Beruflich Dokumente

Kultur Dokumente

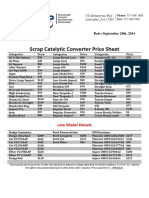

Auto Catalytic Converter

Hochgeladen von

AFLAC ............Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Auto Catalytic Converter

Hochgeladen von

AFLAC ............Copyright:

Verfügbare Formate

A. FORNALCZYK, M.

SATERNUS ISSN 0543-5846

METABK 48(2) 133-136 (2009)

UDC – UDK 669.23:629.113:541.128=111

REMOVAL OF PLATINUM GROUP METALS

FROM THE USED AUTO CATALYTIC CONVERTER

Received – Prispjelo: 2008-06-22

Accepted – Prihva}eno: 2008-09-10

Review Pages – Pregledni rad

Recycling of platinum group metals from the used auto catalytic converters is profitable from ecological and

also economical point of view. This work presents the analysis of the chances of removing the platinum group

metals (PGM) from the used auto catalytic converters applying pyrometallurgical and hydrometallurgical met-

hods. The characteristics of auto catalytic converter is shown as well the available technologies used for proces-

sing the auto catalytic converters are also presented.

Key words: auto catalytic converter, PG metals, platinum removal

Izdvajanje metala iz grupe platina iz kori{tenih automobilskih kataliti~kih convertera. Recikliranje

metala iz grupe platina od kori{tenih automobilskih kataliti~kih konvertera je profitabilno s ekolo{kog i tako|er

s ekonomskog stajali{ta. Ovaj rad prezentira analizu mogu}nosti izdvajanja metala iz grupe platina od kori{te-

nih automobilskih kataliti~kih konvertera uz primjenu pirometalur{kih i hidrometalur{kih metoda. Prikazane su

karakteristike automobilskih kataliti~kih konvertera kao i raspolo`ive tehnologije koje su kori{tene za obradu

automobilskih kataliti~kih konvertera.

Klju~ne rije~i: auto kataliti~ki konverter, GP metali, izdvajanje platine

INTRODUCTION hydrocarbons and nitrogen oxides. During the catalytic

process these gases are transformed into carbon dioxide,

Milions of cars that drive every day on the roads are water, and nitrogen. The following chemical reaction

the source of pollution to the air. This is especially ob- can be written:

served in the big cities and urbanized areas. The average

family car would emit 15 Mg of the toxic and harmful 2CO + O2 = 2CO2 (1)

polluting gases over a 10 year life period [1]. These pol- 2C2H6 + 7O2 = 4CO2 + 6H2O (2)

luting gases can be reduced by catalytic converters (re- 2NO + 2CO = N2 + 2CO2 (3)

move 98 % of pollution). Most modern cars are equipped with three-way cata-

Therefore, current legislation establishes standards lytic converters. This refers to the three regulated emis-

that require the fitting of catalytic converters to all new sions it help to reduce their harmfulness.

cars. The first countries that established such standards Large active surface of catalytic converter is a neces-

were USA and Japan. Then this legislation came into sary condition for its efficient working. This surface is

force in Europe, Australia and parts of Asia in the 1980s, created by the carrier with a honeycomb structure

followed in the 1990s by the developing economies of

Brazil, Mexico and India [2].

It is estimated that this regulations have prevented

emission of 12 billion Mg of harmful polluting gases to

the air [3]. Today over half of the world's 500 million

cars are fitted with a catalytic converters.

CHARACTERISTIC

OF AUTO CATALYTIC CONVERTERS

An auto catalytic converter (Figure 1) reduces the

emission of harmful gases, such as carbon monoxide,

A. Fornalczyk, M. Saternus, Faculty of Materials Science and Metallurgy,

Silesian University of Technology, Katowice, Poland Figure 1. View of an auto catalytic converter

METALURGIJA 48 (2009) 2, 133-136 133

A. FORNALCZYK et al.: REMOVAL OF PLATINUM GROUP METALS FROM THE USED AUTO CATALYTIC CONVERTER

Table 2 also presents the value of recycled PGM. It

can be observed that this value is getting higher every

year.

