Beruflich Dokumente

Kultur Dokumente

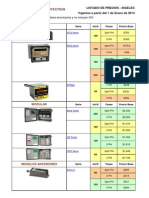

El Compromiso y La Unidad de Despacho de Generación de Una Central Hidroeléctrica en Un Mercado Competitivo de Electricidad

Hochgeladen von

Miguel Angel Miranda UgarteOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

El Compromiso y La Unidad de Despacho de Generación de Una Central Hidroeléctrica en Un Mercado Competitivo de Electricidad

Hochgeladen von

Miguel Angel Miranda UgarteCopyright:

Verfügbare Formate

Unit Commitment and Generation Dispatch of a

Hydropower Plant in a Competitive Electricity Market

J uan I. Prez, J os R. Wilhelmi and Luis A. Arvalo

Departamento de Ingeniera Civil: Hidrulica y Energtica.

ETSI de Caminos, Canales y Puertos. Technical University of Madrid

c/ Profesor Aranguren s/n, 28040 Madrid (Spain)

Phone number: +0034 91 3366705, e-mail address: jiperez@caminos.upm.es

Abstract. This paper presents a model to solve the short-term

scheduling problem of a hydropower plant in a deregulated system,

based on dynamic programming techniques. The objective of this

model is to maximize the revenue obtained by selling energy in a

competitive electricity market. The time horizon of the model is

divided into hourly periods and ranges from one day to one week.

The proposed model determines both the unit commitment and the

power to be generated in each hour of the time horizon. The power

is considered as a nonlinear function of the water discharge and the

reservoir volume; the dependence of the units and plant operating

limits on the available gross head has been taken into account; and

the water discharged through the spillway has been also allowed

for in the model. This approach has been applied to a practical case

study, the results of which are analyzed in detail.

Key words. Hydropower plant, competitive electricity market,

short-term scheduling, head dependence, dynamic programming.

1. Introduction

his paper considers a price-taker hydropower plant that

sells its energy in the day-ahead electricity market, i.e.,

it does not have influence on the hourly market clearing

prices. Bidding strategies considering the effect of the plant

production on the market clearing procedure are therefore

outside the scope of this paper.

One of the main difficulties faced by most hydro scheduling

models lies in the nonlinear relationship existing among the

power generated, the water discharge and the net head. For

short-term studies the head dependence is usually neglected,

especially in the case of large reservoirs, as their variation

throughout the planning time horizon is barely significant.

Nevertheless, in Spain, and in many other countries all over

the world, there are many hydropower plants associated to a

reservoir the regulating capacity of which is weekly, daily

or even smaller, as it is the more and more frequent case of

small to medium head hydropower plants with a limited and

environmentally respectful flooded area. In these cases, the

head dependence should be considered in order to obtain

realistic results.

Several methods have been used to solve the short-term

scheduling of a hydro plant: linear programming [1], mixed

integer linear programming [2], nonlinear programming [3]

and dynamic programming [4], among others. It should be

noted that, depending on the market environment, the plant

regulating capacity and whether the power generation

system is hydro- or thermal-based, the focus of the models

may vary slightly but essentially, most approaches proposed

in the literature are applicable in a broad range of cases.

In linear programming based models, the hydro generation

characteristic is usually reduced to a single unit performance

curve approximated either through a piecewise linear curve

[5], or by modeling the so-called local best efficiency points

[6], the head dependence being therefore neglected. This

dependence has been partially considered in only few mixed

integer linear programming based models: in [7] the hydro

plant generation characteristic is represented by three unit

performance curves, each of which is approximated by a

nonconcave piecewise linearization; in [8,9], an iterative

procedure, formally known as successive mixed integer

linear programming, is presented. The problem in this case

is that there is no guarantee that the algorithm converges to

an optimal solution.

In nonlinear programming based models it is important to

avoid the nonconcavity, or nonconvexity (depending on the

considered approach), of the objective function since it may

result in multiple local optima. In addition, the management

of the unit start-ups and shut-downs by means of binary

variables leads in these cases to nonlinear mixed integer

programming problems [10], the solution of which has not

yet reached the maturity of linear or nonlinear programming

methods [11].

