Beruflich Dokumente

Kultur Dokumente

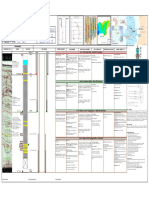

Completion Design Course Detailed Timetable

Hochgeladen von

Isa Cadena GarciaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Completion Design Course Detailed Timetable

Hochgeladen von

Isa Cadena GarciaCopyright:

Verfügbare Formate

Page 1 of 5

www.letstrain.co.uk

COMPLETION DESIGN (MODULAR Course)

Detailed Course Contents

Monday (day 1)

Morning (08:30 12:30)

Introductions venue / instructor / attendees / course overview

1. Completion Architecture

a. Well Objectives / Design Data requirements / Industry Standards /

DCR Regulations

b. Drilling & other well construction considerations

c. Open Hole v Cased Hole

d. Horizontal / Multilateral / Intelligent

e. Slimhole / Monobore / Single / Dual / Insert

f. Key interfaces between elements of completion architecture.

g. Life Cycle Issues

2. Sand Face Completion

a. Hole Size & Liner considerations

b. Sand Control / Sand Production Prediction / Stand Alone Screen and

gravel Pack Screen & Gravel Size Selection / Expandable Screens /

Frac Pack / Inflow Control

c. Perforating Design, Specification & Execution / Estimating Static

under-balance requirement / Dynamic Under-balance

d. Fluids & Filtration

Afternoon (13:30 17:30)

3. Tubing String Components

a. Wellhead , Tree & Tubing Hanger / Surface & Subsea

b. Tubing Size / Tubing Strength / Tubing Connections

c. Subsurface Safety Valves

d. Nipples, Plugs and other Flow Control Devices

e. Packers & Tubing Movement

Page 2 of 5

www.letstrain.co.uk

f. Artificial Lift Equipment

g. Material Selection

h. HPHT considerations

4. Completion & Intervention Operations

a. Outline Completion Program Steps

b. Intervention Equipment & considerations

c. Well Integrity Issues

d. Benchmarking performance, JIPs & networking

Tuesday (day 2)

Morning (08:30-12:30)

1. Strength of Materials & API Documentation

a. Stress & Strain / Yield Strength / Tensile Strength

b. API Documentation

i. Spec 5CT - Manufacture

ii. TR 5C3 (Bulletins 5C2 & 5C3) Performance Calculations

iii. RP 5C5 - Connections

iv. RP 5C7 Coiled Tubing

2. Tubing Movement Hand Calculations

a. Piston

b. Buoyancy

c. Ballooning

d. Buckling

e. Temperature

Afternoon (13:30 17:30)

3. Design Safety Factors & Service Life Load Cases

a. API Uniaxial/Biaxial Stress Calculations

Page 3 of 5

www.letstrain.co.uk

b. Von Mises equivalent Triaxial Stress Calculations

c. API Spec 11D1 Packer Performance Envelope

d. Design Factors vs. Design Safety Factors

e. Typical Service Life Load Cases

f. Deriving Internal, External & Temperature Profiles for Load Cases

4. WellCat & Osprey Tubular Designer Technical Application Software

a. Program introduction

b. Basic Program Workflow

c. Quick Start Guide

d. Basic Case Study Example

e. Pipe weight, grade & connection selection

Wednesday (day 3)

Morning (08:30-12:30)

1. Introduction to Production System Modelling

a. Completion Design

b. Production Optimisation

c. Modelling Method

d. Overview of PROSPER and resources supplied with the software

2. PVT Properties of Fluids

a. Hydrocarbon Fluid Types & Phase Diagrams

b. Black Oil vs. Compositional

c. Black Oil Correlation Selection & Tuning / Importance of Viscosity

d. Working with Lab Reports / Differential vs. Flash vs. Multi-stage

Afternoon (13:30 17:30)

3. Inflow Performance Relationships

a. Straight Line PI vs. Vogel

Page 4 of 5

www.letstrain.co.uk

b. Darcy vs. Forchheimer (rate dependent skin) and others

c. Oil & Gas Model selection

d. Horizontal Well Modelling /pressure loss along wellbore

e. Multilateral Well modelling

4. Well Skin & Damage Modelling & Design Optimisation

a. Skin Definition, Types & Origin

b. Perforation modelling & design / spf & in-situ penetration

c. Gravel Pack modelling & design

d. Stimulation modelling & design

Thursday (day 4)