Table 1. Primary production of palladium, platinum

and rhodium in the years 2001 – 2007 [7]

Year Primary production / Mg

Pd Pt Rh

2001 227,7 182,3 18,8

Figure 2. The carrier auto catalytic converter with a ho- 2002 163,3 185,7 19,1

neycomb structure

2003 200,6 192,8 22,5

(Figure 2) and the catalytic system. Carrier consists of a 2004 265,9 201,9 22,4

ceramic or metallic substrate coated by an aluminium 2005 261,4 206,5 23,5

oxide (Al2O3) with other rare earth oxides such as CeO2, 2006 250,7 211,3 25,6

ZrO2. Platinum group metals (platinum, palladium, rho- 2007 258,8 207,1 25,0

dium) are responsible for the catalytic function.

Platinium is responsible for transforming hydrocar- About 15 - 20 % of the world demand for platinum

bons and carbon monoxide to water and carbon dioxide, comes recycling especially from the used auto catalytic

while rhodium is most efficient in reducing nitrogen ox- converters. However, this amount of platinum is not

ides to nitrogen. Palladium can handle all three pollut- enough to meet the growing demand for this material

ants, but less efficiently than platinium or rhodium. Die- (Table 1 and 2) [8]. All these makes platinum reserves

sel oxidation catalytic converters contain no rhodium. shrink and in consequence platinum prices increase (Ta-

Today’s exhaust systems are characterized by an in- ble 3). For palladium and rhodium present situation is

creased complexity, as one distinguishes oxidation cata- more comfortable, production is, respectively, sufficient

lysts and three-way catalysts for gasoline engines, NOx or nearly sufficient to meet the demands.

adsorbers for lean-burn engines, particulate filters and The high value of PGM (Table 3) encourages recy-

oxidation catalysts for diesel engines, aside from selec- cling from scrap material especially coming from auto

tive catalytic reduction units and NOx adsorbers for die- catalytic converters and is already successfully prac-

sel and many others [4]. tised. Table 4 shows the values of Pt and Pd recovery

from the used auto catalytic converters in different geo-

PGM DEMANDS AND SUPPLIES graphical regions in the years 2001 - 2007. The North

PGM (Pt, Pd, Rh) are used in auto catalytic converters America is the undisputed leader in this recovery.

due to their remarkable resistance to high temperature

corrosion and oxidation. The quantity of platinum, palla- RECYCLING OF AUTO

dium and rhodium used in auto catalysts may vary greatly CATALYTIC CONVERTERS

by vehicle type, manufacturer, country, year and addi-

tional factors. For example depending on the engine ca- Recycling of PGM is very important because it pro-

pacity the auto catalytic converters can contain about 1,5 vides a supplementary source to the mining of these

g of platinum, 0,3 g of rhodium and small amounts of pal- metals, therefore protecting environment by limiting the

ladium [5, 6]. In three-way catalytic converters the ratio number of waste disposal, savings of natural resources

of platinum and rhodium is 5 to 1 and the ratio of palla- exploitation, limiting the electricity consumption, di-

dium and rhodium is 7 to 1. The contents of PGM ranges minishing pollutant emission.

from 1,42 to 1,76 g for 1 dm3 of carrier capacity [5, 6]. At present in Poland there is no plant where PGM

The demand for auto catalytic converters is still in- can be recovered. The used auto catalytic converters are

creasing [6], therefore the demand for PGM is expected purchased, collected and then imported to other coun-

to grow in the nearest future. The driving force behind tries especially Germany. In the world there are some

this is the use of platinum in catalytic converters, partic- firms which recover PGM metals from the used auto

ularly those fitted to diesel vehicles. Tighter restrictions converters. Umicore Autocatalyst Recycling is a good

on the permissible levels of NOx in automotive exhaust example of them. Its plants are presented in Table 5.

continue to drive the demand for rhodium. Auto cata- At first the used auto catalytic converter for recy-

lytic converters now account for over 87 % of the rho- cling must be prepared and homogenized. Then the rep-

dium used [6]. Table 1 presents primary PGM (Pt, Pd, resentative sample is taken and analysis is done. If PGM

Rh) production, whereas Table 2 presents demand for contents is below 30 %, pre-concentration is necessary.

