Beruflich Dokumente

Kultur Dokumente

SSM Lil 0204 NRR

Hochgeladen von

Huynh Thanh TamOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SSM Lil 0204 NRR

Hochgeladen von

Huynh Thanh TamCopyright:

Verfügbare Formate

SIEMENS

Nhon Trach 2 CCPP, Hamlet3, Phuoc Khanh Commune, Nhon Trach District.

Dong Nai Province, Metnam

LILAMA CORPORATION

Nhon Trach 2 Power Project

Nhon Trach District, Dong Nai Province

Phuoc Khanh Village

Viet Nam

Attn.: Mr. Nguyen Van Hung

Project Director

NHON TRACH 2 CCPP

Transportation of Condenser

Dear Sir,

CC: NT2

-

PM

SSM-M

SLT

SPO

Siemens AG

Energy Sector; Management Wolfgang Dehen

Fossil Power Generation Division; Management Michael Suess

Energy Solutions; Management: Rainer Hauenschild

Energy

Name lngo Richter

Department E F ES EC 1

Telephone

Fax

E-mail

Your reference

Our reference

Date

MailNhonTrach-Site-Ll L@pg.siemens.com

vN 1 003/0301 //ssM-Lt L- 0204 NRR

2010-10-05

LILAMA-NT2-PMB

RECEIVED

t to:........1f. J.3..........

Date:....a5..4.9.119

As already announced, please find now the following documentation for the off-loading, transport, and

installation of the condensor, for your information.

- Method Statement: 8972 - MS - LT - 004, rev 0

Roll - off at the

jetty

and transport to site

- Method Statement: 8972 - MS - | - 004. rev A

On-carriage and set down

- Method Statement: 8972 - MS - | - 003, rev B

Installation of Condenser, incl. Risk Assessments

- Time Schedule

With best regards

Siemens Aktiengesellschaft: Chairman of the Supervisory Board: Gerhard Cromme;

Managing Board: Peter Loescher, Chairman, President and Chief Executive Officer; Wolfgang Dehen, Heinrich Hiesinger,

Joe Kaeser, Barbara Kux, Hermann Requardt, Siegfried Russwurm,

peter y.

Solmssen

Registered offices: Berlin and Munich, Germany; Commercial registries: Berlin Charlottenburg, HRB 12300, Munich, HRB 6684

WEEE-Reg.-No. DE 23691 322

scF 1212008 V08.12

Postial address:

SiemensAG

E E.NHT

P.O. Box 10 10 63

63010 Offenbach am Main

Office address:

Kaiserleistr. 10

63067 Ofienbach am Main

Tel: +49 (69) 807-0

Fax +49 (9131) 18 796913

e-

art

irhilr

Pago I of I

SIEMENS

Technlcal Cont?act Conditlon ON CARRIAGE

Siemens

MS{ t(D.|

rrrffa- 4oaff E\ (Gttfu dqr udd od.g d r ffi I s wer

-

ununilon or 6 Mbns ail @actt

hid b tu vht .8'6 nJ'Buihn do tdibrH dl...| d !a nr! ht|. ls DiYdanl ol drnqos I r(hG

Documenl No.:

zEN000{63G&BEC01 9{0fl)O3

Appendix 3 Rev.04

lndex / Date: 04 201G01-19

Contractor: FRACHT FI,VO AG, FKslsteltach/Germany

Proiect: Nhon Tach 2 CCPP, Vlotnam

Customcr: SIEMENS

PKI: NTlfll3

(Ploigcl Codo)

MethodStatemcntNo.iE9T2-MS-LT-,004

lHev':0

Date: 24.00.10 Page: 1 ol 4

Prepared by Service Provlder'):

ALE

Rcvbwed by Scrvlcs Provldor' ):

ALE

Rletsed by scrvlce Prouoer

AI F

Nams / ual

Salheesh Kumat

24 09 10

signalure

A

Name / uat

Er ttri.rn lr{itnlu;uz

14 09 lo

Signah,.c

wan/ IJale

Bcrrtard [tlr,ngt

1-l.r)9 l(J

shnatur

Rcleasc<l by ContEctol: Released by Independent ExPort-r:

,9h^.

Ltr6ffi,p95

24.09.10

t-;r

Name / Oale Signature

Rdcatcd rtwE99r'cyfu/ Rel?a!+PlfrEMEr{s:

2ndilqPdAgrs:!;"f

i2,,1%

za YYT //r,// YTSTLL(A ffi2@r1,x

Neme/oal -r4

ffit" rlt

rrade:

//

'/ //'/r/

Y

c

Component: Condenser Lower & Upper panHhwett t

&2-Shipmenrf4

Scope ot work

9!gg!ggg

trom Roll'off Jotty to conalructlon sltc by Trallcr

Lower & Upper part) & Hotwell 1&2 lron

Roll-rrfl .lett\

(sirrron

rrver-Jctty) l(r Nlruu Trleh ll C(-PP \ite oftl(rlt!!19,1r9.

!iclnartt

Sequencc of opcratlons:

1 Llrrve lhe trarler on the bafge into the requ[ed

oosition

6 The t(atlers slowly matleuver away lrom the barge lhe

desagnated roule

2 Ihe lrailer bed raised till contact the understde ol

tlre item arrd clear from its support

7 Al oltloading area stool sLrpporls are posttioned and

trailer

iack

down

3 T ransoorl ;shtnq-s lre secuted I Remove all lashrngs lhen drrve the trallel out

4 Tire barge rs ballasted as requlred duflng lhe toll-oll 9 Dernobihi. ALE transportallon equlpments tlorn slle

5 Slowl5' dnve llre trailc.r ovet lhe litlk spart bndqe 10

Menagomant slructu|!;

Prolecl administrator / transportali0n

coordinalor

llr.r I laiar)! Lor

Slte superuisor

lJq ri';,1

\,/ir, T.iln0

H&S oflicet l.-lLrr

Oul-of-hours conlact name

Oul-ol-hours

phone no.

i-|8'1

.llir )()-'-lR-

Who checks lhe uork?

tt

SeMce Povider and Conlractor may be same company-

o{bd bt tshl

gEd d ag|alasd ol f, unt mo(H

q

dj(F F

rnl Ne tcEN4

SIEMENS

Technical Contract Condition ON CARRIAGE

Document No.:

ZEN00(H)630-&BEG019 3

Ap dir 3 Rev.04

lndex / Date: 04 I 201GO1 -19

zl

Contracting at SiemEns SPR TL discrtion

Contractor: FRACHT FWO AG, D.Kelsterbach/Germany

#

Project: Nhon Trach 2 CCPP, Vlstnam

Gustomer: SIEMENS

PKZ: NT 1003

(Proiec'l Code)

MethodStatmentl.lo.:8972-MS-LT-004 lRev.:0 Ilate: 24.09.10 Page:2ot 4

(mark wlth a cross / add as necessary)

tr

crane

A

Barge n Skidding system

!

Floating crane

tr

Ocean-going vessel !

E

Heavy-load vehicle, road

tr

Ship lilting gear

tr

D

Heavy-load vehicle, rail

A

Lashings D

tr

Ro-Ro operations tr

Mobile lifting equipment

Must consideration be givn to third-party installations? (power /

9s

/ water i communications egulpment)

lf yes, state neoessary prccaulions:

Transfer in port of arrival

lnformation/data on

floating crane

Maximum load capacity':

I

Model':

I

NA

Name ol contractor': )

' Cryies of: certilicate of last inspeclion / license / drawing ol lifting arrargement

Onto road vehlcles

Heavy-load vehicle Manuf acture/s descriptions:

Manufacture/s drawings:

Manufacturer's load lables:

)

NA

Drawings lor specific

lransporlation operation

with information/data on:

arrx r:'neil B9r2-trl'SS-LT- OO4 Rei

SelFpropelled vehicle wilh power pack:

Lashing Positioning of Lashings (drawing): 8972-T01 , T03, T05, T07, T09,T10, T11,T13-Tl5

Load balance calculation acc. to VDI 2700, Dll,l/Euro-slandards or similar:

Siemens

MS.LT@I

Transmihat, reqodElion. Gsotrtrflt;m ildq edling ol Uis documol as well as ulilizRtitr d ils cmlenls andcmunicaiion

lhreol lo dhss $frNl eDras aulhffraaliil are prorilbled o|londds wi! bs Mld liable ld peyrenl ol dafrqs Al tighis

creahcl by galdl granl d retFlalid o, a uilIty FEdel d dsiJn paldil are re*rtd

SIEMENS

Technical Contract Condltion ON SITE TRANSPORT

Siemens

MS{T'0O4 pag 3

TEnsmllal. rproductio, dis*frnalioo and/o. ditnlg ol lhis dcumeol as wl as utilEalbn ol its Colents ild

comrunicalio lherel lo othcE wilhoul erpt6s illhona0on ole prohrbiled Ollsdcrs wil b hgld bbl lq

payrmt ol damages, Al dghts cGEtad bry Palcil 96nl

d rcgislEtion ol a ulilty tDdd ot d6ign pglan afo

r6sryed

Document No.:

zEN 069>'&BECO1g-fiXXX)3

Appendix 4 Rev.

