Beruflich Dokumente

Kultur Dokumente

NRC Report On FitzPatrick Condenser Leaks

Hochgeladen von

Tim KnaussOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

NRC Report On FitzPatrick Condenser Leaks

Hochgeladen von

Tim KnaussCopyright:

Verfügbare Formate

UNITED STATES

NUCLEAR REGULATORY COMMISSION

REGION I

2100 RENAISSANCE BLVD., SUITE 100

KING OF PRUSSIA, PA 19406-2713

May 12, 2014

Mr. Lawrence Coyle

Site Vice President

Entergy Nuclear Northeast

James A. FitzPatrick Nuclear Power Plant

P.O. Box 110

Lycoming, NY 13093

SUBJECT: JAMES A. FITZPATRICK NUCLEAR POWER PLANT - NRC SUPPLEMENTAL

INSPECTION REPORT 05000333/2014007

Dear Mr. Coyle:

On January 21, 2013, your staff reported the unplanned power change performance indicator

that crossed a threshold from green to white. Based on your report, the U.S. Nuclear

Regulatory Commission (NRC) assigned a White performance indicator Action Matrix input to

the Initiating Events cornerstone in the fourth quarter of 2012. In response to this Action Matrix

input, the NRC informed you that a supplemental inspection under Inspection Procedure 95001,

"Supplemental Inspection for One or Two White Inputs in a Strategic Performance Area, would

be required. On October 28, 2013, you informed the NRC that James A. FitzPatrick Nuclear

Power Plant was ready for the supplemental inspection.

From January 20, 2014, to January 24, 2014, the NRC conducted the onsite portion of the

supplemental inspection. On March 19, 2014, the NRC inspection team discussed the results of

this inspection with you and other members of your staff. The results of this inspection are

documented in the enclosed inspection report. The NRC performed this supplemental

inspection to determine if (1) the root and contributing causes for the risk-significant issues were

understood, (2) the extent of condition and extent of cause for the identified issues were

understood, and (3) your completed or planned corrective actions were sufficient to address and

prevent repetition of the root and contributing causes.

The NRC determined that your staffs evaluation, in general, was thorough and that the planned

corrective actions, which include replacement of the condenser tubes, will be sufficient to

address the performance that led to the White performance indicator. The NRC also determined

that the interim actions until the condenser can be replaced were reasonable; however, they

have not been effective at reducing the number of unplanned power changes. Therefore,

Entergys corrective actions to date have not been sufficient to meet the inspection objective to

preclude repetition of the unplanned power changes and, as a result, this inspection will remain

open until corrective actions to significantly reduce the unplanned power changes are

implemented. The NRC will review Entergys implementation of additional corrective actions

during a future inspection.

L. Coyle 2

The NRC also determined that there were some weaknesses in the root cause evaluation and

corrective actions. Specifically, your staff identified the root cause to be a failure to include

inner diameter condenser tube wear in any component or system monitoring plan. The

inspectors determined that the root cause was narrowly focused and the licensee did not

incorporate applicable operating experience from the 1995 condenser tube replacement into an

appropriate system or program. Additionally, your staff did not adequately address a corrective

action for the contributing cause of not identifying all appropriate internal operating experience

in previous root causes. The NRC determined that these deficiencies were minor since your

staffs additional extent of condition review in response to the inspectors root cause conclusion

did not identify any new or missed issues, and the failure to assign a corrective action was an

isolated example and did not represent a programmatic weakness. The NRC inspectors did not

identify any findings or violations of more than minor significance.

In accordance with Title 10 of the Code of Federal Regulations (10 CFR) 2.390 of the NRC's

"Rules of Practice," a copy of this letter, its enclosure, and your response (if any), will be

available electronically for public inspection in the NRCs Public Document Room or from the

Publicly Available Records System component of NRC's Agencywide Documents Access and

Management System (ADAMS). ADAMS is accessible from the NRC Web site at

http://www.nrc.gov/reading-rm/adams.html (the Public Electronic Reading Room).

Sincerely,

/RA/

Arthur L. Burritt, Chief

Reactor Projects Branch 2

Division of Reactor Projects

Docket No: 50-333

License No: DPR-59

Enclosure: Inspection Report 05000333/2014007

w/Attachment: Supplementary Information

cc w/encl: Distribution via ListServ

L. Coyle 2

The NRC also determined that there were some weaknesses in the root cause evaluation and

corrective actions. Specifically, your staff identified the root cause to be a failure to include

inner diameter condenser tube wear in any component or system monitoring plan. The

inspectors determined that the root cause was narrowly focused and the licensee did not

incorporate applicable operating experience from the 1995 condenser tube replacement into an

appropriate system or program. Additionally, your staff did not adequately address a corrective

action for the contributing cause of not identifying all appropriate internal operating experience

in previous root causes. The NRC determined that these deficiencies were minor since your

staffs additional extent of condition review in response to the inspectors root cause conclusion

did not identify any new or missed issues, and the failure to assign a corrective action was an

isolated example and did not represent a programmatic weakness. The NRC inspectors did not

identify any findings or violations of more than minor significance.

In accordance with Title 10 of the Code of Federal Regulations (10 CFR) 2.390 of the NRC's

"Rules of Practice," a copy of this letter, its enclosure, and your response (if any), will be

available electronically for public inspection in the NRCs Public Document Room or from the

Publicly Available Records System component of NRC's Agencywide Documents Access and

Management System (ADAMS). ADAMS is accessible from the NRC Web site at

http://www.nrc.gov/reading-rm/adams.html (the Public Electronic Reading Room).

