Beruflich Dokumente

Kultur Dokumente

1 s2.0 0094114X82900465 Main

Hochgeladen von

Anonymous 80p9OVOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

1 s2.0 0094114X82900465 Main

Hochgeladen von

Anonymous 80p9OVCopyright:

Verfügbare Formate

Mechanism and Machine Theory Vo[. 17, No, 4, 235-241, 1982 0094-114X/82/040235--07503.

00/0

Printed in Great Britain. Pergamon Press Lt d

ANALYSIS OF LATERAL VIBRATIONS OF ROTATING

CANTILEVER BLADES ALLOWING FOR SHEAR

DEFLECTION AND ROTARY INERTIA BY REISSNER

AND POTENTIAL ENERGY METHODS "

K. B. SUBRAHMANYAM and S. V. KULKARNI

Department of Mechanical Engineering, Regional Engineering College, Kurukshetra, India

and

J. S. RAO

Department of Mechanical Engineering, Indian Institute of Technology, New Delhi, India

(Received 17 November 1980; in revised form 8 July 1981)

Abstract--The lateral vibrations of a uniform rotating blade have been analysed applying the Reissner and the

potential energy methods. Shear deflection and rotary inertia are taken into account. A convergence study of the

two methods is made and the effects of shear deflection, rotary inertia, rotation and stagger angle on the blade

vibration characteristics are discussed. Comparison of the results indicates a quicker convergence and better mode

shapes by the Reissner method than the classical potential energy method.

INTRODUCTION

A turbomachine blade can be treated as a cantilever

beam mounted on the periphery of a disc at a stagger

angle. The cross section of the beam may be of asym-

metric aerofoil shape and it may have pretwist and

taper. Sometimes, a certain number of such blades are

packeted or they may be laced at one or two locations.

Accurate prediction of the natural frequencies and mode

shapes of such blades when rotating becomes a complex

problem. When the blades are stubby and short or when

higher modes are required to be determined, the shear

deflection and rotary inertia effects are to be considered,

which makes the analysis further complicated. Other

factors which are important are the root and disc flexi-

bility, damping and a host of aerodynamic phenomena

which enter into the blade problem when the tur-

bomachine is under operation. The designer is forced to

estimate the natural frequencies and mode shapes and

also predict the stress and the displacement distributions

in a vibrating blade as accurately as possible to avoid any

possible resonances and consequent fatigue failures.

Several methods of solution of the blade vibration

problem are well developed so far. Solution of the equa-

tions of motion is possible under simplified conditions.

The works of Rao and Carnegie[l], Rao[2] using Galer-

kin process, Rao[3] using collocation method, Carnegie

and Dawson[4] using transformation techniques, Car-

negie, Dawson and Thomas[5], Carnegie and Thomas[6]

using finite difference method are some such examples.

In the continuum model approach the potential and the

complementary energy principles have been used exten-

sively. Rayleigh-Ritz principle was applied by Lo and

Renbarger[7], Houboit and Brookes[8], Carnegie[9],

Subrahmanyam, Kulkarni and Rao[10] et al. In the dis-

crete model approach, the application of Holzer Myk-

iestad, Polynomial frequency equation, station function,

matrix and finite element methods are well known.

Targoff[ll], Rosard[12], Rao and Carnegie[13] used

Holzer-Myklestad type of procedures; Rao and

Banerjee[14] used polynomial frequency equation

method; Mendelson and Gendler[15] applied the station

function approach; Thomson[16] and Plunkett[17] used

matrix methods while Dokainish and Rawtani[18], Gupta

and Rao[19] and Putter and Manor[20] applied finite

element technique in solving the blade vibration prob-

lems.

Each of the above mentioned methods has its inherent

advantages and disadvantages. For example, direct solu-

tion of the differential equations of motion is possible

under very much simplified conditions. The solution

from the finite difference or transformation methods

requires some sort of extrapolations or interpolations to

avoid the matrix sizes becoming large, or else the round

off errors in computation make the results unreliable.

The potential and complementary energy principles do

not give a simultaneously good distribution of stresses

and displacements. The discrete model approaches yield

lower bound solutions because of the discretisation

process of the distributed mass and elasticity while the

pure collocation method, though simple, is not definitely

known to give accurate solutions and wherever it has

been applied, lower bound results were obtained.

From the foregoing discussion on the various classical

methods, it is apparent that the simultaneous deter-

mination of the natural frequencies, mode shapes and

the stress and the displacement distributions is not pos-

sible using any single method. These difficulties can be

eliminated by the application of Reissner method where

it is possible to determine accurately the stresses and the

displacements [21-23] as also the natural frequencies and

mode shapes [10, 24, 25] simultaneously. So far, the static

and the dynamic cases of uniform, pretwisted and

asymmetric blades have been studied by the Reissner

method, but its application to a rotating blade allowing

2 3 5

M M T V o l , 17, N o . 4---A

236

for the effects of stagger angle are not studied. The

objectives of the present paper are, thus, to apply the

Reissner method to a uniform blade mounted on the

periphery of a rotating disc at a stagger angle, allowing for

the effects of shear deflection and rotary inertia. The blade

will be assumed to have coincident mass and elastic axes so

that the torsional coupling can be eliminated, and further

that the blade is untwisted, so as to have pure flexible

vibrations. It is also proposed to develop the solution of the

problem by the potential energy approach using the shape

functions that are identical to those used in the Reissner

method, so that a direct comparison will be possible. A

convergence study is proposed to be made for the natural

frequencies obtained by these two methods, and the

present natural frequencies and mode shapes will be

compared with those available in literature.

K. B. SUBRAHMANYAMand S. V. KULKARNI

where

= y cos 0 + x sin 0 t5}

u = ~ ~ [ ( x 3 2 + ( y ' f ] d Z . ( 6 )

.tO

For the present case of pure flexural vibrations in the

YZ-plane, we have the y-deflection uncoupled with x,

and thus, the total kinetic energy, T, is given by

T = T, + T2= ~ foL [pas:2+ Oh ~ z

- pa W2(R + Z) f : (y,)2 dZ + pa W2Y 2 cos 2 0 ] dZ

(7)

ENERGY FUNCTIONALS

A uniform blade of length L, area A, Young's modulus

E, rigidity modulus G and mass density p is mounted on

the periphery of a disc of radius R, rotating at a constant

angular velocity W. xx-, yy-axes are principal centroidal

axes of inertia and I ~ is least moment of inertia, r l ~ - ~

are another set of orthogonal axes through the centroid

of the cross section at root and are placed such that

"0~7-axis lies in the plane of disc rotation and makes an

angle 0 with xx-axis, thus 0 is stagger angle.