(X

lndex / Date: 04 / 2010{1-19

Contractor: FRACHT FWO AG, D-Kelsterbach/Germany

Profect: Nhon Trach 2CCPP, Vletnam

Customer: SIEMENS

PKZ: NT 1003

(Projecl Code)

Method Statement No.:8972-MS-LT-004 Rev.: Date: 24.09.10 Page: 3 of 4

Indication on all necessary load

bearing parls, like load

distribution devices. etc:

Drawings:

Statical calculations:

Certificates:

Mobile lifting equipment

Manufacturer's descriptions, drawings and operating instruclions'

Loads imposed by lifting equipment in outdoor areas as wellas in or on

building structures.

Provisions for load distribution in outdoor areas as well as in or on building

structures, il necessary-

Description of setup and removal ol mobile lifting equipment and auxiliaries

such as: truck crane, buibing crane, rope hoists' etc.

Detalled Level 3 time schedule lor entlre operation

(dellvery ol heavy

lifts and moblle lifting equlpment, setup of lifting equlpment,

transportatlon off slte, etc,).

Static analysis of mobile lifling equipment wilh test certificate issued by

independent third party (TUV, Lloyds, etc.).

Gommercially available conveyor syslems shall be certified by means ol

manufacturers' certificates and/or in-service inspections.

For special designs of conveyor systems the Service Provider shallverify

their safety by means of static analyses'

Information on allowable assembly tolerances (parallelism ol tracks, edge

offset, differences in elevation, angular misalignment, etc.). Compliance

with tolerances shallbe recorded during assembly of mobile lifting

equipment.

Information on allowable tolerances under load (sagging/deflection, angular

misalignment, etc.). Compliance with allowable tolerances shall be

continuously monitored and recorded during entire loundation setdown

operation (lilting, trave rsing, lowering/setting down).

Information on deployed monitoring equipment

(camera, theodolite, spirit

level, etc.) with which compliance with allowable tolerances is checked and

registered during foundation setdown operation.

certificates lor lifting equipment

(lifting system, ropes, shackles, connecting

pieces, etc.).

Organization chart stating names of persons responsible lor individual

activities.

Qualilication records/certificates for all personnel deployed for the various

tasks (incl. managers and H&S officerdrepresentatives).

SIEMENS

Document No.:

zE -063)-&BEC019-000(n3

Appendix 3 Rev.04

lndex / Date: 04 ' 2O1G01-19

Technical Contract Condltlon ON CARRIAGE

ls a more detailed Method Statement required? Yes

I

/ No

I

I yes, specily

List of applicable documents

Tltle: Document No.: Bev.:

Land Transptnattr:n rtl Heav\, Po\t/ef Pianl f

,rr.'r:lnenl:

8972-MS-tr-001

n

It{etlrod Sialenient Sr;,rrna:v lor lhe l-and Trarrsr '"dalion c{

\ttt1'11111i1 -i ( (rrrii!

ri'ii

8972-M-SS-t

r 0C4

A

Siemens

MS,LT(n4

Trng$nal. reprodEfon. dissemrmlbn flnd/or ediling ot thi'. dc|,|tsl c wel c ulifaalbn d ls colsE andwuncatid

lhseol lo glhe6 wih\ol elpro$ aulhdbhlbn are Fohibned Oilo(b6 Yil bo heH iiabl lq gFrGnl ol dats965 Al tights

c.6bd by palcnt

9r6nl

q regislr6td ol a ultlily modolq dsign palol as rFNed

Conlraclor: FRAC HT F1,VO AG, D-Kelsterbach/Germany

Project: Nhon Trach 2 CCPP, Vletnam

Cuslomer: SIEMENS

PKZ: NT 1003

(Proict Code)

Method Slatement No.: 8972-MSLT-OOI Rev.:0 Dato:2.1.09.10 Page: 4 of 4

How will the follorrinq risks/hazards be minimized?

Hazardous substances Hefer to Risk Assessments withirr Do<;umenl 8972-MS-LT-001

High-voftage power lines Beler to Risk Assessments within Docttntetrl 8972-MS-LT-001

Falling objects Reler lo Risk Assessments within Documenl 8972-MS-LT-001

Use of machinery Reler to Risk Assessments vrrithin Dr:cument 8972-MS't T 0O1

Loads weighing more than 1O tons each Refer to Risk Assessments within llocumenl 8972-MS-LT-001

Suspended Loads Reter to Risk Assessments within Documenl 8972-MS-LT 001

Otherc Reler to Risk Assessrtrents within Docurnent 8972-MS-LT-001

What temporary servlces are required?

- Power NA

Provision

by NA

Lighting NA by NA

Water NA by NA

Other NA by NA

Are actions relaled to tratfic control equipment requlred?

lf yes, give details:

Use ol lights and sirerrs crr gr-rods vehrcfes & persorrnel io wear high visibilrty clothrng and salety loolwear Gerlerat public

to be kept clear ivith assislance from Police where necessary Banksmen io be prr:vided necessary- Any use ol mobile

phones whrle driving/operating any vehicle ts prohiflted

SIEMENS

METHOD STATEM ENT-Su mmary

for the

LAND TRANSPORTATION

of

SHIPMENT U

CONDENSER'S

for

NHON TRACH II CCPP

DONGNAI PROVINCE, S.R.V

VIETNAM

Iiroler l ltlulrrirer 8972

f

'r{ijt-.Cl

NHON TRACH II CCPP

{,l!f,r}

SIEM ENs

8972-MSS-LT-004

A 23-09-10 For approval SK EM

0 19-09-10 For approval SK EM

Revision Date Desoiption Prepared Ghecked Approved Approved

ALE Heavy LiftVietnam Co. Ltd-

Client

,

-,re 01/10

i;&t

1

,,r

3

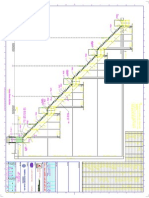

1. INTRODUCTION

This document provides the summary of Land Transportation method using for the transportation

of Condensers from Saigon River Jetty to Nhon Trach ll Project Site.

The initial characteristics of the ltems are as follows:

Quantity Item Description Length

lm)

widrh

(m)

Height

(m)

Weight

(r)

Trailer

Confiouralion

2

Gondenser

DSPPG-Lower Part

9.110 3.650 3.550 43.0

lxAB

Conventional

2

Condenser

DSPPG-Upper Part

9.110 3.650 3.550 43.0

1x2xB

Conventional

2 Hot well 7.330 6.510 3.200 23.63

lx2x8

Conventional

Transportation Operational Llmltlng Parameters

Llmlts Go No oo

Wind speed

<

9m/s

>

gm/s

24hr weather forecast

(wind)

Droppinq lncreasinq

Visibility

>

30m

<

30m

Surface Good Traction Available Poor Traction

2. OPERATIONAL PROCEDURE

-

IAND TRANSPORTATION FROM SAIGON RIVER

JETTY TO NHON TRACH II CCPP SITE

2.1 Prior to anival of the Cargo Barge carrying the condensers, the hydraulic modular traller

are mobilised to Saigon River Jetty, Nhon Trach ll CCPP, aniving on 40'low bed trailer.

2.2 The trailer is then manoeuvred beneath the hot well on the barge into the required position

and aligned.

Once the trailer is in position and aligned, the trailer bed is raised using integral hydraulics

until the trailer bed is in firm contact wiilr the underside of the ltem.

A final check is made on all hydraulic and electrical connections and the bed further raised,

lifting the ltem clear of the temporary supports.

Transport lashings are secured between the trailer and the condenser.

The barge is ballasted as required during the roll-off procedure to ensure that the barge

deck remains levelwith the quayside.

The trailer slowly manoeuvres over the load-out plates and roll-off the barge.

2.4

2.7

2.5

2.6

ALE

@

stExtENs

NHON TRACH II CCPP

SWF14

1.1

8972.ftlSS-LT{04 RaY 0

For Approval

01/10

23

3.

4.

2.8 The trailers slowly manoeuvre away from barge through the designated route from the

Saigon River Jetty towards the Nhon Trach ll CCPP site.

2,9 A bridging arangement at the site entrance to be provided for the aocess of hydraulic

trailerJbided with item. Structural integrity of brldge arrangement to be verified by others.