Sincerely,

/RA/

Arthur L. Burritt, Chief

Reactor Projects Branch 2

Division of Reactor Projects

Docket No: 50-333

License No: DPR-59

Enclosure: Inspection Report 05000333/2014007

w/Attachment: Supplementary Information

cc w/encl: Distribution via ListServ

Distribution w/encl: (via email)

W. Dean, RA

D. Lew, DRA

H. Nieh, DRP

M. Scott, DRP

R. Lorson, DRS

J. Trapp, DRS

A. Burritt, DRP

T. Setzer, DRP

L. McKown, DRP

J. Petch, DRP

E. Knutson, DRP, SRI

B. Sienel, DRP, RI

J. Nick, RI OEDO

RidsNrrPMFitzPatrick Resource

RidsNrrDorlLpl1-1 Resource

ROPreports Resource

R. J. Powell, DRP

DOCUMENT NAME: G:\DRP\BRANCH2\A - FITZPATRICK\REPORTS\FITZ 95001 2014\FITZ 95001 IR2014007 FINAL.DOCX

ADAMS Accession No. ML14133A051

SUNSI Review

Non-Sensitive

Sensitive

Publicly Available

Non-Publicly Available

OFFICE RI/DRP RI/DRP RI/DRP RI/DRP

NAME ETorres/ET JKrafty/JK TSetzer/TCS ABurritt/ALB

DATE 5/8/14 5/8/14 5/8/14 5/9/14

OFFICIAL RECORD COPY

1

Enclosure

U.S. NUCLEAR REGULATORY COMMISSION

REGION I

Docket No: 50-333

License No: DPR-59

Report No: 05000333/2014007

Licensee: Entergy Nuclear Northeast (Entergy)

Facility: James A. FitzPatrick Nuclear Power Plant

Location: Scriba, NY

Dates: January 20, 2014, through January 24, 2014 (on site)

January 27 through March 17 (in-office review)

Inspectors: J. Krafty, Millstone Resident Inspector, Lead Inspector

E. Torres, Calvert Cliffs Resident Inspector

Approved by: Arthur L. Burritt, Chief

Reactor Projects Branch 2

Division of Reactor Projects

2

Enclosure

SUMMARY

IR 05000333/2014007; 01/20/2014 01/24/2014; James A. Fitzpatrick Nuclear Power Plant

(FitzPatrick); Supplemental Inspection Inspection Procedure (IP) 95001

Two resident inspectors from the Division of Reactor Projects, Region I, performed this

inspection. No significant weaknesses or findings of more than minor significance were

identified in this report. The NRCs program for overseeing the safe operation of commercial

nuclear power reactors is described in NUREG-1649, Reactor Oversight Process, Revision 5.

Cornerstone: Initiating Events

The NRC staff performed this supplemental inspection in accordance with IP 95001, Inspection

for One or Two White Inputs in a Strategic Performance Area, to assess Entergys evaluation

associated with the White performance indicator for unplanned power changes documented in

the NRC Annual Assessment Letter, dated March 4, 2013. The inspectors concluded that

Entergy was generally effective at identifying the problem, determining the root cause, extent of

condition, extent of cause, and specifying corrective actions for the root and contributing

causes.

Entergy appropriately identified and reported the unplanned power changes that were, except

for one instance, caused by main condenser tube leaks. They also documented how long the

issue existed, prior opportunities for identification, and plant specific risk consequences

associated with the issue.

Entergy performed a comprehensive evaluation of the unplanned power changes. Entergy

identified the primary root cause of the issue to be the failure to incorporate inner diameter

condenser tube wear in any component or system monitoring plan. Entergy determined that

other heat exchangers could be susceptible to tube wear and appropriately assessed the heat

exchangers in the heat exchanger program to determine if they need to be monitored for inner

diameter tube wall loss. Nonetheless, the inspectors determined that Entergys root cause was

narrowly focused and that the root cause was the failure to incorporate applicable operating

experience into an appropriate system or program. As a result, Entergy expanded their extent

of condition review to adequately address the broader root cause.

Entergys corrective actions resulting from the root cause included establishing a monitoring and

trending program for the main condenser and the East/West Electric Bay Coolers, revising the

Corrective Action Review Board grading sheet for cause evaluations to better identify and

address repetitive failures, and replacing the main condenser tubes with a more erosion

resistant material during their next refueling outage. The inspectors identified that corrective

actions for the contributing cause of not identifying all appropriate internal operating experience

in the root cause had not been adequately addressed. Entergy entered a corrective action to

address the issue through changes to the operating experience section of the root cause

procedure. Entergy also implemented several interim actions to reduce the number of

unplanned down powers as a result of main condenser tube leaks including sleeving the outlet

ends of the condenser tubes. The NRC has concluded that the planned and implemented

corrective actions will be sufficient to address the performance and underlying causes that led to

the White performance indicator. The NRC also determined that the interim actions were

reasonable; however, they have not been effective at reducing the number of unplanned power

changes. Therefore, the corrective actions to date have not been sufficient to meet the

3

Enclosure

inspection objective to preclude repetition of the unplanned power changes and, as a result, this

inspection will remain open until corrective actions to significantly reduce the unplanned power

changes are implemented. The inspectors will review Entergys implementation of additional

corrective actions during a future inspection.

4

Enclosure

REPORT DETAILS

4. OTHER ACTIVITIES

4OA4 Supplemental Inspection (95001)

.1 Inspection Scope

The NRC staff performed this supplemental inspection in accordance with IP 95001 to

assess Entergys evaluation of a White performance indicator, which affected the

Initiating Events cornerstone in the Reactor Safety strategic performance area. The

inspection objectives were to:

Provide assurance that the root and contributing causes of risk-significant issues

were understood;

Provide assurance that the extent of condition and extent of cause of risk-significant

issues were identified; and

Provide assurance that corrective actions for risk-significant issues were sufficient to

address the root and contributing causes and to preclude repetition.

Entergy entered the Regulatory Response Column of the NRCs Action Matrix in the

fourth quarter of 2012 as a result of a White performance indicator for unplanned power

changes due primarily to main condenser tube leaks. The White performance indicator

was documented in the NRC Annual Assessment Letter, dated March 4, 2013, because

the number of Entergys unplanned power changes in the previous four quarters

exceeded the Green/White threshold of six per 7000 critical hours.

Entergy informed the NRC staff on October 28, 2013, that they were ready for the

supplemental inspection. In preparation for the inspection, Entergy performed root

cause CR-JAF-2013-01240, Revision 1, to identify weaknesses that existed in the

organization that were not identified in previous root causes that were performed as a

result of the unplanned power changes. Entergys root cause also examined

weaknesses in the safety culture components that contributed to the unplanned power

changes.

The inspectors reviewed Entergys root cause evaluation (RCE) in addition to other

evaluations conducted in support of the RCE. The inspectors reviewed corrective

actions that were taken or planned to address the identified causes. The inspectors also

held discussions with Entergy personnel to ensure that the root and contributing causes

and the contribution of safety culture components were understood and corrective

actions taken or planned were appropriate to address the causes and preclude repetition.

.2 Evaluation of the Inspection Requirements

2.01 Problem Identification

a. As required by IP 95001, determine that the licensees evaluation of the issue

documents who identified the issue (i.e., licensee-identified, self-revealing, or NRC-

identified) and under what conditions the issue was identified.

