Beruflich Dokumente

Kultur Dokumente

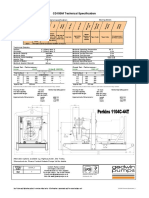

Techniflo Product Brochure

Hochgeladen von

aasenjoy0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

191 Ansichten24 SeitenTechniflo pumps have no mechanical seals or packed glands. The pump liquid is hermetically sealed from the driving end and the driving power is transmitted via magnetic force using powerful synchronous magnets. Pumps can be used with confidence on a full range of extremely corrosive, hazardous, toxic, explosive and dangerous chemicals.

Originalbeschreibung:

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenTechniflo pumps have no mechanical seals or packed glands. The pump liquid is hermetically sealed from the driving end and the driving power is transmitted via magnetic force using powerful synchronous magnets. Pumps can be used with confidence on a full range of extremely corrosive, hazardous, toxic, explosive and dangerous chemicals.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

191 Ansichten24 SeitenTechniflo Product Brochure

Hochgeladen von

aasenjoyTechniflo pumps have no mechanical seals or packed glands. The pump liquid is hermetically sealed from the driving end and the driving power is transmitted via magnetic force using powerful synchronous magnets. Pumps can be used with confidence on a full range of extremely corrosive, hazardous, toxic, explosive and dangerous chemicals.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 24

Engineering Excellence

Chemical & Process Pump Range

S40104

Contents

Introduction

PX & PS Series

PW Series

PW-C Series

TB Series

Options, Accessories and Chemical Mixers

Page 3

Pages 4-7

Pages 8-11

Pages 12-15

Pages 16-21

introduction

small capacity

medium capacity

large capacity

options & accessories

Pages 22-23

are a complete range of

centrifugal pumps. Techniflo pumps have no

mechanical seals or packed glands. The pump liquid is hermetically

sealed from the driving end and the driving power is transmitted via

magnetic force using powerful synchronous magnets. All of the

wetted parts in a Techniflo pump are made of engineered plastics and

high grade ceramics.

means

means

Techniflo is the product of over 20 years experience in Non-

Metallic centrifugal pump design, featuring state-of-the-art

technology and advanced manufacturing procedures.

Designed for extended use in the most difficult duties. Techniflo

pumps can be used with confidence on a full range of extremely

corrosive, hazardous. toxic, explosive and dangerous chemicals.

Manufactured to the highest standards with a premium on Quality

Control, every Techniflo pump is factory tested to verify

operational performance. Years of extended service in numerous

installations are a testimony to the exceptional quality and

reliability of Techniflo.

With the interests of every pump user in mind. Techniflo delivers a

number of significant rewards and benefits:

Exceptional quality and economic prices

Lowoperational and lifetime costs

Reduced downtime and increased production

Ease of maintenance

User health arid safety

Operator confidence

Environmental protection

Zero emissions

non-metallic

sealless mag-drive

Non-metallic outstanding corrosion resistance.

Sealless Magnetic Drive zero leakage.

> Leading Edge Technology

> Designed for the worst

> Proven Performance, Quality & Reliability

> Rewards andBenefits

Introduction

3

PX & PS Series

Brushless DC motor pumps

and variable speed drive

PX Self Priming Versions

PX/PS Typical Applications

> Photographic solutions

Etching machines

Vending machines

Laboratory applications

Ice machines

Chemical controllers

Filtration equipment

>

>

>

>

>

>

4

PX & PS Series

PX/PS Technical Features

> Polypropylene and

ETFE wet ends

> Close coupled motors

> Flows up to 120L/min

> Heads up to 20m

> Liquid SG up to 1.8

> Liquid Temperatures:

70 C for polypropylene

90 C for ETFE

> Self priming option on

most models

> Brushless DC motor versions

available with inbuilt 4-20mA

control option

o

o

PX

Polypropylene

Viton or EPDM

Ceramic

Ceramic

Polypropylene

Polypropylene

TECHNICAL ILLUSTRATION

PART DESCRIPTION MATERIALS OF CONSTRUCTION

Rear Casing

O Ring

Spindle

Bearing

Impeller / Mag Capsule

Front Casing

PS-F

ETFE

Viton or EPDM

Ceramic

Rulon

ETFE

ETFE

PS

Polypropylene

Viton or EPDM

Ceramic

Rulon

Polypropylene

Polypropylene

5

PX & PS Series

Performance curves - PX Series

Head (m)

8

10

6

4

2

10 20 30 40 50 60 70

Discharge Flow (L/Min)

Performance curves - PS Series

Head (m)

4

20

Flow (L/Min)