PGM with special focus on using this PGM in auto cata- This can be done by incineration, by pyrometallurgical

lytic converters. concentration or hydrometallurgical processes. The fol-

134 METALURGIJA 48 (2009) 2, 133-136

A. FORNALCZYK et al.: REMOVAL OF PLATINUM GROUP METALS FROM THE USED AUTO CATALYTIC CONVERTER

Table 2. Demand for palladium, platinum and rho- Table 4. Pt, Pd and Rh recovery from the used auto

dium and the value of recycled PGM from catalytic converters [7]

auto catalytic converters [7]

Year Recovery / Mg

Year Demand / Mg Recycled PGM (3) E J A O

1) 2) Platinum

Palladium 2001 2,18 1,71 11,51 1,09

2001 210,3 158,3 8,7 2003 3,58 1,87 13,06 1,55

2002 150,5 94,9 11,5 2005 5,29 1,09 15,71 1,87

2003 168,9 107,3 12,8 2007 6,69 1,09 17,88 1,87

2004 204,0 117,9 16,5 Palladium

2005 228,8 120,2 19,4 2001 0,93 1,24 6,22 0,31

2006 201,2 125,7 24,9 2003 2,18 1,24 8,40 0,93

2007 205,4 136,2 29,4 2005 5,13 0,93 12,13 1,24

Platinum 2007 9,18 1,09 17,42 1,71

2001 193,8 78,4 16,5 E – Europe, J – Japan, A – North America, O – others

2002 201,2 80,6 17,6

2003 203,1 101,7 20,1 Table 5. Plants working for Umicore Autocatalyst

2004 203,4 108,6 21,5 Recycling [4]

2005 208,2 118,0 23,9 Name of plant Place

2006 209,3 128,8 26,6 Umicore Precious Metals Refining N.V. Hoboken

2007 215,4 131,7 27,5 Umicore AG&Co KG Hanau

Rhodium Umicore Brazil Ltd Sao Paulo

2001 18,0 17,6 2,7 Cycleon SASU Paris

2002 18,4 18,6 3,1 Umicore Autocatalyst Recycling Belgium NV Hoboken

2003 19,3 20,5 3,9 Umicore Autocatalyst Recycling GmbH Alzenau

2004 22,7 23,6 4,4 Umicore Autocatalyst Recycling USA Covington

2005 25,7 25,8 4,3

2006 26,2 27,0 5,3 quantities of energy and can create dangerous solutions.

2007 25,1 26,8 5,6 Processes applied for PGM purification are the follow-

1) amount of primary metal that is acquired by the industry ing: calcinations, ion exchange, (solvent)-extraction,

2) amount of metal for manufacturing auto catalytic converters hydrolysis, reduction and oxidation processes, precipi-

3) PGM recovered from the used auto catalytic converters tation [10].

Figure 3 presents the main steps in PGM recovery

Table 3. Average values of Pt, Pd and Rh prices in the from the used auto catalytic converters, while Table 6

years 2001 - 2008 [9] shows some processes used to PGM recovery from auto

Year Price / $/kg

catalytic converters

In the hydrometallurgical methods PGM contained

Pd Pt Rh

in the used auto catalytic converters were dissolved in an

2001 19,69 17,13 51,54

2002 10,91 17,42 26,95

2003 6,52 22,31 17,05

2004 7,47 27,27 31,50

2005 6,53 28,90 66,02

2006 10,36 36,76 146,44

2007 11,46 42,03 199,24

2008* 14,39 61,47 272,03

* - average value from 4 months (01 – 04)

lowing stages are dissolution and PGM isolation and fi-

nally PGM purification.

PGM purification let to obtain very high purity Figure 3. Main steps in PGM recovery from the used catal-

metal, but after all it is very expensive. It consumes large ytic converters [10]

METALURGIJA 48 (2009) 2, 133-136 135

A. FORNALCZYK et al.: REMOVAL OF PLATINUM GROUP METALS FROM THE USED AUTO CATALYTIC CONVERTER

Table 6. Some processes of PGM recovery from the dium. These two methods can be combined. As a result

auto catalytic converters [11,12] the high level of PGM recovery can be obtained [11].

Process Specification

CN extraction

Hydrometallurgy, SUMMARY

US Bureau of Mining

Segregation N.E. ChemCat The main requirements that the industry has to meet

Aqua regia Hydrometallurgy nowadays are the following: the environmental protec-

Chlorination Tanaka Kikinzoku tion, limiting the amount of wastes, reusing the second-

ary material. So to protect natural environment against

Melting method-1 Pyrometallurgy

harmful polluting gases catalytic converters are in-

ROSETM method Pyrometallurgy, Nippon PGM

stalled in cars. Life time of these converters is limited.

Metal Vapour Treatment Pyrometallurgy, MatsudaSangyo Ltd Thus the recycling of end-of-life catalytic converters is

crucial in order to economise on valuable resources and

to minimise the environmental pollution connected with

PGM production. Processing 2 Mg of the used auto cata-

lytic converters can avoid mining 150 kg of ores and all

the following stages which are necessary to obtain pure

metal.