5

Enclosure

Entergy identified that the performance indicator was exceeded on December 20, 2012,

when an unplanned power change was required due to increased hotwell conductivity.

The inspectors verified that this information was documented in Entergys RCE.

b. As required by IP 95001, determine that the licensees evaluation of the issue

documents how long the issue existed and prior opportunities for identification.

Entergys 2013 RCE documented that opportunities existed in RCEs CR-JAF-2007-

03473 and CR-JAF-2009-00172 to identify previous FitzPatrick condenser operating

experience that would have indicated that the condenser was nearing its end of life.

Additionally, Entergys 2013 RCE identified that, in 2010, an external organizations

assessment identified that Entergy was not effectively addressing condenser issues.

The inspectors determined that Entergys evaluation was adequate with respect to

identifying how long the issue existed and prior opportunities for identification.

c. As required by IP 95001, determine that the licensees evaluation documents the plant

specific risk consequences, as applicable, and compliance concerns associated with the

issue(s).

Entergys RCE documented that the risk consequences of condenser tube leaks were

low. The condenser is not a safety-related component and is not considered risk

significant by Entergys probabilistic risk assessment. Condenser tube leaks are readily

identified by installed instrumentation and the affected waterbox can be isolated while

keeping the plant on line at reduced power. The RCE also noted that condenser tube

leaks, if severe, could result in chemistry and corrosion issues with the reactor coolant

system and fuel cladding. Entergys reactor, feedwater, and condensate chemistry is

routinely monitored and procedures are in place to identify and provide corrective

actions for chemistry issues to protect the reactor and fuel. These procedures are

consistent with Electric Power Research Institute BWRVIP-190, BWR Vessel and

Internals Project BWR Water Chemistry Guidelines. The inspectors concluded that

Entergy appropriately documented the risk consequences and compliance concerns with

the issue.

d. Findings

No findings were identified.

2.02 Root Cause, Extent of Condition, and Extent of Cause Evaluation

a. As required by IP 95001, determine that the licensee evaluated the issue using a

systematic methodology to identify the root and contributing causes.

Entergy used the following systematic methods to complete RCE CR-JAF-2013-01240:

Barrier analysis

Cause-effect charting

Performance Improvement International Methodology (to evaluate organizational and

performance issues)

The inspectors determined that Entergy evaluated the issue using appropriate

systematic methodologies to identify the root and contributing causes.

6

Enclosure

b. As required by IP 95001, determine that the licensees RCE was conducted to a level of

detail commensurate with the significance of the issue.

Consistent with EN-LI-118, Cause Evaluation Process, Entergy conducted an RCE that

included a comprehensive timeline of the condenser tube leak events, causal factors,

extent of condition and extent of cause, a safety culture evaluation, a safety significance

evaluation, operating experience reviews, corrective actions, and an effectiveness

review. The RCE documented that the root cause was the failure to include inner

diameter main condenser tube wear in any component or system monitoring plan.

Entergy also determined that other heat exchangers needed to be evaluated in order to

determine if they required monitoring for inner diameter wear. The significant

contributing causes were that the corrective action process did not effectively identify all

causes of condenser degradation, and that the 2007 and 2009 RCEs missed

opportunities to identify the 1995 condenser re-tubing operating experience.

The inspectors concluded that Entergys stated root cause was narrowly focused and

only captured part of the root cause. The inspectors determined that the root cause was

the failure to incorporate applicable operating experience into an appropriate system or

program. Specifically, the knowledge that the condenser tubes would be expected to

last only fifteen years and that sleeving the outlets ends of the tubes could extend the

useful life of the condenser had not been adequately captured in programs and

processes such as capital planning, preventive maintenance, and system health reports.

The inspectors determined that the root cause for the condenser issues was inadequate

and was a performance deficiency since, as a consequence of the narrow focus, the

extent of condition review was limited to monitoring of heat exchanger tube wear rather

than considering broader operating experience such as component service life. The

inspectors concluded that the performance deficiency was of minor significance and not

subject to enforcement action in accordance with the NRCs Enforcement Policy.

Specifically, the issue was minor since it was not indicative of a programmatic weakness

in Entergys ability to perform adequate RCEs. Additionally, when Entergy expanded

their extent of condition review in response to the inspectors conclusion, they did not

identify any new or missed issues. Entergy entered this issue into their corrective action

process as CR-JAF-2013-01240, corrective action 40. The extent of condition

associated with this issue is discussed in Section 2.02.d below.

c. As required by IP 95001, determine that the licensees RCE included a consideration of

prior occurrences of the issue and knowledge of operating experience.

Entergy reviewed operating experience from multiple sources including the Institute of

Nuclear Power Operations, the Entergy fleet database, and the site corrective action

process, as well as relevant NRC generic information and communication items.

Entergys RCE identified several internal and external operating experience items that

were relevant to condenser tube leaks. Entergy used that information to inform their

efforts in determining the root cause of the condenser tube leaks and developing

corrective actions. The RCE also identified that RCE CR-JAF-2011-0170 and other

earlier RCEs on condenser tube leaks did not adequately consider the operating

experience from the 1995 condenser re-tubing. The corrective action for this issue is

discussed in section 2.03.a. Based on Entergys evaluation and conclusion, the

inspectors determined that Entergys most recent RCE included consideration of prior

occurrences and knowledge of prior operating experience.

7

Enclosure

d. As required by IP 95001, determine that the licensees RCE addresses the extent of

condition and extent of cause of the issue.

The inspectors concluded that, in general, Entergys RCE adequately addressed the

extent of condition and extent of cause of the issue. Entergys evaluation considered the

extent of condition associated with lack of monitoring wear of condenser tubes. Entergy

determined that this was applicable to all the heat exchangers in the heat exchanger

monitoring program and reviewed past monitoring of these heat exchangers to

determine if they require inner diameter tube wear measurements. Entergy evaluated

these heat exchangers based on tube material, fluid type and velocity, and whether the

heat exchanger was in continuous service or in standby. Entergy concluded that only

the East/West Electric Bay Coolers required inner diameter measurements and

implemented a preventive maintenance program for these coolers. The inspectors

reviewed Entergys evaluation and determined that their conclusions were reasonable.

