Beruflich Dokumente

Kultur Dokumente

VBN Vib 13 062 e C Ac3mo 038

Hochgeladen von

roberto_monguzziOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

VBN Vib 13 062 e C Ac3mo 038

Hochgeladen von

roberto_monguzziCopyright:

Verfügbare Formate

11-13, Avenue de Bel Air ALSTOM Transport SA

69627 VILLEURBANNE Cedex (France) ACCRDITATION Sige social : 3 avenue Andr Malraux

Tl. : 33 (0) 4 72 81 46 27 N 1-1082 92300 LEVALLOIS PERRET (France)

Fax : 33 (0) 4 72 81 46 58 PORTE SIRET 389 191 982 00088

DISPONIBLE SUR

www.cofrac.fr

COFRAC accreditation certifies that the laboratories are competent only for the tests covered by the accreditation, which are identified by

one in the table defined in chapter 1.

Transport

I nf or mat i on Sol ut i ons

EQ Labs

Test report n: VBN VIB 13 062 E C

Revision: A

Date: 18/11/2013

MECHANICAL TEST REPORT

T TY YP PE E T TE ES ST TS S

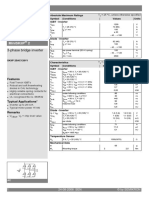

Equipment under test:

AC3MO-038

DTR0000264992

Issue:

Recipient name Company name Ex number.

Confidential

issue

Mr. Christophe CROZET

Copy:

Mr. Adrien DAGOIS

ALSTOM TIS Villeurbanne

ADENEO

1

1

Mr. Carlos QUEIROS DE OLIVEIRA

Laboratory Manager

Test report N

Date : 18/11/2013

VBN VIB 13 062 E C

Revision: A

page 2 / 28

MECHANICAL TEST REPORT T TY YP PE E T TE ES ST TS S

CONFIDENTIAL all rights reserved ALSTOM

Passing on and copying of this document, use and communication of its content are not permitted without prior written authorization.

A copy of this report has to be allowed only by unabridged facsimile.

IT CONTAINTS 28 PAGES INCLUDING 3 APPENDICES

C O N T E N T S

1 TESTS IDENTIFICATION AND CONCLUSION ........................................................3

2 GENERALITIES ......................................................................................................4

3 INFORMATION RELATING TO THE EQUIPMENT UNDER TEST .............................5

3.1 Generalities ................................................................................................................................ 5

3.1.1 Equipment description .............................................................................................................. 5

3.1.2 Test means .............................................................................................................................. 7

3.2 Installation diagram..................................................................................................................... 7

3.3 Checking procedure of the Equipment under Test .......................................................................... 8

4 PERFORMANCE CRITERIA .....................................................................................9

4.1 General definition ....................................................................................................................... 9

4.2 Manufacturer specification ........................................................................................................... 9

5 REFERENCE FILE .................................................................................................10

6 EQUIPMENT AC3MO-038 ..................................................................................12

6.1 Test program (EN 61373 category 1 class B) .............................................................................. 12

6.2 Test progress (EN 61373 category 1 class B) ............................................................................... 12

6.2.1 Initial visual inspection ........................................................................................................... 12

6.2.2 Tests results ........................................................................................................................... 13

6.2.3 Final visual inspection ............................................................................................................ 13

6.2.4 Curves results ........................................................................................................................ 14

7 APPENDIX A: REFERENCES OF USED MAIN TEST EQUIPMENTS ........................26

8 APPENDIX B: GLOSSARY ...................................................................................27

9 APPENDIX C: TESTS SHEET .................................................................................28

9.1.1 Random vibration .................................................................................................................. 28

9.1.2 Shocks test ............................................................................................................................ 28

Test report N

Date : 18/11/2013

VBN VIB 13 062 E C

Revision: A

page 3 / 28

MECHANICAL TEST REPORT T TY YP PE E T TE ES ST TS S

WARNING: The results in this test report apply only to the equipment under test.

It does not presume conformity of the whole of the products identical to the equipment under test.