2

6

8

10

12

14

6

18

20

0

10 30 40 50 60 70 80 90 100 110 120 0

6

PX & PS Series

Dimensions

Model W H L A B C D E F G inlet/outlet motor size

10PX

30PX

40PX

50PX-Z

50PX

50PX-X

100PX-Z

100PX

100PX-X

100PX-ZZ

125PS

150PS

200PS

200PS.3

200PS-Z

250PS

250PS.3

250PS-IEC

300PS

74

95

95

95

120

120

120

120

120

120

120

120

156

156

156

156

156

164

160

92

115

115

125

130

135

130

130

135

150

135

164

165

165

165

165

165

195

175

145

197

210

226

247

255

236

262

270

243.5

255

300

355

345

355

365

355

424

385

-

30

30

30

40

40

40

40

40

40

43

40

70

70

70

70

70

95

80

30

50

50

50

64

64

64

64

64

64

62

64

100

100

100

100

100

140

110

73

117

131.5

134

169

176.5

152

169

176.5

160

175

200

205

205

205

195

195

173

230

60

85

68

68

100

100

100

100

100

100

62

100

110

110

110

110

110

134

140

45

55

55

55

60

60

60

60

60

60

60

66

66

66

66

66

66

87

75

31

39

38.5

39.5

48

50

39.5

48

50

38.5

50

70

70

70

70

70

70

80

55

17

21.5

28.5

38.5

31

26

38.5

31

26

44.5

26

43.5

43.5

43.5

43.5

43.5

43.5

43.5

59

12

12

16

16

20

25

16

20

25

16

20

20

25

25

25

25

25

25

25/20

5W

10W

20W

20W

45W

45W

45W

70W

60W

70W

70W

90W

150W

150W

150W

250W

250W

250W

300W

NOTE: Pump models with suffix '.3' have 3 phase motor.

Standard hose tail ports with BSP male thread option.

All motors are IP44 except IEC versions.

All dimensions in millimetres.

7

PW Series

PW Typical Applications

> PCB machines

Electroplating solutions >

> Fume scrubbers

> Salt & brine solutions

> CIP cleaning systems

> Deionizing equipment

> Hydrochloric Acid

> Sodium Hydroxide

8

PW Series

PW Technical Features

> Solid Polypropylene (PW) and ETFE (PW-F) wet ends

> Close coupled IEC standard motors

> Flows up to 1400L/m (84m /hr)

> Heads up to 37m

> Liquid SG up to 1.9

> Liquid Temperatures - up to 70 C for PW

- up to 90 C for PW-F

> Flanged ports with universal bolt pattern to match Table E, DIN or

ANSI 150

> Rear earth magnets above 2.2kW motor size

> Self priming versions up to 4kW (see page 22)

3

o

o

PW VERSION

Cast Iron

Polypropylene

High purity alumina ceramic

Viton or EPDM

Carbon

Polypropylene

Polypropylene

Polypropylene

TECHNICAL ILLUSTRATION

PART DESCRIPTION MATERIALS OF CONSTRUCTION

Front Support

Rear Casing

Spindle

O Ring

Bearing

Mag Capsule

Impeller

Front Casing

1

2

3

4

5

6

7

8

PW-F VERSION

Cast Iron

EFTE

High purity alumina ceramic

Viton or EPDM

High purity alumina ceramic

EFTE

EFTE

EFTE

9

PW Series

Performance curves - PW Series

Head (m)

Flow (m /hr)

3

80 70 60 50 40 30 20 10

10

20

30

40

10

PW Series

Dimensions - PW Series

NOTE: Explosion proof motors available on request.

Motor dimensions may vary slightly depending on type used.

All dimensions in millimetres.