Morning (08:30-12:30)

5. Vertical Lift Performance

a. Multi-phase Flow

b. MPF Correlation Selection & tuning

c. Surface Roughness & Erosional Velocity

d. Turner Velocity and Sand Particle Transport

6. Tubing Size Selection

a. Life of Well Sensitivities

b. Tubing Equipment

c. Stable Rates

d. Velocity Strings & Insert Gas Lift Strings

Afternoon (13:30 17:30)

7. Detailed Nodal Analysis Options & Solutions Review

a. Matching Real Field Data for Performance Prediction and Network

Optimisation

b. Enthalpy Balance Temperature Prediction

c. Gas Lift Injection Line and Subsea Flowline Modelling

Page 5 of 5

www.letstrain.co.uk

d. Plotting & Reporting

e. OpenServer Automation

8. Artificial Lift

a. Gas Lift Rate & Depth of Injection Optimisation

b. Gas Lift Design & Troubleshooting Options (Basic Introduction)

c. ESP Design (Basic Introduction)

d. Other Lift Methods

Friday (day 5)

Morning (08:30-12:30)

1. Team Design Exercise Part 1

a. Problem Introduction

b. Outline Architecture & Equipment Selection

2. Team Design Exercise Part 2

a. Well Production System Modelling

b. Tubing Size Selection

c. Sand Control &/or Perforation Design

Afternoon (13:30 17:30)

3. Team Design Exercise Part 3

a. Tubing Stress Analysis

b. Equipment Specification Review

4. Team Design Results Presentation & Course Review

a. Team Design Presentations & Actual Well Design Review

b. General Course Q&A session

c. Course Feedback & Award of Certificates

END

Das könnte Ihnen auch gefallen

- TBG Stress AnalysisDokument2 SeitenTBG Stress AnalysisazareiforoushNoch keine Bewertungen

- API Modified 4010NMDokument25 SeitenAPI Modified 4010NMzhiqianxuNoch keine Bewertungen

- Wire Line Pipe Recovery Client Considerations PDFDokument6 SeitenWire Line Pipe Recovery Client Considerations PDFAliNoch keine Bewertungen

- Introduction To Wellbore Positioning - V4 05 2016Dokument197 SeitenIntroduction To Wellbore Positioning - V4 05 2016willyNoch keine Bewertungen

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsVon EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNoch keine Bewertungen

- WBPDokument426 SeitenWBPahmed_497959294Noch keine Bewertungen

- Design Process For Completion and WorkoversDokument72 SeitenDesign Process For Completion and WorkoversDianaEstefaniaValdez100% (1)

- OPM10207-13 WellaheadDokument125 SeitenOPM10207-13 WellaheadThomas DuNoch keine Bewertungen

- ENM200 Subsurface Course Work 2 FinalDokument9 SeitenENM200 Subsurface Course Work 2 FinalArief Budiman Hermani100% (1)

- The Value of Comprehensive Well Integrity Analysis in Deep-Ultradeepwater High-Pressure, High-Temperature ScenariosDokument12 SeitenThe Value of Comprehensive Well Integrity Analysis in Deep-Ultradeepwater High-Pressure, High-Temperature ScenariosVishal100% (1)

- Well IntegrityDokument2 SeitenWell IntegrityAnubhuti Purohit BhatnagarNoch keine Bewertungen

- Master Thesis - Jose Maria MoratallaDokument80 SeitenMaster Thesis - Jose Maria MoratallaorlandoNoch keine Bewertungen

- Tdas West Shell 091602Dokument15 SeitenTdas West Shell 091602amin peyvandNoch keine Bewertungen

- Underbalanced Coiled Tubing Drilled Horizontal Well in The North SeaDokument6 SeitenUnderbalanced Coiled Tubing Drilled Horizontal Well in The North Seatarang_tusharNoch keine Bewertungen

- 2011 Horizontal Underbalanced Drilling Technology Successfully Applied in Field AA - Libya PDFDokument11 Seiten2011 Horizontal Underbalanced Drilling Technology Successfully Applied in Field AA - Libya PDFcarlorgsNoch keine Bewertungen