2.10 On arrival at the Nhon Trach ll CCPP site offloading area, support stools are positioned

and hot well is

jacked

down by the trailer. Transport lashings are removed. The ltem is

lowered onto the temporary support steelwo* using the traller hydraulics. The trailer is

withdrawn from underneath the Condenser.

Note: Condenser lower & upper part will be delivered under crane hook for assembly by

others.

2.11 The other condensers will be transported to site following the above procedure.

DEMOBILISATION OF ALE EQUIPMENT

3.1 After all the condensers are offloaded at Nhon Trach 11 CCPP site, the ALE transportation

equipments are removed from site.

PROJECT DRAWINGS AND REFERENCE DOCUMENTS

DRAWING

NUMBER

RE\I DESCRIPTIOI{

8972-T13 A

Transportation Anangement of 43.0 t Lower Condenser (DSPPG-

0034167) on a Conventional Hydraulic Trailer

8972-114 A

Transportation Arrangement of 43.0 t Upper Condenser (DSPPG'

0034167) on a Conventional Hvdraulic Trailer

8972-T23 0 Transoortation ananqement of Hot well on Conventional Trailer

8972-0F08 A

Offloading Arrangement of 43.0 t Lower Condenser (DSPPG-

0034167) on to Suooort Stillaqes in Laydown Area

8972-0F09 A

Offloading Anangement of 43.0 t Upper Condenser

(DSPPG-

0034167) on to Support Stillages in Laydown Area

8972-RT05 D

Required Area for the Transportation of GT Transformers (10UBF) &

Condenser-l at Delivery Nea lOff-Loading Position

8972-RTo8 A

Required Area for the Transportation of Condenser'2 al Delivery

Area I Off-Loadinq Position

stEltENs

I{HON TRACH II CCPP

SWFl4

1.1

8972.tlSS.l-T-{10{ Rev 0

For Approval

01/10

33

ALE

@

5a

;EE

22

?o

o

3

3

ll

!

lF

]I

3i

oc

It

tf

xa

:c

I

t

I

o

(,

=

=

=

G

2

e

F

5

u

o

2

U

3

o

2

2

c.

3

F

z

{

E

?l

(i

ol

gl

oi

tl

ll

@l

sl

6l

ol

EI

FI

UI

=l ol

UI

0l

u

E

tlc

5Ul

f;EE,

SHEi

EEEEEg

EgEEEEE

EEEBEiE

rqi

tl

r1

I

E

.D

c!

3l r:

::

"l

-o

oJ

Je

J2

qtf

go

IC

to

d

I

I

I

s

:

I

z

U

I

g

,,

t

o

raifi

oi

!

t

I

I

,

I

t,

ll

fr

oi

rxl

JI

(l

G

E

!

I

I

E

I

ll

E'

:t

90

u9

it

!f

at

to

e

t

3

g

o

(9

z

=

=

g

2

a

s

g

U

o

z

U

)

iE'

EE

EEe

qJ

,

E

HE'

igE

EIgE

EEE1

EEEEEEE

EEEEE:E

t

l-5

toa

l3l\

!:i

,

JE

IJ'

rHe

I

l

i'#

g

l"_f_

q

-dl

it i'i

lirr

I

I

t

E

x

,

t

I

I

t

-a

E'

F

a

uf

J

(

3l

o

<l

ol

9l

=l

Ii

Ei

7

5

u

o

z

u

H*

H2

9u

f,H

EEHg

eEFHi

EfiEFg

HEEHIS

!EsEid

EgEEE;

_t

:i

o

?5

or

Jo

J2

--ut

ro

A!

JO

tt

E

0

E

o

U

I

IE

6

o

s

0

I

E

I

I

7

I

r

I

I

I

t

i

u

lt

EI

x!|

$B

i

U

B

rgE

EfE

l,

;--

t

.a

-'6

F

a

+d

.l

EI

fi

sfr

ii

EF

OF

glg

:{

.a

s{

*e

F<

E?

>z

SE

;*

i7

6{

gE

{1

3

3

U

t

,i

-ffi0!r-lo*-F'

'

nL.

-BL*r-

t

E

t

I

!

x

x

6

E

F

=f

I

!

l-l

tl

i;

l"

E

It

l5,

l3 i r

IU d I

I

I

I

I

I

I

I

a

I

3

a

I

a

a

J

I

,

,

a

c

2

o

t

j

g

f

I

I

;

I

l-

m

-9-00.,-

I

aii .i.i - -o*:F-

,

I

l

s

I

6

l

ill

irrl

I

"l

I

,f

I

I

,l

i

2

I

,z

o

ts

t'

U

,U

;,

.l

fi

d

!

!

+

i

i

5

I

I

I

7

t

t

I

t

I

I

I

t

I

I

I

I

I

I

I

i

t

I

t

I

I

2

i

;

t

t

8

a

I

a2g

ge9

frFE

PEgE

frgsE

60Hg

qF?:

!Eg$

;EEE

EEHS

r11t

I

tEl

6lJ

TEE

EEfi

3

i

.l

a'i

F

o

z

I

a

7

-

wr '! mzr

-

!*tf;-

-

or.f,

-tf

*r-

EE

E!J

Ei

$

F; I

E; E

gE

Hx

sfr sH

el eil

{E E3

;-.

Il

lr

Il

L-i

fH

bl

3s

: E-

fEE

letF

!Er+

a9

iI

!i

llr r

tftli

iiit tl

F* ri

o

uf

J

(

-

--

|

I

I

Etll

g

E

T

6

I

t

T,

I

t^t

aarttra+

t'

I.I

llL..lgEt{rd;

mrS -Or0rtEL

-Df/t

r

tl

r

+I

L

it.lli

t,t'

I

t

't

t

t

t

fiTn

'liil

'I-f

1:

I

I

t

I

-t

E

E

ff,fi

tiii

r I

O

lll

J

(

EHEsEEiT

HE

5?

SE

EEs

iEE

IgEF

I

!

I

I

I

t

I

I

a

E

it

E

9

I

a

T

I

P

t

i

t

a

E

il

E

5

i

I

i

6

-+ -rF-,+

It

I

t

t

t

t

t

t'

t

t

t

t

t

t

t

t

t

t

ffit

t

I

t

t

t

-

G6Ei

*"--@i01

-

--ni.it'

mi

Contractor : FRAC HT FWO AG, O-Kel sterbach/Germany

Prolect Nhon Trach 2 CCPP, Vletnem

Customer: SIEMENS

PKZ: NT 1008

Method Statement No.: 8972-M$l-fi14

Rev.: A Oate: 26.09.2010 Pagc: 1 of 4

Prepared by Service Provldertl: Revlewed by Servlce Provlderrl: Releassd by Serulce Providerr):

Name /Dale

Satheesh kumar

ALE Mridb East

,6 00 2nlo

Signature

*

Name /Date

Binu K.T

26.0e.?0 t0

uqnarure

,.&rt'/

'-

Name / Dale

Binu K T

26.09 2010

Stgnarur

.&:*t

7

Released by Contractor:

Beleasad by Independent Erpe#l:

.Qi"-

KarlSchmidt

27.09.10

Sf E

w

/

VlEr

turc

rL+

W

flamo/ Dale Shnature

'H--%i'

Slgnature

$ose/scdan

Released ov

QS[,F[

Tfanrporl

Rcleasad by SIEMENS PG EP4:

38ffiffiI";?: ;?

rlQ /0, /0 W

ffi^o

iignat|'t

. Vlolo

Nam / Oal Slgnantra-'t)

Trade: U

Component: Condenser (llotwell'Lower &

Uoocr Part of Condenserl

Scope of work On-carriaqe at contruction silc includlng setdown on foundallone

Brlef desorlptlon of work to be performed:

Installallon ol Condensers using sldddlng

Sequence of operatione:

As per attached document 8972-MS9l-fit4 Rev A

1 6

2

'l

3 8

4 I

5 10

Managemenl structure:

Project administrator / transpoilatbn

coordinalor

r! I ifrc I

Site suoervisor Binu K.T.

H&S otficer

r",1

t1 ,. i

,.'

T

Out-oFhours contact name

liri\,";f i :.1,,A,

rL

t"ffi

Contractor: FRACHT FWO AG, DKelsterbach/Germany

Prolect Nhon Trach 2 CCPP, Vietnam

Gustomen SIEMENS

PKZ: NT 1fl13

Method Statement No.: 8972-Ms-l-ql4

Rev.: A Date: 26,09.2010 Page:2 of 4

Out-of-hours phone no. 0084-918-207-087

Who checks lhe work? Binu K.T.

ll

Servte Provider and Contractor may be same company.