Model W H L A B C D E F G

inlet/

outlet

motor

size

400PW/-F

401PW/-F

402PW/-F

403PW/-F

405PW/-F

655PW/-F

657PW/-F

6510PW/-F

6515PW/-F

140

160

260

260

260

260

260

260

350

216

254

255

255

270

360

360

360

385

394

488

551

591

617

715

746

746

904

110

130

208

208

208

210

210

210

300

51

57.5

65

65

65

85

85

85

85

98

130

200

200

200

270

270

270

270

95

115

115

115

130

175

175

175

200

121

139

140

140

140

185

185

185

185

87

102.5

89

89

89

118

118

118

118

150

184

158

158

158

240

240

240

240

40/40

40/40

50/40

50/40

50/40

80/65

80/65

80/65

80/65

0.37kW

0.75kW

1.5kW

2.2kW

4.0kW

4.0kW

5.5kW

7.5kW

11.0kW

J K

125

148

158

158

158

158

249

249

287

12

121

14

14

14

14

14

14

14

11

PW-C Series

PW-C Typical Applications

> Fume scrubbers

> Water treatment plants

> Tanker unloading

> Battery industry

> Metal degreasing

> Glass etching

> Pulp & paper industry

> Chemical refining

> Sulphuric Acid

> Hydrofluoric Acid

> Flousilicic Acid

> Sodium Hypochlorite

12

PW-C Series

PW-C Technical Features

> Heavy duty cast iron casing with moulded EFTE liner

for extreme chemical reistance

> Close coupled IEC standard motors

> Flows up to 1500L/m

> Heads up to 44m

> Liquid SG's up to 1.9

> Liquid Temperatures to 90 C

> Choice of bearing and shaft materials

> Flanged ports with universal bolt pattern to match

Table E, DIN or ANSI 150

> Rare earth magnets above 2.2kW motor size

> Epoxy resin paint finish

o

EFTE

High purity alumina ceramic or silicon carbide

Viton, EPDM or Aflas

Carbon, 99.5% high purity alumina ceramic or silicon carbide

EFTE

EFTE

EFTE

Cast Iron

Cast Iron

TECHNICAL ILLUSTRATION

PART DESCRIPTION MATERIALS OF CONSTRUCTION

Rear Casing

Spindle

O Ring

Bearing

Mag Capsule

Impeller

Inner Casing (Lining)

Outer Casing

Foot Support & Motor Bracket

1

2

3

4

5

6

7

8

9

13

Performance curves - PW-C Series

Head (m)

Flow (m /hr)

3

PW-C Series

405

403

402

401

250

505

507

657

6510

6515

14

Dimensions - PW-C Series

NOTE: Explosion proof motors available on request.

Motor dimensions may vary slightly depending on type used.

All dimensions in millimetres.

Model W H L A B C D E F G

inlet/

outlet

motor

size

250PW-C

401PW-C

402PW-C

403PW-C

405PW-C

505PW-C

507PW-C

657PW-C

6510PW-C

6515PW-C

155

195

200

200

200

260

260

280

280

350

237

275

295

295

295

325

325

360

360

385

490

528.5

603

603

675.5

720

786

797.5

797.5

983.5

110

130

140

140

140

210

210

220

220

300

51

57.5

65

65

65

62

62

0

0

0

88

104.5

87

87

87

110

110

118

118

118

115

135

155

155

155

175

175

175

175

200

122

140

140

140

140

150

150

185

185

185

147

152

166

166

188

188

261

261

261

281

95

111

106

106

106

130

130

193

193

193

25/25

40/40

50/40

50/40

50/40

65/50

65/50

80/50

80/50

80/50

0.37kW

0.75kW

1.5kW

2.2kW

4.0kW

4.0kW

5.5kW

5.5kW

7.5kW

11.0kW

J K

146

250

275

275

275

305

305

320

320

320

14

14

14

14

14

14

14

14

14

14

PW-C Series

15

TB Series

TB Typical Applications

> Petrochemical industry

> Volatile & low flashpoint liquids

> Mineral processing

> Chemical manufacturing

> Chemical processing

> Steel making industry

> Heat transfer liquids

> Hot liquors

> Water & wastewater treatment

> Sulphuric acid

> Hydrofluoric acid

> Methyl Chloride

> Chromic acid

> Hydrogen peroxide

> Titanium Pentachloride

> Ammonia

16

TB Series Technical Features

TB Series

TB Series Bare Shaft Pump

> Heavy duty ductile casing with bonded PTFE or PFA lining

> Patented world first thrust balanced design (see page 19)

> Completely open impeller eye on all models for optimum NPSHr

and efficiency

> One bolt size for ease of maintenance

> Close coupled and bare shaft versions

ANSI 150 flanges

Fluid temperatures from -29 to 120 C

System pressures up to 20.6 bar (300psi)

Conforming with ASME/ANSI B73.1 M footprint

Back pullout design - liquid end and drive end independently

serviceable

Flows up to 300 m /hr

Heads up to 100m

Fluid SG up to 2.5

Rare earth magnets on all pumps

Secondary containment design available

Epoxy resin paint finish with all AAPU top coat

Two bolt flanged drain

100% replaceable wearing parts

>

>

>

>

>

>

>

>

>

>

>

>

>

o o

3

17

TECHNICAL ILLUSTRATION - TB SERIES

TB Series

OUTER MAGNET

ASSEMBLY

CONTAINMENT

SHELL

RADIAL BEARINGS IMPELLER/MAG

CAPSULE

One drive size per

motor frame. Simple

keyless design means

assembly with motor

shaft is quick and easy.