Today it is estimated that almost 30 % of all PGM

ever mined have been used for auto catalytic converters

and more than 2 000 Mg of these is still globally “on the

road”. So taking into account the prices of Pt, Pd and Rh

it is profitable to recover these metals from catalytic

converters. Commonly hydrometallurgical methods are

used in this recovery. However they also give some dan-

gerous by-products.

Taking into consideration the cost of the used auto

catalytic converters and the cost of available technolo-

gies it seems appropriate not only to export catalytic

converters but to start recycling them in Poland.

REFERENCES:

Figure 4. Scheme of hydrometallargical method [11] [1] www.ipa-news.net

[2] www.sfa-oxford.com/environment.html

[3] www.davisconverters.com/catalyticconstruction.shtml

aqueous solution of chlorate, perchloric acid, Cl2, H2O2, [4] www.autocatalyst-recycling.umicore.com

[5] Emission Sub System – Catalytic Converter, Toyota Motor

bromate, nitrate, and aqua regia. As a result PGM are

Sales, USA.

mostly in the form of chloro-complex (MCl62-). The ob- [6] Chevalier P.: PGM, Canadian Minerals Yearbook, 2004. p.

tained solution contains PGM, but their concentration is 41.1 – 41.16.

low. So the next stage is to concentrate the solution and [7] Platinum 2007, Interim Review, Johnson Matthey, UK,

extract them from this solution. However, in hydro- 2007, p.1-32.

metallurgical methods liquid wastes can be created in [8] C. Hagelüken: Markets for the catalyst metals platinum, pal-

large numbers. This wastes might be very dangerous to ladium and rhodium, Metall, 1-2, (2006), p. 31-42.

[9] www.platinum.matthey.com

the natural environment. Figure 4 presents the example

[10] C. Hagelüken: Precious metals process catalysts – material

of hydrometallurgical method. flows and recycling, Supplement to Chamica Oggi/Che-

In pyrometallurgical methods broken-up carriers mistry Today, 2(24), (2006).

covered by the PGM are melted with the addition of [11] J.S. Yoo: Metal recovery and rejuvenation of metal-loaded

other metal which has a special function - to be a liquid spent catalyst, Catalyst Today 44, (1998), 27-46.

matrix. PGM pass into the alloy, while carriers are sepa- [12] Y. Kayanuma, T. Okabe, M. Maeda: Metal Vapour Treat-

ment for Enhancing the Dissolution of Platinum Group Me-

rated and scrapped. Obtained metal is rich in PGM, so tals from Automotive Catalyst Strap, Metallurgical and Ma-

the next stage is the PGM purification [11,12]. terial Transactions, 35B, (2004), 817-824.

Both methods are very effective. Using them it is

possible to recover 95 % of platinum and 70 % of rho- Note: The responsible translator for English language are the Authors.

136 METALURGIJA 48 (2009) 2, 133-136

Das könnte Ihnen auch gefallen

- Cadillac Converter Price ListDokument1 SeiteCadillac Converter Price ListJoseph Warren75% (4)

- AP (Acid-Peroxide) Process Flow SheetDokument1 SeiteAP (Acid-Peroxide) Process Flow SheetAFLAC ............100% (1)

- Catalytic Converter Weights and PGM ContentDokument39 SeitenCatalytic Converter Weights and PGM ContentAFLAC ............67% (6)

- Escraper's Refiners Cheat SheetDokument7 SeitenEscraper's Refiners Cheat SheetAFLAC ............100% (21)

- Escraper's Refiners Cheat SheetDokument7 SeitenEscraper's Refiners Cheat SheetAFLAC ............100% (21)

- Refining Precious Metal Wastes C M HokeDokument369 SeitenRefining Precious Metal Wastes C M HokeAFLAC ............86% (43)

- Gold Extraction From Electronic ScrapDokument7 SeitenGold Extraction From Electronic ScrapAFLAC ............100% (2)

- Gold Refining Forum Handbook Vol 2 (6-24-09)Dokument72 SeitenGold Refining Forum Handbook Vol 2 (6-24-09)AFLAC ............83% (6)

- Platinum Group Metals and CompoundsDokument72 SeitenPlatinum Group Metals and CompoundsAFLAC ............100% (7)

- Recovery of Platinum From Scrap Automotive Catalytic ConvertersDokument8 SeitenRecovery of Platinum From Scrap Automotive Catalytic ConvertersAFLAC ............100% (3)