Any point on the blade axis is measured with the

co-ordinate Z, along the longitudinal axis ZZ with the

origin at root section. The blade is assumed to perform

pure flexible vibrations in the YZ-plane. Denoting the

dynamic deflection and bending slope by y and 4' and the

bending moment and the shearing force by M and V,

with dash over a quantity representing differentiation

w.r.t. Z, and a dot over a parameter representing a time

derivative, we can write the Reissner functional IR and

Potential energy functional 7r as follows[10]

V 2 M 2

(1)

~r -- ,~ ( L [ ELAn' ) 2 + KGA( y ' - 402] dZ. (2)

Jo

In writing the above equation, we have taken the shear

deflection into account, thus K is the shear coefficient.

The kinetic energy for vibrations in YZ-plane, T1,

allowing for rotary inertia effects[10] is given by

fO L

T I = [pAy: 2 + pI~ck 21 d Z . (3)

The additional kinetic energy due to centripetal effects,

T2, as given by Carnegie[9] for the case of coupled

vibrations, neglecting higher order effects, is

T2 = rio L [2pAW2( R + Z)u + pAWZ z

+ 2pAW(~u - niJ) dZ ( 4 )

Us i ng eqns (1, 2, 7), we can f or mul a t e t he

d yn a mi c Re i s s ne r f unct i ona l and t he La gr a ngi a n

as f ol l ows

LR = T - IR (8)

L,, = T - ~r. (9)

The t i me a ve r a ge d val ues of t he a bo ve f unc-

t i onal s can be obt a i ne d by Ri t z a ve r a gi ng pr oce s s

as

2w/p

L~ = LR dt

fO 1rIp

LTr = L~ dt .

t he f ol l owi ng I nt r oduci ng

pa r a me t e r s

and

( 1 o )

(11)

non- di me ns i ona l

Z R

z = - - ; 1~ =

L

~2= Lx/ AL2; dz d Z

L

2

a = h W 2 whe r e m = pA (12)

= mL4/ Eh~ ; ~2= GK/ E, (13)

We can r e wr i t e e qns (10, 11) as f ol l ows a f t e r

pe r f o r mi n g t he n e ce s s a r y ca l cul us and not i ng t he

t r a n s f o r ma t i o n of t he i nt egr al t e r ms unde r an i n-

tegral sign as given by Kilmister and Carnegie[26]

fo I [P2AEI,~, 2 a2EI,~

LR

- 2 L ~ ( y ' ) ~ { / ~ ( l - z ) + ( I - z 2 ) } + M~'

~2L2 2 E~ ]

- V( y' - ~) + ~ V2+ ~dZ ( 1 4 )

Lateral vibrations of a uniform rotating blade

~rEI~, f ~ [p2Xy2 + p2A~2L2~2_ o t 2 L2 ( y, ) 2

x {/](1 - z) + (1 - z 2) + ot2y 2 cos 2 0

- L ' ( * ' ) - ~ ( y ' - * ) 2] dz. (15)

In t he a bo ve e qua t i ons , X is t he nondi me ns i ona l

f r e que n cy pa r a me t e r , a 2 i s t he r ot a t i ona l

pa r a me t e r , /~2 is t he non- di me ns i ona l s he a r

pa r a me t e r and ~ i s t he r a di us of gyr a t i on pe r uni t

l engt h.

FREQUENCY EQUATIONS

Shape lunctions

The following shape functions for y, ~b, M and V are

assumed in series form

y = ~ {A,z' + A,+~z '+t} (16)

$ = ~ {B,z' + B,+,z '+t} (17)

M = ~ {C,(I - z)' + C,+,(I - z) '~} (18)

V = ~ {D,(1 - z)' + D,+,(1 - z) ' +' } (19)

which satisfy the boundary conditions

y = 4 ~ = 0 a t Z = 0

M= V = 0 a t Z = L . (20)

The arbitrary constants A,+I and B,+, are eliminated

from the conditions

( y ' - ~) = $' = 0 at z = 0 (21)

and C,+, and D,+t are eliminated from the conditions

M' = V; V' = 0 (22)

throughout the length of blade.

Eigen value problems

Substituting the shape functions developed above in

eqns (14) and (15), performing the necessary calculus and

applying the Ritz process, wherein

3 LR=0 ; OLR 3LR ^ 3L~

0A---~- ~ = 0; ~ = U; ~ = 0 (23)

0L~r =0; OLzr ^

OAk ~ = O; k = 1., 2 . . . . . (24)

We get the familar eigenvalue problems which can be

written in the following form

A + p 21] = 0. (25)

In the above equation, k and B are symmetric square

237

matrices and hence only the elements in the upper trian-

gular portion are mentioned in Appendix 1 for each

method treated, for a finite n-term solution.

METHOD OF SOLUTION

The eigen value problems defined by eqn (25) are

solved using computer programs developed in fortran

language. The program evaluates the magnitude and al-

gebraic sign of the determinant A=I A+p2 BI for an

arbitrary chosen value p sufficiently lower than the fun-

damental flexible mode of standstill blade. The value of p

is increased in small steps till the determinant tends to

zero. The true natural frequency lies at the value of p

making A equal to zero, but to accelerate the frequency

evaluation, we set the accuracy such that any two suc-

cessive iterations separated by an interval equal to 0.0001

times the starting value and having opposite algebraic

signs of the determinant will give the natural frequency

of the mode. Next higher mode will be obtained in the

same fashion as above but with a starting trial value

being taken as 1.01 times the natural frequency of pre-

vious mode. In present investigation, the starting trial

frequency is taken as classical flexural frequency of the

blade (in flexible direction) in cycles per second. The

value obtained from the computer program will be in

radians per second.

The mode shapes are obtained by solving any (n - 1)

of the total n-equations in the matrix equations A+

p2B = 0 in terms of the nth one taken as unity, substitut-

ing the values of the arbitrary parameters thus deter-

mined for each natural frequency in the respective shape

functions and normalizing them to represent the relative

amplitude along the length of the blade.

NUMERICAL EXAMPLE AND RESULTS

The following numerical example relating to a typical

turbomachine blade [2] is chosen to check the analysis

L = 91.948 mm

A = 82.580 mm 2

p = 0.00783 kg/cm 3

E = 206.85 GPa

hx = 577.729 mm 4

W = 540.350 rad/sec

R = 263.652 mm

G = 82.74 GPa

K = 10(1+ v)/(12+ l l v)

(3.62 in.)

(0.128 sq. in.)

(0.283 Ib/in. 3)

(30 x 106 Ib/in. 2)

(0.001388 in?)

(10.38 in.)

(12 x 106 lb/in. 2)

where v is Poi sson' s ratio.

The results obtained are discussed below.