However, as previously described in Section 2.02.b, to address the extent of condition

associated with the broader root cause identified by the inspectors, Entergy wrote

corrective action 40 to CR-JAF-2013-01240 and performed a review of major equipment

replacements from 1985 through 2000 to determine if there were any lessons learned

that were not incorporated into appropriate programs. Entergy determined that the

feedwater heaters were the only additional equipment replacements that met the review

criteria. The review determined that organizational learnings were incorporated into the

new feedwater heater design and inspection requirements, and that adequate

replacement plans were in place.

Entergys evaluation also considered the extent of cause associated with the corrective

action process not identifying all the causes of condenser degradation. Entergy

determined that this was applicable to RCEs related to equipment failures and a

corrective action was developed to review these RCEs for the past five years to verify

that age-related degraded conditions were properly identified. Entergys review of the 43

cause evaluations concluded that nine had age-related degradation. The inspectors

verified that the respective cause evaluations had corrective actions in place for the nine

age-related issues. The review also recommended a collective review of the causal

evaluations on the high pressure coolant injection system. The inspectors reviewed the

results of Entergys corrective action and determined that their review was adequate.

The inspectors noted that the extent of condition and extent of cause in RCE CR-JAF-

2013-01240 did not provide the reasons for limiting the scope and did not determine the

associated risk as required by EN-LI-118. The inspectors determined that not

documenting scope limits and the associated risk consistent with procedure

requirements was a performance deficiency. The inspectors concluded that the

performance deficiency was of minor significance since they were able to confirm,

through staff interviews, that Entergys scope of extent of condition and extent of cause

reviews were appropriate and thereby did not result in any missed opportunities to

identify problems. Therefore, this documentation issue is not subject to enforcement

action in accordance with the NRCs Enforcement Policy. Entergy entered this issue into

their corrective action process as CR-JAF-2014-01181.

e. As required by IP 95001, determine that the licensees root cause, extent of condition,

and extent of cause evaluations appropriately considered the safety culture components

as described in Inspection Manual Chapter (IMC) 0305.

8

Enclosure

Entergy identified weaknesses in the following two cross-cutting areas in the most recent

RCE:

Human Performance, Decision Making Component

Entergy identified that the decision to delay condenser tube replacement from 2012 to

2014 was based on the risk of implementing the project on an accelerated schedule.

However, they identified that this decision was made without a comprehensive cost

benefit analysis, which would have evaluated the potential cost and plant impact of not

re-tubing the condenser in 2012. Entergys corrective actions included developing a

Kepner-Tregoe decision analysis process to review and provide detailed documentation

of the risk of not implementing large projects in the future.

Problem Identification and Resolution, Corrective Action Program Component

While reviewing older RCEs on condenser tube leaks, Entergy identified that previous

root causes failed to identify and correct repeat condenser tube failures. Entergy also

identified that they failed to put in place actions to monitor and track condenser service

life after replacing the condenser in 1995. Entergys corrective action was to develop a

grading sheet for RCEs to challenge previous corrective actions that did not resolve

previous failures.

Overall, the inspectors determined that Entergys most recent RCE included proper

consideration of whether a weakness in any safety culture component was a root cause

or a significant contributing cause of the issue.

The inspectors also noted that in a previous root cause, RCE CR-JAF-2009-00172, the

root and contributing causes identified weaknesses in the Human Performance, Work

Practices and Continuous Learning Environment cross-cutting areas, but the safety

culture evaluation section of the report did not identify any weaknesses. The inspectors

determined that this issue was a performance deficiency of minor significance since it

was a limited to a documentation problem and corrective actions had already been

established to address the safety culture issues. Therefore, it is not subject to

enforcement action in accordance with the NRCs Enforcement Policy. Entergy entered

this observation into their corrective action process as CR-JAF-2014-00405.

f. Findings

No findings were identified.

2.03 Corrective Actions

a. As required by IP 95001, determine that (1) the licensee specified appropriate corrective

actions for each root and/or contributing cause, or (2) an evaluation that states no

actions are necessary is adequate.

To address the root cause of not including condenser tube inner diameter wear in a

monitoring plan, Entergy developed a monitoring plan for the main condenser that

includes measuring and trending tube wall thinning and replacing the tubes in the main

condenser as necessary. To address the contributing causes, Entergy developed a

grading sheet for cause evaluations to question previous corrective actions that did not

prevent recurrence and developed a Kepner-Tregoe decision process to evaluate the

risks and costs of not implementing large projects.

9

Enclosure

The inspectors determined that the contributing cause of not identifying all appropriate

internal operating experience in previous root causes had not been adequately

addressed through corrective actions. The inspectors determined that this issue was of

minor significance because it was an isolated example and did not represent a

programmatic weakness in assigning corrective actions. Therefore, it is not subject to

enforcement action in accordance with the NRCs Enforcement Policy. Entergy entered

this issue into their corrective action process as CR-HQ-2014-00066 to address this by

providing additional guidance in EN-LI-118 for determining the scope of the operating

experience search.

Entergys planned corrective actions to address the age related wear of the main

condenser tubes is to replace them with a more erosion resistant material during the

next refueling outage. Entergy also implemented a number of interim actions to reduce

the number of unplanned down powers as a result of main condenser tube leaks,

including sleeving the outlet ends of the condenser tubes. The inspectors determined

that the interim actions were reasonable; however, they have not been effective at

reducing the number of unplanned power changes.

The inspectors concluded that Entergys planned and implemented corrective actions

were appropriate and addressed the root and contributing causes. Nonetheless, while

the interim corrective actions to reduce the number of unplanned downpowers were

reasonable, they were not effective. As a result, the corrective actions to date are not

sufficient to meet the inspection objective to preclude repetition of the unplanned down

powers.

b. As required by IP 95001, determine that the licensee prioritized corrective actions with

consideration of risk significance and regulatory compliance.

Entergys corrective actions to address the root and contributing causes were prioritized

in accordance with procedure EN-LI-102, Corrective Action Process. In setting priority,

Entergy considered plant risk and evaluated the condenser as a low risk component.

The inspectors determined that the majority of the corrective actions were completed

and remaining corrective actions had appropriate due dates. The inspectors noted that

Entergy considered replacing the tubes in the main condenser in their refueling outage in

the fall of 2012. However, Entergy was concerned that the accelerated project would

create concerns with project quality, vendor and material availability, and other potential

undesirable outcomes related to design inadequacy. Entergy believed that sleeving the

outlet ends of the condenser in the fall 2012 outage would be sufficient to limit

unplanned power changes until the 2014 outage. The inspectors concluded that the

basis for project delay was reasonable. Based on the guidance in EN-LI-102, the

inspectors determined that the corrective actions were prioritized with consideration of

the risk significance and regulatory compliance.

c. As required by IP 95001, determine that the licensee established a schedule for

implementing and completing the corrective actions.