2)Contracting

at Slmens WSLG's dlsiretlon

Safetv and operational detalls: (mark with a cross I add as neceseary)

A

Grane

n

Barge

E

Skidding system

tr

Floating crane

tr

Ocean-going vessel

A

Fork Lift Truck

X

Heavy-load vehicle, road

D

Ship lifting gear

tr

n

Heavy-load vehicle, rail

A

Lashings tr

n

Ro-Ro operations

n

Litt & Lock System

Must conslderatlon be glven to thlrd-parly Installallons? (power / gas / water / communications equipment)

lf yes, state necessary precautions:

Uaison with Site Management and Siemens HSE, Site Manager/Project Manager on site for coordination.

Operations to proceed

onlywith Approved Method Statement

ADoendix 4 to TCC ZENOC0-DDO4-06:|GqR. Rev.l: Onarrlsoe at Slle

('setdown

onto foundatlon"l

Contractor: FRACHT FWO AG, D'Kelsterbach/Germany

Profecl: Nhon Trach 2 CCPP, Vletnem

Customer: SIEMENS

PKZ: NT 1003

Method Statement No.: 8072-MS-l-qX

Rev.: A Dats 26.00.2010 Page: 3 of 4

Mobile ltftlng equlpment

As per

attached

document 8972-

MSS-l-004

Man uf acture/s description s, drawings and operating instructions.

Loads imposed by lifting equipment in outdoor areas as wellas in or on

building structures.

Provisions for load distribution in outdoor areas as well as in or on building

structures, if necessary.

Description of setup and removalof mobile lifting equipment and auxiliaries

such as: truck crane, building crane, rope hoists, Etc.

Detailed Level 3 time schedule for entire operation (delivery ol heavy lifts

and mobile lifting equipment, setup of liftlng equipment,lransportatbn off

site, etc.).

Static analysis of mobile.lifting equipment with test certifbate issued by in-

dependent third party (TUV, Lloyds, etc.).

Commercially available conveyor systems shall be certilied by means of

m an uf acturers' certif icates and/or in-service inspections.

For special designs of convelor systems the Service Provider shallverffy

lheir safety by means of static analyses-

Information on allo,'rable assembly tolerances (parallelism of tracks, edge

offset, diflerences in elevation, angular misalignment, etc.). Compliance

with tolerances shall be recorded during assembly of mobile lifting equip-

ment.

Information on allowable tolerances under load (sagging/deflection, angular

misalignment, etc.). Compliance with allowable tolerances shallbe conti-

nuously monitored and recorded during entire foundation setdown opera-

tion (lifting, lraversing, lowering/setling down).

Information on deployed monitoring equipment (camera, theodolile, spirit

level, etc.) with which compliance with allowable tolerances is checked dur-

ing foundation setdown operation.

Certificates for lifting equipment (tifting system, ropes, shackles, connecting

pieces, etc.),

Organization chart stating nams of persons responsible lor individual ac-

tivities.

Qualilication records/certificates for all personnel deployed lor the various

tasks (incl. managers and H&S officers/representatives).

Contractor: FRACHT FWO AG, DKelsterbach/Germany

Prolect: Nhon Trach 2 CCPP, Vletnam

Guetomer: SIEMENS

PKZ: NT 1fi)3

Method Statement No.: 8972-MS.F004

Rev,: A Date: 26.09.2010 Page: 4 of 4

How will the following risks/hazards be mlnlmlzed?

[See

ALE Risk Assessrnent doc 8972-MS-l-0q[

- Falling / sinking / burial

Hazardous substances

- High-voltage power lines

Drowning

Confined spaces / tanks

Falling objects

Use ol machinery

Loads weighing more than

10 tons each

Suspended Loads

Others

What temporary servicee are rcquired?

- Power NA

Provision

by

Lighting NA by

Water NA by

Other NA by

fue actlons related to trafllc control equlpment required?

lf ves, oive details: See ALE Risk Assessment Doc 8972-MS-l-003

ls a rnore detalted Method Statement required? Ves E / No I ll

yes,

speclty

Llst of applicable docurnents

Tltle: Document No.: Rev.:

Summary Method Statement: Installation of,

Condenser

8972-MSS-l-00,4 A

Method Statement: Installation of Condenser 8972-MS-l-003 A

o

o

slEMENsffiil

METHOD STATEMENT-Summ ary

for the

INSTALI.ATION

of

SHIPMENT H

CONDENSERS

for

NHON TRACH II CCPP

DONGNAI PROVINCE, S.R.V

VIETNAM

Prolecl Numher 8972

Pro;ecl NHON TRACH IICCPP

Ctient

SIEMENS

L]trt : u n:*nt i'ir,r f"f rl-rii r 8972-MSS-t-004

B 30{9-10 For approval SK RM

A 26-09-10 For approval SK EM

0 19-09.10 For aoDroval SK EM

Revision Date Descriptkrn Prepared Checked Approved 4pproved

ALE Heavy Lift Metnam Go. Ltd. Clienl

ll*tt 01/10

P:191

| ui $

t. r{TROt}t6T|ON

this rloo.unent prwides tte nrrunry of lnsilallaliur meftod of Gonden*r at Nhst Trafi ll

fr{ed $te.

the initid dramctedslics dthe lkrns arc as fdlsrs:

Arufity Itcm De*ripfrqr tength

(m)

v\{dsl

(m)

Hoidtt

fm\

wr$r

{t)

Trallcr

Cmfcrutdqr

2

Codenser

DSPPGLoveT Part

7.350 3.688 3.496 z7.E

lr@r8

Con enitiofial

2

Condenser

DSPPGupper Part

7.450 3.688 3.405 27.15

1)xB

Cowen$onal

2 Hotwell 7.283 6.110 2.U5 n.78

Iffi

Corwentimd

Transprtation Operational Limitirg Parametere

Lknits Go Ho

qo

tMrd soeed

<

gfii/s

>

gnls

Vlsibilitv

>

3On

< 3(ln

OPERATIONAL PROCEDURE

-

INSTALT.ATION AT NHON TRACH II CCPP SITE

The condsrser items are anives at the inSdldlon are6 on hyffadic failerE, cmdnser

Perts

(Hotwdl, Modlle lower E t

bper

Parts) are assernbled and aligned with fte fourdatm bilvresl

axis 13i/10 UMAF15/10 UMA by others.

Assembled Condenser module shanld be ptaced m suitable silflages at a nt'nimum helglil of

lffinm above gromdlevd, for inser&rg ddd beams & skates bdor modde.

Two no. *id tracks are assembled sr tre cmcrele forndatsr extending torards & beneaththe

condenser canple{e wtth skates & hydradic propdling q6tern.

The condenser is

jacked

dorn onto the dcates on the sldd hacks.

The cmdener is d<abd dang the ddd tradc md orer the frd positm m the pfin&, powered

by the hydnaulic prope$ig q$em-

fice rlirec$y over tlre ffral po*tian, the csrdenser is

jad<etl

up ofi the skate and d<id beans,

rArfricfi

are remoled forn betreen lhe cordenser & pfinfi.

The condenser is

iadred

down wr b the final poc*tlon.

A[ ALE eq.riprcnt ls dsnobbed and rernored from tte area.

2.

2.1

2.2

2.3

2.6

2.4

2.5

2.7

2.8

,ALE

(*rqrl1

!$lli

f'' ij; I

silEIEt&t

il{O}'TRACHilGCPP

$rfft{

l!

!.,'

:1r.:,

Slll{SStSlRrvB

:j;::r!r:.j: FeaADptDtl

. a:f 0lllo

ttr:

2 -"r3

PROJECT DRAWINGS AND REFERENCE DOCUMENTS

DRAwlNG

NIIMBER

REI'

DESCRIFTION

8972-106

(Sheets

1 of 2)

B

ffidure

for condenser on low level

olinth-Staoes 1 & 2

8972-106

(Sheets

2ot2l

B

ffidure

for Condenser on low level

olintlr-Staoes 3 & 4

8972-111

(Sheets

1 of 2)

A

-FrovisffiAilnstallation

Procedure for Condenser on low level

olinth-Staoes 1 & 2

8972-111

(Sheets

2ot2l

A

ffi Prmdure forGondenseron

low level

olinth-Staoes 3 & 4

8972-110

f2 sheets)

B

Rigging of Condenser

parts

.:,'.-i',t

SIEIIENS

P:: ': ,i:,(

i NHON TRACII ll CCPP

i.lr{ SWFltl

Hr, 1.1

i-:',

r,l..jrri'r*'

E972{fi}tl.l{04RevB

Ir**,s ForApptot/d

tl.iit 0l/10

't;,;".