Due to the inherent complexity of the problem, it is usual to

find in the literature approaches that decompose it into a

unit commitment subproblem (UCS) to determine the unit

status (on/off), and a generation dispatch subproblem (GDS)

to determine the optimal power generation. In [12], the UCS

is solved by means of a heuristic approach and Lagrangian

relaxation is used to solve the GDS, whereas in [13], a

genetic algorithm solves the UCS and Lagrangian relaxation

is again used to solve the GDS.

Dynamic programming is probably one of the first methods

used to solve hydro scheduling problems, whatever the time

horizon or the predominant source of energy in the system.

T

Recent studies [14,15] have shown that interest on this

technique is still relevant. Although it can easily overcome

the nonlinear and nonconcave character of the hydro

scheduling problem, it poses difficulties to manage the unit

start-ups and shut-downs.

This paper presents a dynamic programming model to solve

the short-term scheduling problem of a hydropower plant

associated to a reservoir the regulating capacity of which is

weekly, daily or even smaller. The model provides both the

unit commitment and the generation dispatch by means of a

suitable discretization of the feasible region. Due to the

short-term planning period, the model has been developed

in a deterministic framework in the sense that certain

variables, such as the water inflow to the reservoir and the

hourly market clearing prices, are represented by their

forecasted average values. Also, the reservoir volumes at the

end and at the beginning of the planning period are assumed

to be determined by a longer term planning procedure. The

model has been applied to a practical case study, the results

of which will be reported and discussed in detail.

This paper is organized as follows: in section 2, the method

used to obtain the plant generation characteristic is briefly

described; next, in section 3 the approach proposed to solve

the short-term scheduling problem is thoroughly described;

in section 4, results from a practical case study are reported

and discussed; and finally, main conclusions obtained in this

study are presented in section 5.

2. Plant generation characteristic

The plant generation characteristic describes the nonlinear

and in general nonconcave relationship existing among the

power generated, the water discharge and the net head, and

is usually represented by a series of power-discharge curves

that correspond to different gross head or reservoir volume

values. The procedure used in this paper to obtain the plant

generation characteristic is based on the method proposed in

[4] to solve the instantaneous load dispatch of a hydro plant.

Some aspects of said method have been modified in order to

consider the variation of the units operating limits with the

gross head and to take into account the possibility that the

units might have different permissible ranges of net heads. It

should be noted that although there exist several heuristic

approaches to describe the power production phenomenon

in a hydropower plant [16], so far, no analytical expressions

have been found in the technical literature.

The procedure proposed in this paper to obtain points of the

plant generation characteristic assumes that the following

data are known in advance:

a. The curve that relates the gross head (m) to the reservoir

volume (hm

3

).

b. The variation of the tailrace elevation that depends on the

water discharged, and that is generally considered as a

polynomial function of different degrees [12, 17].

c. The coefficient that relates the friction head losses in the

penstock to the square of the water discharge, usually

given in s

2

/m

5

. It should be noted that throughout this

paper it is considered that water is conveyed to the units

through a single penstock.

d. The turbine efficiency hill curves of all units of the plant,

expressed in terms of unit speed and unit discharge, as

well as their runner diameters and synchronous speeds.

The proposed procedure consists of repeating the following

steps for as many operating points as possible, these being

given by the water discharge and the reservoir volume:

Step 1. The net water head is calculated by subtracting to

the gross head the head losses in the penstock and those due

to the variation of the tailrace level. If that value is out of

the allowable range of net heads of some unit, this unit will

be discarded for the following steps.

(1)

t p g

h h h h =

(2)

2

q h

p

=

(3) ) (q f h

t

=

Step 2. Unit speeds of all available units are calculated by

means of the following equation.

h

D n

n

j j j

I

= (4)

Step 3. From the turbine efficiency hill curves and equations

(5)-(8), maximum and minimum flow limits of all available

units must be calculated. Maximum power output depends

on the generator characteristics whereas turbine efficiency is

generally forced to be higher than a certain value in order to

avoid operational problems such as cavitation or draft tube

pressure oscillations.

h D

q

q

j

j j

I

2

= (5)

(6) h q p

j j j

=

(7)

max

j j

p p

(8)

min

j j

Step 4. The dynamic programming approach presented in

[4] to solve the instantaneous load dispatch of a hydro plant

is applied to calculate the maximum power generated by all

available units: the feasible region of the problem is divided

into as many stages as the number of available units; the

available flow at the beginning of each stage is taken as the

state variable of the problem; and the water flow through

each unit is taken as the decision variable of the problem.

