

LS Industrial Systems SV-iG5A

Page 13

This guide has been produced by The Inverter Drive Supermarket Ltd.

All content, including but not limited to graphics, text and procedures copyright The Inverter

Drive Supermarket and must not be reproduced or altered without prior written permission.

Parameter Description How to set

drv Run/Stop Command Source Set to for Run/Stop via Input 1 P1" and Fwd/Rev via Input 2 P2". 2

12.1 Parameters to change in the Drive Group

Press left/right to find 0.00 (or selected frequency) then up/down to find parameter

The parameters described in Section 5 enable

Run/Stop operation via the red and green

buttons on the Inverter.

Section 11 explains how to enable remote

Run/Stop via a switch instead.

This section extends the functionality added in

section 11 to allow Forward/Reverse direction

toselected as well as Run/Stop.

12.2 Connectingthe Switch

Digital Input

A wiring diagram is shown in the illustration

opposite.

Note that this switch should be used in

conjunction with a Run/Stop switch as

described in section 11.

When the switch is in position F (forward), the

circuit between P2 and CM is incomplete and

the motor direction is set toforward.

When the switch is in position R (reverse),

the circuit between P2 and CMis complete and

the motor direction is set toreverse.

This behaviour is known as a .

If the switch is changed from"F" to "R" (or vice

versa) whilst the motor is running, the motor

will slow to a stop before starting in the

opposite direction.

Any 24V DC signal from an external source

such as a PLC connected to P2 will set the

direction of rotation.

Use shielded SYcable between the switch and

Inverter and ensure that the cable screen is

earthed as described in section 11.

CM

Screen to

Earth Terminal

Switch

SY Cable

2

P2

1

R

1 2

iG5A I/O

Terminal

Blocks

Easy Start Guide

13. How to reset the Inverter to Factory Defaults

Page 14

This guide has been produced by The Inverter Drive Supermarket Ltd.

All content, including but not limited to graphics, text and procedures copyright The Inverter

Drive Supermarket and must not be reproduced or altered without prior written permission.

13.1 Use the navigation pad to navigate to parameter

H93.

Press the right navigation key to cycle through the

parameter groups until the screen displays H0".

Press the down arrowrepeatidly until H93" is displayed.

13.2 Press "ENT" tochange the value of parameter H93.

Once the display shows H93", press "ENT" to select the

parameter and edit its value.

The display will showthe default value of 0".

13.3 Press the up arrow on the navigation pad to

change the value from0 to1.

Press the up arrow on the navigation pad to change the

value of H93 from0 to1.

Press "ENT" to save the changes. The display will flash to

indicate that the change needs tobe confirmed.

Press "ENT" again to confirm the change. The display will

return toH93.

All parameters have nowbeen reset tofactory defaults.

LS Industrial Systems SV-iG5A

Easy Start Guide

14. Notes

Page 15

This guide has been produced by The Inverter Drive Supermarket Ltd.

All content, including but not limited to graphics, text and procedures copyright The Inverter

Drive Supermarket and must not be reproduced or altered without prior written permission.

LS Industrial Systems SV-iG5A

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Solutions Manual For Mechanics and ThermodynamicsDokument112 SeitenSolutions Manual For Mechanics and ThermodynamicsPaduraru Giani83% (24)

- Guide To Insulating Oil 2003-149 V01Dokument34 SeitenGuide To Insulating Oil 2003-149 V01Charlie IsraelNoch keine Bewertungen

- Brain, Chaos, Quantum MechanicsDokument26 SeitenBrain, Chaos, Quantum MechanicsKristina SipNoch keine Bewertungen

- Shot NoiseDokument11 SeitenShot NoiseKyle Mhiron BumagatNoch keine Bewertungen

- An Overview of Protection SystemDokument162 SeitenAn Overview of Protection SystemEdward DineshNoch keine Bewertungen

- A.W.shaw - How To Write Letters That WinDokument88 SeitenA.W.shaw - How To Write Letters That Winsatstar0% (1)

- A Guide To Transformer Oil Analysis: BY I.A.R. GRAY Transformer Chemistry ServicesDokument12 SeitenA Guide To Transformer Oil Analysis: BY I.A.R. GRAY Transformer Chemistry ServicesAnonymous OCDJg17Z100% (1)

- Carritech AXE10 - 810 September 2015Dokument27 SeitenCarritech AXE10 - 810 September 2015MiguelNoch keine Bewertungen