3

rt 3

ALE

a

ii

'

i&!i

o

5r

(;

[*[['Eli

IislE[#

i1

e+lsED,sf 0.ru.{}lryrc-

* ii-

+

+

t

a

+

I

I

t

t

t

t

t

t

I

t

I

t

+

+

J

I

T

p

1

i:'- i

'-g",

''l'

:it-:

..r

I

I

I

I

I

I

t

I

t

I

t

I

I

t

- +-Swil;Prilnilrlff ra'

-

-

t

I

I

I

|t

!t

!l

o

ltf

J,

(;

irl

i url

8l

,Tl

3

:91

ia

,EI

;

l

|T]

l1

l,

['Elllll

i[flsllil

i 6D::

+

t

I

+

+

t

+

t

+

I

+

I

+

I

I

I

+

I

t

I

t

t

I

t

I

,---ll

r-:T1

ti

eg

r,T

H68

g

f;"g

,irEli

F

T

rg

q

{o

E'[!

:g HR

igEi!

0

o

f;

d

U

F

E

I

I

g

c

fJd

fE

g

T

o

E

q

a

I

2

q

6

a

6

I

I

6

t

I

I

I

I

I

a

!

I

I

I

I

I

t

I

I

I

t

I

I

I

I

,

SIEMENS

METHOD STATEMENT

for the

INSTALLATION

oof

CONDENSER

for

NHON TRACH II CCPP

DONGNAI PROVINCE, S.R.V

VIETNAM

o

Project Number 8972

Project NHON TRACH II CCPP

Client

SIEMENS

Document number 8972-MS-t-003

B 30-09-1 0 For aooroval SK RM

A 26-09-10 For approval SK BKT

0 1 9-09-1 0 For approval SK BCM

Revision Date Description Prepared Checked Approved Approved

ALE Heavy Lift Vietnam Co. Ltd. Client

Doc. SWF14 Date: 01/10 Page 1 of 13

MANAGEMENT OF OPERATIONS

3. PREREQUISITES AND INITIAL CONDITIONS

,A.LE

@

Client: S|EmENS

Project: NHON TRACH ll CCPP

Doc: SWF14

Rev: 1.1

Doc Number:

Status:

Date:

Page:

8972-MS-l-003 Rev B

For Approval

01/10

2o113

SHAFtft. BAfEn, SrRgt{6En

1. INTRODUCTION

1.1. SCOPE OF DOCUMENT

This Method Statement is concemed with the installation of Condensers for Nhon Trach ll CCPP,

Dongnai Province, S.R.V, Vieham, and is subjecl to our normal terms and conditions of caniage.

This method slatement represenb the procedure to be followed, drawings, back up engineering

and risk assessnents to ensure the safe and professional installation of the Condensers.

The initial chanacteristics of the ltems are as follo,vs:

Quantity Item Description

Len$h

(ml

wdth

fm)

Height

{m)

Weight

(t)tunit

2

Condenser

DSPPGLoweT Part

7.350 3.668 3.495 27.25

2

Condenser

DSPPGUppa Part

7.450 3.668 3.495 27.15

2 Hotwell 7.283 6.110 2.844 22.78

Included in the preliminary scope of work for the proiect is:

1.1.1 Supply of all installation equipments fry the installation Condensers at Nhon Trach ll CCPP

site, Dongnai ProMnce, S.R.V. Metnam.

1.1.2 Supply of engineering support for all relevant operations and procedures.

It is the aim of this Method $tatement to define and describe the equipment, safe qBtem of work

and procedures that will be employed by ALE Heavylift Vietram Co.Ltd to conduct the operations

in compliance with fte fdlouing legislative and guidance doormentation:

APPROVED CODES OF PRACTICE

BS code 5950-2000

lift Vidnam Co.Ltd General

ALE

a

Client: SIEMENS

Project; NHON TRACH ll CCPP

Doc: S\ /F'14

Rev: 1.1

Doc Number:

Status:

Date:

Page:

8972+ls{.01t Rcv B

ForApproval

01/10

3 of 13

silAntEn. saF6n. SrnorGEn

1.2. PARTIES

The relevant parties involved with the installation are listed below:

- SIEMENS

- FRACHT

- Client

- Sub contractor Transportation & Installation

- ALE Heavy lift Vietnam Co.Ltd - Service Provider Transportation & Installation

ALe

a

Client:

Project:

Doc:

Rev:

SIEMENS

NHON TRACH II CCPP

SWF14

1.1

Doc Number:

Status:

Date:

Page:

8972-MS-l-003 Rev B

For Approval

01/10

4o113

gl'AN'EN. gAfCF.

9TBOIGEN

2. MANAGEMENT OF OPERATIONS

Outlined below are the responsibilities of ALE personnel. This section also details the procedures to

follow if a deviation from the original operations procedure occurs.

2.1. THE ALE ENGINEER & PROJECT MANAGER

The ALE Engineer will prepare the method statement along with all drawings and calculations, which

will be checked by the ALE authorised Manager. lt is the responsibility of the ALE Project Manager to

ensure that the on-site Operations Supervisor is adequately briefed on the content of this method

statement.

2.2. THE ALE OPERATIONS SUPERVISOR

Prior to the commencement of the works the supervisor must ensure that all site personnel are

adequately briefed on the contents of this method statement. This briefing shall take the form of a

short 'toolbox talk'. The supervisor must liaise with the ALE manager should site circumstances require

material change to the methods to be employed during the operation and follow the'ALE management

of change procedure' provided within this document. lt is the responsibility of the supervisor to have

completed all safety checklists and briefings as identified within this scope of works.

2.3. MANAGEMENT OF CHANGE

This procedure has been prepared to categorise and authorise any intended deviation from the

intended scope of works outlined within this safe system of work. The ALE Operations Supervisor on

site is responsible for the work being conducted in accordance with the current approved method

statement. Any deviation from that approved method is categorised as follows:

2.3.1. Category 1

-

(Minor) Deviation

The ALE Operations Supervisor on site considers a deviation from the intended scope of work to be a

small adjustment to meet local site conditions. They must bring this matter to the attention of the

clients' on-site representative. \A/here the client agrees that the adjustment is minor and would not

introduce any risk to personnel or the integrity and safe operation of the equipment, authorisation to

proceed may be approved by both parties concerned by signing of the changes to the method

statement in the record of changes box provided within the method statement.

Any changes must be communicated back to the ALE Engineer / Project Manager and communicated

to the work force by means of a toolbox talk, which must also be recorded. The work may then

proceed.

Any change from the intended scope of work must comply with the manufacturer's recommendations

for the use of the equipment and any associated procedural documentation, i.e. ALE and client

procedures and / or requirements. Where there is any doubt as to the implications changes may have

on the safety and / or integrity of the system/equipment or any conflict from the client's representative

on site, for whatever reason, this change will become a category 2

-

Major and the appropriate

category 2 action will apply.

2.3.2. Category 2

-

(Major) Deviation

Category 2 deviations are those that the ALE Operations Supervisor or the client's nominated

representative considers to be significant or deviations from category 1 that become category 2 as

identified in 2.3.1 above. Any proposed deviations / changes to the intended scope of work under this

category shall be communicated to the ALE Engineer / Project Manager who will revise the method

statement and liaise with the client representative to agree any changes for approval prior to

commencement of work.

ALE

a

Client: SlEtllENS

Project: NHON TRACH ll CCPP

Doc: SWF14

Rev: 1.1

Doc Number: 8972-lllS-l-003 Rev B

Status: ForApproval

Date: 01/10

Page: 5 of 13

3Henttn, 3AFCt,

gTFOitGan

\A/here necessary, engineering deviations / changes will be approved by the client or nominated third

party. On approval, any changes in the method statement and / or intended scope of work affecting the

safe system of work will be communicated to the work force by means of a recorded toolbox talk. All

deviations and / or changes will be recorded and authorised within the record box provided within this

method statement.

A record of authorised changes during scope of work is available within the template of any

Method Statement devised for the erection and/or operation of any (ALE) equipment. An example

is provided below:

2.4. SITE SAFETY

When at the site there is a situation or area that is considered unsafe but beyond the abilities of

ALE personnel to make safe. All ALE work activities in that area will cease and the unsafe

situation or activity will be reported to the site supervisor for action.

The unsafe situation / activities I area will be reported to the client for the client to take measures

to make it safe again for the activities to continue.

No ALE activities will be performed until the situation or area is again made safe for working by

the client or the client's agent. Should the measures taken by the client prove inadequate, the

works can and will be stopped until adequate steps have been taken. ALE cannot be held

responsible for any delays resulting from works being stopped due to unsafe situations.

