Beruflich Dokumente

Kultur Dokumente

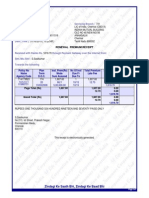

AIW Technical Proposal - TAFE TC CH - 25114

Hochgeladen von

Balaji0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

17 Ansichten9 SeitenOK

Copyright

© © All Rights Reserved

Verfügbare Formate

XLS, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenOK

Copyright:

© All Rights Reserved

Verfügbare Formate

Als XLS, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

17 Ansichten9 SeitenAIW Technical Proposal - TAFE TC CH - 25114

Hochgeladen von

BalajiOK

Copyright:

© All Rights Reserved

Verfügbare Formate

Als XLS, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 9

Sl.

no Tooling Details Operation

Feed in

mm/min

Speed (S)

in RPM

Sl. no

1

Dia.100 mm milling

cutter

Rough

milling

1600 to

2240

675 1

2

Dia.100 mm milling

cutter

Finish

milling

4800 800 2

3 Dia. 80 boring bar

Rough

boring

238 564 3

4 Dia. 100 boring bar

Rough

boring

246 575 4

5 Dia. 101 boring bar

Rough

boring

380 762 5

6 Dia. 104 boring bar

Rough

boring

250 716 6

7 Dia. 90 boring bar

Rough

boring

282 640 7

8 Dia. 97 boring bar

Rough

boring

262 653 8

9 Dia.25 mm U drill drilling 200/254 1273 9

10 9.5 Burnnishing drill Dowelling 600 3344 10

11

Dia. 25.2 excentric

boring bar

Boring 150/1000 850/1100 11

12 Finish Dia. 90/100/101 F. Boring 180 1273 12

13 Dia. 90 boring bar F. Boring 200 1238 13

14 Dia. 80 boring bar F. Boring 230 1393 14

15 Dia. 104 boring bar F. Boring 171 1064 15

16

Dia.19 mm burnishing

Drill

drilling

516/65

/170

2065/300/

1000

16

17

18

18

19

20

TAFE TR.CASE TAFE CENTRE HSG.

Tooling Details Operation

Feed in

mm/min

Speed (S)

in RPM

Dia.100 mm milling

cutter

Rough

milling

2200 600

Dia.100 mm milling

cutter

Finish

milling

3200 716

Dia. 15.88 drill Drilling 300 2231

Dia. 100 mm Milling

Cutter for Egle milling

Milling 796 696

Dia. 100 mm Milling

Cutter for S/F

Milling 1150 960

Dia. 100 mm Milling

Cutter FOR LH/RH

Rough

boring

1800/2800 764

Drill Dia. 10.7 mm Drilling 800 3570

Drill Dia. 6.5 mm

Rough

boring

500 2500

5/16 18 UNC Tap Tapping 847 600

17.5 Burnnishing drill Drilling

1050/60/90

/75/90

720

Drill Dia. 9.3 mm Drilling 150 1500

Drill Dia. 17.465 mm drilling 150 1800

Dia. 107 boring bar R. Boring 100 200

Dia. 50.5 boring bar R. Boring 120 410

Dia. 334 boring bar R. Boring 60 133

7/16 16 UNC Tapping 544.285 300

Dia. 334 boring bar F. Boring 60 354

Dia. 15.95/20.65 Drilling 335 2002

Dia. 14.27/20.65 Drilling 180 1750

Dia. 75/82 mm Boring 544 300

3/4 16 UNF Tapping 396.88 250

TAFE CENTRE HSG.

Opn.

No.

Machin

e

Operation

Existing

CT in

min

Direct

Man

power

in nos

Observations

80

SPM

Drilling

Rear face and HLC face

drilling

4 min 3

90

SPM

Tapping

Bottom,Rear,sleeve face

and HLC face Tapping.

4.5 min 3

100

SPM

Tapping

LH and RH face tapping

in two set ups

5.5 min 3

0

27

1.All bore finish boring

and Dia.41.25 mm bore

rough to finish.