- Drill Bit Selection and Evaluation ParsselDokument10 SeitenDrill Bit Selection and Evaluation ParsselKaveh Bahiraee100% (1)

- Drilling Planning To Reporting Workflows: © 2011 HalliburtonDokument26 SeitenDrilling Planning To Reporting Workflows: © 2011 HalliburtonNothingNoch keine Bewertungen

- Spe 36761 MSDokument13 SeitenSpe 36761 MSKarla CotesNoch keine Bewertungen

- Well Control Simulation PDFDokument8 SeitenWell Control Simulation PDFSalem HalbaouiNoch keine Bewertungen

- Accuracy Prediction For Directional MWDDokument16 SeitenAccuracy Prediction For Directional MWDJohnSmithNoch keine Bewertungen

- Api RP 78Dokument28 SeitenApi RP 78hdgmNoch keine Bewertungen

- Tomax AST Tool User ManualDokument4 SeitenTomax AST Tool User ManualChinyere NkereNoch keine Bewertungen

- 5 - Bit Hydraulic OptimizationDokument31 Seiten5 - Bit Hydraulic OptimizationFarouq EngNoch keine Bewertungen

- Openwells® Performance Reviews Version 5000.1.12.0: Release Notes and User GuideDokument19 SeitenOpenwells® Performance Reviews Version 5000.1.12.0: Release Notes and User GuideWALDO DAVID SILVA SANCHEZNoch keine Bewertungen

- Analysis, Comparison and Application of CWD Against Conventional Drilling OperationsDokument104 SeitenAnalysis, Comparison and Application of CWD Against Conventional Drilling Operationsprakharmathur14100% (1)

- Completions DesignDokument22 SeitenCompletions DesignAbiodun AkalaNoch keine Bewertungen

- Multilateral Wells Outline 1-05Dokument3 SeitenMultilateral Wells Outline 1-05abdounouNoch keine Bewertungen

- Managed Pressure Drilling & Underbalanced Operations: Platinum SponsorsDokument4 SeitenManaged Pressure Drilling & Underbalanced Operations: Platinum SponsorsSyed IrtazaNoch keine Bewertungen

- 37 Coiled TubingDokument45 Seiten37 Coiled TubingBrahim LetaiefNoch keine Bewertungen

- Part 2 Well DesignDokument12 SeitenPart 2 Well DesignAbdelaziz Mohamed Abdelmoaty ArafaNoch keine Bewertungen

- Carney, Guven, McGrew - 1982 - Investigation of High-Temperature Fluid Loss Control Agents in Geothermal Drilling FluidsDokument9 SeitenCarney, Guven, McGrew - 1982 - Investigation of High-Temperature Fluid Loss Control Agents in Geothermal Drilling FluidsCATALINA MEDRANONoch keine Bewertungen

- Brine Fluids PlanningDokument4 SeitenBrine Fluids PlanningKolawole AdisaNoch keine Bewertungen

- Hole Conditioning Before Running Casing or LinerDokument1 SeiteHole Conditioning Before Running Casing or LinerYougchu LuanNoch keine Bewertungen

- Spe 106346 MSDokument0 SeitenSpe 106346 MSManthan MarvaniyaNoch keine Bewertungen

- Capillary Injection System Restores Production in Offshore Gas WellsDokument6 SeitenCapillary Injection System Restores Production in Offshore Gas WellsLuisAlbertoVazquezNoch keine Bewertungen

- Spe 103184 MSDokument7 SeitenSpe 103184 MSRamanamurthy PalliNoch keine Bewertungen

- Wellplan Software: Key ValueDokument4 SeitenWellplan Software: Key Valuebyed100% (1)

- Round I Rules - WE & CWIDokument2 SeitenRound I Rules - WE & CWIKhalid ZaeemNoch keine Bewertungen

- W04 Completion+DesignDokument2 SeitenW04 Completion+DesignFawzi Al-RubasiNoch keine Bewertungen

- Directional Drilling PDFDokument2 SeitenDirectional Drilling PDFArpan BiswasNoch keine Bewertungen

- Integrated EDM™ WorkflowsDokument7 SeitenIntegrated EDM™ WorkflowsEnrique DiazNoch keine Bewertungen