- Motor Power FactorDokument2 SeitenMotor Power FactorejhagunNoch keine Bewertungen

- Motor ClasstyDokument128 SeitenMotor Classtywatep_08Noch keine Bewertungen

- OT-60 Oil Insulation Dielectric Tester ManualDokument15 SeitenOT-60 Oil Insulation Dielectric Tester ManualMikhail YudhiantaraNoch keine Bewertungen

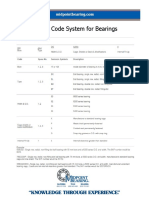

- AFBMA Code System For BearingsDokument1 SeiteAFBMA Code System For BearingsejhagunNoch keine Bewertungen

- Reflector Cr-Hinds PDFDokument4 SeitenReflector Cr-Hinds PDFMichael UnzuetaNoch keine Bewertungen

- Bearing Identification AFBMA Bearing Numbers - U.SDokument2 SeitenBearing Identification AFBMA Bearing Numbers - U.Sejhagun100% (1)

- Jobdes Example at PremierOilDokument1 SeiteJobdes Example at PremierOilejhagunNoch keine Bewertungen

- STR 385 392Dokument8 SeitenSTR 385 392ejhagunNoch keine Bewertungen

- Find and Replace A Color in CorelDRAWDokument3 SeitenFind and Replace A Color in CorelDRAWejhagunNoch keine Bewertungen

- SD LogoDokument1 SeiteSD LogoejhagunNoch keine Bewertungen

- Search GoogleDokument2 SeitenSearch GoogleejhagunNoch keine Bewertungen

- Scribd - Penelusuran GoogleDokument3 SeitenScribd - Penelusuran GoogleejhagunNoch keine Bewertungen

- How To Create Repeating Stripe Patterns in PhotoshopDokument10 SeitenHow To Create Repeating Stripe Patterns in PhotoshopejhagunNoch keine Bewertungen

- Electrical Engineer Job Oil Gas ProjectsDokument2 SeitenElectrical Engineer Job Oil Gas ProjectsejhagunNoch keine Bewertungen

- Features: Model DH-60 (2W) For 2-Wire ApplicationsDokument2 SeitenFeatures: Model DH-60 (2W) For 2-Wire ApplicationsejhagunNoch keine Bewertungen

- Features: Model DH-60 (2W) For 2-Wire ApplicationsDokument2 SeitenFeatures: Model DH-60 (2W) For 2-Wire ApplicationsejhagunNoch keine Bewertungen

- Series E Speakers Series E/ET Speaker-Strobes: FeaturesDokument4 SeitenSeries E Speakers Series E/ET Speaker-Strobes: FeaturesejhagunNoch keine Bewertungen

- Isbn ManualDokument39 SeitenIsbn ManualejhagunNoch keine Bewertungen

- Fenwall Ionization Smoke DetectorDokument4 SeitenFenwall Ionization Smoke Detectormetal_dung2Noch keine Bewertungen

- Series 3200 Manual Pull Station: FeaturesDokument1 SeiteSeries 3200 Manual Pull Station: FeaturesejhagunNoch keine Bewertungen

- F-71 55 Screen.Dokument4 SeitenF-71 55 Screen.ejhagunNoch keine Bewertungen

- Intelligent Interface: (IIM-2000 FN-2000 PANEL MOUNT)Dokument2 SeitenIntelligent Interface: (IIM-2000 FN-2000 PANEL MOUNT)ejhagunNoch keine Bewertungen

- 2320 Fire/Suppression Control Panel: FeaturesDokument2 Seiten2320 Fire/Suppression Control Panel: FeaturesejhagunNoch keine Bewertungen

- Fenwal: Series 27000Dokument2 SeitenFenwal: Series 27000ejhagunNoch keine Bewertungen

- Omega Fuse Catalogues Quatest3 Test ReportDokument4 SeitenOmega Fuse Catalogues Quatest3 Test ReportThuý Ngọc PhạmNoch keine Bewertungen

- India Country Report On Smart GridsDokument69 SeitenIndia Country Report On Smart GridsNikumoni HazarikaNoch keine Bewertungen

- Department of Electrical Engineering: Government Engineering College, BharuchDokument56 SeitenDepartment of Electrical Engineering: Government Engineering College, BharuchPatel NeelNoch keine Bewertungen

