Beruflich Dokumente

Kultur Dokumente

Reverse Osmose System

Hochgeladen von

virtualmecanica0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

20 Ansichten1 SeiteOsmosis is used to remove a wide range of salts to provide water of a high purity. It is the process that feeds the cells in our bodies and how water gets to the leaves at the top of trees. The size of the RO and choice of membrane will be determined by the permeate quantity required, feed water salinity and permeate quality expected.

Originalbeschreibung:

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenOsmosis is used to remove a wide range of salts to provide water of a high purity. It is the process that feeds the cells in our bodies and how water gets to the leaves at the top of trees. The size of the RO and choice of membrane will be determined by the permeate quantity required, feed water salinity and permeate quality expected.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

20 Ansichten1 SeiteReverse Osmose System

Hochgeladen von

virtualmecanicaOsmosis is used to remove a wide range of salts to provide water of a high purity. It is the process that feeds the cells in our bodies and how water gets to the leaves at the top of trees. The size of the RO and choice of membrane will be determined by the permeate quantity required, feed water salinity and permeate quality expected.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

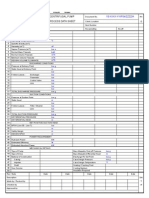

21 ECOTHERM Steam Solutions

Reverse Osmose Systems

The plant consist of:

High pressure membranes mounted on a

stainless steel base frame

Checkvalve feedwater

Checkvalve cleansystem

Pressure switch as dry-run-protection

High pressure pump

Polysulfon/polyamid-membrane

Pressure gauges

Concentrate-, accumulation- and backfow-

valve made of stainless-steel

Flowmeter permeate, concentrate and

backfow

Control system with full automatic

monitoring

Conductivity meter, digital display, operating

hour meter

Adjustable limit value and alarm contact for

low pressure and conductivity

Connection for niveau control, adjustable

pressure- and interval fushing

Storage tanks made of stainless steel or

plastic

Reverse Osmosis is a process that is used to remove a

wide range of salts to provide water of a high purity. Osmo-

sis is a natural process involving fuid fow across a semi-

permeable membrane barrier. It is the process by which

nutrients feed the cells in our bodies and how water gets to

the leaves at the top of trees. Reverse Osmosis systems,

in their basic form, consist of a pressure pump, housing

and the membrane. Water is forced into the housing under

pressure and the pure water (or permeate) is collected and

passed to service.

Reject water (or concentrate) is collected from another out-

let and routed to drain, with a portion of the concentrated

water recycled back to the inlet of the pump. This means

that the portion of water sent to drain is kept to a minimum.

The controller used on the RO system constantly monitors

the quality of the permeate water and is also linked with

safety controls on the system.

RO plants must be supplied with softened, de-chlorinated

or de-chlorinated anti scalent dosed water. A duplex sof-

tener is recommended for continuous operation.

The size of the RO and choice of membrane will be deter-

mined by the permeate quantity required, feed water salini-

ty and permeate quality expected. Low energy membranes

allow the units to run at pressures around 10 to 13bar, and

as such the pressure booster pumps required to generate

the pure water are smaller, and the power consumption is

reduced signifcantly.

Additional recommended is also a storage tank which is

used for reception of the pure-water.

The size of this tank / these tanks should be in coordination

with minimum and maximum RO water demand to ensure

constant operation of the RO system.

Products: Water Treatment

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Hydrofoils Tom SpeerDokument7 SeitenHydrofoils Tom SpeerVeters2650% (1)

- Oil Pumps - Mycom Screw CompressorDokument7 SeitenOil Pumps - Mycom Screw CompressorCarlos CarreraNoch keine Bewertungen

- General Installation and Maintenance InstructionsDokument12 SeitenGeneral Installation and Maintenance InstructionsLuciusNoch keine Bewertungen