2.PPS milling, drilling and

reaming 3.

Axle bore finish boring.

4. 5/16 Tapping

6 min

70

SPM

Drilling

with

Double

Station.

1st Station: RH side,

sleeve pinion face and

dowel hole drilling. 2nd

Station : Bottom 4 hole

drilling

5.5 min 3

For SS operation

CT become 9

minand 54 sec

1.All bore Rough boring

except Dia.41.25 mm

bore. 2.sleeve

face facing,hub face

rough to finish 3.

Axle bore rough boring

6 min

3

60

SPM

Drilling

with

Double

Station.

1st Station: PTO Cover

drilling,Drain plug and

TCFF face drilling.

2nd Station : Yoke yole

drilling

5 min 3

50

1 HMC

(a81

Makino)

(2 pallet of

same set

up)

3

For SS operation

CT become 9

minand 54 sec

30

1 HMC

(a81

Makino)

(2 pallet of

same set

up)

1.Rough and Finish

Milling - LH/RH Axle face

milling.

2.Crown face and side

face rough and finish

milling.

3. Top and bottom egle

milling. 4.

LH side 15 hole drilling

with champer.

5. 6.53mm LH/RH drilling.

6 min

and

side

shift 9

min

3

Dia.125 mm Side

face milling cutter

is using for Egle

milling.

40

1 HMC

(a81

Makino)

(2 pallet of

same set

up)

In TAFE (SEBM)

TAFE CH PROCESS AND CYCLE TIME

20

HMC

Hundai.

KH630

(2 pallet of

same set

up)

1.Rough Milling - Front

(TCFF) & Rear face

2. Rough & Finish Milling-

SBFF & Bottom

3. Drilling 14 hole at HLC

FF and Dowelling 2 holes.

5 min,

53 sec

3

1. 4 side Hyd.

clamping

(Outside)

2. Machining

allowance 3 to 5

mm.

Op. No. Machine

CT in

min.

Direct

man

power

Connec

ting

load in

HP

Connecti

ng load

in KW

Usage

load in

KW

1 20 Duplex 7.15 39 29.25 11.7 Evaluation criteria Data

Saving/

loss

2 30 Duplex 7.5 37 27.75 11.1 1.Through put Time in min. 112

3 40

MSD 3 way

5.45 16.16 12.12 4.8 2. Capacity/day in nos. 151

4 50

MSD 2 way

3 20.66 15.5 6.2 3. Manpower (Direct) in nos 36

5 60

Horizontal

Milling

7.45 40.75 30.56 12.2 4. Manpower (In direct) in nos 3

6 70

Horizontal

Milling

7 6 4.5 1.8

5. Production Qty / Workmen in

nos.

3.87

7 75 Milling 3 10 7.5 3.0 6. Connected Load in KW 226

8 80

Horizontal

R Boring

7 13 9.75 3.9 7. Usage Load in KW 88

9 90

Horizontal

F Boring

7.6 14 10.5 4.2

10 100

Duplex

Milling

7.45 15 11.25 3.4 8 No. of machines 18

11 110

Horizontal

Boring

7.25 13 9.75 3.9

12 120 MSD 6.75 33 24.58 9.8

13 130 R-Drill 6.5 3 8 6 2.4

14 140 R-Drill 7 3 8 6 2.4

15 150 R-Drill 7.6 3 8 6 2.4

16 160 R-Drill 7 3 8 6 2.4

160A 4.3 2.4

165 3 0.0

18 185

Leak

testing

7.6 3 5 6

Total 112 36 302.57 226 88

3

3

3 6 8

Date :25.1.14

17

FOR Capacity 150 per day.

TAFE Transmission Case New Proposal

Existing line- SPM and GPM Route

R-Drill

3

3

3

3

0

1

2

3

4

5

6

7

8

9

10

2

0

4

0

6

0

7

5

9

0

1

1

0

1

3

0

1

5

0

1

6

0

A

C

y

c

l e

T

i m

e

i n

m

i n

Operation No.