ALE

I

Client: SIEMENS

Project: NHON TRACH ll CCPP

Doc: SWF14

Rev: 1.1

Doc Number: 8972-MS-l-003 Rev B

Status: ForApproval

Date: 01/10

Page: 6 of 13

during the execution of work within an ALE method statement

SHAFtEn. tArFn.

gTnOtaGen

2.5. TOOLBOX TALK RECORD

The following toolbox talk record is provided for the purpose

of recording the initialtoolbox talk on

commencement of the works under the scope of this method statement. A toolbox talk record

sheet is also provided

within the appendix of this document and should be used to record any

future toolbox talks conducted on site. A minimum of one daily toolbox talk should be conduited

at the earliest opportunity prior to commencement of works.

The record is to be completed by all ALE and subcontracted labour personnel

employed within

the scope work and working to this Method Statement and associated Risk Assessment.

Prior to commencing the operation all site personnel

are to sign below to confirm that a clear

briefing explaining the

job

has been given and is understood:

'l

am satisfied that I understand the work to be canied out. Att known hazards have been

identified to me and I have been made fully aware of the control measures in place to reduce any

risk to both myself and others'.

EMPLOYEE NAME:

SIGNATURE: DATE:

Content of TBT:

Supervisors Signature:

A,LE

@

Client: SIEMENS

Project: NHON TRACH lt CCPP

Doc: SWF14

Rev: 1.1

Doc Number: 8972-MSl-003 Rev B

Status: ForApproval

Date: 01110

Page: 7 oI 13

FXAnttF, 9APen, 9tnOt{6Ee

3. PREREQUISITES AND INITIAL GONDITIONS

3.1. GENERAL

Method Statement is subject to approval prior to the commencement of work.

Method Statement to be read in conjunction with the attached Risk Assessment

Documentation.

SJA (Safe Job Analysis), if necessary, to be carried out

prior to work starting.

Afier any break in the operational procedure, a walk round and visual inspection will be made

of the equipment in its current set up to check that nothing has changed since leaving the

work place.

Minimum Personnel Protective Equipment (PPE) to be worn on site is as follows:

a. Overalls,

b. Hard Hat,

c. Safety Footwear,

d. Eye Protection,

e. Gloves,

f. Full Safety Harnesses (where necessary).

3.2. RESPONSIBILITIES

Clear area for working afforded at all times by client.

SJA (Safe Job Analysis), if necessary, to be carried out

prior to work starting.

Ground preparatory work to be carried out prior to arrival of transport and to be able to

withstand the loadings imposed during this operation.

Centre of gravity to be clearly marked on the item.

3.3. CONTROL OF OPERATION

Outlined below are the responsibilities of ALE personnel associated with ALE's on-site operations.

The ALE site supervisor is responsible for the performance of the operational disciplines,

which can be divided into two main areas, namely on-site operations and equipment

maintenance.

All operations associated with the installations of the Condenser are under the direct control

of the ALE site supervisor.

During the installation of the Condenser the ALE supervisor will monitor the installation

equipment.

After any break in the operational procedure, a walk round and visual inspection will be made

of the equipment in its current set-up to check that nothing has changed since leaving the

work place.

The ALE technicians are capable of fixing most problems that can occur during the

operations.

Other maintenance engineers are available on call to assist in rectifoing any equipment

malfunction in the shortest possible

time.

5.

1.

2.

3.

4.

1.

2.

3.

4.

5.

6.

1.

2.

3.

4.

ALE

a

Client: SIEMENS

Project: NHON TRACH ll CCPP

Doc: SWF14

Rev: 1.1

Doc Number:

Status:

Date:

Page:

8972-MS-l-003 Rev B

For Approval

01/10

8 of 13

rHAFrtL SAFCn. 9rnoflGEn

3.4. ORGANOGRAM

ALE

I

Client:

Project:

Doc:

Rev:

SIEIUIENS

NHON TRACH II CCPP

SWF14

1.1

Doc Number:

Status:

Date:

Page:

8972-MS-l-003 Rev B

For Approval

01/1 0

9 of13

SHARITF, 3A'f,R, STNOXGEN

4. OPERATIONAL PROCEDURE

On the days that preparation

of equipment will take place there will be a 'toolbox' meeting prior to

the start of activities that will review the following items:

a) Procedures, requirements and details specified in the work plans and drawings.

b) Review of safety items such as weather concerns,

plant activity, escape routes,

contingency plans, locations of fire-fighting and personalsafety equipment etc.

Note: Weather forecasts will be obtained prior to the movement. lf the forecasts, in

conjunction with the actual wind speed readings taken on the site / crane wind speed

indicators, do not give a sufficient window a suitable weather then the movement will be re-

assessed.

c) Designate key personnel, such as signalmen, tagline handlers etc.

d) Complete and sign off all appropriate checklists and safety permits.

e) Check the placement

of all banners and barricades that define the safety boundaries of the

work areas.

Discuss and give due consideration to any additional appropriate steps that any participant

feels is necessary to perform a safe and timely operation.

Note: Weather forecasts will be obtained prior to the operation. lf the forecasts, in conjunction with

the actual wind speed-readings taken, do not give a sufficient window a suitable window a

suitable weather then the lift programme will be re-assessed.

Limits Go No

qo

Wind speed <

9m/s

>

9m/s

24hr weather forecast

(wind)

Droooino Increasino

Visibilitv >

30m

<

30m

.A.LE

a

Client:

Project:

Doc:

Rev:

SIEMENS

NHON TRACH II CCPP

SWF14

1.1

Doc Number: 8972-MSJ-003 Rev B

Status: ForApproval

Date: 0'l/10

Page: 10 of 13

SHARtEn. 9AFEn, StnOil6n

4. 1 . PRE-OPERATION PREPARATORY WORKS

4.1.1 Clear and free access is to be provided for all ALE personnel and equipment during the

operations at the project

site.

4.1.2 Structural integrity of the Condenser, the plinth and the ground is the responsibility of others,

and must be confirmed that they are capable of withstanding the loadings imposed during

installation operations.

4.'1.3 The areas around the relevant plinths,

suitably prepared by others, and must

equipment during complete operations.

and between the plinth and the roadway, are to be

be able to withstand the loadings imposed by ALE

4.1.4 Centre of gravity position

to be clearly marked on the items.

4.1.5 Centrelines to be clearly marked on the plinths and Condenser sets by others.

4.1.6 Sufficient area to be provided as when required for positioning the crane to setup installation

equipment on the foundation.

4.2. OPERATIONAL PROCEDURE

-INSTALLATION

OF CONDENSER

4.2.1 The condenser items are arrives at the installation area on hydraulic trailers, condenser parts

(Hotwell, Module Lower & Upper Parts) are assembled and aligned with the foundation between

axis 13/10 UMA-15/10 UMA by others.

4.2.2 Assembled Condenser module should be placed on suitable stillages at a minimum height of

1000mm above ground level, for inserting skid beams & skates below module.

4.2.3 Two no. skid tracks are assembled on the concrete foundation extending towards & beneath the

condenser complete with skates & hydraulic propelling system.

4.2.4 The condenser is

jacked

down onto the skates on the skid tracks.

4.2.5 The condenser is skated along the skid tracks and over the final position on the plinth, powered

by the hydraulic propelling

system.

4.2.6 Once directly over the final position,

the condenser is

jacked

up off the skates and skid beams,

which are removed from between the condenser & plinth.

4.2.7 The condenser is

jacked

down on to the final position.

4.3. DEMOBILISATION OF ALE EQUIPMENT

4.3.'l After Condensers are offloaded on to foundation, the ALE equipments are removed from Project

Site.

.A.Le

a

Client: SIEMENS

Projectr NHON TRACH ll CCPP

Doc: SWF14

Rev: 1.1

Doc Number:

Status:

Date:

Page:

8972-MS-l-003 Rev B

For Approval

01/10

11 of 13

SHAPtfn. SArEn, SItOXOEf,

PROJECT DRAWINGS AND REFERENCE DOCUMENTS

DRAWING

NUMBER

REV DESCRIPTION

8972-106

(Sheets

1 of 2\

B

Provisional Installation Procedure for Condenser on low level

plinth-Staoes

1 & 2

8972-106

(Sheets

2 of 2l

B

Provisional Installation Procedure for Condenser on low level

plinth-Staqes

3 & 4

8972-111

(Sheets

I of 2\

A

Provisional Installation Procedure for Condenser on low level

plinth-Staqes

1 & 2

8972-111

(Sheets

2 of 2\

A

Provisional Installation Procedure for Condenser on low level

plinth-Staoes

3 & 4

8972-110

(2sheets)

B

Rigging of condenser parts

.A.LE

a

Glient:

Project:

Doc:

Rev:

SIEMENS

NHON TRACH II CCPP

SWF14

1.1

Doc Number:

Status:

Date:

Page:

8972-MS-l-003 Rev B

For Approval

01/1 0

'12 ol 13

9Ftntti. 53f

gR,

stFoilgan

APPENDICES

5.1 . APPENDIX 'A'

-

PROJECT DRAWINGS

5.2.