- Professor Vijay Gupta Department of Chemical Engineering Indian Institute of Technology, Delhi Lecture 2A Internal FlowsDokument6 SeitenProfessor Vijay Gupta Department of Chemical Engineering Indian Institute of Technology, Delhi Lecture 2A Internal FlowsShahzaib Anwar OffNoch keine Bewertungen

- Project ListDokument10 SeitenProject ListCleetus KoshyNoch keine Bewertungen

- Kala Amb ValleyDokument3 SeitenKala Amb ValleyShivani SoniNoch keine Bewertungen

- Gas LiftDokument2 SeitenGas LiftArmando O GarciaNoch keine Bewertungen

- GS Ep PVV 102 enDokument48 SeitenGS Ep PVV 102 ensenthil muruganNoch keine Bewertungen

- Part 1Dokument3 SeitenPart 1Jester NavarquezNoch keine Bewertungen

- Pump Layout & PipingDokument91 SeitenPump Layout & Pipingrahult19100% (6)

- Lecture 7 Waste Heat RecoveryDokument29 SeitenLecture 7 Waste Heat RecoveryUsman AliNoch keine Bewertungen

- Thesis CFD ChapterDokument12 SeitenThesis CFD ChapterPrassanna PrabagaranNoch keine Bewertungen

- Distillation Technology and Need of Simultaneous Design and Control A ReviewDokument24 SeitenDistillation Technology and Need of Simultaneous Design and Control A ReviewHesam AhmadianNoch keine Bewertungen

- Chap 2Dokument39 SeitenChap 2Van Nguyen Phuong NganNoch keine Bewertungen

- Lecture 2 Introduction. Unit Operation IDokument8 SeitenLecture 2 Introduction. Unit Operation IOmar MontesNoch keine Bewertungen

- HC-EX38: Flow Sharing Compensated ValveDokument44 SeitenHC-EX38: Flow Sharing Compensated ValvemehmetNoch keine Bewertungen

- Why Compressors Fail?Dokument83 SeitenWhy Compressors Fail?Neil LachicaNoch keine Bewertungen

- Fuel Flex - GT13E2Dokument13 SeitenFuel Flex - GT13E2Thanapaet RittirutNoch keine Bewertungen

- Presentation: University of Gujrat Hafiz Hayat CampusDokument17 SeitenPresentation: University of Gujrat Hafiz Hayat CampusMg HNoch keine Bewertungen

- Lesson 2Dokument17 SeitenLesson 2charmaine fosNoch keine Bewertungen

- HCR 15-IiDokument470 SeitenHCR 15-IiElizabeth OctagonNoch keine Bewertungen

- Lab Manual Separation Tech Jan 2021Dokument43 SeitenLab Manual Separation Tech Jan 2021Abdul QayyumNoch keine Bewertungen

- Distillation Equipment Parts and FunctionsDokument1 SeiteDistillation Equipment Parts and FunctionsNika Lutfiana60% (5)

- StarPak ExtremeDokument2 SeitenStarPak ExtremeMannar1Noch keine Bewertungen

- Refrigeration SystemDokument54 SeitenRefrigeration SystemEdrian Diaz100% (1)

- 2021.05.31 - PVL Price List - Apr 2021Dokument1 Seite2021.05.31 - PVL Price List - Apr 2021Abdul RohmanNoch keine Bewertungen

- CN5191 - L2 - A1-Centrifugal Pump Process Data SheetDokument1 SeiteCN5191 - L2 - A1-Centrifugal Pump Process Data SheetMochi CumilinaNoch keine Bewertungen

- Eb-33 Oxygen Cleaning ProceduresDokument1 SeiteEb-33 Oxygen Cleaning ProceduresMeesookNoch keine Bewertungen

- AL-905-R-11202 Spec AG01 Rev. T02Dokument3 SeitenAL-905-R-11202 Spec AG01 Rev. T02altipatlarNoch keine Bewertungen

- (DX225LCA) 0005 Main Control Valve Basic PDFDokument9 Seiten(DX225LCA) 0005 Main Control Valve Basic PDFNaing Min Htun100% (3)