TAFE Tr.Case existing SPM and GPM route Cycletime Chart

Takt time

7.6 min

Op. No. Machine

CT in

min.

Direct

man

power

Connecti

ng load

in KW

Usage

load in

KW

1 20 Duplex 25 7.15 39 29.25 11.7 Evaluation criteria Data

Saving/

loss

2 30 Duplex 25 7.5 37 27.75 11.1 1.Through put Time in min. 87 25

3 40

MSD2 way

20 5.45 16 12.12 4.8 2. Capacity/day in nos. 151 0

4 50 HMC 225 3 65 48.49 19.4 3. Manpower (Direct) in nos 27 9.00

5 70

Horizontal

Milling

10 7 6 4.5 1.8 4. Manpower (In direct) in nos 3

6 95+75+130+140 HMC 225 7.5 3 65 48.49 14.547

5. Production Qty / Workmen in

nos.

5.03 1.2

7 80

Horizontal

Boring

15 7.45 13 9.75 3.9 6. Connected Load in KW 292

8 90

Horizontal

Boring

10 7 14 10.5 4.2 7. Usage Load in KW 105 -16

9

60+100+160+16

0A

HMC 225 7.6 3 65 48.49 14.547

10 120 MSD 15 6.75 33 24.58 9.8

11 110

Horizontal

Boring

10 6.5 13 9.75 3.9

12 150 RD 10 7 3 8 6 2.4

13 165 RD 10 7.3 3 8 6 2.4

14 185

Leak

testing

10 7.6 3 8 6

87.2 27 391.0 292 105

835

Comparision of AOP proposal w.r.t existing set up

8. No. of machines 14 4

Total

3

3

3

3

Proposal - Add 3 HMC & improve handling by Removing 1 MSD, 3 RD,2 FN2H and 1 small Duplex

0

1

2

3

4

5

6

7

8

9

10

2

0

3

0

4

0

5

0

7

0

9

5

+

7

5

+

1

3

0

+

1

4

0

8

0

9

0

6

0

+

1

0

0

+

1

6

0

+

1

6

0

A

1

2

0

1

1

0

1

5

0

1

6

5

C

y

c

l e

T

i m

e

i n

m

i n

Operation No.

TAFE Tr.Case AOP proposal Cycletime Chart

Takt time

7.6 min

Op. No. Machine

CT in

min.

Direct

Man

power

Connectin

g Load in

KW

Usage

load

in KW

Evaluation criteria Data

1 20 Duplex 1 20 7.6 26 11

2 30 Duplex 2 20 7.5 25 10

3 40 MSD 3 WAY 4.0 26 11

4 50 Duplex 3 7.5 30 12

5 55 HMC (SS) 8.0 30 9

6 60 SPM R.Boring 6.5 4 1

7 70 SPM F.Boring 7.3 41 16

8 80 H.Milling 7.0 11 4

9 90 MSD4 WAY 6.8 36 15

10 110 SPM Facing 6.8 21 8

11 100 Simplex 5.0 13 5

12 120 SPM R Boring 7.5 11 5

13 130 SPM F Boring 7.6 10 4

14 140 RD1 7.6 3 6 2

15 150 RD2 7.2 3 6 2

16 160 RD3 6.0 3 6 2

17 160A RD4 5.5 3 6 2

18 170 B TAPFAST1 7.0 3 2 1

19 170 A TAPFAST2 7.2 3 2 1

20 180 TAPFAST3 7.5 3 2 1

21 215 Leak testing 7.6 3 4 1

144.7 39 318 124

Date :25.1.14

151

39

1.Through put Time in min.

6. Connected Load in KW

7. Usage Load in KW 124

Existing line- SPM and GPM Route

145

8. No. of machines 21

2. Capacity/day @ 85% OEE in nos.

3. Manpower (Direct) in nos

3

3

Total

318

3.4

6

FOR Capacity 150 per day.