Then, the dynamic programming recursion equation (9) is

solved sequentially backwards from the last stage to the first

one, subject to constraints (10)-(12).

(9) )} ( ) ( { max ) (

1 +

+ =

j j j

j

j

x F h u u x F

u

, (10)

j j j

u x x =

+1

1 , , 1 = nu j K

(11)

max

0

j j

q u

(12) q u

nu

j

j

=

=1

Numerical efficiency in equation (9) is estimated by

interpolating in the corresponding turbine efficiency hill

curves the unit speed and unit flow values, calculated in turn

by substituting u

j

and h in (4) and (5). The generation

characteristic of a hydro plant with four generating units is

plotted in Fig. 1.

Fig. 1: Generation characteristic of a hydro plant with four

generating units.

3. Short-term scheduling problem

Once the plant generation characteristic has been obtained,

the short-term scheduling problem is solved by means of a

novel approach based on dynamic programming. The

solution of the problem provides in each stage of the time

period considered the optimum values of the following

variables: the plant status (on/off); the power output; the

reservoir volume; the flow released through the turbines;

and the flow spilled through the spillway. It should be noted

that the units status (on/off) is implicit in the plant

generation characteristic.

A. Discretization of the feasible region

One of the main contributions of this model lies in the way

the feasible region is discretized. This discretization allows

to consider the possibility that the plant might be shut-down

in any of the stages of the time period considered, as well as

that of spilling water over the lip of the spillway. As it was

said in the introduction, this approach has been developed in

a deterministic framework, i.e., some random variables are

represented by their forecasted average values. Such is the

case of the water inflow to the reservoir, the forecasted

average value of which can vary from one stage to another.

The reservoir volumes at the beginning and at the end of the

time period considered are in turn assumed to be determined

by a longer term planning procedure.

Firstly, the time period is divided into hourly stages. Then,

intermediate states of the feasible region are obtained in two

different manners, depending on the point, or state, from

which the procedure begins.

Forward discretization. Starting from the initial reservoir

state, trajectories corresponding both to discharge the

absolute maximum flow and to shut-down the plant are

plotted sequentially in all stages of the time horizon. At the

first stage, the segment defined by the extremes of these

trajectories is divided into an integer number of intervals of

the same length, v (see Fig. 2), which define the mesh size

of the state diagram. Then, if the reservoir volume surpasses

at the end of any stage the maximum volume, this is taken

in said stage as the upper limit of the feasible region. On the

other hand, when the reservoir volume falls at the end of

any stage below the minimum volume, v is added

successively until the reservoir volume is greater or equal

than the minimum volume (see Fig. 2). This option allows

shutting-down the plant in every stage of the time horizon

from any initial state of said stage, whenever feasible, as it

can be observed from black trajectories in Fig. 2. If on the

contrary, the minimum volume were taken as the lower limit

of the feasible region, the resulting mesh (red points in Fig.

2) would not include the states reached when the plant is

shut-down, thus eliminating this option.

q [m

3

/s]

p

[

k

W

]

v

n

>v

n-1

>>v

2

>v

1 v

n

v

n-1

v

n-2

v

1

v

2

v

3

Fig. 2: Obtaining the limits of the feasible region.

Intermediate states at the end of each stage are obtained by

adding successively constant volume increments (v) from

the lower limit of the feasible region. The magnitude of this

increment depends on the degree of accuracy required. A

preliminary, or relaxed, feasible region similar to that shown

in Fig. 3 is obtained in this manner.

Next, starting from the final reservoir state, trajectories

corresponding to discharge the absolute maximum flow and

to shut-down the plant are plotted sequentially backwards in

all stages of the problem. If the initial state of the trajectory

corresponding to shut-down the plant is in any of the stages

above the lower limit of the preliminary feasible region, the

former is taken as the lower limit of the definitive feasible

region. Otherwise, the latter will be taken as the lower limit

of the definitive feasible region. All points belonging to the

preliminary feasible region that are between the upper and

lower limits of the definitive feasible region will also belong

to the definitive feasible region. Thus, a definitive feasible

region similar to that shown in red in Fig. 4 is obtained.