Table 1 shows the theoretical classical frequencies and

frequencies corrected for shear and rotary inertia

effects[27] for the blade example considered. Tables 2

and 3 show the convergence pattern shown by the

potential energy method and the Reissner method, res-

pectively, for various number of terms in the assumed

solution for a standstill blade. The convergence pattern

observed in the case of a rotating blade is similar to the

one shown for the standstill case and thus, the frequen-

cies obtained with the 3- and 4-term solutions of the

Reissner method and those obtained with a 5 term

potential energy solution are presented in Table 4. Two

238 K.B. SUBRAHMANY~M

Table 1. Theoretical natural frequencies (rad/sec)

Mode Number 1 I1 I11

Uncorrected

classical value 5654.07 35436JX) 99231.82

Corrected for Shear

and rotary inertia

effects[27/ 5608.84 33664.20 87323.28

cases of stagger angle setting are consi dered, that is

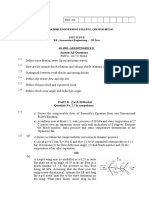

0 = 9 0 and 0=47. 8696 . Figure 1 shows the mode

shapes obtained from the potential energy approach and

Figure 2 shows the mode shapes gi ven by the Rei ssner

met hod for a standstill blade. Figure 3 shows t he mode

shapes obtained from t he Rei ssner met hod for bot h the

stagger angle settings. Fr om t hese results, the individual

effects are discussed below.

CONVERGENCE

Fr om Tables I-3(A), it can be seen that the Rei ssner

met hod indicates a qui cker convergence. The fundamen-

tal tlexural fr equency is obtained with an error of about

3.6% for both standstill and rotating blades using only

one term as compared to the exact value in t he Rei ssner

met hod and t here is negligible error with a 2-term solu-

tion. Correspondi ng errors in case of potential energy

met hod are 128% with a l-t erm solution and about 1.05%

with a 2-term solution. A 5-term Rei ssner solution gi ves

the first t hree modes accur at ely while a 6-term solution

shows a similar accur acy in the case of t he potential

energy method.

and S. V, KI I.K,',.RNI

Comparing the converged values of the naturat

fr equenci es of the standstill blade with the correspondi ng

classical values gi ven in Table 1, we obser ve that there is

a reduct i on in these fr equency values and that the

present standstill frequenci es agree closely with those

from Southerland and Goodman[27/.

Effects of shear deflection and rotary inertia

Table 3(B) gives the rotating blade frequenci es per-

taining to a 4-term Rei ssner solution of the present

i nvest i gat i ons and those by Galerkin process given by

Rao[2] neglecting shear and rotary inertia effects. Also

the squared values of t he fr equency ratio (theoretical

fr equency of rotating blade/standstill uncorrect ed clas-

sical fr equency) 2 are calculated and are compared with

t hose of Rao[2] in Table 4. This table shows also a

furt her compari son with the squared values of fr equency

ratios proposed in the form of fr equency relations for the

first t hree modes by Rao[2].

From t hese tables it can be seen that when the stagger

angle is 90 , the percent age reduct i ons in the squared

value of the fr equency ratio calculated on the basis of

the Rei ssner method results are 1. 507, 10. 508 and

22.774%, respect i vely, for the first three modes in com-

parison with the Galerkin values, which ignores the shear

and rotary inertia effects. When the stagger angle is

47.87(cos 2 0 = 0.45) the correspondi ng reduct i ons in the

fr equency ratio squared values are 1.4896, 10.4969 and

22.774%, respect i vely, for the first three modes. Fr om

t hese results, it is obvi ous that the shear and the rot ary

inertia effects when taken into account , lower the

fr equency values of the rotating blade, such reduct i on

being more predomi nant af higher modes. Further, it may

Tabte 2. Convergence pattern: potential energy

method standstill blade

Number of Natural frequency (rad/sec)

terms in

solution I Mode II Mode Ill Mode

1 12788.05 - - - -

2 5667.96 64773.1 - -

3 5612.30 3 4 2 61 . 6 154548.2

4 5612.30 3 3 8 4 3 . 7 91962.7

5 5612.30 3 3 7 0 3 . 1 90244.0

6 5612.30 33703.1 89101.4

Table 3(A). Convergence pattern, Reissner method

standstill blade

Number of Nature of frequency (rad]sec)

terms in

solution I Mode II Mode 1II Mode

1 5812.8 - - - -

2 5609. 9 38368.2 - -

3 5612.3 3 3 7 0 8 . 9 111778.2

4 5612.3 3 3 6 7 1 . 8 89581.9

5 5612.3 33671.8 89019.9

Table 3(B). Rotating blade frequencies

to = 540.35 rad/sec : ~ = 2.86743

Mode

number

cos 2 0 Presented results by % increase Results by

Reissner method over the Galerkin process

allowing for shear corresponding Rao[2], neglecting

and rotary inertia standstill shear and

frequency rotary inertia

% increase

over the corres-

ponding standstill

classical frequency

1 0.0 5576.83 2.58 5800.04

II 0.0 33832.0 0.313 35565.0

III 0.0 89677.6 0.107 99365.6

I 0.45 5746.09 - - 5788.73

II 0.45 33832.0 - - 35563.3

III 0.45 89677.6 - - 99365.6

2.58

0.364

0.135

Lateral vibrations of a uniform rotating blade

Table 4. Comparison of rotating blade frequencies

[ Theoretical frequency of rotating blade ]2

P r= (Pt[Ps)2 = LClassi-~al ~ ~ u e n c - ~ - d ~ blade

w = 540.35 rad/sec; J~ = 2.86743

239

Present results allowing for shear and rotary inertia

Reissner Method (P2r) Potential energy (P~)

Mode cos 2 0 3-term 4-term 5-term

number solution solution solution

Rao [21

Neglecting shear &

rotary inertia (p2)

Galerkin Frequency

relation

I 0.0 1.036679 1.036679 1.036679 1.0523 1.0518

II 0.0 0.911837 0.911519 0.911519 1.0073 1.0073

III 0.0 1.271713 0.816706 0.829743 1.0027 1.0025

I 0.45 1.032815 1.032815 1.032815 1.0482 1.0478

II 0.45 0.911519 0.911519 0.911519 1.0072 1.0072

III 0.45 1.271713 0.816706 0.829743 1.0027 1.0025

also be observed that the percentage reduction in the

natural frequency due to shear and rotary inertia cor-

rection value for the stand still blade and the rotating

blade with 0 = 90 o or 0 = 47.87 is almost same, if we

compare the present results with the standard classical

values in case of standstill blade with the results of

Rao[2] using Galerkin process for the rotating blade.

This implies that the percentage reduction due to shear

and rotary inertias will be almost the same whether the

blade is standstill, or rotating with any stagger angle

setting.

Effects of rotation and stagger angle setting

Comparing the results, given by the Reissner method

with a 4-term solution, of the rotating blade with the

corresponding standstill values, we observe that the

flexural modes are stiffened due to the rotational effect.

The stiffening pattern can be understood by considering

the percentage increase in the first two modal frequen-

cies because of rotation, which are 2. 58 and 0.313%,

respectively for the first two modes as shown in Table

3(B). The corresponding values from the Galerkin

process for the rotating blade and standstill classical

frequencies are 2.58 and 0.364%, respectively.

From these results, it can be concluded that the first

bending mode is having the largest percentage increase in

the frequency value due to rotation and higher modes

show little variation in the frequency value due to rota-

tion. Further, the present results show a similar trend of

stiffening pattern as observed by Rao[2] using Galerkin

process.