TAFE Centre housing new proposal

3

3

3

3

4. Manpower (In direct) in nos

5. Production Qty / Workmen in nos.

0.0

2.0

4.0

6.0

8.0

10.0

2

0

4

0

5

5

7

0

9

0

1

0

0

1

3

0

1

5

0

1

6

0

A

1

7

0

A

C

.

T

i

n

m

i

n

Operations no.

TAFE CH existing SPM & GPM Route Cycle time . chart

Takt time 7.6 min.

Op. No. Machine

CT in

min.

Direct

Man

power

Connectin

g Load in

KW

Usage

load

in KW

1 20 Duplex 1 20 7.6 26.37 10.5 Evaluation criteria Data

2 30 Duplex 2 20 7.5 24.75 9.9 1.Through put Time in min. 96

3 40+170 New HMC1 225 6.76 48.4 14.5 2. Capacity/day in nos. 151

4 50+55 Existing HMC 150 7.00 30 9.0 3. Manpower (Direct) in nos 27

5 60 SPM R.Boring 10 6.5 3.5 1.4 4. Manpower (In direct) in nos 3

6 70 SPM F.Boring 10 7.3 40.5 16.2 5. Production Qty / Workmen in nos. 5.03

7 80+90 New HMC2 225 7.60 1.5 48.4 14.5 6. Connected Load in KW 336

8 100 Simplex 10 5.0 11.5 4.60 7. Usage Load in KW 117

9 110 SPM Facing 10 6.8 12.5 5.00

10 120 SPM R Boring 10 7.5 21 8.4 8. No. of machines 15

11 130 SPM F Boring 10 7.6 5 2.0

12

140+18

0

New HMC3 225 6.86 1.5 48.4 14.5

13 160 RD3 10 6.0 3 6 2.40

14 160A RD4 10 5.5 3 6 2.40

15 215 Leak testing 10 7.6 3 4 2

95.5 27 336.32 117.0

336.32

3

3

3

New Proposal- Add 3HMC by Removing 2 MSD,1 DUPLEX,1 FN3H,2 RD and 3 Tapfast machines

3

Total

Comparision of New proposal w.r.t existing set up.

3

0.0

2.0

4.0

6.0

8.0

10.0

2

0

3

0

4

0

+

1

7

0

5

0

+

5

5

6

0

7

0

8

0

+

9

0

1

0

0

1

1

0

1

2

0

1

3

0

1

4

0

+

1

8

0

1

6

0

1

6

0

A

C

.

T

i

n

m

i

n

Operations no.

TAFE CH New proposal Cycle time chart

Takt time 7.6 min.

Date :25.1.14

Benefit /

Loss

49.13

0

12.00

3.00

1.7

7.04

6

New Proposal- Add 3HMC by Removing 2 MSD,1 DUPLEX,1 FN3H,2 RD and 3 Tapfast machines

Comparision of New proposal w.r.t existing set up.

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Ooly Ooly Sp19 CatalogDokument76 SeitenOoly Ooly Sp19 Cataloggrei quirozNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Anexo 06 - PA - Process Audit v1.1Dokument19 SeitenAnexo 06 - PA - Process Audit v1.1BalajiNoch keine Bewertungen

- Anexo 06 - PA - Process Audit v1.1Dokument19 SeitenAnexo 06 - PA - Process Audit v1.1BalajiNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Tools Needed: Diy Patio Cooler Ice Chest PlansDokument15 SeitenTools Needed: Diy Patio Cooler Ice Chest PlansBruno BenitezNoch keine Bewertungen

- Global 8D WorkbookDokument52 SeitenGlobal 8D WorkbookBalaji100% (10)

- 05G Compressor Spare Parts ManualDokument26 Seiten05G Compressor Spare Parts ManualCircle ChanNoch keine Bewertungen

- Screws and Screw MakingDokument328 SeitenScrews and Screw MakingloosenutNoch keine Bewertungen

- Name Category $ Damage B H Group Traits (All Uncommon)Dokument4 SeitenName Category $ Damage B H Group Traits (All Uncommon)rick.bullard6348Noch keine Bewertungen