Entergy assigned due dates for corrective actions in accordance with procedure

EN-LI-102s requirements for timeliness. Completion dates for corrective actions were

established and documented in the RCE. The inspectors verified that corrective actions

10

Enclosure

scheduled to be completed before the date of this inspection were completed and

appropriately documented, and reviewed the status of other assigned corrective actions.

The inspectors determined that a schedule had been appropriately established for

implementing and completing the corrective actions.

d. As required by IP 95001, determine that the licensee developed quantitative and/or

qualitative measures of success for determining the effectiveness of the corrective

actions to prevent recurrence.

As documented in RCE CR-JAF-2013-01240, Entergy established measures for

determining the effectiveness of the corrective actions. These measures included

measuring the inner diameter of the main condenser tubes in accordance with the

condenser heat exchanger program during their refueling outages in 2016 and 2018,

and verifying that tube wear is consistent with the program monitoring plan. The

inspectors determined that quantitative and qualitative measures of success had been

developed for determining the effectiveness of the corrective actions to preclude

repetition.

e. As required by IP 95001, determine that the licensees planned or taken corrective

actions adequately address a Notice of Violation that was the basis for the supplemental

inspection, if applicable.

This item was not applicable since there are no underlying NRC requirements for the

unplanned power change performance indicator. Additionally, the primary contributor to

the unplanned power changes was age related wear of the main condenser tubes. The

main condenser is not a safety-related component and therefore is not directly

addressed by the Fitzpatrick license, technical specifications, or 10 CFR 50, Appendix B.

f. Findings

No findings were identified.

2.04 Evaluation of IMC 0305 Criteria for Treatment of Old Design Issues

The inspectors determined this issue did not meet the IMC 0305 criteria for treatment as

an old design issue.

4OA6 Inspection Debrief Meeting

On March 19, 2014, the inspectors presented the inspection results to Mr. Larry Coyle,

Site Vice President, and other members of the FitzPatrick staff, who acknowledged the

findings. The inspectors asked Entergy if any of the material examined during the

inspection should be considered proprietary. Entergy did not identify any proprietary

information.

ATTACHMENT: SUPPLEMENTARY INFORMATION

A-1

Attachment

SUPPLEMENTARY INFORMATION

KEY POINTS OF CONTACT

Licensee Personnel

L. Coyle, Site Vice President

C. Adner, Manager Regulatory Assurance

D. Bittinger, Supervisor E-FIN

B. Bock, Chemistry Specialist

D. Deretz, Supervisor Code and Plant Programs

W. Drews, Supervisor Reactor Engineering

G. Duffy, Licensing Contractor

S. Egnaczyk, PM and PdM Engineer

D. Huwe, Quality Assurance

S. Malone, Supervisor BOP Systems

L. Normandeau, Engineering Liaison

M. Sassone, System Engineer

D. Starczewski, Coordinator Equipment Reliability

LIST OF ITEMS OPENED, CLOSED AND DISCUSSED

None

LIST OF DOCUMENTS REVIEWED

Condition Reports

2007-03473

2008-01189

2009-00172

2009-01109

2011-00170

2011-01575

2011-01679

2011-02696

2012-00329

2013-01240

2014-00066*

2014-00384*

2014-00404*

2014-00405*

2014-00417*

2014-01181*

*Issued as a result of NRC inspection.

Procedures

AP-19.14, Eddy Current Testing of Heat Exchanger Tubes, Revision 0, 9, and 10

EN-DC-159, System Monitoring Program, Revision 7

EN-DC-324, Preventive Maintenance Program, Revision 11

EN-LI-102, corrective Action Process, Revision 23

EN-LI-118, Root Cause Evaluation Process, Revision 18 and 20

EN-NF-105, Reload Process, Revision 4

SP-01.02, Reactor Water Sampling and Analysis, Revision 24

A-2

Attachment

Work Orders

JF-030039300

JF-030039100

Miscellaneous

Anatec Eddy Current Inspection Report, May 2011

BWRVIP-190, BWR Vessel and Internals Project, 2008

EPRI Balance-of-Plant Heat Exchanger Condition Assessment and Inspection Guide,

December 1999

iTi Eddy Current Report, October 2006

JCS-95-149, New York Power Authority Memo, June 19, 1995

Mistras Eddy Current Report, October 2010

Mistras Eddy Current Report, October 2012

Nuclear Oversight Fleet Trimester Report, March-June 2011,

PM Template for Horizontal Pumps, Revision 4

PM Template for Main Condenser, Revision 3

TR-106857-R1, Preventive Maintenance Basis, November 1998

1003088, Condenser Application and Maintenance Guide, August 2001

2011 Mid Cycle Assessment January 17-26, 2011

LIST OF ACRONYMS USED

ADAMS Agencywide Document Access Management System

Entergy Entergy Nuclear Northeast

FitzPatrick James A. FitzPatrick Nuclear Power Plant

IMC Inspection Manual Chapter

IP Inspection Procedure

NRC U. S. Nuclear Regulatory Commission

RCE Root Cause Evaluation

Das könnte Ihnen auch gefallen

- Organization and Functions, Office of Enforcement, About Enforcement, Then Enforcement Policy and Select (Enforcement Policy)Dokument42 SeitenOrganization and Functions, Office of Enforcement, About Enforcement, Then Enforcement Policy and Select (Enforcement Policy)Ishu VohraNoch keine Bewertungen

- San Onofre Nuclear Generating Station - NRC Radiation Safety Team Inspection Report 03-11-2004Dokument22 SeitenSan Onofre Nuclear Generating Station - NRC Radiation Safety Team Inspection Report 03-11-2004EnformableNoch keine Bewertungen

- Pilgrim 2016011 FinalDokument230 SeitenPilgrim 2016011 FinalMatthew NadlerNoch keine Bewertungen

- Byron Inspection 2018Dokument32 SeitenByron Inspection 2018FACULTY / LITNoch keine Bewertungen

- Grand Gulf LetterDokument3 SeitenGrand Gulf LetterSteve WilsonNoch keine Bewertungen

- Subject: Unlr: United StatesDokument24 SeitenSubject: Unlr: United StatesEarlNoch keine Bewertungen