A comparison of the natural frequencies of the rotat-

ing blade with different stagger angle settings indicates

that there is a lowering of the fundamental frequency

value when the stagger angle is changed from 90 to

47.870 . The second and the third modes show in-

significant changes. Schilhansl[28], Rao[2], Rao and

Carnegi e[l], Carnegie, Stifling and Flemming[29] et al.

have observed that the frequency decrease can be

represented by a linear variation proportional to cos20

and that the effect of stagger angle setting becomes

insignificant for modes other than the fundamental

flexural mode. Present results are consistent with their

observation.

Mode shapes

Figure 1 and 2 show the mode shapes of a standstill

blade obtained from the potential energy method and the

Reissner method, respectively. The nodal location shown

by the modal curves of the Reissner method are close to

the exact ones[30] while such agreement is relatively

poor in case of the potential energy method. Considering

,o[

i 0 , t I . . . . j /

z o2~ i . . J r ' - ' ,,. /

, , '..

' f

-0"2 5612.3 r od/ see. \ I ~

"~ I l l Mode - ~' X"x j / x

06[ n Mode ~ ' ,

" " [ 89101"/., 3 rod/see. ~ - " / ~ x

J 33703"1 r a d i s h , x

. I . 0 / I I I I i i I ' ,

0 0.2 0. 4 0-6 O.O 1.0

z = Z / t

Fig. I. Rexu ral mode shapes: potential energy method (Standstill

blade).

I ~ Mode 3 . , i

~ " I~ Mo d e ~ ' \ / . ' ~

~._0.6 I. 89019'9rod/see. "\.... / ' ~f' ~

| II ModJ-3" ' , ,

_, . 0 [ . . . . . o /se t ' ,

0 0 . 2 0 " 4 0 " 6 0 . 8 1 '0

z = Z/ L

Fig. 2. Flexural mode shapes: Reissner method (Standstill blade).

240

1.0[ ( 5756.83 r o d / s e e /

/

I

o L-~' (~ ' ~

I BENDING

K. B, SUBRAHMANYAM and S. V. KIilKARNI

w : SZ, 03S rc~d/~ec co~ @: 0

1.0[ ( 33852.0 radlsec )

1 \ 1 . o

:?ol \

I I BENDING

w : 540.35 rod/ sec , c ol ~ : 0 4 5

, o r ( 8 9 6 7 7 . ~ , r a d l s e c ) [

III BENDING

1.0

CtTS

Y o.5o

(9.25

o

05 1.0

I BENDING

1 , 0 [ ( 338 32 . 0 r a d/ s ec )

/

I I BEND(NG

1.0 F ( 8967Z6 rctd~ec I I

/ o / , 0

III BENDING

Fig. 3. Model curves of rotating uniform blade: Reissner Method.

the case of rotating blade, the mode shapes obt ai ned

from the pot ent i al energy met hod are similar to those

from the Rei ssner met hod (Fig. 3) but the second mode

shown slightly less relative magni t ude at z = 0.5 and the

third mode shape, being obt ai ned with the 5-term solu-

tion where the fr equency has not converged, could not

properly be compared. Thus onl y the modal curves given

by the Rei ssner method for 0 = 90 and 0 = 47.87 are

presented. It can be seen from these mode shapes that

they resemble very closely the respect i ve standstill

modes (Fig. 2) and furt her that the stagger angle

setting does not alter the mode shapes of the rotating

blade.

CONCLUSIONS

The Rei ssner and the potential energy methods are

successfully applied to the case of a uni form rotating

blade execut i ng lateral vibrations. It has been observed

that the Reissner method indicates a quicker con-

vergence and gives bet t er mode shapes in compari son

with the classical potential energy approach. It is expec-

ted that the present investigation would be of consi der-

able use in developing the Rei ssner method to a more

complicated blade vi brat i on problem i nvolvi ng pretwist,

taper and asymmet ry, and i n det ermi ni ng the forced

response of the bladi ng since the met hod shows excellent

convergence for stresses [22] and displacements.

Acknowledgements--The authors gratefully acknowledge the

financial assistance rendered by the University Grants Com-

mission, Government of India, for this investigation.

REFERENCES

I. J. S. Rao and W. Carnegie, Aero. J. Roy. Aero. Soc. 74, 161

(1970).

2. J. S. Rao, J. Aero. Soc. India 22, 257 (1970).

3. J. S. Rao, Proc. Ind. Soc. Theo. App. Mech. 17, 211 (1972).

4. W. Carnegie and B. Dawson, Aero. Q 20, 178 (1969).

5. W. Carnegie, B. Dawson and J. Thomas, Proc. Inst. Mech.

Engrs 180, 71 (1965).

6. W, Carnegie and J. Thomas, Aero. Q. 18, 309 (1%7).

7. H. Lo and J. Renbarger, Ist. Proc. U.S. Nat. Cong. AppL

Mech. 75 (1952).

8. J. C. Houbolt and G. Brookes, NACA Report 1346 (1958).

9. W. Carnegie, J. Mech. Engng Sci. 1 235 (1959).

10. K. B. Subrahmanysm, S. V. Kulkarni and J. S. Rao, J. Sound

and Vib. 75, Preprint I (1981).

11. W. P. Targoff, J. Aero. Sci. 14, 579 (1947).

12. D. D. Rosard, J. App. Mech. Trans. ASME 20, 241 (1953).

13. J. S. Rao and W. Carnegie, Int. J. Mech. Engng Educ. 1, 37

(1973).

14. J. S. Rao and S. Banerjee, Mechanism and Machine Theory

12, 271 (1977).

15. A. Mendelson and S. Gendler, NACA TN 2185 (1949).

16. W. T. Thomson, J. App. Mech. Trans ASME 17, 337 (1950).

17. R. Plunket, J. Aero. Sci. 18, 278 (1951).

18. M. A. Dokainish and S. Rawtani, AIAA J. 1O, 1397 (1972).

19. R. S. Gupta and S. S. Rao, 3". Sound Vib. 56, 187 (1978).

20. S. Putter and H. Manor, J. Sound Vib. 56, 175 (1978).

21. K. B. Subrahmanyam, S. V. Kulkami and J. S. Rao, Proc.

23rd Cong, ISTAM, 113 (1978).

22. K. B. Subrahmanyam, S. V. Kulkarni and J. S. Rao, Proc.

24th Cong. ISTAM Paper No. MS-33 (1979--80).

23. K. B. Subrahmanyam, S. V. Kulkarni and J. S. Rao, Sub-

mitted to J. Aero. Soc. India (1980).

24. J. S. Rao, S. V. Kulkarni and K. B. Subrahmanyam, To

appear in J. Appl. Mech. ASME shortly.

25. K. B. Subrahmanyam, S, V. Kulkarni and J. S. Rao, Proc.

Int. Syrup. Nonlin. Cont. Mech. and Silver Jub. Cong.

ISTAM. Kharaqpur, Dec. 17-20 (1980).