- Catalytic ConverterDokument75 SeitenCatalytic ConverterJuan-pierre JacobsNoch keine Bewertungen

- Cars With Most Expensive Catalytic Converters For ScrapsDokument3 SeitenCars With Most Expensive Catalytic Converters For ScrapsNabin Pradhan100% (1)

- Gold Content List in CPU ChipsDokument6 SeitenGold Content List in CPU ChipsAFLAC ............89% (53)

- Separating The Six Platinum MetalsDokument9 SeitenSeparating The Six Platinum MetalsAFLAC ............100% (1)

- Separating The Six Platinum MetalsDokument9 SeitenSeparating The Six Platinum MetalsAFLAC ............100% (1)

- Recovering Gold & Other Precious Metals from Electronic ScrapVon EverandRecovering Gold & Other Precious Metals from Electronic ScrapBewertung: 3 von 5 Sternen3/5 (6)

- Recovery Catalytic Converters RefiningDokument20 SeitenRecovery Catalytic Converters RefiningAFLAC ............80% (5)

- Recovering Precious Metals From Waste Liquid ResiduesDokument394 SeitenRecovering Precious Metals From Waste Liquid ResiduesAFLAC ............100% (12)

- Mine Scams Gold OreDokument30 SeitenMine Scams Gold OreAFLAC ............Noch keine Bewertungen

- Escrap Refiners Shopping Cheat Sheet - Rev 0.6Dokument10 SeitenEscrap Refiners Shopping Cheat Sheet - Rev 0.6ulfheidner910367% (3)

- Mine Ore and Gold Scams Paul Jones McDermitt NVDokument4 SeitenMine Ore and Gold Scams Paul Jones McDermitt NVAFLAC ............Noch keine Bewertungen

- 4-Storey Commercial Bldg. by Staadpro Using UBC & American CodeDokument35 Seiten4-Storey Commercial Bldg. by Staadpro Using UBC & American CodeBilal Ahmed Barbhuiya50% (2)

- Ebay Gold RecoveryDokument11 SeitenEbay Gold RecoveryAFLAC ............90% (10)

- Silver Cleaning and ConservationDokument14 SeitenSilver Cleaning and ConservationAFLAC ............Noch keine Bewertungen

- Recovering Silver From Photographic MaterialsDokument32 SeitenRecovering Silver From Photographic MaterialsAFLAC ............100% (5)

- Silver and Palladium Recycling From The Secondary ResourcesDokument5 SeitenSilver and Palladium Recycling From The Secondary ResourcesAFLAC ............Noch keine Bewertungen

- PGM Catalyst Handbook USADokument93 SeitenPGM Catalyst Handbook USAAFLAC ............Noch keine Bewertungen

- Chemical Resistance of PlasticsDokument2 SeitenChemical Resistance of PlasticsAFLAC ............100% (2)

- EC 49StateCatalog08Dokument347 SeitenEC 49StateCatalog08Lee Prine0% (1)

- ROK Bros Cat NumbersDokument4 SeitenROK Bros Cat NumbersLetty Estrada100% (1)

- Gold in Processor ChipsDokument24 SeitenGold in Processor ChipsAFLAC ............100% (9)

- Gold Recovery Correctly - 12 StepsDokument25 SeitenGold Recovery Correctly - 12 Stepsjuan9gonzalez_9Noch keine Bewertungen

- Properties of Gold ColloidsDokument13 SeitenProperties of Gold ColloidsAFLAC ............100% (1)

- Gold Refining Forum Hanbook Vol 1Dokument128 SeitenGold Refining Forum Hanbook Vol 1AFLAC ............96% (52)

- Gold Content List in CPU ChipsDokument6 SeitenGold Content List in CPU Chipsesam a gad71% (7)

- Monolithic Chip Capacitors Source of Palladium and SilverDokument4 SeitenMonolithic Chip Capacitors Source of Palladium and SilverNoreen Castardo- MontemayorNoch keine Bewertungen

- Gold Chemistry 2Dokument189 SeitenGold Chemistry 2Radulescu Eugen100% (3)

- Converting PGM Colored Salts With ZincDokument3 SeitenConverting PGM Colored Salts With ZincAFLAC ............100% (2)

- Rhodium Recovery and Recycling From Spent MaterialsDokument9 SeitenRhodium Recovery and Recycling From Spent MaterialsLựuLiềuLìNoch keine Bewertungen