Magnets bolted and

sealed inside 316

stainless steel carrier.

Epoxy paint with AAPU

top coat.

One-pice carbon fibre

Teflon moulding for a

combination of strength

and chemical resistance.

Patented reinforced

socket for shaft

mounting. Outer pressure

housing made from a

Kevlar composite.

Dual carbon graphite or

sintered silicon carbide

(SiC). Individually

replaceable and flexibly

mounted for full

alignment with shaft.

Unique one-piece design

with magnets potted and

sealed inside 316

stainless steel cover, and

all encapsulated in

Teflon for optimum

chemical resistance.

ADAPTER CONTAINMENT

RING

SHAFT CASING

Mates flanged motors to

the pump. Can mount a

range of sizes directly

without spacer plates.

Integral foot mates to

existing ANSI base

plates. All mounting bolts

conveniently accessed

from outside the

adapter to simplify

motor/pump mating.

Epoxy paint finish with

AAPU top coat.

Extra-heavy duty one

piece cast ductile iron

casting. Precisely aligns

and supports the

containment shell in the

casing. Is separate from

the adapter to allow

servicing motor without

opening the liquid end

of the pump.

U

Epoxy

paint finish with AAP

top coat.

Replaceable, straight,

sintered silicon carbide

shaft cantilevered from

the containment shell.

Oversized to safely

handle all load

combinations.

Cantilever design

leaves impeller suction

open for best possible

performance.

Top centreline discharge,

one piece cast ductile

iron with bonded Teflon

lining. Lining minimum of

1/8" (3mm).

Provides nearly

universal corrosion

resistance and extremely

low maintenance.

Casing drain is standard.

Epoxy paint finish with

AAPU top coat.

18

Unique Patented Thrust Balancing Feature

TB Series

The TB Sries 'Thrust Balancing'

is a revolutionary engineering

concept.

As seen in Fig.1 the discharge

pressure causes liquid to flow

past the clearance rings and

around the Magnet Capsule. At

higher flows the variable orifice

opens and decreases the balance

pressure to negate forward thrust

of the impeller (Fig. 2).

At lower flows the variable orifice

closes and increases the balance

pressure to negated the back-

thrust of the impeller (Fig. 3).

The net result is an extremely

stable axial position that does not

require axial bearings. Compare

the axial thrust loads of the TB

Series to other mag drive pumps.

(see Fig. 4).

Clearance Rings & Solids

TB Series clearance rings restrict solids greater than

0.1mm from entering the containment shell area,

keeping all bearings and critical flow paths clear. this

enables the pump to successfully handle solids.

Concentrations up to 30% and particle sizes to 6mm

in size are possible.

Pressurised Radial Bearings & Volatile Liquids

The TB Series radial bearings operate in a pressurised

fluid environment, which enables volatile liquids to be

pumped safely without flashing off.

1000

900

800

700

600

500

400

300

200

100

0

6"

8"

10"

TB Mag

Other

Sealless

Pumps

Pump Impeller Diameter

Back

Wear

Rings

Front

Wear

Rings

Clean,

Filtered

Liquid

Liquid/Solids:

Microns to

Figure 2

Opening at

higher flows.

Figure 3

Closing at

lower flows.

Figure 1

Figure 4

Discharge

Pressure

Balance

Pressure

Suction

Pressure

19

TB Series

3x2x6B

3x2x6A 1.5x1x6A

Performance Curves - TB Series

Flow m /hr

3

Head (m)

2900 rpm

100

50

50 100 150 200

2x1x10C 3x1.5x10C 3x2x10C 4x3x10C

1.5x1x8B 3x1.5x8B

3x2x8C

4x3x8C

4x3x6B

Performance Curves - TB Series

Flow m /hr

3

1450 rpm

30 50 100 200 300

10

20

30

6x4x10C 4x3x10H 4x3x10C

3x2x10C 3x1.5x10C

2x1x10C

1.5x1x8B

3x1.5x8B

3x2x8C

4x3x8C

3x2x6B

3x2x6A

1.5x1x6A

4x3x6B

Head (m)

20

Dimensions

NOTE: Pump flanges are ANSI 150. Other drillings are available on request.

Explosion proof motors are available on request.

Motor dimensions will vary depending on size and type used.

All dimensions in millimetres.