26. C. W. Kilmister and W. Carnegie, Bulletin Mech. Eng. Edu.

4, 49 (1965).

27. R. L. Southerland and L. E. Goodman, Rep. N6-ORI-71

TO-6 Project NR-064-183. 1 (1951).

28. M. J. Schilhansi, J. App. Mech. Trans ASME 25, 28 (1951).

29. W. Carnegie, C. Stifling and J. Flemming, Proc. Inst. Mech.

Eng. 180, 124 (1%5).

30. C. M. Harris and C. E. Crede, Shock and Vibration Hand-

book, Vol. 1, p. 7. McGraw-Hill, New York (1%1).

L a t e r a l v i b r a t i o n s o f a u n i f o r m r o t a t i n g bl a d e 241

APPENDIX

ELEMENTS OF MASS AND b'l'ltl,~f..g.S MATRI CES

Rei ssner met hod

A,.~ = T A ( T 4 + T I . c o s 2 0 ) / L

Ai, i+. = T A ( T 2 . c o s 2 0 - R4 . $ 3 . T5 )

Ai, i . 2, = - T7

A~+.,~+. --- L . T A{ R2 . $ 2 . co s 2 / ( Q + 3) - T6}

Ai+.,i+2. = T8

A i + . , i ~ 3 . = T7

A~+2.,i+3. = U I. R3. S3/(Q + I) + U 2 . R2. S2/(Q + 3)

Ai +2, , j +3, = - U1 . R3 . S21L( Q + 1)

Ai+3,,i*~. = R 3 . $ 3 . UI / L ~ ( Q+ 1)

Bi, j +. = T B . T2

Bi , j = T B . T l l L

B~+.,~+. = T B . R 2 . S2 / ( Q + 3) + 52 . T I l L

T A = a 2EL~/ L ~

TB = hEI , ~/ L ~

T I = I ( Q+ I ) - ( R I + S1) I ( Q+ 2) + R I . S I / ( Q+ 3)

T2 = S 2 / ( _ Q+ 2 ) - R 1 . S2 / ( Q + 3)

T4 = i . i [ 6R( Q - 2 ) ! / ( Q + 2 ) ! - ( Q - 2 ) ! / ( Q + 1)!

- Q ! I ( Q + 3 ) ! ]

T5 = 2 R( Q - 1) ! / ( Q + 2)! + ( Q - 1) ! / 2( Q + 1)!

- ( Q + I ) I / 2 ( Q + 3 ) !

T6 = R 3 . S3{ RQ! I ( Q + 2)! + 0 . 5 / ( Q + 1 ) - 0. 51(Q + 3)}

T7 = i ! j ! / L ( Q + 1)!

T8 = - R3 . S 3 . L . T7

U 1 = L2~21EIxxk 2

U2 = Le / ELx ; Q = ( i + j )

R1 = i(i + i ) ; R2 = 1(i + i ) i R3 = l ( i + 1); R4 = i

S1 = j / (j + 1); S2 = 1(] + 1) ; S3 = 1(] + 1); S4 = j

Pot ent i al energy met hod

Ai,~ = - c t 2 T 4 - [ z T9/~Z + a 2 T I c o s 2 O

Ai , j . = - a 2 L . R4 . $ 3 . T5 + / ~ 2 U3/ P2

+ a ~ . L . T2 . c o s 2 0

Ai ,,~+. = - a2L 2 T 6 - L ~ . T 9 - ~2, T5/~2

+ ~2 L 2 . R2 . $ 2 COS 2 O/(Q + 3)

B~, j = - h . Tl

Bi, j +. = - h. L , T2

Bi +. , i . = - ~.. L ~ , R2 . S2 / ( Q + 3) - L 2 ~ . TI

T9 = 2 . R4 . S 4 ( Q - 2 ) ! / ( Q + 1)!

u3 = 2. L . R 4 . S I ( Q- 1) ! / ( Q + 2)!

A N ~ E DER S E I T ~ h ~ N G U N G ~ N ~ O T ~ E E E N D ~ BALEEN UNTER ~SRUCEBICHTIGUNG DER SCHUBVERSCHIEB~NG

R O T A T I ~ T I ~ G H E ~ T IIIT~JILB ANSTZ N~CH , P ~ S N E R UND I~Y~ENTIELLE-ENE~GIE-m~ETHODE

K. B. Bub~ahman~am, S. V. Kulkarni u n d J. B. Rao

K ~ G C a s s u n H - Die Beitensohwingtuagen elnez gleichmKSig rotle~enden S c h a u f e l warden un~er A n w e n -

d u n g des Ansatzes n a o h ReissneE u n d des k l a s s l s c h e n Ansatzes dee potentlellen Eme~gie analyllert.

Die 8ohubve~sohieb~ng u n d R o t & t l o n s t r ~ h e l t w e z d e n be~Gckslahtigt. Die Konvergenz der zwei M e t h o -

d e n w i E d un~e~muaht 0 u n d die Einflt~sse der 8ohubveEschiebungp der R o t a t i o n s - u n d 8 t a f f e l u n g s w l n -

k e l auf d i e Sohwingun~selgensohAften w e ~ d e n besp~ochen. E l m V e r g l e l c h der Ergebnisse zeigt~ da~

d e ~ RelssneEansatz sohnelle~e Konve~genz bzin~t u n d b e s s e ~ e 8ohwlngungsfo~men im V e r g l e i c h zum

k l a s s i s ~ h e n Ansatz de~ po~entlellen E n e ~ i e e~glbt.

Das könnte Ihnen auch gefallen

- Understanding Vector Calculus: Practical Development and Solved ProblemsVon EverandUnderstanding Vector Calculus: Practical Development and Solved ProblemsNoch keine Bewertungen

- Multilinear Functions Of Direction And Their Uses In Differential GeometryVon EverandMultilinear Functions Of Direction And Their Uses In Differential GeometryNoch keine Bewertungen

- A Higher-Order Shear Deformation Theory of Laminated Elastic ShellsDokument12 SeitenA Higher-Order Shear Deformation Theory of Laminated Elastic Shellsadel8888Noch keine Bewertungen

- Young's Modulus, Shear Modulus, and Poisson's Ratio in Silicon and GermaniumDokument5 SeitenYoung's Modulus, Shear Modulus, and Poisson's Ratio in Silicon and GermaniumMisti LucasNoch keine Bewertungen

- (Received 20 July 1999 Accepted For 9 December 1999) : 0093-6413 0t$ - T Mater P L L: I 3 (N) N O ? 8 - 1Dokument8 Seiten(Received 20 July 1999 Accepted For 9 December 1999) : 0093-6413 0t$ - T Mater P L L: I 3 (N) N O ? 8 - 1Leonardo LagoNoch keine Bewertungen

- M. Herrmann - Modeling Primary Breakup: A Three-Dimensional Eulerian Level Set/vortex Sheet Method For Two-Phase Interface DynamicsDokument12 SeitenM. Herrmann - Modeling Primary Breakup: A Three-Dimensional Eulerian Level Set/vortex Sheet Method For Two-Phase Interface DynamicsPonmijNoch keine Bewertungen