Backward discretization. This procedure is identical to the

previous one except that it begins from the final reservoir

state.

B. Dynamic programming approach

After obtaining both feasible regions, the following process

must be carried out sequentially backwards from the last

stage to the first one.

Step 1. Flow and average volume are calculated in each

trajectory. It should be noted that the duration of all stages,

t, is one hour.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Stages

v

[

h

m

3

]

v

max

v

min

v

0

Fig. 3. Preliminary feasible region.

c k cw k j v k i v k j i q / )) ( ) , ( ) 1 , ( ( ) , , ( + = (13)

2

) , ( ) 1 , (

) , , (

k j v k i v

k j i v

+

= (14)

Step 2. Maximum and minimum flow limits are obtained in

each trajectory by interpolating the average volume in the

plant generation characteristic.

Step 3. Power generated is calculated in each trajectory, the

following conditions being taken into account:

i. If )) , , ( ( ) , , ( )) , , ( (

max min

k j i v q k j i q k j i v q ,

is calculated by interpolating in the plant generation

characteristic and .

) , , ( k j i p

0 ) , , ( = k j i s

ii. If 0 ) , , ( = k j i q , the plant is shut-down, so 0 ) , , ( = k j i p ,

and 0 ) , , ( = k j i s .

iii. If )) , , ( ( ) , , ( 0

min

k j i v q k j i q < < and

max

, a

certain amount of water is spilled through the spillway,

) , ( v k j v =

) , , ( ) , , ( k j i q k j i s = .

iv. If )) , , ( ( ) , , (

max

k j i v q k j i q > and

max

, a certain

amount of water is discharged through the spillway,

) , ( v k j v =

)) , , ( ( ) , , ( ) , , (

max

k j i v q k j i q k j i s = , and is

calculated by interpolating in the plant generation

characteristic.

) , , ( k j i p

v. In any other case and M k j i p = ) , , ( 0 ) , , ( = k j i s .

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Stages

v

[

h

m

3

]

v

0

v

max

v

min

v

f

Fig. 4. Definitive feasible region.

Step 4. Income from selling energy are calculated

in each trajectory by multiplying the power generated by the

energy price (k).

) , , ( k j i I

Step 5. The dynamic programming recursion equation (15)

is solved to obtain the maximum income accumulated from

the initial state i to the final reservoir state v

f

.

)} 1 , ( ) , , ( { max ) , (

) , , (

+ + = k j I k j i I k i I

k j i q

(15)

30 35 40 45 50 55 60 65 70 75

5.000

10.000

15.000

20.000

25.000

30.000

35.000

q [m

3

/s]

p

[

k

W

]

p

max

Fig. 5. Case study: Plant generation characteristic.

The search procedure is to be carried out in both feasible

regions: the optimal solution will be the one that provides

the maximum income accumulated.

4. Case study

The proposed approach has been applied to a realistic case

study the results of which are reported and discussed in this

section. For the sake of simplicity, the hydro plant analyzed

has a single Francis unit the efficiency hill curves of which

were taken from [18] (these hill curves have been already

used by the authors in [19]). In order to determine the unit

operating limits, some criteria presented in [20] were used.

The variation of the tailrace elevation is described by a

fourth order polynomial function, the coefficients of which

have been estimated from those of J urumirim hydro plant,

located in the Paranapanema river, in Brasil (several data

from this hydro plant were provided by the company Duke-

Energy Brasil). The plant generation characteristic has been

obtained following the methodology presented in section 2

and can be seen in Fig. 5.

The performance of the proposed model has been evaluated

under different operating conditions, given by different

values of: the forecasted water inflows that vary from one

stage to another; and the initial and final reservoir volumes,

that were identical in all cases analyzed. The time horizon

considered was divided into hourly stages and ranges from

one day to one week. The hourly energy prices were taken

from the Spanish Market Operator (OMEL) web page [21].

The approach presented in section 3.B has been developed

in MATLAB

and has been executed in a Dell PWS 390,

Intel dual-core 2.40-GHz processor with 2.00 GB of RAM.