- Dissolving Material With Sulfric AcidDokument61 SeitenDissolving Material With Sulfric AcidAFLAC ............Noch keine Bewertungen

- Nickel TestingDokument1 SeiteNickel TestingAFLAC ............Noch keine Bewertungen

- ASTME466 07ConductingForceControlledConstantAmplitudeAxialFatigueTestsDokument5 SeitenASTME466 07ConductingForceControlledConstantAmplitudeAxialFatigueTestsam100% (1)

- Automotive Catalytic Converter RefiningDokument54 SeitenAutomotive Catalytic Converter RefiningAFLAC ............100% (3)

- Matching Your Crucible To Your ApplicationDokument9 SeitenMatching Your Crucible To Your ApplicationAFLAC ............100% (3)

- Smelting SilverDokument15 SeitenSmelting Silverminerales&materialesNoch keine Bewertungen

- Silver Recovery With NaOH IIDokument4 SeitenSilver Recovery With NaOH IIAFLAC ............100% (1)

- Silver Recovery With NaOH IIDokument4 SeitenSilver Recovery With NaOH IIAFLAC ............100% (1)

- How To Refine Gold From Electronic ScrapDokument5 SeitenHow To Refine Gold From Electronic ScrapSma Harmoni100% (3)

- Metal Content of Modern United States CoinsDokument8 SeitenMetal Content of Modern United States CoinsAFLAC ............100% (2)

- Cats GuideDokument6 SeitenCats GuideTazeen Fatima43% (7)

- Cpu Scrap Au RecoveryDokument14 SeitenCpu Scrap Au RecoveryAmainod Damâlo Inial100% (3)

- Purifying Palladium Precipitated From Dirty SolutoinsDokument5 SeitenPurifying Palladium Precipitated From Dirty SolutoinsAFLAC ............Noch keine Bewertungen

- Assay Room Setup DFCDokument14 SeitenAssay Room Setup DFCAFLAC ............Noch keine Bewertungen

- Catalytic ConvertersDokument14 SeitenCatalytic Convertersmonabansal143099Noch keine Bewertungen

- Gold and Silversmiths 1911Dokument68 SeitenGold and Silversmiths 1911AFLAC ............Noch keine Bewertungen

- BOQ Ductile IronDokument2 SeitenBOQ Ductile IronAshraf SalehNoch keine Bewertungen

- Gold Cpu Chip Price GuideDokument9 SeitenGold Cpu Chip Price GuideAvi Oziel SEO Toronto Internet Marketing - Toronto Web Design - Social Media Toronto100% (6)

- Safe Recovery of Platinum From Scrap AUTO CATALYTIC CONVERTERDokument6 SeitenSafe Recovery of Platinum From Scrap AUTO CATALYTIC CONVERTERAFLAC ............86% (7)

- Basic Filtration ConceptsDokument3 SeitenBasic Filtration ConceptsAFLAC ............Noch keine Bewertungen

- Pyro Hydro Methods RECOVERY PTDokument4 SeitenPyro Hydro Methods RECOVERY PTManojlovic VasoNoch keine Bewertungen

- Method To Convert Silver Sulphide Into Metalic SilverDokument9 SeitenMethod To Convert Silver Sulphide Into Metalic SilverAFLAC ............100% (3)

- Inspection Test & Plan: Pondasi Bangunan NOMOR: I-QAC-027/100.19Dokument21 SeitenInspection Test & Plan: Pondasi Bangunan NOMOR: I-QAC-027/100.19pahrizan100% (2)

- Proses Pembuatan KertasDokument124 SeitenProses Pembuatan Kertasgarispante07100% (7)

- Fuel Types and Firing SystemsDokument80 SeitenFuel Types and Firing SystemsIrshad HussainNoch keine Bewertungen

- Process For Silver Recovery From Digital FilmsDokument7 SeitenProcess For Silver Recovery From Digital FilmsAFLAC ............100% (1)

- Catalytic Converter RecyclingDokument10 SeitenCatalytic Converter RecyclingValmirNoch keine Bewertungen

- Auto Catalyst Wash CoatDokument5 SeitenAuto Catalyst Wash CoatAFLAC ............Noch keine Bewertungen

- Development and Performance AnalysisOf Nicel Based Catalytic ConverterDokument4 SeitenDevelopment and Performance AnalysisOf Nicel Based Catalytic ConverterRojil GhufronNoch keine Bewertungen