- 1 s2.0 S0020740396000781 MainDokument17 Seiten1 s2.0 S0020740396000781 MainAgustín Erasmo Juárez MartínezNoch keine Bewertungen

- 2-67-1380635423-13. Calculating Static Deflection - FullDokument12 Seiten2-67-1380635423-13. Calculating Static Deflection - Fullniaz kilamNoch keine Bewertungen

- RR Solution For Sym Angle-Ply - Liew Et AlDokument14 SeitenRR Solution For Sym Angle-Ply - Liew Et AlnadipallsrirajNoch keine Bewertungen

- A Finite-Difference Scheme For Three-Dimensional Incompressible Flows in Cylindrical CoordinatesDokument13 SeitenA Finite-Difference Scheme For Three-Dimensional Incompressible Flows in Cylindrical CoordinatesGalyna RomanNoch keine Bewertungen

- Eigen-Energies and Wavefunctions of Symmetroidal Quantum DotsDokument14 SeitenEigen-Energies and Wavefunctions of Symmetroidal Quantum DotsCarlos EduardoNoch keine Bewertungen

- Non-Linear Vibrations of Simply Supported Rectangular Cross-Ply PlatesDokument14 SeitenNon-Linear Vibrations of Simply Supported Rectangular Cross-Ply PlatesadigraduNoch keine Bewertungen

- Vibration of Non-Uniform Rods An - TuyenDokument14 SeitenVibration of Non-Uniform Rods An - TuyenNguyen Danh TuyenNoch keine Bewertungen

- FulltextDokument15 SeitenFulltextjinshadNoch keine Bewertungen

- Torsional Vibration Analysis of Shafts Based On Adomian Decomposition MethodDokument18 SeitenTorsional Vibration Analysis of Shafts Based On Adomian Decomposition MethodRonald GeorgeNoch keine Bewertungen

- C. Ruth Le Sueuer Et Al - On The Use of Variational Wavefunctions in Calculating Vibrational Band IntensitiesDokument10 SeitenC. Ruth Le Sueuer Et Al - On The Use of Variational Wavefunctions in Calculating Vibrational Band IntensitiesPassammNoch keine Bewertungen

- Geometrically Exact 3D Beam Theory: Implementation of A Strain-Invariant Finite Element For Statics and DynamicsDokument31 SeitenGeometrically Exact 3D Beam Theory: Implementation of A Strain-Invariant Finite Element For Statics and DynamicsAleff Gonçalves QuintinoNoch keine Bewertungen

- Rotation Formulations For Dynamic Relaxation - With Application in 3D Framed Structures With Large Displacements and RotationsDokument8 SeitenRotation Formulations For Dynamic Relaxation - With Application in 3D Framed Structures With Large Displacements and RotationsGene KaoNoch keine Bewertungen

- Disk New OrleansDokument11 SeitenDisk New Orleansd882011Noch keine Bewertungen

- OATAO Repository Provides Free Access to ResearchDokument16 SeitenOATAO Repository Provides Free Access to ResearchAnonymous LU3Dz3TKtVNoch keine Bewertungen

- I. Senjanović, N. Alujević, I. Ćatipović, D. Čakmak, N. VladimirDokument47 SeitenI. Senjanović, N. Alujević, I. Ćatipović, D. Čakmak, N. VladimirEok Su LeeNoch keine Bewertungen

- Transverse Vibrations of A Rotating Uniform Cantilever Beam With Tip Mass As Predicted by Using Beam Characteristic Orthogonal Polynomials in The Rayleigh-Ritz MethodDokument12 SeitenTransverse Vibrations of A Rotating Uniform Cantilever Beam With Tip Mass As Predicted by Using Beam Characteristic Orthogonal Polynomials in The Rayleigh-Ritz MethodHassanImranNoch keine Bewertungen

- Slope Stability Analysis Based On The Rigid FiniteDokument17 SeitenSlope Stability Analysis Based On The Rigid FiniteLutfiadji Agung HidayatNoch keine Bewertungen

- Resonant Column Technical PaperDokument8 SeitenResonant Column Technical PaperMichele PusateriNoch keine Bewertungen

- 1992 ASCE (1992) Seismic Response of Rotating MachinesDokument16 Seiten1992 ASCE (1992) Seismic Response of Rotating MachinesBilal LoveNoch keine Bewertungen

- J P DwivediDokument15 SeitenJ P DwivediManoj UpadhyayNoch keine Bewertungen

- Louise Dolan and Peter Goddard - Tree and Loop Amplitudes in Open Twistor String TheoryDokument54 SeitenLouise Dolan and Peter Goddard - Tree and Loop Amplitudes in Open Twistor String TheoryGum0000Noch keine Bewertungen

- Trindade Wolter Sampaio 2005 JSVDokument22 SeitenTrindade Wolter Sampaio 2005 JSVhlsmonteiroNoch keine Bewertungen

- 1 s2.0 0013794483900048 Main PDFDokument8 Seiten1 s2.0 0013794483900048 Main PDFshashank soniNoch keine Bewertungen

- Incidence Angle NormalizationDokument3 SeitenIncidence Angle NormalizationNguyen Ba DuyNoch keine Bewertungen

- Non-linear vibrations of cantilever skew platesDokument14 SeitenNon-linear vibrations of cantilever skew platesMOFEEZALAMNoch keine Bewertungen

- L.O. Baksmaty Et Al - Tkachenko Waves in Rapidly Rotating Bose-Einstein CondensatesDokument4 SeitenL.O. Baksmaty Et Al - Tkachenko Waves in Rapidly Rotating Bose-Einstein CondensatesPomac232Noch keine Bewertungen

- Direct numerical simulations reveal vortex ring dynamics at ReΓ = 7500Dokument11 SeitenDirect numerical simulations reveal vortex ring dynamics at ReΓ = 7500Shakib AhmedNoch keine Bewertungen

- Theories and Analyses of Thin and Moderately Thick Laminated Composite Curved BeamsDokument14 SeitenTheories and Analyses of Thin and Moderately Thick Laminated Composite Curved BeamsTejas GotkhindiNoch keine Bewertungen

- orris1973Dokument20 Seitenorris1973Supantho ChaudhuriNoch keine Bewertungen

- Finite Element Analysis of Natural Whirl Speeds of Rotating ShaftsDokument7 SeitenFinite Element Analysis of Natural Whirl Speeds of Rotating ShaftsmanojNoch keine Bewertungen

- Mindlin Eshel 1968Dokument16 SeitenMindlin Eshel 1968Don't BeCuriousNoch keine Bewertungen

- Application of Differential Transform Method in Free Vibration Analysis of Rotating Non-Prismatic BeamsDokument8 SeitenApplication of Differential Transform Method in Free Vibration Analysis of Rotating Non-Prismatic BeamsKhairul Anuar RahmanNoch keine Bewertungen

- Airfoil AnalysisDokument38 SeitenAirfoil Analysistanha56313955Noch keine Bewertungen