CPU time consumed to reach an optimal solution ranges

from few seconds to one minute for daily scheduling and

from one to five minutes for weekly scheduling, depending

on the number of intermediate states of the feasible region.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

0

1

2

3

4

5

6

7

8

c

e

n

t

.

/

k

W

h

Stages

Fig. 8. Hourly energy prices.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

0

10

20

30

40

50

60

70

80

Stages

q

[

m

3

/

s

]

Maximumincome:19470

Fig. 6. Results: hourly water flow through the turbine.

Results from one of the cases analyzed can be seen in Figs.

6-8. These figures show respectively: the hourly water flow

through the turbine, the reservoir trajectory and the hourly

energy prices. As it can be observed in Fig. 7, the reservoir

stores water during stages preceding peak hours in order to

take advantage of the water head in the latter. During peak

hours the reservoir volume decreases rapidly, the maximum

flow being released through the turbine, whereas during the

last four stages the reservoir stores water again in order to

meet the reservoir target level at the end of the day. It is

worthwhile to mention that in none of the stages water is

spilled through the spillway, thus utilizing all water inflow

to produce energy.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

0

0.5

1

1.5

2

2.5

3

Stages

v

[

h

m

3

]

Fig. 7. Results: reservoir trajectory.

5. Conclusions

This paper presents a novel approach based on dynamic

programming to solve the short-term scheduling of a

hydropower plant in a competitive electricity market. This

approach provides both the plant status (on/off) and the

generation dispatch in each stage of the time horizon

considered (from one day to one week). Unit commitment is

implicit in the solution of the problem since the plant

generation characteristic has been previously obtained by

solving successively a series of load dispatch problems by

dynamic programming.

The generation characteristic considers the power generated

as a function of both the water discharge and the reservoir

volume as well as the dependence of the units and plant

operating limits on the gross head. This is especially

important in the case that the regulating capacity of the

reservoir associated to the plant is weekly, daily or even

smaller. The possibility of spilling water above a certain

reservoir volume has been also considered.

Most approaches based on dynamic programming pose

difficulties to obtain simultaneously the generation dispatch

and the unit commitment. This problem is effectively

overcome in this paper by means of a suitable discretization

of the feasible region.

Acknowledgement

Authors want to acknowledge the company Duke-Energy

Brasil for providing data from some Brazilian hydro plants.

Appendix-Nomenclature

The notation used throughout the paper is presented next:

h Net water head [m]

h

g

Gross head [m]

h

p

Penstock head losses [m]

h

t

Variation of the tailrace level [m]

j

I

n Unit speed of unit j [rpm]

n

j

Synchronous speed of unit j [rpm]

D

j

Runner diameter of unit j [m]

Friction head losses coefficient [s

2

/m

5

]

q Total water discharge [m

3

/s]

q

j

Water discharge of unit j [m

3

/s]

j

I

q Unit flow of unit j [m

3

/s]

p

j

Power generated by unit j [kW]

Specific weight of water [9.81 kN/m

3

]

j

Global efficiency of unit [pu]

max

j

p Maximum power output of unit j [kW]

min

j

Minimum global efficiency of unit j [pu]

F(x

j

) Maximum power output from state x

j

[kW]

x

j

State variable of the load dispatch problem

[hm

3

]

u

j

Decision variable of the load dispatch problem

[m

3

/s]

max

j

q Maximum water discharge of unit j [m

3

/s]

nu Number of available units

q(i,j,k) Flow in trajectory i-j during stage k [m

3

/s]

v(i,k) Reservoir volume in state i at the end of stage k

[hm

3

]

c Conversion factor [0.0036 hm

3

/h/m

3

/s]

w(k) Water inflow to the reservoir in stage k [m

3

/s]

) , , ( k j i v Average reservoir volume in trajectory i-j

during stage k [hm

3

]

) , , (

min

k j i q Minimum flow of the plant in trajectory i-j

during stage k [m

3

/s]

) , , (

max

k j i q Maximum flow of the plant in trajectory i-j

during stage k [m

3

/s]

) , , ( k j i p Plant power output in trajectory i-j during stage

k [kW]

) , , ( k j i s Water spilled through the spillway in trajectory

i-j during stage k [m

3

/s]

max

M Arbitrary positive real number great enough to

discard the corresponding trajectory

v Maximum reservoir volume [hm

3

]

) , , ( k j i I Income from selling energy in trajectory i-j

during stage k []

) (k Energy price during stage k []

) , ( k i I Maximum income accumulated from state i at

the beginning of stage k [].