It cannot be reproduced partially without written approval of the laboratory.

1 TESTS IDENTIFICATION AND CONCLUSION

Accreditation

Standard

(Kind of tests)

Product standard Results Comments

EN 60068-2-64 (2008)

Simulated Long Life

Random Vibration test

EN 61373 (1999)

C

EN 60068-2-27 (2009)

Shocks test

EN 61373 (1999)

C

EN 60068-2-64 (2008)

Functional Random

vibration test

EN 61373 (1999)

C

C: Compliant

NC: Not Compliant

Miss Elodie GOURSAUD Mr. Loc LEVIS

In charge of tests Technical Manager

Test report N

Date : 18/11/2013

VBN VIB 13 062 E C

Revision: A

page 4 / 28

MECHANICAL TEST REPORT T TY YP PE E T TE ES ST TS S

WARNING: The results in this test report apply only to the equipment under test.

It does not presume conformity of the whole of the products identical to the equipment under test.

It cannot be reproduced partially without written approval of the laboratory.

2 GENERALITIES

Name and address of the client: Mr. Cristophe CROZET

ALSTOM Transport

Information Solutions

11-13, Avenue de Bel Air

69627 VILLEURBANNE Cedex (France)

Test location: EQ Labs - Villeurbanne

ALSTOM Transport

Information Solutions

11-13, Avenue de Bel Air

69627 VILLEURBANNE Cedex (France)

Date of the tests: From the 17/10/2013 to the 18/10/2013

Test applicant: Mr. Adrien DAGOIS

Telephone: 39 94

Person attending the tests: Mr. Adrien DAGOIS

Telephone: 39 94

Offer reference: 13 062

Test report N

Date : 18/11/2013

VBN VIB 13 062 E C

Revision: A

page 5 / 28

MECHANICAL TEST REPORT T TY YP PE E T TE ES ST TS S

WARNING: The results in this test report apply only to the equipment under test.

It does not presume conformity of the whole of the products identical to the equipment under test.

It cannot be reproduced partially without written approval of the laboratory.

3 INFORMATION RELATING TO THE EQUIPMENT UNDER TEST

3.1 Generalities

3.1.1 Equipment description

The voltage supply of the UUT is 24Vdc @7A

The EUT can be decomposed into 2 parts:

the supervisor part : it is constituted by NPU, BIMN, EVR and inputs/outputs boards (EBT,

SBT, SST1). The main functions of the supervisor are :

Command control equipment chain of traction

Management of the MVB interface with the command control system

Management of the maintenance and control-command Ethernet interfaces

the CRT4 part : it is constituted by the CCN4-2, CCA4 and CCB4 boards. The main

functions of the CRT4 are :

The command of the inverter

The command of the rheostatic chopper

The command of the PMCF

Auxiliary equipment for the functional test

Test report N

Date : 18/11/2013

VBN VIB 13 062 E C

Revision: A

page 6 / 28

MECHANICAL TEST REPORT T TY YP PE E T TE ES ST TS S

WARNING: The results in this test report apply only to the equipment under test.

It does not presume conformity of the whole of the products identical to the equipment under test.

It cannot be reproduced partially without written approval of the laboratory.

Identification of the EUT

The constitution of the product is:

BPM2

EVR

A

L

N

V

1

A

L

A

1

N

P

U

B

I

M

N

C

C

N

4

C

C

A

4

C

C

B

4

C

C

B

4

E

B

Y

1

S

S

T

1

E

B

Y

1

S

B

T

S

S

T

1

A

L

A

1

The hardware configuration of the UUT is described in the table below:

Address Board TRV/DTR

0002 BPM2 DTR0000254169

0022 EVR DTR0000228337

0301 ALNV1 TRVS339673001

0302 ALA1 TRVS339339001

0304 NPU DTR0000239158

0306 BIMN DTR0000248258

0308 CCN4-2 TRVS339568000

0309 -

0310 CCA4 TRVC062437000

0312 CCB4 TRVC062117000

0313 CCB4 TRVC062117000

0314 - -

0315 EBY1 TRVC062314000

0316 SST1 TRVC062461000

0317 EBY1 TRVC062314000

0318 SBT TRVC070789000

0319 SST1 TRVC062461000

0320 ALA1 TRVS339339001

Test report N

Date : 18/11/2013

VBN VIB 13 062 E C

Revision: A

page 7 / 28

MECHANICAL TEST REPORT T TY YP PE E T TE ES ST TS S

WARNING: The results in this test report apply only to the equipment under test.