- Review Paper On Catalytic Converter For Automotive Exhaust EmissionDokument6 SeitenReview Paper On Catalytic Converter For Automotive Exhaust Emissionpamela garciaNoch keine Bewertungen

- Reduction of Diesel Engine Emissions Usi PDFDokument6 SeitenReduction of Diesel Engine Emissions Usi PDFSalar AhmedNoch keine Bewertungen

- Recycling of PGM Secures The Supplies of Key Industry SectorsDokument12 SeitenRecycling of PGM Secures The Supplies of Key Industry Sectorsapi-94537271Noch keine Bewertungen

- Design, Fabrication and Testing of A Mno Based Catalytic ConverterDokument8 SeitenDesign, Fabrication and Testing of A Mno Based Catalytic ConverterJimsNoch keine Bewertungen

- Minerals 12 00361 v2Dokument14 SeitenMinerals 12 00361 v2kimba worthNoch keine Bewertungen

- Europe Recycling WasteDokument2 SeitenEurope Recycling Wastedwi santosoNoch keine Bewertungen

- Liu 2015Dokument24 SeitenLiu 2015chintz BhatNoch keine Bewertungen

- SATERNUS Mariola, FORNALCZYK Agnieszka, WILLNER JoannaDokument6 SeitenSATERNUS Mariola, FORNALCZYK Agnieszka, WILLNER JoannaLuisJorgeMaldonadoRincónNoch keine Bewertungen

- The Recent Progress and Future of Oxygen Reduction Reaction Catalysis-A ReviewDokument14 SeitenThe Recent Progress and Future of Oxygen Reduction Reaction Catalysis-A ReviewoceanforestNoch keine Bewertungen

- metal2016 - fornalczyk - metal - копияDokument6 Seitenmetal2016 - fornalczyk - metal - копияFlexMashNoch keine Bewertungen

- Oxygen Reduction Reaction Catalyzed by Noble Metal ClustersDokument18 SeitenOxygen Reduction Reaction Catalyzed by Noble Metal ClustersoceanforestNoch keine Bewertungen

- Cleaner Vehicle EmissionsDokument7 SeitenCleaner Vehicle EmissionsDikra BkNoch keine Bewertungen

- Unesco - Eolss Sample Chapters: Catalysis For The Protection of The Environment and The Quality of LifeDokument8 SeitenUnesco - Eolss Sample Chapters: Catalysis For The Protection of The Environment and The Quality of Lifejann youngNoch keine Bewertungen

- 10.1016@S1359 02860200108 0Dokument11 Seiten10.1016@S1359 02860200108 0Meita PratiwiNoch keine Bewertungen

- Automobile Catalytic ConverterDokument9 SeitenAutomobile Catalytic Converterสุทิมา ศรีวิภาสถิตย์Noch keine Bewertungen

- Chem Select 2020, 5, 3805-3814Dokument1 SeiteChem Select 2020, 5, 3805-3814Malaya SahooNoch keine Bewertungen

- A Catalytic Converter: ConstructionDokument2 SeitenA Catalytic Converter: ConstructionSrinivas PratapNoch keine Bewertungen

- Catalytic ConverterDokument20 SeitenCatalytic ConverterSanskarrRathiiNoch keine Bewertungen

- Fabrication and Testing of A Catalytic ConvertorDokument5 SeitenFabrication and Testing of A Catalytic ConvertorInternational Journal of Application or Innovation in Engineering & ManagementNoch keine Bewertungen

- Paper II de Convertidor Catalitico PDFDokument4 SeitenPaper II de Convertidor Catalitico PDFAldair RamosNoch keine Bewertungen

- CRL. Hamilton, D. Methods of Conserving Archaeological Material From Underwater Sites. 1999Dokument110 SeitenCRL. Hamilton, D. Methods of Conserving Archaeological Material From Underwater Sites. 1999Trinidad Pasíes Arqueología-Conservación100% (1)

- The Boy ChemistDokument323 SeitenThe Boy ChemisteshomitesNoch keine Bewertungen

- What Happens When You Breath Niric Acid FumesDokument4 SeitenWhat Happens When You Breath Niric Acid FumesAFLAC ............100% (1)

- Osterberg's E-Tower Gold RecoveryDokument1 SeiteOsterberg's E-Tower Gold RecoveryAFLAC ............100% (1)

- Calm Morrison HokeDokument1 SeiteCalm Morrison HokeAFLAC ............Noch keine Bewertungen