References

[1] A.J . Wood and B.F. Wollenberg, Power Generation,

Operation and Control, 2

nd

ed., New York: J ohn Wiley &

Sons, 1996.

[2] G. W. Chang et al., Experiences with mixed integer linear

programming based approaches on short-term hydro

scheduling, IEEE Trans. Power Syst., vol. 16, pp. 743-749,

November 2001.

[3] J .P.S. Catalao et al., Parameterisation effect on the behaviour

of a head-dependent hydro chain using a nonlinear model,

Electric Power Systems Research, vol. 76, pp. 404-412, 2006.

[4] R. B. Allen and S. G. Bridgeman, Dynamic programming in

hydropower scheduling, ASCE Journal of Water Resources

Planning and Management, vol. 112, pp. 339-353, J uly 1986.

[5] M. R. Piekutowski, T. Litwinowicz and R. J . Frowd, Optimal

short-term scheduling for a large scale-cascaded hydro

system, IEEE Trans. Power Syst., vol. 9, pp. 805-811, May

1994.

[6] N. Tufegdzic, R.J . Frowd and W.O. Stadlin, A coordinated

approach for real-time short-term hydro scheduling, IEEE

Trans. Power Syst., vol. 11, pp. 1698-1704, November 1996.

[7] A. J . Conejo, J. M. Arroyo, J . Contreras and F. Apolinar

Villamor, Self-scheduling of a hydro producer in a pool-

based electricity market, IEEE Trans. Power Syst., vol. 17,

pp. 1265-1272, November 2002.

[8] J . Garca-Gonzlez et al. Under-relaxed iterative procedure

for feasible short-term scheduling of a hydro chain, in Proc.

of IEEE PowerTech Conference, Bologna, Italy, J une 23-26,

2004.

[9] O. B. Fosso and M. M. Belsnes, Short-term hydro scheduling

in a liberalized power system, in Proc. of IEEE PowerCon,

Singapore, November 21-24, 2004.

[10] E. C. Finardi and E.L. da Silva, Unit commitment of single

hydroelectric plant, Electric Power Systems Research, vol.

75, pp. 116-123, 2005.

[11] R.S.V. Teegavarapu and S.P. Simonovic, Short-term

operation model for coupled hydropower reservoirs, ASCE

Journal of Water Resources Planning and Management, vol.

126, no. 2, pp.98-106, March/April 2000.

[12] S. Soares, T. Ohishi, M. Cicogna and A. Arce, Dynamic

dispatch of hydro generating units, in Proc. of IEEE

PowerTech Conference, Bologna, Italy, J une 23-26, 2004.

[13] E.F. Santos and T. Ohishi, A hydro unit commitment model

using genetic algorithm, in Proc. of IEEE Congress on

Evolutionary Computation, Portland, Oregon, J une 19-23,

2004.

[14] A. Arce, T. Ohishi and S. Soares, Optimal dispatch of

generating units of the Itaip hydroelectric plant, IEEE

Trans. Power Syst., vol. 17, pp. 154-158, February 2002.

[15] J . Yi, J .W. Labadie and S. Stitt, Dynamic optimal unit

commitment and loading in hydropower systems, ASCE

Journal of Water Resources Planning and Management, vol.

129, no.5, September 2003.

[16] M. E. El-Hawari, Optimal parameter estimation for hydro-

plant performance models in economic operation studies,

IEEE Trans. Power Syst., vol. PWRS-1, pp. 126-131,

November 1986.

[17] S. Soares and C.T. Salmazo, Minimum loss predispatch

model for hydroelectric power systems, IEEE Trans. Power

Syst., vol. 12, pp. 805-811, August 1997.

[18] C. Mataix, Turbomquinas hidrulicas, Madrid: ICAI, 1975.