- NRC's Nine Mile Point Inspection ReportDokument73 SeitenNRC's Nine Mile Point Inspection ReportTim KnaussNoch keine Bewertungen

- Safety Inspection Report and Compliance Inspection: 1. Licensee/Location Inspected: 2. Nrc/Regional OfficeDokument3 SeitenSafety Inspection Report and Compliance Inspection: 1. Licensee/Location Inspected: 2. Nrc/Regional OfficeNathan BlockNoch keine Bewertungen

- Nuclear Regulatory Commission - Columbia Generating Station Report - May 6 2019Dokument28 SeitenNuclear Regulatory Commission - Columbia Generating Station Report - May 6 2019NWPB NewsNoch keine Bewertungen

- United States Nuclear Regulatory CommissionDokument92 SeitenUnited States Nuclear Regulatory CommissionSouthern California Public RadioNoch keine Bewertungen

- PilgrimSpecialInspectionReport 5!27!2015Dokument68 SeitenPilgrimSpecialInspectionReport 5!27!2015Matthew NadlerNoch keine Bewertungen

- NRC Westinghouse Inspection Report, April 2012Dokument21 SeitenNRC Westinghouse Inspection Report, April 2012The State NewspaperNoch keine Bewertungen

- 2011 Technical Systems Audit ReportDokument57 Seiten2011 Technical Systems Audit ReportJames BruggersNoch keine Bewertungen

- Talen Energy's Nuclear Reactors Restored To Highest Federal RatingDokument6 SeitenTalen Energy's Nuclear Reactors Restored To Highest Federal RatingAnonymous arnc2g2NNoch keine Bewertungen

- Pilgrim 2013008 Final-PublicDokument22 SeitenPilgrim 2013008 Final-PublicMatthew NadlerNoch keine Bewertungen

- Leak Sealing ProcedureDokument83 SeitenLeak Sealing ProcedureKrishna RaiNoch keine Bewertungen

- ML23111A291Dokument27 SeitenML23111A291Nathan BlockNoch keine Bewertungen

- North Anna Unit 1 and Unit 2 ROOT CAUSE EVALUATIONDokument133 SeitenNorth Anna Unit 1 and Unit 2 ROOT CAUSE EVALUATIONEnformableNoch keine Bewertungen

- Pilgrim 2016 Annual Assessment Letter & ReportDokument6 SeitenPilgrim 2016 Annual Assessment Letter & ReportCape Cod TimesNoch keine Bewertungen

- Check Valve FailureDokument28 SeitenCheck Valve FailureKailas GophaneNoch keine Bewertungen

- NEDU TR Colomb Barber 02022015 Turn in PDFDokument1.049 SeitenNEDU TR Colomb Barber 02022015 Turn in PDFdenis colombNoch keine Bewertungen

- Engineering Management Support IncDokument5 SeitenEngineering Management Support Inccreek_girlNoch keine Bewertungen

- 7"-Entergy: River Bend Station 5485 U. S. Highway 61N St. Francisville, LA 70775 Tel 225 381 4149 Fax 225 635 5068Dokument5 Seiten7"-Entergy: River Bend Station 5485 U. S. Highway 61N St. Francisville, LA 70775 Tel 225 381 4149 Fax 225 635 5068RajAnandNoch keine Bewertungen

- Seabrook EP IR 2022-502Dokument12 SeitenSeabrook EP IR 2022-502Boston 25 DeskNoch keine Bewertungen

- Degraded Buried Piping SystemsDokument174 SeitenDegraded Buried Piping SystemsdikimNoch keine Bewertungen

- Materials Reliability Program: Finite-Element Model Validation For Dissimilar Metal Butt-Welds (MRP-316 Revision 1) : Volumes 1 and 2Dokument350 SeitenMaterials Reliability Program: Finite-Element Model Validation For Dissimilar Metal Butt-Welds (MRP-316 Revision 1) : Volumes 1 and 2RafaelNoch keine Bewertungen

- Nondestructive Evaluation Indication, Evaluatio and Disposition Guide LinesDokument126 SeitenNondestructive Evaluation Indication, Evaluatio and Disposition Guide LinesEdison Walit100% (1)

- Florida Power & Light Company 700 Universe Boulevard, Juno Beach, FL 33408Dokument3 SeitenFlorida Power & Light Company 700 Universe Boulevard, Juno Beach, FL 33408Yasir NASSERALLAHNoch keine Bewertungen

- Transformer Load Tap Changer Management Diagnostics - Contact Coking - and On - Line Oil FiltrationDokument118 SeitenTransformer Load Tap Changer Management Diagnostics - Contact Coking - and On - Line Oil Filtrationap_venezuela100% (2)

- ML 101031254Dokument84 SeitenML 101031254அன்புடன் அஸ்வின்Noch keine Bewertungen

- BWR Vessel and Internals ProjectDokument236 SeitenBWR Vessel and Internals Projectgweberpe@gmailcomNoch keine Bewertungen

- TSAUtility Survey Guidance Notes Issue 4 Low Res 1Dokument61 SeitenTSAUtility Survey Guidance Notes Issue 4 Low Res 1divizioniNoch keine Bewertungen

- 1949 NavalRadarSystemsDokument145 Seiten1949 NavalRadarSystemsTom NorrisNoch keine Bewertungen

- Buried Pipe NDTDokument224 SeitenBuried Pipe NDTDemian PereiraNoch keine Bewertungen

- Fluor Hanford, Inc. Groundwater and Technical Integration Support (Master Project) Quality Assurance Management PlanDokument88 SeitenFluor Hanford, Inc. Groundwater and Technical Integration Support (Master Project) Quality Assurance Management PlanKYVER PACAÑANoch keine Bewertungen

- Theranos 2567 04-25-2016Dokument148 SeitenTheranos 2567 04-25-2016TechCrunchNoch keine Bewertungen

- FCC Test Report (15.107, 15.109) - RM191Dokument26 SeitenFCC Test Report (15.107, 15.109) - RM191Manohar T MNoch keine Bewertungen

- A Stochastic Model For Piping Failure Frequency Analysis Using OPDE DataDokument9 SeitenA Stochastic Model For Piping Failure Frequency Analysis Using OPDE DataWei ZhangNoch keine Bewertungen

- Volume1 Sismico PDFDokument280 SeitenVolume1 Sismico PDFFabian AndresNoch keine Bewertungen