5.3.

APPENDIX 'B'

-

RISK ASSESSMENTS

APPENDIX 'C' TOOLBOX TALK PROFORMA

.A,LE

sFrAnrrn,

gaFEn

@

Glient:

Project:

Doc:

Rev:

SIEMENS

NHON TRACH II CCPP

SWF14

1.1

Doc Number:

Status:

Date:

Page:

8972-illSl-003 Rev B

For Approval

0'u't0

13 of 13

5.1 APPENDIX'A'- PROJECT DRAWINGS

Nl

UI

oi

sl

6l

't

3l

-ul r>l

'z

1l

c

E>I

-UtrE=

: $

=

9^

=

6 F' t=

;EEEEH

EiEEsEE!

giE

;cE HE

Ffi=rEEEE

EEssEEEE

IE E E'A EE

E;6

Ea5 iE

;q 3 ;H E' EE

efis;gf;E EE

cF Eg iE H, En*

;i E; ffi ;; ;Eg

!;)

l

l

,;]

I

t.^

F.:l

H t,;r

+

T

,lrrrr', o,r,

[

./

d*rNs / sNreunl w*rs r c-l-

uru

L

o

z

=v

ge

ez.^ .E

ff E E ,;69

n E I GP)

H 4 ; Exi

H

-

g

iiH

5 i'

g g;"6

z - - *tz

9

E

E 6Hfi

g.g

3 EtrE

qaE p

cnE

l1-Z

fr

VEEfi

HEE=P {:gE

EEEE*gHfipE

E;ggEEEEHa

ria

r-9

s?

6=

6n

aifi

k=o

n6=

U33l

B!1dt

e-)

tag

il?6

=E<

2,,>

eFl

iE=

piE

|rt|

G6i

>Ei;

6;6

G,

i

I

I

I

(:)

.T

I

I

I

I

I

.U

o

t<

l6

=

-U tt

lz

{

lEEEEE

giEETEEi

iEEEEEEE

Fgisigfi,ggs

,:l

_*'.n

l

t.-

A

JII''-'

T

aoiwlN3e /3Nunt nEls

L:]

I

t

I

I

I

t

t

t

I

I

I

I

l

I

I

T

I

I

+

I

I

=i+-=

I

I

I

I

t

I

t

.I

r|_

l+

T

=>

XP

z': la . l

9 .---l

,

:=-

- f

l- :,

-:--=:r.:::a-:-rT--f-

.' i1..,' ,1 I o

t\

^l\('

>rl<

sl 2

llc=

4 | e9 e

:---36=-f- 5l

e= '21

Ed r1

,:.

i-",1

i

I

I

''-', . _,l

.-

-

l-:' i

-..

- -.-+u\

EA

di

?2.- .*2

E E i

";fis

;

q g

Egi

J

=

4 v-,v)

H E e iiff

5 # I s;E

2

=

-

=Y2

FgE6Hfi

s** e

ptrE

qE;

p qHS

!I: fi {EHfi

Es;=;=;fas

EHEsFEE{HE

ci2

r-P

fe

h=

a#

eifi

i+5

FFF

ooF

lxafl

=vl; <-6

fr=a

^at

az6

=ts<

2,,>

cEl

;==

U:H

<ua

2\V

EH*

636

IUUJ

)-

(csl) (csD

,[]. o,r.

t'"---=i,iJ;;t-

l/

ilg*-E

glE*TEgE

ig=EEEHE

EEHEEEEE

sun;*FslE

EE5;ffiE EE

gfEgxaE,gn=

;i Efr ;6 ;= ;EE

-.

J-

ttlel?...!.-lli:i'-

I

I

I

t

I

I

t

t

t

t

t

I

I

I

t

z

F

z

+

t

+

rl

t

+r

+

{

t

t

F6

3E

6=

UE

eiF

i -'5

FFF

@ots

u8fr

:i{

l^s

Yg<

!t.=2

:E<

2..>

=

a'<

Etz

i3=

v2E

2\V

a6i

=trui 636

ljj

oo

qul

d=

l<

94. 6

-F,^oZ

B E E o$s

a t I Eir

,E A ; tg+

-.=;;6?6

:F;EEa

z < - E=z

9

g

E aHfi

g,E

E EfiE

EeE e

esE

1i"2 fr

afi\fi

ei;=F=teEE

figEEEE;EHg

s

2d

==

-fi

ail

3d

;z

a

E

2

o

E

F

g

F

3

z

o

:

8

=

5

z5

=>

2;

0u

+=

tfi

z.

}U

iz

o

E E E

c

z

a

3

o

6

f

f

I

Ee

= Hr l

":FO

fr244

=-did

;EA:

t s Hsi

d

=

;*o

* o 3:f

i*FEugi

z

o

s

uil

trl

E

z

UF

2Z

o4

OG

&3

I

I

E

g

E

;.

:

e

9

3

;

E

I

5

F

{

I

rt

5

E

I

F

t

3

I

n

E

i

T

p

t

6

z

g

t

6

P

l"

FO

ig

ht

t.r

lg

E

h

j

8

z

n

l

d<

I

<E

==

tb

i0

zl

>u

iz

t-

l

e

2

z

Ee

= Hn l

bqrh

frAiq"

2 o j

oJ

? E

a

?3

i

4

F1t.E1

T

: ?gRF

2 iz6-e33

E,EEEgEE

iF96P?"

z

z

z

o

s

ul1

trl

I

=F

=N

U

=

6

e

z

UF

z^

*:

(6H

jg.

I

E

g

I

5

I

E

P

i

,,

I

*

4

E

:

I

5

t

I

I

6

E

il

3

P

6

E

E

5.2APPENDIX'B'

-

RISK ASSESSMENTS

N

E

9

n

5

a

L

96

ur

EH

i

o'=6[,

R B H

F=O=

-.9!0.)

6E:, F

F

;-t=

vj:

6el

-Ei<

Lt

-sE

o/

EZ

7

O'X

I5

n

P

T

ONA/\

(Jrrt

o

z

t

o

o

o

r

=

uJ

Y

.9

o-

L

o

a

o)

o

L

f

=

3

c

o

'^

.C

-

o

o

q)

o

=

o

;

a

E

o

.;

:l

a

o

o

o

E

E

:o

o

c

(!

f

-o

-

G)

o-

o

E

'o

z.c

f

o

a

o

o

L

@

o

o

c

.9-

E5

cQ

=>

=o

-

_\z

o-=

o_

a\

;E

-c)

^-

(J6

f

;

.\,

q)

.=

q

o

-o

E

o

3

a

L

o

o

C

.F

o

-o

E

o

L

o

c

o

!

q)

.=

f

o

o)

L

c)

E

o

=o

L

o

o

o

o

)v=

.= .^

-o

;(

Es

oQ

oo

9p

ts(J

<.c

q)

o

J

.G

E

o

()

>

o

.Y

o

-a

o

J

=

o

o

>o

.!(E

=I

.>

o

:

c

f

E

o

o

=

o

.:<

=

i

o

i

c

D

I

to tf

(Y)

o|

>\c

GO

=t

taE

NE

o

(o

\f

(\

.>

o

x

=

I

(Yt

o) @ clt

->

o

I

=

L

o

I

r+

t

g

t!

tr

o

o

a

ro

o

ro

o

z

Y

z

u

Y

o

d.

(E

o

o

I

ro

L

.=

o

o

E

I

t

L

.=

o

E

o

o

I

ct

o,

=o

o

tr

o

E

o

q)

(E

.9

EI

o)

=

I

N

o

.=

o

c

o

p

o

o

f

c

;

o

.=

=

I

Alueneg

C

o)

-

C

c)

c

c)

ft\

a

oO

E

P

rTt

UJ

I

x

L

o

E

tr

o

E

o

Q

o)

Q

o

.Y

.9,

u

o

6

o

o

N

j

a

Lrl

o

o

o

E

E

o

o

I

(g

o

o

CL

o

o-

c

.9

(J

E

o

c

c

-g

o-

o

tu

o

-o

o

0)

o

f,

!2

3

o

!t

o-

E

o

.lt

o

0)

o

3

o

o

o

(U

o

o

E

q)

x

o,

o

-o

TA

o

o

o-

c)

o

E

=

o

:

!t

0)

c

o

-o

.!

()

o

5

E

I

o

E

o)

o

(u

E

.o

G

0)

c

c)

E

c

.g

c)

c

o

ct

o-

E

o

(.)