[19] J .I. Prez and J .R. Wilhelmi, Nonlinear self-scheduling of a

single unit small hydro plant in the day-ahead electricity

market, in Proc. of ICREPQ07, paper no. 254, Sevilla,

Spain, March 2007.

[20] US Department of Interior: Bureau of Reclamation. Selecting

hydraulic turbines. A Water Resources Technical Publication,

Engineering Monograph no. 20, 1976.

[21] Operador del Mercado Ibrico de Energa Polo Espaol,

S.A [Online]. www.omel.es

Das könnte Ihnen auch gefallen

- AstroHalo - CHSM6612P - 40mm Frame - 20181212Dokument2 SeitenAstroHalo - CHSM6612P - 40mm Frame - 20181212Miguel Angel Miranda UgarteNoch keine Bewertungen

- Cptg003 en (Web)Dokument2 SeitenCptg003 en (Web)Miguel Angel Miranda Ugarte100% (1)

- High Bay 200w LedDokument3 SeitenHigh Bay 200w LedEdizon Ramos OrtizNoch keine Bewertungen

- Technical Information: TI 04L01L01-06ENDokument4 SeitenTechnical Information: TI 04L01L01-06ENMiguel Angel Miranda UgarteNoch keine Bewertungen

- La Supervisión de Las Energías Renovables y El Control Real de Tiempo de Producción en EspañaDokument6 SeitenLa Supervisión de Las Energías Renovables y El Control Real de Tiempo de Producción en EspañaMiguel Angel Miranda UgarteNoch keine Bewertungen

- Asociación de La Energía Fotovoltaica, Gas Micro Turbina y Sistema de Almacenamiento A Largo Plazo Corto para Participar en El Control de FrecuenciaDokument6 SeitenAsociación de La Energía Fotovoltaica, Gas Micro Turbina y Sistema de Almacenamiento A Largo Plazo Corto para Participar en El Control de FrecuenciaMiguel Angel Miranda UgarteNoch keine Bewertungen

- AN008 SigmaDeltaADC v1.0 - 0Dokument10 SeitenAN008 SigmaDeltaADC v1.0 - 0Miguel Angel Miranda UgarteNoch keine Bewertungen

- Tvss PreciosDokument5 SeitenTvss PreciosMiguel Angel Miranda UgarteNoch keine Bewertungen

- Definition - Classification of Power System Stability IEEE-CIGRE Joint Task Force On Stability Terms and DefinitionsDokument15 SeitenDefinition - Classification of Power System Stability IEEE-CIGRE Joint Task Force On Stability Terms and Definitionslepton1892100% (1)

- A02-0220 e LRDokument2 SeitenA02-0220 e LRMiguel Angel Miranda UgarteNoch keine Bewertungen

- P3 CSEUG Iss9Dokument392 SeitenP3 CSEUG Iss9Miguel Angel Miranda UgarteNoch keine Bewertungen

- Environment MagazineDokument24 SeitenEnvironment MagazineMiguel Angel Miranda UgarteNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Science7 q4 Mod2 Earthsresources-2Dokument24 SeitenScience7 q4 Mod2 Earthsresources-2ROSSELLE SANTOSNoch keine Bewertungen

- Penstock Pipe: Length, Diameter, and Material: Assessment Task 6Dokument3 SeitenPenstock Pipe: Length, Diameter, and Material: Assessment Task 6Joshua SalvadorNoch keine Bewertungen

- H57H58Dokument1 SeiteH57H58MinamPeruNoch keine Bewertungen

- Chap 1 5 Group 1 Research FINALDokument50 SeitenChap 1 5 Group 1 Research FINALKyles JumaritoNoch keine Bewertungen

- Zambia Chapter 4 CDokument22 SeitenZambia Chapter 4 Cdoud98Noch keine Bewertungen

- Jurnal Energi TerbarukanDokument7 SeitenJurnal Energi TerbarukanHafiz Al BajiriNoch keine Bewertungen

- Components and Operation Op Power HouseDokument45 SeitenComponents and Operation Op Power Housesensiblesakshi_21939100% (1)

- t3390 e StreamDiver 20150907 Screenmanual VOITHDokument8 Seitent3390 e StreamDiver 20150907 Screenmanual VOITHLuisZuluagaRodriguezNoch keine Bewertungen