Pump

Size

A B C D E1 E2 F G H J

inlet/

outlet

Bare

Pump kg

1.5 x 1 x 6A

3 x 2 x 6A

1.5 x 1 x 8B

3 x 2 x 6B

3 x 1.5 x 8B

4 x 3 x 6B

3 x 2 x 8C

4 x 3 x 8C

2 x 1 x10C

3 x 1.5 x 10C

3 x 2 x 10C

4 x 3 x 10C

4 x 3 x 10H

6 x 4 x 10C

133

133

133

210

210

210

210

210

210

210

210

210

210

254

165

165

165

209

216

209

241

279

216

216

241

279

279

343

298

298

298

419

425

419

451

489

425

425

451

489

489

597

300

300

300

281

316

350

306

372

351

361

306

372

372

477

152

152

152

248

248

248

248

248

248

248

248

248

248

248

0

0

0

184

184

184

184

184

184

184

184

184

184

184

102

102

102

102

102

102

102

102

102

102

102

102

102

102

16

16

16

16

16

16

16

16

16

16

16

16

16

16

221

287

287

312

287

287

287

287

287

287

287

287

287

287

184

184

184

318

318

318

318

318

318

318

318

318

318

318

40/25

80/50

40/25

80/50

80/40

100/80

80/50

100/80

50/25

80/40

80/50

100/80

100/80

150/100

34

39

59

63

64

75

67

83

93

96

101

107

113

116

L

718

784

784

809

784

946

784

784

784

784

784

784

784

784

TB Series

21

PW-N Series - Self Priming Magnetic Drive Pumps

Options and Accessories

Technical Illustration

PW Typical Applications

> Heavy duty reinforced polypropylene

construction

Advanced design with gas and water

separation chamber

Available in 5 models with max flow rate

of 510 L/min

Max suction lift 4 M

Adaptable with standard IEC motor

>

>

>

>

W

H

L

A

B

C

D

E

F

G

J

160

390

613

130

308

130

20

115

285

105

212

400 401 402 403 405

160

390

615

130

308

130

20

115

285

105

212

260

420

762

200

333

208

30

115

315

105

250

260

420

762

200

333

208

30

115

315

105

250

260

435

866

200

333

208

30

130

330

105

250

PW-N DIMENSIONS

All dimensions in mm

Performance Curves

Head (m)

Flow (L/m)

22

20

18

16

14

12

10

8

6

4

2

100 200 300 400 500

50 Hz

22

Options & Acceessories

Sump Pump Versions

Pump Control Panels

Current Sensing

Dry Run Protection

Chemical Valves

Chemical Mixers

PA Series

> 240V TEFC

Motor

> Polypropylene

Flange mount

- 4 bolt

> Shaft lengths:

490 mm

690mm

890mm

> Available in

PVDF or 316

Stainless Steel

wetted materials

> Effective

mixing for a

wide range of

closing chemicals

23

Chemical & Process Pump Range

Stock Availability

> A comprehensive range of pumps & spares is held in stock

to meet immediate requirements

EVERY REQUIREMENT COVERED

Expertise

> Trained and experienced product specialists with expertise

in the complete range of Techniflo products

Technical Support

> Full Technical Information covering all aspects

of pump performance including material

compatibility and system design

Advice

> Reliable advice regarding pump unit

assembly, installation, operation,

preventative maintenance programming

and spare parts inventory

Service Support

> Full repair and service capability including

scheduled servicing

Quality Control

> Techniflo pumps are manufactured strictly in

accordance with the requirements of ISO 9001:2001 to

ensure the highest levels of product quality

Das könnte Ihnen auch gefallen

- Someflu FP ECO-N ENDokument2 SeitenSomeflu FP ECO-N ENAnonymous r3MoX2ZMTNoch keine Bewertungen

- CD150M Technical Specification: Standard Pump Material SpecificationDokument2 SeitenCD150M Technical Specification: Standard Pump Material SpecificationAbcehmu EgiNoch keine Bewertungen

- Dv300 STD MMDokument40 SeitenDv300 STD MMjacklyn ade putraNoch keine Bewertungen

- Manual Techniflo TB - All Pumps PDFDokument28 SeitenManual Techniflo TB - All Pumps PDFJorge Gustavo Goyechea100% (1)

- NTTDokument48 SeitenNTTNatasha AnsuwattanaNoch keine Bewertungen

- American Manufacturing Aw1122bcd Parts BookDokument6 SeitenAmerican Manufacturing Aw1122bcd Parts BookFelipe MalleaNoch keine Bewertungen

- Mixed Flow PumpsDokument2 SeitenMixed Flow PumpssahildhingraNoch keine Bewertungen

- Submersible Turbine Pumps Franklin and Red Jacket Part CompatibilityDokument3 SeitenSubmersible Turbine Pumps Franklin and Red Jacket Part CompatibilitySarge ChisangaNoch keine Bewertungen