- Final Report - September 7, 2017 Incident InvestigationDokument4 SeitenFinal Report - September 7, 2017 Incident InvestigationDan Lehr100% (1)

- ML13119A154 Assessment GuideDokument32 SeitenML13119A154 Assessment GuidepreeshnabalaNoch keine Bewertungen

- Preliminary Assessment of NDE Methods On Inspection of HDPE Butt Fusion Piping Joints For Lack of FusionDokument73 SeitenPreliminary Assessment of NDE Methods On Inspection of HDPE Butt Fusion Piping Joints For Lack of FusionvolvarosNoch keine Bewertungen

- Technical Root Cause Spectra 20161014Dokument115 SeitenTechnical Root Cause Spectra 20161014mohamed ashorNoch keine Bewertungen

- Us Navy Practical Guide Flame Bending PipeDokument102 SeitenUs Navy Practical Guide Flame Bending PipeBrian DohertyNoch keine Bewertungen

- Design of Axis Symmetric NozzleDokument127 SeitenDesign of Axis Symmetric NozzleSanjay KumarNoch keine Bewertungen

- Boric Acid Corrosion EvaluationDokument140 SeitenBoric Acid Corrosion EvaluationEuNoch keine Bewertungen

- NUREG - CR-6372 Vol 2 PDFDokument888 SeitenNUREG - CR-6372 Vol 2 PDFErich SchlenderNoch keine Bewertungen

- Condition Assessment of Substation Ground GridsDokument62 SeitenCondition Assessment of Substation Ground GridsDeputy Manager P&I Division PeshawarNoch keine Bewertungen

- Root Cause Evaluation (Unit 3 Steam Generator)Dokument106 SeitenRoot Cause Evaluation (Unit 3 Steam Generator)azwrisNoch keine Bewertungen

- SCC Report BattelleDokument115 SeitenSCC Report Battelleulanfiutti100% (1)

- Board Approved Blackout RecommendationsDokument25 SeitenBoard Approved Blackout RecommendationsArianna IsabelleNoch keine Bewertungen

- EPRI Acoustic Emission For High-Energy PipingDokument134 SeitenEPRI Acoustic Emission For High-Energy PipingManuel L LombarderoNoch keine Bewertungen

- Rai 6Dokument4 SeitenRai 6songsdocumentsNoch keine Bewertungen

- Intro To MV Femp Super EspcDokument14 SeitenIntro To MV Femp Super EspcIgor PancevskiNoch keine Bewertungen

- Chemours GenX OPRADokument135 SeitenChemours GenX OPRAEmily ScottNoch keine Bewertungen

- GTI/AGA ECDA Project - Protocol /implementation Plan DevelopmentDokument6 SeitenGTI/AGA ECDA Project - Protocol /implementation Plan DevelopmentPako RosasNoch keine Bewertungen

- NRC 2008 0122 0158 2Dokument3 SeitenNRC 2008 0122 0158 2femalefaustNoch keine Bewertungen

- Draft HPNS Report - Parcels D-2 and UC Soil - 103117Dokument74 SeitenDraft HPNS Report - Parcels D-2 and UC Soil - 103117cb0bNoch keine Bewertungen

- S M Department of Environment, Great Lakes, and Energy Warren District OfficeDokument5 SeitenS M Department of Environment, Great Lakes, and Energy Warren District OfficeWDIV/ClickOnDetroitNoch keine Bewertungen

- Well Testing Project Management: Onshore and Offshore OperationsVon EverandWell Testing Project Management: Onshore and Offshore OperationsNoch keine Bewertungen

- The FEIS Executive Summary of The I-81 Viaduct ProjectDokument42 SeitenThe FEIS Executive Summary of The I-81 Viaduct ProjectNewsChannel 9Noch keine Bewertungen

- 81 Travel Time EstimatesDokument6 Seiten81 Travel Time EstimatesTim KnaussNoch keine Bewertungen

- National Grid Energy Vision NYDokument32 SeitenNational Grid Energy Vision NYTim KnaussNoch keine Bewertungen

- The FEIS Executive Summary of The I-81 Viaduct ProjectDokument42 SeitenThe FEIS Executive Summary of The I-81 Viaduct ProjectNewsChannel 9Noch keine Bewertungen

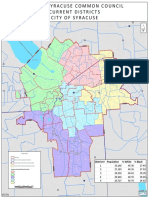

- Syracuse Council Districts MapDokument1 SeiteSyracuse Council Districts MapTim KnaussNoch keine Bewertungen

- Destiny OffensesDokument1 SeiteDestiny OffensesTim KnaussNoch keine Bewertungen

- 12 Worst DealsDokument17 Seiten12 Worst DealsTim KnaussNoch keine Bewertungen

- Onondaga County Police Reform PlanDokument59 SeitenOnondaga County Police Reform PlanTim KnaussNoch keine Bewertungen

- Veto MSG BOE Pay CutDokument2 SeitenVeto MSG BOE Pay CutTim KnaussNoch keine Bewertungen

- B&L Sanitation Study 2.23.22Dokument12 SeitenB&L Sanitation Study 2.23.22Tim KnaussNoch keine Bewertungen

- Vaccination Rates by ZIP CodeDokument1 SeiteVaccination Rates by ZIP CodeTim KnaussNoch keine Bewertungen

- Report of The County Executive 11-22-21Dokument1 SeiteReport of The County Executive 11-22-21Tim KnaussNoch keine Bewertungen

- Letter To President Biden On Ukraine RefugeesDokument1 SeiteLetter To President Biden On Ukraine RefugeesTim KnaussNoch keine Bewertungen

- Onondaga County DecisionDokument15 SeitenOnondaga County DecisionTim KnaussNoch keine Bewertungen

- FAQ On COBRA SubsidyDokument10 SeitenFAQ On COBRA SubsidyTim KnaussNoch keine Bewertungen

- Assembly Senate Response.2.10.21. Final PDFDokument16 SeitenAssembly Senate Response.2.10.21. Final PDFZacharyEJWilliamsNoch keine Bewertungen

- TranscriptDokument3 SeitenTranscriptNick Reisman100% (1)

- NYCLU Letter To OCSO Re COVID Restrictions at Justice Center - 12-24-2020Dokument3 SeitenNYCLU Letter To OCSO Re COVID Restrictions at Justice Center - 12-24-2020Tim KnaussNoch keine Bewertungen