It does not presume conformity of the whole of the products identical to the equipment under test.

It cannot be reproduced partially without written approval of the laboratory.

3.1.2 Test means

The aim of the tests is to verify that the UUT is working correctly during and/or after each test.

It is carried out in a configuration as close as possible from the real conditions, typically the wiring rules

applied to the train are used and the system environment is re-created:

MVB and EHERNET interfaces,

LV inputs/outputs,

Analog inputs of voltage sensors, line current,

Speed sensor inputs,

Pulse/status return interface for inverters and rheostatic chopper

3.2 Installation diagram

The synoptic of the test bench is:

UUT

24Vdc

PowerSupply

Resistiveloads

MVBmiror

Shieldedcablescomingfromsupplyboards

MVBlinks

Analog

loads Analoginputs/outputsshieldedcables

Supplywires

Ethernetlink(10Mb/s)

Software of tests is used to check the functioning of the UUT:

SYSTEM test : check power supplies and SYSFAIL and the functioning of CCN4 boards

I2C test : read/write in the I2C EEPROM

CCN4 test : check the state of the CCN4 board

CAN-IO test : check the CAN IO topology and the connections between EBT/SBT/SST

NETWORK test : check the dialogue with an AL3 equipment connected to the MVB

network and Ethernet communication

The version of the software is identified as follows:

Clearcase Label : 0.0.0.5

Acronym : citadis2_mas

Note: the LED SPD is ON but it is not a defect.

Test report N

Date : 18/11/2013

VBN VIB 13 062 E C

Revision: A

page 8 / 28

MECHANICAL TEST REPORT T TY YP PE E T TE ES ST TS S

WARNING: The results in this test report apply only to the equipment under test.

It does not presume conformity of the whole of the products identical to the equipment under test.

It cannot be reproduced partially without written approval of the laboratory.

3.3 Checking procedure of the Equipment under Test

The visualization interfaces are a users friendly mean to quickly get basic information on the AG3 status:

Type Signal name Abbrev

LED

Id.

LED

Id.

Abbrev Signal name Type

System

status

DELVISU1#

OFF after startup

ON if SYSFAIL = 0 V

SFL DS4 DS5 SRT

DELVISU2#

OFF after startup

ON if SYSRST = 0 V

System

status

DELVISU3#

OFF after startup

ON if SYSBLP = 0 V

SBP DS6 DS7 SBS Not Used

Applicatio

n

status

DELVISU5#

Application free use

UR1 DS8 DS9 UR2

DELVISU6#

Application free use

Applicatio

n

status

DELVISU7#

Application free use

UR3 DS10 DS11 UR4

DELVISU8#

Application free use

DELVISU9#

Application free use

UR5 DS12 DS13 UR6

DELVISU10#

Application free use

Not used Not Used SR1 DS14 DS15 SG2 Not Used Not used

Power

Supply

Status

OKNU#

ON if ALNV

output OK

NU DS16 DS17 15V

OK15V#

ON if ALAX

output OK

Power

Supply

Status

OK24P#

ON if ALAX

output OK

24P DS18 DS19 24S

OK24S#

ON if ALAX

output OK

OKUENU#

ON if ALNV

input OK

UEN DS20 DS21 UES

OKUES#

ON if ALAX

input OK

OKUEP#

ON if ALAX

input OK

UEP DS22 DS23 URN

URGNU#

ON 0,2ms before loss

of ALNV out

Ethernet

status

LEDET1# (LILED)

ON if speed >

10Mb/s

SPD DS1 DS24 DAS Not Used

IDE Status

Not Used

LI DS3 DS2 ACT

LEDET2# (ACTLED)

ON if link integrity OK

BLINK if activity on link

Ethernet

status

Test report N

Date : 18/11/2013

VBN VIB 13 062 E C

Revision: A

page 9 / 28

MECHANICAL TEST REPORT T TY YP PE E T TE ES ST TS S

WARNING: The results in this test report apply only to the equipment under test.