E

E

o

o

f

(u

E

x

0)

=

3

E

c)

E

o

o

..t

o

o)

F

(U

I

o

-

c)

.s

c

o

o

E

o

.E

-o

o

o

(u

3

o

.=

E

o

o

o

.=

o

c)

o

o

o-

.o

E

c

O

E

o

0)

o)

*

o-

at,

o

T'

c)

o

f

E

.U

o

(E

E

c)

-o

o

o

-o

(E

E

c

(5

U'

=l<

'a

U)

c

.9

=

o

o.

O

{t)

o

E

o

.9

z

c)

o

E

(u

o

'6

'6

E

s

CD

E

c)

o

o

o

'6,

UJ

o

.q

=

.2

(u

UJ

J

o,

o

-c,

E

(l)

o)

(u

E

o

o

lt

c)

o-

,o

E

c)

(lt

(!

:

(u

!t

(E

(E

o

o

z

q,

0

f

;

o

c

0)

c

!

o

o

c)

.c

o

o

at

o

:

o

o

= ts

o

E

o

c

o

q)

o

.g

o.

o.

o

t

o

_q

o

(I'

E

.g

f

I

o

c

0)

;

o

E

c)

.o

o,

'i=

.9)

J

o

E

.9

(E

o

c)

(5

o

=o

x

6

o

at,

o

c)

c

E

(D

.E

o.

E

o

o)

P

c)

E

llj

o

o.

o

CL

o

c)

o

o

o.

.o

E

E

o

o.

E

o

(E

-9

o

.o

c

.9

=

o

o.

ui

(l'

o-

.E

E

c)

o

:

(o

o

c)

o

.9

E

'6

o)

'=

'(u

o

o

:

o

L.

0)

E

c

o

E

E

c)

,6

'6

E

c,

3

(t'

;

=o

o

c)

r

o.

ct)

.g

(o

-g

t

o

o

UJ

J

-o

E

o

$

.t2

-o

o

E

c)

!t

(')

.E

zt

o

.9

(E

o

c)

o

o

o)

'6.

o

0)

I

c)

o

o

I

d

c)

.9)

o

E

c

o

;

-e

.9,

v

o

0)

E

o

E

c

(5

o)

't

o

E

o

.9

o.

D

0)

l4

o

o

E

o

E

(s

E

c)

E

o

o

u,

(u

o

o

0,

(E

E

a

C

o

E

E

o

O

(s

c

.9

=

T'

E

o

o

=

-c

o

L

(5

(u

z

I

L

o

o

.E

c')

C

ul

a

(J

o

.6.

L

(L

c

o

'-a

o

(L

L

o

E

f

Y

E

o

o

o

-g

(E

a

;

m

E

o

C

c

(E

(L

r

o

o

ii

z

= .c)

o

t

(J

(E

CL

.E

(!

c

o

E

o

.:

c

uJ

o

g

o-

U)

o

=

o

o

.a

o

z

o

CD

*

o-

U)

p

=

LL

o

o

o

o

(o

-c

x

lJJ

o

o

E

=

Lr

G

C

(5

LL

g

-9

lL

c

o

E

o

E'

o

c

o

g)

o

c

uJ

o

.q)

o

c

0)

P

o

E

[rJ

(s

c

o)

E

c

o

.=

c

uJ

c

o

:

o

o-

E

C

o

J

E

c

=

o

o-

E

o

o

o)

=

a

c

.9

(5

L

o

CL

@

G

t[

o

L

o

(5

o

o

N

I

ro

o

T

N

N

irt

(g

o

(L

rL

O

O

-c

o

(g

L

F

c

o

-c

z

?

G

-

o-

o

.t

q

-G

{ra

F

-

o

E

F

-

o

L

F

IJJ

(o

o

o

o,

(E

(L

jv

ur

g

,;dEE

d E.E E E.;

:

g:;

c.E

E *BH F8

o

z

o

U)

c)

(L

o

ct

z

o

@

o

(L

at

ci

z

o

a

o

L

o

I

=

l

o

o

.J

lt

o

E

t

E

o

F

.E

x

o

=

=o

E

(!

x

o

E

tl

t

ro

o

o

a)

o

o;

o

sl

o

a

e

o

o

E

o

x

o

'=

=

0)

Y

:

tl

J

to

o

o

o

o

ai

E

E

a

o

o

o

E

.g

x

=

3

'tr

o

o

tn

tl

o

o

G

IA

q)

o

o

o

o

3

o

J

o

E

tl

E

E

rl

rl

-

F

o

o

IL

F

u

IL

(

a

o

-

(

(,

-

-

.

F

o

J

(,

F

f

o

-o

.

I

.

F

rl

-

J

rl

-

F

Il

L

(

o

2

6

g

E

t9

J

J

(

-

o

rl

a

a

-

D

=

=

-

F

=tu

=ut

o

U

o

o

(

x

2

E

UJ

I

F

?lU

trE

-rt

36

r lll

=(,

=o l-rl

OA

z

t

?

z

o

o

z

o

lu

o

3

lt

o

o

l-

,;

e

c

o

E

-E

.9

E

o!,

OE

Eo

o-o

>=

5ii

sc

cE

o>l

o9

(o_

E6

.e3

g!t

(oC'

E

se

crQ 6

E

gf;

FE,

-od)

.-=g=

E3E

EEg

=+

o

ts!=

o6:

i,

Elfr

'=,

l;

I|iDtE

:l=t=

Illll

rE-

+3rt

A Aor

I

I

I

I

I

.I

;l

ol

ol

-ol

ol

ol

ol

E't

ol

fl

q

r!l

El

:l

6l

El

ol

el

cl

;l

ot

E

6l

ol

6l

El

ol

ol

o,I

ol

ul

ol

EI

ol

ol

EI

5l

El

6l

x

arl

>l

ol

ol

ol

ctt

OJ

-l

>{

ol

ol

=l

tDl

'-l

ol

Fl

El

oul

tl

I

---l

..1

cl

ol

|Ul

GI

>l

t!l

I

I

g

o

t)

o

D

c

a

E

T

.9,

E

J J J J

(f)

N C! c')

it

EE-

fi

-FfiF;E:E5

g:rEfiE

a+.:fi

igiiggEiiE-

FuE*E

ruP Ps

iEEgIis

;C)

gE

?E

6(u

O6

EO

I or-

or5

:E

*o

_vg

s

ia

o.cr o

#^(l)

Ea 8

F.9

o

Er B

oof

iss

c)

o

o

(5

E

(,

=

.=

o

o

-ct

o

o

o

E

o

o

c

L

o

;

q)

-o

o

tu

(L

(L

o

o

-g

o

n

o

G

=!t

!,

(!

E

c,

'6

q)

o

o

=

=

o

=6)

I

J

tl

J

= = =

(t) (f) (f)

N

(v) (f,

c!

(f)

zi0)

,=

ct

oo

e;0

'=98

lFs

FEE

33 u

;o

-=

06p.+

E O.

(5.=

"E.6

:3

gp

!JO

_ att

8,ts

=F

'--

-=

co

'69

.=o

o=

E

(o

.c,

3

E'

o

-o

ai

o

L

=

:tr

E

c

(E

I

g

=o

o

o.

=

E

o

=

E'

o

!

c

c

c

;:

g

C

E

t

t

C

t

o

E

u

E

t

-

C

u

tl

tt

ggasFr

ctl

339

sE

I

AE

G- E

=

Pg

gE

f

;*;e

; PEE

FFEffE

E

o

o

c

6

c

o

E

o

'5

o

UJ

(\l (')

$

(o

o

C\l

o

CD

o

(L

ci

z

o

a

o

(L

o

ct

z

o

a

L

o

(L

o

ct

z

o

U)

L

o

(L

o

ci

z

o

U)

o

o-

o

ci

z

o

U)

L

o

(L

o

r

ci

z

L

o

@

L

o

(L

o

=

J J J J J

N

(e

|f) N

(f) lr,

5 E b*

te

,$ 3+

$FEEgF$

:

gg

IE sE

.Hs;E*r*F3

gFIHEEE

-9

-o

o

=

o

o

o

o)

c

-Y

L

(U

!t

6!t

.-o

g1t

f';

oo

-L

;o-

.=

c)

oDll

Cs

.=o

otr

3;

cc

(I)'E

-c,

E

=g

cc

F

>-c

(Eg

i9 c

o oE

o-

(E

r6

b

eEg

EE;

ETE

EH

ao=

3 A.E

-

-q)

0'6

g

z,co

'!our

IEgF$Eg

s#esEtg

.9-

o 5.9

FEA

fi

EDa O

gEE

EE8

6 E.9

gEo

ge

i

.9 or6

o.EuJ

9;E

BE

+fr

?t Be

oo

=

H*

;E

lSet;

bE.9ae

3 o:E

e'E

e"E E

gBggE

= = =

ct,

(f)

c\I

(o

s

(Y)