- Completation Inteligent RevistaDokument9 SeitenCompletation Inteligent RevistaGabriel Castellon HinojosaNoch keine Bewertungen

- SPT Group Olga ABC v2Dokument2 SeitenSPT Group Olga ABC v2Kriztopher UrrutiaNoch keine Bewertungen

- WELLFLO Oil and Gas Well Design Software - Well Engineering SoftwareDokument2 SeitenWELLFLO Oil and Gas Well Design Software - Well Engineering SoftwareagrajitNoch keine Bewertungen

- PE ReleaseNotesDokument94 SeitenPE ReleaseNotesahmed_497959294Noch keine Bewertungen

- Nation 16 3 Hour On: Pet-A, Oil Gas Well Drillin Ompletion For 016Dokument7 SeitenNation 16 3 Hour On: Pet-A, Oil Gas Well Drillin Ompletion For 016سالم العيساويNoch keine Bewertungen

- Wellbore Quality Characterization For Drilling and Casing Running in Challenging WellsDokument54 SeitenWellbore Quality Characterization For Drilling and Casing Running in Challenging WellsDVScherbakovNoch keine Bewertungen

- 4.500 in 18.90 PPF 0.430 in SM2535-125 VAM HTF-NR Ref. 27-11-17Dokument1 Seite4.500 in 18.90 PPF 0.430 in SM2535-125 VAM HTF-NR Ref. 27-11-17Ahmed Elwany100% (1)

- Depth Issues in The Trajectory (Oil Patch) - Wellbore Position Uncertainty (Ekofisk)Dokument101 SeitenDepth Issues in The Trajectory (Oil Patch) - Wellbore Position Uncertainty (Ekofisk)Roger GuevaraNoch keine Bewertungen

- Fundamentals and Applications of Bionic Drilling FluidsVon EverandFundamentals and Applications of Bionic Drilling FluidsNoch keine Bewertungen

- RGU ENM 201 Wells Coursework-May2017 FinalDokument7 SeitenRGU ENM 201 Wells Coursework-May2017 FinalEmenike Donald EjiejiNoch keine Bewertungen

- Determining Depth To Set CasingDokument8 SeitenDetermining Depth To Set CasingWaldinho Gaucho da SilvaNoch keine Bewertungen

- Master Thesis - Casing Wear in Multilateral Wells - Steven Ripman PDFDokument110 SeitenMaster Thesis - Casing Wear in Multilateral Wells - Steven Ripman PDFBogdan StanciuNoch keine Bewertungen

- SCA2016-098 - Paper - D Whitby - NOV - Offshore Wireline Coring PDFDokument6 SeitenSCA2016-098 - Paper - D Whitby - NOV - Offshore Wireline Coring PDFdave_whitbyNoch keine Bewertungen

- 6-Petroleum Equipment PDFDokument16 Seiten6-Petroleum Equipment PDFFilipe Gonçalves FerreiraNoch keine Bewertungen

- 1001 385v2-STIMPRO ISDokument2 Seiten1001 385v2-STIMPRO ISRodolfo PerezNoch keine Bewertungen

- Banda East Well Montage 28sept08 A4 SizeDokument1 SeiteBanda East Well Montage 28sept08 A4 SizeSyed IrtazaNoch keine Bewertungen

- MBAL CompleteDokument246 SeitenMBAL CompleteZoha Ahmed83% (6)

- Microbial Enhancement of Oil Recovery - Recent AdvancesVon EverandMicrobial Enhancement of Oil Recovery - Recent AdvancesNoch keine Bewertungen

- Drive Engineering - Practical Implementation SEW Disc Brakes 09202218 - G1Dokument90 SeitenDrive Engineering - Practical Implementation SEW Disc Brakes 09202218 - G1Anonymous ntE0hG2TPNoch keine Bewertungen

- IOTA Observers Manual All PagesDokument382 SeitenIOTA Observers Manual All PagesMarcelo MartinsNoch keine Bewertungen

- Fluid Mechanics and Machinery Laboratory Manual: by Dr. N. Kumara SwamyDokument4 SeitenFluid Mechanics and Machinery Laboratory Manual: by Dr. N. Kumara SwamyMD Mahmudul Hasan Masud100% (1)