- Z22 DoubleSuctionAxiallysplitSingleStageCentrifugalPump60HzUS E10118 USDokument2 SeitenZ22 DoubleSuctionAxiallysplitSingleStageCentrifugalPump60HzUS E10118 USediNoch keine Bewertungen

- Catalogo ESCODokument29 SeitenCatalogo ESCOcarolina Portocarrero100% (1)

- High Pressure Pumps - Slim Catalogue 2015 Cod.93202Dokument36 SeitenHigh Pressure Pumps - Slim Catalogue 2015 Cod.93202Momen Al-HimonyNoch keine Bewertungen

- Amfg L0918BCDDokument5 SeitenAmfg L0918BCDLuis AparcanaNoch keine Bewertungen

- CP100i STD Pump Build & Service Manual Revision 1Dokument10 SeitenCP100i STD Pump Build & Service Manual Revision 1ISRAEL GONZALESNoch keine Bewertungen

- TECHNICAL Layne Engineering ManualDokument34 SeitenTECHNICAL Layne Engineering ManualAnonymous CMS3dL1TNoch keine Bewertungen

- User Instructions: Durco® Mark 3™ ISO Frame MountedDokument52 SeitenUser Instructions: Durco® Mark 3™ ISO Frame MountedJaluk 1zinNoch keine Bewertungen

- Curves 50hz 2731 451 01 en MegacpkDokument142 SeitenCurves 50hz 2731 451 01 en MegacpkAnonymous LtNzmXjVRNoch keine Bewertungen

- TMP - 6810-Delco History IC1488159342 PDFDokument123 SeitenTMP - 6810-Delco History IC1488159342 PDFAnonymous NwinYA8x2100% (1)

- Sulzer Pumps Finland Oy Product Specification: GeneralDokument3 SeitenSulzer Pumps Finland Oy Product Specification: GeneralGerman Zuleta100% (1)

- Camisas Refrigeracion Flowsleeves Pi-058 GB 2013-06-12Dokument38 SeitenCamisas Refrigeracion Flowsleeves Pi-058 GB 2013-06-12daniel2rialNoch keine Bewertungen

- Fristam FP ManualDokument20 SeitenFristam FP ManualatlimacoNoch keine Bewertungen

- 2020 Style 688 Split SealtekDokument8 Seiten2020 Style 688 Split SealtekdiamsamNoch keine Bewertungen

- API Vertical FlowayDokument8 SeitenAPI Vertical FlowayRaja RamachandranNoch keine Bewertungen

- Ebsray Bypass ManualDokument6 SeitenEbsray Bypass ManualŁukasz OlszewskiNoch keine Bewertungen

- Características Técnicas Bombas Mark IIIDokument60 SeitenCaracterísticas Técnicas Bombas Mark IIIBORISINHO2975Noch keine Bewertungen

- Dean Pump® Series PHDokument12 SeitenDean Pump® Series PHEnrique FuentesNoch keine Bewertungen

- Katalog STP Red Jaket All PDFDokument198 SeitenKatalog STP Red Jaket All PDFwarung1bensin100% (1)

- OmegaDokument20 SeitenOmegaمنير أحمدNoch keine Bewertungen

- Dokumen - Tips Dv200 Manual Master1Dokument45 SeitenDokumen - Tips Dv200 Manual Master1Fermín Duarte RodríguezNoch keine Bewertungen

- Ej PDFDokument20 SeitenEj PDFduongpnNoch keine Bewertungen

- Hh80 - Spec Sheet - Sykes - AustraliaDokument7 SeitenHh80 - Spec Sheet - Sykes - AustraliaDavid ReskyNoch keine Bewertungen

- ITT Gould PumpsDokument2 SeitenITT Gould PumpsBilly ZununNoch keine Bewertungen

- Salomix SLG GearDrive E00506 PDFDokument4 SeitenSalomix SLG GearDrive E00506 PDFgilbertogatoNoch keine Bewertungen

- Ahlstar: Characteristic Curve K18490Dokument1 SeiteAhlstar: Characteristic Curve K18490api-3759223Noch keine Bewertungen

- RSV Series BookletDokument24 SeitenRSV Series BookletmajidNoch keine Bewertungen

- Bole TinDokument12 SeitenBole TinCoordinación De Medios UneNoch keine Bewertungen

- HH125 Smanual Completed - Master Updated 30-3-06Dokument41 SeitenHH125 Smanual Completed - Master Updated 30-3-06jacklyn ade putra0% (1)

- 811 GUIDE Pump InterchangeabilityDokument68 Seiten811 GUIDE Pump Interchangeabilitykztro066100% (1)