- A Study On Cost Control and Cost Reduction at Karanataka Power Corporation Limited BangaloreDokument11 SeitenA Study On Cost Control and Cost Reduction at Karanataka Power Corporation Limited BangaloreNithya RajNoch keine Bewertungen

- IEA Renewables Information 2011Dokument498 SeitenIEA Renewables Information 2011aksharchandraNoch keine Bewertungen

- Manual For Micro-Hydropower DevelopmentDokument38 SeitenManual For Micro-Hydropower DevelopmentVirgil CaballeroNoch keine Bewertungen

- Reservoir Sedimentation Analysis: A Case Study: June 2018Dokument8 SeitenReservoir Sedimentation Analysis: A Case Study: June 2018Karan GuptaNoch keine Bewertungen

- Department of Mechanical Engineering: Regulation 201 7Dokument7 SeitenDepartment of Mechanical Engineering: Regulation 201 7S.VenkatesanNoch keine Bewertungen

- Gilgit Baltistan's Energy EconomicsDokument42 SeitenGilgit Baltistan's Energy EconomicsEngr. Dr. Nazir Hussain60% (5)

- 2016 A Review of Pumped Hydro Energy Storage Development in Significant International Electricity MarketsDokument12 Seiten2016 A Review of Pumped Hydro Energy Storage Development in Significant International Electricity MarketsViana RvNoch keine Bewertungen

- Europac Work SampleDokument56 SeitenEuropac Work Sampleapi-238672136Noch keine Bewertungen

- Catálogo Turbinas GilkesDokument12 SeitenCatálogo Turbinas GilkesEdú Brizuela100% (1)

- Tamil Nadu EconomyDokument8 SeitenTamil Nadu Economykani mozhiNoch keine Bewertungen

- Business Plan Perpetual Power Solution Co., LTD: 15 July 2016Dokument49 SeitenBusiness Plan Perpetual Power Solution Co., LTD: 15 July 2016Ko Aung KoNoch keine Bewertungen

- Main Sentences - Review Report On Existing Studies - Hasang HPP Project 130225 PDFDokument94 SeitenMain Sentences - Review Report On Existing Studies - Hasang HPP Project 130225 PDFMuhammad TrayaNoch keine Bewertungen

- Pro & Contra Hydropower: AdvantagesDokument16 SeitenPro & Contra Hydropower: AdvantagesbarukomkssNoch keine Bewertungen

- Kseb Annual Report2017-18 PDFDokument292 SeitenKseb Annual Report2017-18 PDFJabir Mohammad AckNoch keine Bewertungen

- NES5100 ExcitationDokument46 SeitenNES5100 ExcitationDoan BaoNoch keine Bewertungen

- SARDILLA-Hydro Electric Power PlantDokument7 SeitenSARDILLA-Hydro Electric Power PlantAldrin Esplana SardillaNoch keine Bewertungen

- IEC White Paper - Electrical Energy Storage PDFDokument78 SeitenIEC White Paper - Electrical Energy Storage PDFRizqi PriatnaNoch keine Bewertungen

- University of Cambridge International Examinations International General Certificate of Secondary EducationDokument16 SeitenUniversity of Cambridge International Examinations International General Certificate of Secondary EducationHany ElGezawyNoch keine Bewertungen

- Erection Testing and CommissioningDokument70 SeitenErection Testing and CommissioninghaqjmiNoch keine Bewertungen

- Project Review Report: Norochcholai Coal Power Plant ProjectDokument10 SeitenProject Review Report: Norochcholai Coal Power Plant ProjectPraneeth HettiarachchiNoch keine Bewertungen

- 22-09-2011 - Feasibility Stage Petition For Determination of Tariff For 720 MW Karot Hydropower Project.Dokument88 Seiten22-09-2011 - Feasibility Stage Petition For Determination of Tariff For 720 MW Karot Hydropower Project.MunimNoch keine Bewertungen

- Uttarakhand Existing Under Construction and Proposed Hydropower Projects August2013Dokument13 SeitenUttarakhand Existing Under Construction and Proposed Hydropower Projects August2013swabrightNoch keine Bewertungen