- 8209-Models D, DA, DAB and DB Retainer Production Packers FoDokument12 Seiten8209-Models D, DA, DAB and DB Retainer Production Packers Fodanonnino0% (1)

- Shear Capacity of Stainless Steel BoltsDokument2 SeitenShear Capacity of Stainless Steel BoltsAnil kumar RNoch keine Bewertungen

- SBOM-Session 2 - Quality ManagementDokument54 SeitenSBOM-Session 2 - Quality ManagementBalajiNoch keine Bewertungen

- Total Quality ManagementDokument47 SeitenTotal Quality ManagementSumayya Samreen0% (1)

- Six Sigma ToolsDokument24 SeitenSix Sigma ToolsPriyaprasad PandaNoch keine Bewertungen

- Inspiring Quotes, BooksDokument4 SeitenInspiring Quotes, BooksD CristinaNoch keine Bewertungen

- ISO 9001 - Moving From 2008 To 2015Dokument8 SeitenISO 9001 - Moving From 2008 To 2015IvoMigVazNoch keine Bewertungen

- J100.32 LumaStar LED Flat Glass EPL100Dokument2 SeitenJ100.32 LumaStar LED Flat Glass EPL100BalajiNoch keine Bewertungen

- F1 Driving Course Rates and ProgrammesDokument16 SeitenF1 Driving Course Rates and ProgrammesBalajiNoch keine Bewertungen

- Ace Employment Practices Liability Fact SheetDokument2 SeitenAce Employment Practices Liability Fact SheetBalajiNoch keine Bewertungen

- QMPDokument12 SeitenQMPkbl27Noch keine Bewertungen

- David Riklan-501 Inspirational QuotesDokument0 SeitenDavid Riklan-501 Inspirational Quotesjoshua1331Noch keine Bewertungen

- Renewal Premium Receipt: Collecting Branch: E-Mail: Phone: Transaction No.: Date (Time) : Servicing BranchDokument1 SeiteRenewal Premium Receipt: Collecting Branch: E-Mail: Phone: Transaction No.: Date (Time) : Servicing BranchBalajiNoch keine Bewertungen

- DocumentDokument3 SeitenDocumentBalajiNoch keine Bewertungen

- 2015 Formula 1 Singapore Airlines Singapore Grand Prix Conditions of Sale & EntryDokument12 Seiten2015 Formula 1 Singapore Airlines Singapore Grand Prix Conditions of Sale & EntryBalajiNoch keine Bewertungen

- QMPDokument12 SeitenQMPkbl27Noch keine Bewertungen

- 2015 STW Infographic en LRDokument1 Seite2015 STW Infographic en LRBalajiNoch keine Bewertungen

- Renault Energy F1-2015: Media GuideDokument26 SeitenRenault Energy F1-2015: Media GuideBalajiNoch keine Bewertungen

- VDA 6.3 Issue 04Dokument15 SeitenVDA 6.3 Issue 04Umit KaramanNoch keine Bewertungen

- F1 Driving Course Rates and ProgrammesDokument16 SeitenF1 Driving Course Rates and ProgrammesBalajiNoch keine Bewertungen

- VDAqmc2013 EnglishDokument133 SeitenVDAqmc2013 EnglishSeenivasagam Seenu100% (1)

- EX - NO: 2A Chart in Spread SheetDokument8 SeitenEX - NO: 2A Chart in Spread SheetBalajiNoch keine Bewertungen

- 52 Income Tax Full Notes GudDokument156 Seiten52 Income Tax Full Notes GudBalajiNoch keine Bewertungen

- Leonardo Da Vinci Florence LouvreDokument2 SeitenLeonardo Da Vinci Florence LouvreBalajiNoch keine Bewertungen

- FishDokument94 SeitenFishBalajiNoch keine Bewertungen

- Performance Evaluation of Three Phase Induction Motor Based On No Load and Blocked Rotor Test Using MatlabDokument7 SeitenPerformance Evaluation of Three Phase Induction Motor Based On No Load and Blocked Rotor Test Using MatlabBalajiNoch keine Bewertungen