- Mdaq AN7 EncoderDokument9 SeitenMdaq AN7 EncoderMOHAMED IBRAHIMNoch keine Bewertungen

- Wide Input Voltage 3.0 A Step Down Regulator: Features and Benefits DescriptionDokument10 SeitenWide Input Voltage 3.0 A Step Down Regulator: Features and Benefits DescriptionFarouq BendjimiNoch keine Bewertungen

- CPT Cirprotec V Overvoltage and Surge ProtectionDokument44 SeitenCPT Cirprotec V Overvoltage and Surge ProtectionFredy J GCNoch keine Bewertungen

- Optimal Design of Electrical MachinesDokument10 SeitenOptimal Design of Electrical MachinesShammi Shekhar ParmarNoch keine Bewertungen

- Prac. Summer 2014Dokument19 SeitenPrac. Summer 2014Praful KakdeNoch keine Bewertungen

- Meas Vi - Fluke 430-II (Com3) .FpqoDokument3 SeitenMeas Vi - Fluke 430-II (Com3) .FpqoHendro SuryonoNoch keine Bewertungen

- Durabrand DCT1303R - DCT1903R Manual de ServicioDokument55 SeitenDurabrand DCT1303R - DCT1903R Manual de ServicioaldoNoch keine Bewertungen

- Differences Between Pv-M2079-K and Pv-M2079: Comparison ChartDokument3 SeitenDifferences Between Pv-M2079-K and Pv-M2079: Comparison ChartAndre BaezNoch keine Bewertungen

- TCY BH Series Catalog PageDokument2 SeitenTCY BH Series Catalog PageBaldoreNoch keine Bewertungen

- Plano Electrico Cargador 938KDokument34 SeitenPlano Electrico Cargador 938KANDRES FUENTES FANDIÑONoch keine Bewertungen

- Ground Floor Lighting Layout Second Floor Lighting Layout: A B C A B CDokument1 SeiteGround Floor Lighting Layout Second Floor Lighting Layout: A B C A B CJerome AdduruNoch keine Bewertungen

- AlllablsDokument1 SeiteAlllablsCarlos RamirezNoch keine Bewertungen

- Dwyer Ms2 w101 102 LCD ManualDokument8 SeitenDwyer Ms2 w101 102 LCD Manualg3qwsfNoch keine Bewertungen

- Poster, Dissertation and Oral PresentationDokument27 SeitenPoster, Dissertation and Oral PresentationThasleem ReyasNoch keine Bewertungen

- 0625 s10 QP 32Dokument20 Seiten0625 s10 QP 32silNoch keine Bewertungen

- Chapter 2 - Waveguide PDFDokument38 SeitenChapter 2 - Waveguide PDFHiroshi RayNoch keine Bewertungen

- Power Quality Case StudiesDokument54 SeitenPower Quality Case StudiesAnonymous Wu6FDjbNoch keine Bewertungen

- Beep Electric Circuits ProblemsDokument11 SeitenBeep Electric Circuits ProblemsVinod Shanker ShringiNoch keine Bewertungen

- Semiconductors and Doping: How Impurities Change ConductivityDokument94 SeitenSemiconductors and Doping: How Impurities Change ConductivityNITHISH KANNANoch keine Bewertungen

- 32 KV High Voltage Power Transmission Line and Stress On Brassica JunceaDokument4 Seiten32 KV High Voltage Power Transmission Line and Stress On Brassica Junceamuhammad mushofahNoch keine Bewertungen

- Dr. Seema Sharma: Book PublishedDokument5 SeitenDr. Seema Sharma: Book PublishedMajid_Darrodi_366Noch keine Bewertungen

- PDokument11 SeitenPFatima ShahNoch keine Bewertungen

- D D D D D D D D: TLC556, TLC556Y Dual Lincmos TimersDokument24 SeitenD D D D D D D D: TLC556, TLC556Y Dual Lincmos Timerselfak.2000Noch keine Bewertungen

- Astm D 149 2020 PDFDokument13 SeitenAstm D 149 2020 PDFIyan LauwNoch keine Bewertungen

- 4MSPS, 24-Bit Analog-to-Digital Converter: Features DescriptionDokument37 Seiten4MSPS, 24-Bit Analog-to-Digital Converter: Features DescriptionEric ChenNoch keine Bewertungen