It does not presume conformity of the whole of the products identical to the equipment under test.

It cannot be reproduced partially without written approval of the laboratory.

4 PERFORMANCE CRITERIA

4.1 General definition

The criteria defined below come from the generic standards: EN 50121-1.

Criterion A: The apparatus shall continue to operate as intended. No degradation of performance or loss of

function is allowed below a performance level specified by the manufacturer, when the apparatus is used as

intended. In some cases the performance level may be replaced by a permissible loss of performance. If the

minimum performance level or the permissible performance loss is not specified by the manufacturer then

either of these may be derived from the product description and documentation and what the user may

reasonably expect from the apparatus if used as intended.

Criterion B: The apparatus shall continue to operate as intended after the test. No degradation of

performance or loss of function is allowed below a performance level specified by the manufacturer, when the

apparatus is used as intended. In some cases the performance level may be replaced by a permissible loss of

performance. During the test, degradation of performance is however allowed. No change of actual operating

state or stored data is allowed. If the minimum performance level or the permissible performance loss is not

specified by the manufacturer then either of these may be derived from the product description and

documentation and what the user may reasonable expect from the apparatus if used as intended.

Criterion C: Temporary loss of function is allowed, provided the loss of function is self-recoverable or can be

restored by the operation of the controls.

4.2 Manufacturer specification

Performance level or permissible loss of performance:

For criterion A: No errors events should appear in the fault log of the tool TrainTracer UTM

(citadis2_mas).

Test report N

Date : 18/11/2013

VBN VIB 13 062 E C

Revision: A

page 10 / 28

MECHANICAL TEST REPORT T TY YP PE E T TE ES ST TS S

WARNING: The results in this test report apply only to the equipment under test.

It does not presume conformity of the whole of the products identical to the equipment under test.

It cannot be reproduced partially without written approval of the laboratory.

5 REFERENCE FILE

Test report N

Date : 18/11/2013

VBN VIB 13 062 E C

Revision: A

page 11 / 28

MECHANICAL TEST REPORT T TY YP PE E T TE ES ST TS S

WARNING: The results in this test report apply only to the equipment under test.

It does not presume conformity of the whole of the products identical to the equipment under test.

It cannot be reproduced partially without written approval of the laboratory.

Test report N

Date : 18/11/2013

VBN VIB 13 062 E C

Revision: A

page 12 / 28

MECHANICAL TEST REPORT T TY YP PE E T TE ES ST TS S

WARNING: The results in this test report apply only to the equipment under test.

It does not presume conformity of the whole of the products identical to the equipment under test.

It cannot be reproduced partially without written approval of the laboratory.

6 EQUIPMENT AC3MO-038

6.1 Test program (EN 61373 category 1 class B)

Test standard

EN 60068-2-64 (Random vibrations test)

EN 60068-2-27 (Shocks test)

Category 1 class B

Product standard EN 61373

Performance criterion A

Test parameters

OX

Simulated Long Life Random Vibration

Shocks

Functional Random vibration

5.5m/s

rms

50m/s / 30ms

0.7m/s

rms

OY

Simulated Long Life Random Vibration

Shocks

Functional Random vibration

5.5m/s

rms

50m/s / 30ms

0.7m/s

rms

OZ

Simulated Long Life Random Vibration

Shocks

Functional Random vibration

7.9m/s

rms

30m/s / 30ms

1m/s

rms

U Supply voltage Un=24V

DC

6.2 Test progress (EN 61373 category 1 class B)

6.2.1 Initial visual inspection

Points examined Results / Comments

EUT:

Fixation mobiles connectors

Oxidation of the hardware

Fixing brackets

OK

OK

OK

Sub-rack:

Connectors

Oxidation of the hardware

Slides

Checking the torque

Fixing mechanical shielding

OK

OK

OK

M3: 1N.m Board

M6: 6.5N.m Rack/Sub-rack

M8: 16.5N.m Sub-rack/Assembly

OK

Wiring of test:

Connectors

Oxidation of the hardware

Fixing mechanical shielding

OK

OK

OK

Board:

Fixation board (mezzanine, Front face, )

Fixation internal cables

OK

OK

Test report N

Date : 18/11/2013

VBN VIB 13 062 E C

Revision: A

page 13 / 28

MECHANICAL TEST REPORT T TY YP PE E T TE ES ST TS S

WARNING: The results in this test report apply only to the equipment under test.

It does not presume conformity of the whole of the products identical to the equipment under test.

It cannot be reproduced partially without written approval of the laboratory.

6.2.2 Tests results

Date, hour Axis Duration Test Results Comments

17/10 09:51 AM

OZ

(Vertical)

5 hours

Simulated Long Life

Random Vibration

C

17/10 03:07 PM 30ms/shock Shocks C

17/10 03:12 PM 10 minutes

Functional Random

vibration

C

17/10 05:09 PM

OY

(Transversal)

5 hours

Simulated Long Life

Random Vibration

C

18/10 08:52 AM 30ms/shock Shocks C

18/10 08:54 AM 10 minutes

Functional Random

vibration

C

18/10 09:33 AM

OX

(Longitudinal)

5 hours

Simulated Long Life

Random Vibration

C

18/10 02:59 PM 30ms/shock Shocks C

18/10 03:08 PM 10 minutes

Functional Random

vibration

C

6.2.3 Final visual inspection

Points examined Results / Comments

EUT:

Fixation mobiles connectors

Oxidation of the hardware

Fixing brackets

OK

OK

OK

Sub-rack:

Connectors

Oxidation of the hardware

Slides

Checking the torque

Fixing mechanical shielding

OK

OK

OK

M3: 1N.m Board

M6: 6.5N.m Rack/Sub-rack

M8: 16.5N.m Sub-rack/Assembly

OK

Wiring of test:

Connectors

Oxidation of the hardware

Fixing mechanical shielding

OK

OK

OK

Board:

Fixation board (mezzanine, Front face, )

Fixation internal cables

OK

OK

No cracks

No Breaks

No lost screws

OK

OK

OK

Test report N

Date : 18/11/2013

VBN VIB 13 062 E C

Revision: A

page 14 / 28

MECHANICAL TEST REPORT T TY YP PE E T TE ES ST TS S

WARNING: The results in this test report apply only to the equipment under test.

It does not presume conformity of the whole of the products identical to the equipment under test.

It cannot be reproduced partially without written approval of the laboratory.

6.2.4 Curves results

Pilotage

During random vibration tests, the control of the driver is performed on a strategy average (Average signals

provided by each reference point).

In shocks tests, the control of the driver is performed by the signal supplied by a single reference point.

Definition measurement:

Measurement Explication

Reference Point

Control and this transverses represent a picture of the

control of the vibrator to a given template.

Profile(f), high-alarm(f), low-alarm(f) Template

according to standard

Control(f) Average of the control points Input1 (f)

and Input2 (f) = reference point fictive

The single point of control for shocks

Input3(f), Input4(f) Transverses

Response Point

A picture of the control of the vibrator to a given template.

Profile(f) Template according to standard

InputX(f) Response of measurement point

Transfer function

The presentation of vibratory behaviour of EUT is

translated by the transfer function following:

excitation

response

F

X

H = =

Cursors are on the frequencies of resonance of EUT:

TransX_c0 Transfer function at the beginning of test

TransX Transfer function at the end of test

Test report N

Date : 18/11/2013

VBN VIB 13 062 E C

Revision: A

page 15 / 28

MECHANICAL TEST REPORT T TY YP PE E T TE ES ST TS S

WARNING: The results in this test report apply only to the equipment under test.