- 3500 Ha027988 7Dokument384 Seiten3500 Ha027988 7Gigi ZitoNoch keine Bewertungen

- 01 Childrenswear Safety Manual 2009 - ClothingDokument57 Seiten01 Childrenswear Safety Manual 2009 - Clothingmorshed_mahamud705538% (8)

- Welcome Speech For Seminar in College 2Dokument4 SeitenWelcome Speech For Seminar in College 2Niño Jay C. GastonesNoch keine Bewertungen

- InvoiceDokument1 SeiteInvoiceKidambi SureshNoch keine Bewertungen

- Problem Sheet 3 - External Forced Convection - WatermarkDokument2 SeitenProblem Sheet 3 - External Forced Convection - WatermarkUzair KhanNoch keine Bewertungen

- Eimco Elecon Initiating Coverage 04072016Dokument19 SeitenEimco Elecon Initiating Coverage 04072016greyistariNoch keine Bewertungen

- Body Wash Base Guide Recipe PDFDokument2 SeitenBody Wash Base Guide Recipe PDFTanmay PatelNoch keine Bewertungen

- Concept of InsuranceDokument4 SeitenConcept of InsuranceNazrul HoqueNoch keine Bewertungen

- Harvester Main MenuDokument3 SeitenHarvester Main MenuWonderboy DickinsonNoch keine Bewertungen

- Banking Adbl EnglishDokument74 SeitenBanking Adbl Englishdevi ghimireNoch keine Bewertungen

- Ocular Trauma - BantaDokument211 SeitenOcular Trauma - BantaLuisa Fernanda Arboleda100% (1)

- 1353apni KakshaDokument43 Seiten1353apni KakshaArush GautamNoch keine Bewertungen

- Pex 03 02Dokument5 SeitenPex 03 02aexillis0% (1)

- Fin 320 - Individual AssignmentDokument14 SeitenFin 320 - Individual AssignmentAnis Umaira Mohd LutpiNoch keine Bewertungen

- Caribbean Career Opportunity - Cayman Island Water Authority - Plant Operator Cayman Brac Plant Operator (Overseas)Dokument1 SeiteCaribbean Career Opportunity - Cayman Island Water Authority - Plant Operator Cayman Brac Plant Operator (Overseas)Cawasa St-LuciaNoch keine Bewertungen

- Syllabus Financial AccountingDokument3 SeitenSyllabus Financial AccountingHusain ADNoch keine Bewertungen

- Airline and Airport Master - OdsDokument333 SeitenAirline and Airport Master - OdsGiri KumarNoch keine Bewertungen

- WikipediaDokument29 SeitenWikipediaradhakodirekka8732Noch keine Bewertungen

- The Sphere Circumscribing A TetrahedronDokument4 SeitenThe Sphere Circumscribing A TetrahedronRaghuveer ChandraNoch keine Bewertungen

- Alma Matter SpeechDokument1 SeiteAlma Matter Speechlariza gallegoNoch keine Bewertungen

- Jibachha's Textbook of Animal Health Volume-IIDokument16 SeitenJibachha's Textbook of Animal Health Volume-IIjibachha sahNoch keine Bewertungen

- Harmonica IntroDokument5 SeitenHarmonica Introapi-26593142100% (1)

- 2015.15009.fundamental Principles of Physical Chemistry - Text PDFDokument782 Seiten2015.15009.fundamental Principles of Physical Chemistry - Text PDFAnoif Naputo Aidnam100% (1)

- Viva Questions For Even SemestersDokument22 SeitenViva Questions For Even SemestersSiddhanta DuttaNoch keine Bewertungen

- BE 503 - Week 1 - Analysis 7.18.11Dokument6 SeitenBE 503 - Week 1 - Analysis 7.18.11dwoodburyNoch keine Bewertungen

- Packet Tracer - VLSM Design and Implementation Practice TopologyDokument3 SeitenPacket Tracer - VLSM Design and Implementation Practice TopologyBenj MendozaNoch keine Bewertungen

- CHAPTER 5 Ground ImprovementDokument47 SeitenCHAPTER 5 Ground ImprovementBeman EasyNoch keine Bewertungen