- Uniform Asymptotic Formulae For The Spheroidal Radial FunctionDokument9 SeitenUniform Asymptotic Formulae For The Spheroidal Radial FunctionLuLa_IFNoch keine Bewertungen

- Aeroelastic Analysis of A Flexible Airfoil With A Freeplay NonlinearityDokument24 SeitenAeroelastic Analysis of A Flexible Airfoil With A Freeplay NonlinearityDhrubajyoti SarmaNoch keine Bewertungen

- Study of Dynamic Properties of Rocks Around An Underground Opening Using Seismic Inverse TechniquesDokument11 SeitenStudy of Dynamic Properties of Rocks Around An Underground Opening Using Seismic Inverse Techniquesavijitdey1975Noch keine Bewertungen

- Davis 1972Dokument16 SeitenDavis 1972Akshat RastogiNoch keine Bewertungen

- Rare-Earth Nuclei: Radii, Isotope-Shifts and Deformation Properties in The Relativistic Mean Field TheoryDokument52 SeitenRare-Earth Nuclei: Radii, Isotope-Shifts and Deformation Properties in The Relativistic Mean Field TheoryBayer MitrovicNoch keine Bewertungen

- Steven Miller Et Al - Infrared Emissions of H3 + in The Atmosphere of Jupiter in The 2.1 and 4.0 Micron RegionDokument20 SeitenSteven Miller Et Al - Infrared Emissions of H3 + in The Atmosphere of Jupiter in The 2.1 and 4.0 Micron RegionPassammNoch keine Bewertungen

- Icwe Full-Paper PDFDokument10 SeitenIcwe Full-Paper PDFAnonymous FYiVPYgXVUNoch keine Bewertungen

- Longitudinal Deformation Profile of A Tunnel Driven Within A Burger Rock MassDokument9 SeitenLongitudinal Deformation Profile of A Tunnel Driven Within A Burger Rock MasswolvesyNoch keine Bewertungen

- Bending of Thin Circular RingsDokument14 SeitenBending of Thin Circular RingsozkanhasanNoch keine Bewertungen

- Modeling and Analysis of A Jeffcott Rotor As A Continuous Cantilever Beam and An Unbalanced Disk System (#98112) - 83763Dokument9 SeitenModeling and Analysis of A Jeffcott Rotor As A Continuous Cantilever Beam and An Unbalanced Disk System (#98112) - 83763YasirNoch keine Bewertungen

- CS 2006Dokument7 SeitenCS 2006Dhana JayanNoch keine Bewertungen

- Analysis of The Moiré Pattern of Moving Periodic Structures Using Reciprocal Vector ApproachDokument10 SeitenAnalysis of The Moiré Pattern of Moving Periodic Structures Using Reciprocal Vector Approachklounas2003Noch keine Bewertungen

- Hoa 1979Dokument13 SeitenHoa 1979Ciprian ComanNoch keine Bewertungen

- 1-Wave Propagation in A Curved Waveguide With Arbitrary Dielectric Transverse ProfilesDokument20 Seiten1-Wave Propagation in A Curved Waveguide With Arbitrary Dielectric Transverse ProfilesNaserYousefzadehNoch keine Bewertungen

- Global Attitude/position Regulation For Underwater Vehicles: D M. B M KDokument8 SeitenGlobal Attitude/position Regulation For Underwater Vehicles: D M. B M KЋирка ФејзбуџаркаNoch keine Bewertungen

- Dynamic Interaction of Surface Machine Foundations Under Vertical Harmonic ExcitationDokument18 SeitenDynamic Interaction of Surface Machine Foundations Under Vertical Harmonic ExcitationSayed ElarabyNoch keine Bewertungen

- Hydroelastic Behaviour and Analysis of Marine StructureDokument18 SeitenHydroelastic Behaviour and Analysis of Marine StructureAnonymous JEe6LWPNoch keine Bewertungen

- Infinite Elements For 3 Dimensional Wave - Structure Interaction Problems 1992Dokument12 SeitenInfinite Elements For 3 Dimensional Wave - Structure Interaction Problems 1992ciscoNoch keine Bewertungen

- Sivam Oh An 1985Dokument15 SeitenSivam Oh An 1985DEGAGA AMENUNoch keine Bewertungen

- Shel ElementDokument5 SeitenShel ElementGurpreet SinghNoch keine Bewertungen

- Large Deflections of Cantilever BeamsDokument4 SeitenLarge Deflections of Cantilever BeamsHasan Ayouby100% (1)

- Change LogDokument2 SeitenChange LogAnonymous 80p9OVNoch keine Bewertungen

- Wind Sheer: It Is The Vertical Gradient in The Wind Velocity Developed Because of The FrictionDokument12 SeitenWind Sheer: It Is The Vertical Gradient in The Wind Velocity Developed Because of The FrictionAnonymous 80p9OVNoch keine Bewertungen

- CDDokument13 SeitenCDAnonymous 80p9OVNoch keine Bewertungen

- Wind Sheer: It Is The Vertical Gradient in The Wind Velocity Developed Because of The FrictionDokument12 SeitenWind Sheer: It Is The Vertical Gradient in The Wind Velocity Developed Because of The FrictionAnonymous 80p9OVNoch keine Bewertungen

- GDokument2 SeitenGAnonymous 80p9OVNoch keine Bewertungen

- Program 14.6: MATLAB Program To Find The Frequency of A Timoshenko BeamDokument4 SeitenProgram 14.6: MATLAB Program To Find The Frequency of A Timoshenko BeamAnonymous 80p9OVNoch keine Bewertungen

- 2Dokument5 Seiten2Anonymous 80p9OVNoch keine Bewertungen

- AeroDyn PDFDokument60 SeitenAeroDyn PDFAnonymous 80p9OVNoch keine Bewertungen

- DocumentDokument2 SeitenDocumentAnonymous 80p9OVNoch keine Bewertungen

- Forced VibrationsDokument2 SeitenForced VibrationsAnonymous 80p9OVNoch keine Bewertungen

- Analysis of A StructuralDokument1 SeiteAnalysis of A StructuralAnonymous 80p9OVNoch keine Bewertungen

- Ffap V 110 Dynstall PDFDokument56 SeitenFfap V 110 Dynstall PDFAnonymous 80p9OVNoch keine Bewertungen

- With Large Scale Wind TurbinesDokument1 SeiteWith Large Scale Wind TurbinesAnonymous 80p9OVNoch keine Bewertungen

- Me509 FN sp2016 Sol PDFDokument8 SeitenMe509 FN sp2016 Sol PDFAnonymous 80p9OVNoch keine Bewertungen

- Program 14.6: MATLAB Program To Find The Frequency of A Timoshenko BeamDokument4 SeitenProgram 14.6: MATLAB Program To Find The Frequency of A Timoshenko BeamAnonymous 80p9OVNoch keine Bewertungen

- License en USDokument1 SeiteLicense en USGilang Budi AriawanNoch keine Bewertungen