- Pump CurveDokument3 SeitenPump CurveAnton PaneNoch keine Bewertungen

- Sec - 1701 - Non-Jacketed 4127 Q Viking PumpDokument13 SeitenSec - 1701 - Non-Jacketed 4127 Q Viking PumpkishorsinghNoch keine Bewertungen

- Gear PumpsDokument6 SeitenGear Pumpsmahdi gazeriNoch keine Bewertungen

- Sykes Pump BookletDokument105 SeitenSykes Pump BooklethipsterzNoch keine Bewertungen

- Dean RA Pump ManualsDokument23 SeitenDean RA Pump ManualscoltonNoch keine Bewertungen

- Brosur Pompa KSB Type CLTDokument20 SeitenBrosur Pompa KSB Type CLThenryhh111Noch keine Bewertungen

- Brochure B1510-50Hz Horizontal - Inline Selection Rev 12-14-06Dokument14 SeitenBrochure B1510-50Hz Horizontal - Inline Selection Rev 12-14-06احمد الجزار2007Noch keine Bewertungen

- Model 3196 ANSI B73.1M Process Pump: Engineered Performance For Increased Plant ReliabilityDokument74 SeitenModel 3196 ANSI B73.1M Process Pump: Engineered Performance For Increased Plant Reliabilityscottt_84Noch keine Bewertungen

- PH Series ManualDokument30 SeitenPH Series ManualChaerul UmamiNoch keine Bewertungen

- 3127 PDFDokument68 Seiten3127 PDFAseem Vivek MasihNoch keine Bewertungen

- Split Case Pumps Technical Brochure - XylemDokument12 SeitenSplit Case Pumps Technical Brochure - Xylemneurolepsia3790100% (1)

- CpkoDokument24 SeitenCpkoDeepak SparkleNoch keine Bewertungen

- 10x10 DF Reddy Buffaloes PumpDokument19 Seiten10x10 DF Reddy Buffaloes PumpsinahimsNoch keine Bewertungen

- CP CatalogDokument20 SeitenCP CatalogCentral Hydraulics100% (1)

- Hoja de Datos Vican Serie 124Dokument1 SeiteHoja de Datos Vican Serie 124jarpeasvNoch keine Bewertungen

- Slurry High Pressure PumpDokument15 SeitenSlurry High Pressure PumpOhmar Jamon LuzanoNoch keine Bewertungen

- Canned Motoer PumpDokument5 SeitenCanned Motoer PumpSteve WanNoch keine Bewertungen

- Warman Technical CatalogueDokument1 SeiteWarman Technical CatalogueMamiherintsoa Issaia RanaivoarimananaNoch keine Bewertungen

- Pumping Plumbing - Diesel Pumps - Pumpcent 6in HF HH160i - Operation Manual PDFDokument114 SeitenPumping Plumbing - Diesel Pumps - Pumpcent 6in HF HH160i - Operation Manual PDFSyaiful Azhar SchmidwaldNoch keine Bewertungen

- ROTEX Flex Coupling GR Instruction ManualDokument21 SeitenROTEX Flex Coupling GR Instruction ManualIzzi Al-AkbarNoch keine Bewertungen

- Horizontal & SuHorizontal & Sump Pumpmp PumpsDokument105 SeitenHorizontal & SuHorizontal & Sump Pumpmp PumpsAnonymous dHLFEZuhBa50% (2)

- Attachment 2 - Warman® 108G Pump Performance Curve - Condition 1 MudfloDokument1 SeiteAttachment 2 - Warman® 108G Pump Performance Curve - Condition 1 Mudfloachmadj1405Noch keine Bewertungen

- Hydraulic MotorsDokument8 SeitenHydraulic MotorsAnonymous OFKjccHONoch keine Bewertungen

- Variable Trim Compressor - A New Approach To Variable Compressor GeometryDokument10 SeitenVariable Trim Compressor - A New Approach To Variable Compressor GeometryAlbert CalderonNoch keine Bewertungen

- Compressor Exams SolutionsDokument18 SeitenCompressor Exams SolutionsMohamed BalbaaNoch keine Bewertungen

- Folleto KTZ - ENDokument4 SeitenFolleto KTZ - ENAnonymous CMS3dL1TNoch keine Bewertungen

- MEP M ES 012 - Centrifugal Process Pumps To API 610Dokument26 SeitenMEP M ES 012 - Centrifugal Process Pumps To API 610Anonymous wIPMQ5rh100% (1)

- Tank Coils - Design and UseDokument7 SeitenTank Coils - Design and UseMartin DanzeNoch keine Bewertungen