- Attorney General James Releases Report On Nursing Homes' Response To COVID-19Dokument76 SeitenAttorney General James Releases Report On Nursing Homes' Response To COVID-19News 8 WROCNoch keine Bewertungen

- 2020 Poll Watcher Certificate GeneralDokument1 Seite2020 Poll Watcher Certificate GeneralTim KnaussNoch keine Bewertungen

- LEO #19 (Signed) (37003)Dokument1 SeiteLEO #19 (Signed) (37003)Tim KnaussNoch keine Bewertungen

- Mayor Walsh Letter On Orange ZoneDokument2 SeitenMayor Walsh Letter On Orange ZoneTim KnaussNoch keine Bewertungen

- Onondaga Zones OnlyDokument1 SeiteOnondaga Zones OnlyTim Knauss0% (1)

- 138 Brownfield PropertiesDokument4 Seiten138 Brownfield PropertiesTim KnaussNoch keine Bewertungen

- Brownfield PropertiesDokument5 SeitenBrownfield PropertiesTim KnaussNoch keine Bewertungen

- DeWitt Warehouse EAFDokument48 SeitenDeWitt Warehouse EAFTim KnaussNoch keine Bewertungen

- Redistricting ResolutionDokument2 SeitenRedistricting ResolutionTim KnaussNoch keine Bewertungen

- AEI Round 2 Allocation Recommendations ESDDokument3 SeitenAEI Round 2 Allocation Recommendations ESDTim Knauss100% (2)

- Resolution To Roll Back Bail ReformDokument4 SeitenResolution To Roll Back Bail ReformTim KnaussNoch keine Bewertungen

- Ways & Means Budget ChangesDokument12 SeitenWays & Means Budget ChangesTim KnaussNoch keine Bewertungen

- Difference Between MCB and MCCB, ELCB, RCCB and Its CharacteristicsDokument7 SeitenDifference Between MCB and MCCB, ELCB, RCCB and Its CharacteristicsSamudhbhav PrabhuNoch keine Bewertungen

- LS Inverter Series PDFDokument16 SeitenLS Inverter Series PDFQuang Chánh NguyễnNoch keine Bewertungen

- Javed ChattaDokument35 SeitenJaved ChattaMuhammad TalhaNoch keine Bewertungen

- Single Phase DC - AC Inverters - Electrical Engineering (MCQ) Questions and AnswersDokument3 SeitenSingle Phase DC - AC Inverters - Electrical Engineering (MCQ) Questions and AnswersH Aries OñaNoch keine Bewertungen

- Peters 1921Dokument7 SeitenPeters 1921rishabhNoch keine Bewertungen

- Design and Analysis of High Efficiency DC - DC Boost Converter For EV Charging ApplicationsDokument9 SeitenDesign and Analysis of High Efficiency DC - DC Boost Converter For EV Charging ApplicationsIJRASETPublicationsNoch keine Bewertungen

- EirGrid Transmission Forecast Statement 20102016Dokument200 SeitenEirGrid Transmission Forecast Statement 20102016yuntiam78Noch keine Bewertungen

- Grounding Vs BondingDokument2 SeitenGrounding Vs BondingVictor HutahaeanNoch keine Bewertungen

- Specification For CCVTDokument8 SeitenSpecification For CCVTUsman BabarNoch keine Bewertungen

- 500hp Parameter PDFDokument122 Seiten500hp Parameter PDFcaressessNoch keine Bewertungen

- New Electricity Tariff RatesDokument2 SeitenNew Electricity Tariff RatesAda DeranaNoch keine Bewertungen

- IEC 62271 202 Standards enDokument27 SeitenIEC 62271 202 Standards endineshkrish80% (5)

- A Steverson Chapter 11 Pages 416-468Dokument54 SeitenA Steverson Chapter 11 Pages 416-468Gerson NetoNoch keine Bewertungen

- Unit 2 Voltage and Current SourcesDokument33 SeitenUnit 2 Voltage and Current SourcesVimala ElumalaiNoch keine Bewertungen

- ACS100 Manual EngDokument52 SeitenACS100 Manual EngMárcio FernandesNoch keine Bewertungen

- Delegation of Powers BP 71 Dated 29 6 2011Dokument15 SeitenDelegation of Powers BP 71 Dated 29 6 2011NelsonNoch keine Bewertungen

- What Is A Solar PanelDokument3 SeitenWhat Is A Solar Panelyashwanthkanakam03Noch keine Bewertungen

- Fluke 1744 Power Quality AnalyzerDokument5 SeitenFluke 1744 Power Quality AnalyzercemavacaNoch keine Bewertungen

- HV Cable CommissioningDokument2 SeitenHV Cable CommissioningAtchut Rao100% (1)

- Abb Shunt ReactorDokument4 SeitenAbb Shunt ReactorMuthu KumaranNoch keine Bewertungen

- Ross Hill Controls, Variable Speed Motor Drives Applications ManualDokument158 SeitenRoss Hill Controls, Variable Speed Motor Drives Applications ManualPaulo H Tavares100% (1)

- Electrical Power Systems Wadhwa 6Dokument1 SeiteElectrical Power Systems Wadhwa 6teceeeNoch keine Bewertungen

- Chap 3Dokument32 SeitenChap 3Bonsa100% (1)

- 1 Chapter One Part 2Dokument34 Seiten1 Chapter One Part 2Arazw AbdulrahmanNoch keine Bewertungen

- Lincoln-Electric Welding Inverter PC65-PC105Dokument33 SeitenLincoln-Electric Welding Inverter PC65-PC105andtib100% (1)

- 415V Motor Sample ReportDokument2 Seiten415V Motor Sample ReportSiva NandhamNoch keine Bewertungen

- Vela Motors Vl2-Series Catalogue Electric MotorsDokument3 SeitenVela Motors Vl2-Series Catalogue Electric Motorsangel flores añezNoch keine Bewertungen

- TEM57-MK2 (A) TEM67A TEM67APlus OperationDokument11 SeitenTEM57-MK2 (A) TEM67A TEM67APlus OperationAbdilbasit HamidNoch keine Bewertungen

- 2 Schedules For Connection AgreementDokument9 Seiten2 Schedules For Connection AgreementSud JoshiNoch keine Bewertungen

- Sungrow SG3400HV 30 3400kW Inverter Datasheet TRDokument2 SeitenSungrow SG3400HV 30 3400kW Inverter Datasheet TRjeanNoch keine Bewertungen