- g8 Ysp Gp5 Presentation (Ammended) 1Dokument18 Seiteng8 Ysp Gp5 Presentation (Ammended) 1BalajiNoch keine Bewertungen

- g8 Ysp Gp5 Presentation (Ammended) 1Dokument18 Seiteng8 Ysp Gp5 Presentation (Ammended) 1BalajiNoch keine Bewertungen

- Commercial invoice for customsDokument2 SeitenCommercial invoice for customsHarry GaddumNoch keine Bewertungen

- Saunier Duval Themafast F30Dokument18 SeitenSaunier Duval Themafast F30Eduardo RazerNoch keine Bewertungen

- Module 3a. Suplementary ProblemsDokument1 SeiteModule 3a. Suplementary Problemsaileen angelesNoch keine Bewertungen

- Din 934Dokument1 SeiteDin 934Chuan ChuNoch keine Bewertungen

- Natural Gas System Training UlDokument15 SeitenNatural Gas System Training UlBadrul HishamNoch keine Bewertungen

- Manual de Instrucciones Manual de Instruções Instruction ManualDokument15 SeitenManual de Instrucciones Manual de Instruções Instruction ManualKaren Morales de LeonNoch keine Bewertungen

- 9802/5830 F4-6-1 Motor Gearbox Components, 332/K1192Dokument3 Seiten9802/5830 F4-6-1 Motor Gearbox Components, 332/K1192Manuel felipe PalmaNoch keine Bewertungen

- Industrial Catalogue WebDokument132 SeitenIndustrial Catalogue WebMurali ShanNoch keine Bewertungen

- Valv Pressost PennDokument3 SeitenValv Pressost PennTecnoar09Noch keine Bewertungen

- EOS01204Dokument1 SeiteEOS01204Lesley-Anne RowandNoch keine Bewertungen

- 1 Carroceria Test de Progreso 1Dokument4 Seiten1 Carroceria Test de Progreso 1efaliteraturaNoch keine Bewertungen

- Ai 15522 01 User Manual, Ax50 PDFDokument50 SeitenAi 15522 01 User Manual, Ax50 PDFRod HarrisNoch keine Bewertungen

- Caterpillar Cat 324d LN Excavator Prefix TRH Service Repair Manual trh00001 and Up 1616111112Dokument29 SeitenCaterpillar Cat 324d LN Excavator Prefix TRH Service Repair Manual trh00001 and Up 1616111112Ali EndrisNoch keine Bewertungen

- Leveling The Lathe BedDokument22 SeitenLeveling The Lathe BedSHAJAKHAN RNoch keine Bewertungen

- Gun Nozzle Tip Maintenance and ReplacementDokument2 SeitenGun Nozzle Tip Maintenance and ReplacementjoecentroneNoch keine Bewertungen

- Iso - 666 - 2006, Is 15299:2013Dokument20 SeitenIso - 666 - 2006, Is 15299:2013anand.bharadwajNoch keine Bewertungen

- Revolutionary Onsite Crankshaft GrindingDokument11 SeitenRevolutionary Onsite Crankshaft GrindingJackson_Dsouza_1551Noch keine Bewertungen

- 1.1.5.a.ak GearspulleydrivessprocketspracticeproblemsDokument4 Seiten1.1.5.a.ak Gearspulleydrivessprocketspracticeproblemsmoliveri426Noch keine Bewertungen

- Drilling MachineDokument30 SeitenDrilling MachinePuneeth KumarNoch keine Bewertungen

- Floor PropsDokument5 SeitenFloor Propsidesawy1982Noch keine Bewertungen

- Model V45 Manual Assembly DisassemblyDokument51 SeitenModel V45 Manual Assembly Disassemblyysabel martinezNoch keine Bewertungen

- FNX - 45 Tactical: Carry The Future™Dokument2 SeitenFNX - 45 Tactical: Carry The Future™ATC26Noch keine Bewertungen

- Drip IrrigationDokument9 SeitenDrip Irrigationshirin vohraNoch keine Bewertungen