- With Large Scale Wind TurbinesDokument1 SeiteWith Large Scale Wind TurbinesAnonymous 80p9OVNoch keine Bewertungen

- A Novel Dynamic Aeroelastic Framework For Aeroelastic Tailoring and Structural OptimisationDokument1 SeiteA Novel Dynamic Aeroelastic Framework For Aeroelastic Tailoring and Structural OptimisationAnonymous 80p9OVNoch keine Bewertungen

- Analysis of A StructuralDokument1 SeiteAnalysis of A StructuralAnonymous 80p9OVNoch keine Bewertungen

- AbstractDokument1 SeiteAbstractAnonymous 80p9OVNoch keine Bewertungen

- AbstractDokument1 SeiteAbstractAnonymous 80p9OVNoch keine Bewertungen

- New 1Dokument106 SeitenNew 1Anonymous 80p9OVNoch keine Bewertungen

- DocumentDokument2 SeitenDocumentAnonymous 80p9OVNoch keine Bewertungen

- Plot FASToutputDokument1 SeitePlot FASToutputAnonymous 80p9OVNoch keine Bewertungen

- DocumentDokument2 SeitenDocumentAnonymous 80p9OVNoch keine Bewertungen

- 2Dokument5 Seiten2Anonymous 80p9OVNoch keine Bewertungen

- Coupling of An Unsteady Lifting Line Free Vortex Wake Code To TheDokument17 SeitenCoupling of An Unsteady Lifting Line Free Vortex Wake Code To TheAnonymous 80p9OVNoch keine Bewertungen

- Run DTU 10MW RWT turbine files with FASTDokument1 SeiteRun DTU 10MW RWT turbine files with FASTAnonymous 80p9OVNoch keine Bewertungen

- Plot FASToutputDokument1 SeitePlot FASToutputAnonymous 80p9OVNoch keine Bewertungen

- ParametersDokument1 SeiteParametersAnonymous 80p9OVNoch keine Bewertungen

- HEB200Dokument1 SeiteHEB200giulioNoch keine Bewertungen

- MOM I - Module 37Dokument6 SeitenMOM I - Module 37Muhammad HabibNoch keine Bewertungen

- © 2016 Pearson Education, LTDDokument48 Seiten© 2016 Pearson Education, LTDArvind KumarNoch keine Bewertungen

- 180 TOP Concrete Technology & Design of Concrete SDokument49 Seiten180 TOP Concrete Technology & Design of Concrete SQaria shehzadiNoch keine Bewertungen

- John Dirk Walecka - Introduction To Classical Mechanics-WSPC (2020)Dokument184 SeitenJohn Dirk Walecka - Introduction To Classical Mechanics-WSPC (2020)Saiyad AliNoch keine Bewertungen

- Commercial In Situ Testing TechniquesDokument1 SeiteCommercial In Situ Testing TechniquesPonco SujarmikoNoch keine Bewertungen

- Basic Concept: By:-Harjit Singh MEC106Dokument12 SeitenBasic Concept: By:-Harjit Singh MEC106nirobNoch keine Bewertungen

- Aeletters 2023 8 2 2Dokument8 SeitenAeletters 2023 8 2 2miskoscribdNoch keine Bewertungen

- v11.0.1 System DocumentationDokument4.258 Seitenv11.0.1 System DocumentationJOSE LUIS HDZNoch keine Bewertungen

- Lesson 2.0 - Introduction To Vapour Power SystemsDokument87 SeitenLesson 2.0 - Introduction To Vapour Power SystemsBilly JhunNoch keine Bewertungen

- Assignment - 13: Name - Harsh Rai Branch - CE Sec-3M1 University Roll No - 1801000029Dokument9 SeitenAssignment - 13: Name - Harsh Rai Branch - CE Sec-3M1 University Roll No - 1801000029Suraj PatwaNoch keine Bewertungen

- Annotated Physics Data Booklet 2016Dokument17 SeitenAnnotated Physics Data Booklet 2016okiknkjkbiNoch keine Bewertungen

- Hydraulics and Irrigation Engineering Lab ManualDokument43 SeitenHydraulics and Irrigation Engineering Lab ManualMuhammad Faisal AsifNoch keine Bewertungen

- Steel-Concrete Composite Coupling Beams - Behavior and DesignDokument11 SeitenSteel-Concrete Composite Coupling Beams - Behavior and DesigncyrusnasiraiNoch keine Bewertungen

- Equation Sheet For ThermodynamicsDokument3 SeitenEquation Sheet For ThermodynamicsQuazar001Noch keine Bewertungen

- Chapter - Work Power Energy SampleDokument18 SeitenChapter - Work Power Energy SampleJeny SharmaNoch keine Bewertungen

- Flow Coefficients of Orifice and Mouthpiece ExperimentDokument5 SeitenFlow Coefficients of Orifice and Mouthpiece ExperimentAshish VermaNoch keine Bewertungen

- Armfield F1 21 Datasheet v2b Web 1Dokument1 SeiteArmfield F1 21 Datasheet v2b Web 1Ibrahim ALsultanNoch keine Bewertungen

- Test Bank: Chapter 1, Problem 2Dokument12 SeitenTest Bank: Chapter 1, Problem 2miladNoch keine Bewertungen

- Philip Oloibe Soil Mech ReportDokument9 SeitenPhilip Oloibe Soil Mech Reportsydney augustNoch keine Bewertungen

- CH 9 WeldingDokument18 SeitenCH 9 WeldingHazim KhalilNoch keine Bewertungen

- Wind TunnelsDokument240 SeitenWind TunnelsshoshonkoNoch keine Bewertungen

- Som Unit - 1.2.1 Stepped Bar 3 Regions ProblemDokument2 SeitenSom Unit - 1.2.1 Stepped Bar 3 Regions ProblemNagamani ArumugamNoch keine Bewertungen

- Chapter 3 - Fluid StaticsDokument6 SeitenChapter 3 - Fluid StaticsKristine Joy BagaporoNoch keine Bewertungen

- Ad II (Ae6503)Dokument2 SeitenAd II (Ae6503)Raahini IzanaNoch keine Bewertungen

- Midas Civil ManualDokument33 SeitenMidas Civil ManualAyoola Oluwadotun100% (2)

- Appendix A Thermodynamic Data: (HJ) (HJ)Dokument18 SeitenAppendix A Thermodynamic Data: (HJ) (HJ)jhNoch keine Bewertungen

- 02-Lignos EtAl-11NCEE ATC PaperRev1Dokument12 Seiten02-Lignos EtAl-11NCEE ATC PaperRev1faisaladeNoch keine Bewertungen

- Finite Element Methods For Unsaturated Porous Solids and Their Acallari2009 PDFDokument17 SeitenFinite Element Methods For Unsaturated Porous Solids and Their Acallari2009 PDFAndrésHermannR.LeónNoch keine Bewertungen

- Stepper MotorDokument6 SeitenStepper MotorAsith Savinda100% (1)