- A Centrifugal PumpDokument10 SeitenA Centrifugal PumpZain Ulabideen100% (1)

- Product Service Update 2011Dokument104 SeitenProduct Service Update 2011fabbromauricioyahoo.com.arNoch keine Bewertungen

- SNW 600-535Dokument80 SeitenSNW 600-535pablopadawan1100% (1)

- Agitator HW3 SolutionDokument7 SeitenAgitator HW3 SolutionPrashant MalveNoch keine Bewertungen

- Catalog Pompe City PumpsDokument52 SeitenCatalog Pompe City PumpsoanaNoch keine Bewertungen

- Interactive E-Training Module For Training Plant Engineers On Operations (Final)Dokument69 SeitenInteractive E-Training Module For Training Plant Engineers On Operations (Final)Manoj MishraNoch keine Bewertungen

- Technical Data: 150x125 CNHA 5 18.5Dokument5 SeitenTechnical Data: 150x125 CNHA 5 18.5سمير البسيونىNoch keine Bewertungen

- NADI Centrifugal Fan Manual PDFDokument46 SeitenNADI Centrifugal Fan Manual PDFVinay KumarNoch keine Bewertungen

- Pumps With Peripheral Impeller: Range of Performance Guarantee 2 Years Construction CharacteristicsDokument2 SeitenPumps With Peripheral Impeller: Range of Performance Guarantee 2 Years Construction Characteristicsnadalina10% (1)

- 4 - Hydrokinetic Fluid Couplings and Torque Con - 2002 - Advanced Vehicle Techno PDFDokument19 Seiten4 - Hydrokinetic Fluid Couplings and Torque Con - 2002 - Advanced Vehicle Techno PDFgobiNoch keine Bewertungen

- Iom Paco Pumps LF PartsDokument9 SeitenIom Paco Pumps LF PartsChristian TolentinoNoch keine Bewertungen

- Subaru Pumps Pkv101 Pkx201h Pkx201 Pkx301 Pkx201st Pkx301st Pkx201t Pkx301t ServiceDokument88 SeitenSubaru Pumps Pkv101 Pkx201h Pkx201 Pkx301 Pkx201st Pkx301st Pkx201t Pkx301t ServiceEdgardo M. Diolola100% (1)

- Catalogo Bomba Gabbioneta Modelo DHDokument2 SeitenCatalogo Bomba Gabbioneta Modelo DHcristobal_tl2277Noch keine Bewertungen

- Rotating EquipmentDokument202 SeitenRotating EquipmentJithin Rajan Joseph100% (1)

- Brochure American-Marsh VTPDokument16 SeitenBrochure American-Marsh VTPAlex Arma del CarpioNoch keine Bewertungen

- Dischargepump Manual WWT LC 01 enDokument12 SeitenDischargepump Manual WWT LC 01 entudor.tafalanNoch keine Bewertungen

- WearRingClearance CentrifugalPumpDokument3 SeitenWearRingClearance CentrifugalPumpAyipNoch keine Bewertungen

- Balance LineDokument0 SeitenBalance Linewsjouri2510Noch keine Bewertungen

- B-901 Mixer Impellers LTN 12Dokument5 SeitenB-901 Mixer Impellers LTN 12Abidin RahmanNoch keine Bewertungen

- LSA Pump Series - Low Maintenance, Abrasion Resistant: LSA-S, LSA-Expanded Range, LHD, MHDDokument8 SeitenLSA Pump Series - Low Maintenance, Abrasion Resistant: LSA-S, LSA-Expanded Range, LHD, MHDJuanPabloGonzalezFiblasNoch keine Bewertungen

- Mark 3 ASME Pumps PDFDokument94 SeitenMark 3 ASME Pumps PDFInf IngNoch keine Bewertungen

- Dredger Pumps For SlurryDokument4 SeitenDredger Pumps For SlurryvehptNoch keine Bewertungen

- Fall 2023 Chapter 7, 9 & 10 CHEM 517 Bioreactor Processing & ControlDokument78 SeitenFall 2023 Chapter 7, 9 & 10 CHEM 517 Bioreactor Processing & ControlskyliairojoNoch keine Bewertungen

- Ruhrpumpen CPP - IOM - ENGLISH - V7.120722Dokument166 SeitenRuhrpumpen CPP - IOM - ENGLISH - V7.120722jarivillasNoch keine Bewertungen

- Rotrex Technical Datasheet EK10 Rev2.2Dokument8 SeitenRotrex Technical Datasheet EK10 Rev2.2trebeheiramNoch keine Bewertungen