- Morphology and Roughness of Silver Deposit Formed by CementationDokument10 SeitenMorphology and Roughness of Silver Deposit Formed by CementationAFLAC ............Noch keine Bewertungen

- Boulanger, Idriss - Soil Liquefaction During Earthquakes - 2008Dokument263 SeitenBoulanger, Idriss - Soil Liquefaction During Earthquakes - 2008Roberto MonettaNoch keine Bewertungen

- Innovative TechnologiesDokument11 SeitenInnovative TechnologiesKantishNoch keine Bewertungen

- Activity 1 - Chemical Safety (GHS-SDS)Dokument11 SeitenActivity 1 - Chemical Safety (GHS-SDS)John Joshua Latras ManticahonNoch keine Bewertungen

- REGO - Pressure Builder - Economizer CBH CBCDokument1 SeiteREGO - Pressure Builder - Economizer CBH CBCcriuvosNoch keine Bewertungen

- SL Somos WaterClear Ultra Material Specifications PDFDokument2 SeitenSL Somos WaterClear Ultra Material Specifications PDFTushar Prakash ChaudhariNoch keine Bewertungen

- 7.aldehydes and Ketones NewDokument36 Seiten7.aldehydes and Ketones NewMohd NazriNoch keine Bewertungen

- CIV-MS-010-07-Rapid Chloride PermeabilityDokument7 SeitenCIV-MS-010-07-Rapid Chloride PermeabilityAdil faridNoch keine Bewertungen

- Tin Is A Chemical Element With The Symbol SNDokument1 SeiteTin Is A Chemical Element With The Symbol SNemieZNoch keine Bewertungen

- Quarter3 Exam Ict 9 ANSWER KEYDokument4 SeitenQuarter3 Exam Ict 9 ANSWER KEYJenelyn RusianaNoch keine Bewertungen

- Novel Hybrid Structural Core Sandwich Materials For Aircraft ApplicationsDokument4 SeitenNovel Hybrid Structural Core Sandwich Materials For Aircraft Applicationsphd.meethaqNoch keine Bewertungen

- Waste Management PDFDokument16 SeitenWaste Management PDFKunal ThakurNoch keine Bewertungen

- EPF3701 - Lec8 ClosuresDokument57 SeitenEPF3701 - Lec8 ClosuresMuhd Khairul AmriNoch keine Bewertungen

- G40 Ready Mix Data Sheet: PropertiesDokument4 SeitenG40 Ready Mix Data Sheet: Propertieswadi ajanaNoch keine Bewertungen

- Lecture 22 Thinfilm Deposition-Sputteringr 9 PDFDokument6 SeitenLecture 22 Thinfilm Deposition-Sputteringr 9 PDFu11ee079Noch keine Bewertungen

- Product & Service Datasheet: Medium Voltage (6kV To 36kV) Subsea Power Cable Repair JointDokument2 SeitenProduct & Service Datasheet: Medium Voltage (6kV To 36kV) Subsea Power Cable Repair Jointnader mahfoudhiNoch keine Bewertungen

- Manufacturing Lab PDFDokument30 SeitenManufacturing Lab PDFShivam VarshneyNoch keine Bewertungen

- New Pump Connection Scheme (Anudan Yojna)Dokument15 SeitenNew Pump Connection Scheme (Anudan Yojna)souvikbesu89Noch keine Bewertungen

- Oxygen BarrierDokument20 SeitenOxygen BarrierKarina ArdizziNoch keine Bewertungen

- Iso 527 2 2012 PDFDokument16 SeitenIso 527 2 2012 PDFRafael CastroNoch keine Bewertungen

- GCC - Plastic IndustryDokument44 SeitenGCC - Plastic IndustrySeshagiri KalyanasundaramNoch keine Bewertungen

- Bom of Studs & Nuts For Balance SystemDokument4 SeitenBom of Studs & Nuts For Balance SystemmishtinilNoch keine Bewertungen

- Device Technology For Nanoscale III-V Compound Semiconductor Field Effect TransistorsDokument161 SeitenDevice Technology For Nanoscale III-V Compound Semiconductor Field Effect TransistorsRaghu Vamsi ChavaliNoch keine Bewertungen

- Katalog Techno VeneerDokument24 SeitenKatalog Techno VeneerMarina JocicNoch keine Bewertungen

- Brønsted-Lowry Acids and BasesDokument39 SeitenBrønsted-Lowry Acids and BasesEr Bipin VermaNoch keine Bewertungen