It does not presume conformity of the whole of the products identical to the equipment under test.

It cannot be reproduced partially without written approval of the laboratory.

Position of measurement accelerometers:

Accelerometers were glued with cyanoacrylate glue.

Accelerometric measurements:

Curves n 1 to 3: Control accelerometer during Long Life Random Vibration

Test

Curves n4 to 9: Transfer functions measured during the Long Life Test.

Curves n10 to 12: Control accelerometer during the Functional Random

Vibration Test

Curves n13 to 18: Control accelerometers during the Shocks Test. (Purple and

red curves presents the transversal movement; blue curve

presents the limit requested by the standard EN 60068-2-27

(2009)).

Reference Point n2

Response Point n1

OZ (Verticale)

OX (longitudinal)

OY (transversal)

Reference Point n1

Response Point n2

Test report N

Date : 18/11/2013

VBN VIB 13 062 E C

Revision: A

page 16 / 28

MECHANICAL TEST REPORT T TY YP PE E T TE ES ST TS S

WARNING: The results in this test report apply only to the equipment under test.

It does not presume conformity of the whole of the products identical to the equipment under test.

It cannot be reproduced partially without written approval of the laboratory.

CURVE N 1

Axis: OZ Specimen: AC3MO-038

Title: Long Life random vibration test

Measurement: Reference Point

profile(f)

high-alarm(f)

low-alarm(f)

input3(f)

input4(f)

control(f)

150.00 5.00 10.00 100.00

0.1122

1.78E-07

1.00E-06

1.00E-05

0.0001

0.0010

0.0100

Frequency (Hz)

(gn)/Hz

CURVE N 2

Axis: OY Specimen: AC3MO-038

Title: Long Life random vibration test

Measurement: Reference Point

profile(f)

high-alarm(f)

low-alarm(f)

input3(f)

input4(f)

control(f)

150.00 5.00 10.00 100.00

0.0891

3.98E-09

1.00E-08

1.00E-07

1.00E-06

1.00E-05

0.0001

0.0010

0.0100

Frequency (Hz)

(gn)/Hz

Test report N

Date : 18/11/2013

VBN VIB 13 062 E C

Revision: A

page 17 / 28

MECHANICAL TEST REPORT T TY YP PE E T TE ES ST TS S

WARNING: The results in this test report apply only to the equipment under test.

It does not presume conformity of the whole of the products identical to the equipment under test.

It cannot be reproduced partially without written approval of the laboratory.

CURVE N 3

Axis: OX Specimen: AC3MO-038

Title: Long Life random vibration test

Measurement: Reference Point

profile(f)

high-alarm(f)

low-alarm(f)

input3(f)

input4(f)

control(f)

150.00 5.00 10.00 100.00

0.0891

1.00E-08

1.00E-07

1.00E-06

1.00E-05

0.0001

0.0010

0.0100

Frequency (Hz)

(gn)/Hz

Test report N

Date : 18/11/2013

VBN VIB 13 062 E C

Revision: A

page 18 / 28

MECHANICAL TEST REPORT T TY YP PE E T TE ES ST TS S

WARNING: The results in this test report apply only to the equipment under test.

It does not presume conformity of the whole of the products identical to the equipment under test.

It cannot be reproduced partially without written approval of the laboratory.

CURVE N 4

Axis: OZ Specimen: AC3MO-038

Title: Long Life random vibration test

Measurement: Transfer function point n1

Trans1

Trans1_0

150.00 5.00 10.00 100.00

25.1189

0.5012

1.0000

10.0000

Frequency (Hz)

1

2

Si gnal X Y

1 Tr ans1_0 114. 075 4. 11481

2 Tr ans1 113. 342 9. 98809

CURVE N 5

Axis: OY Specimen: AC3MO-038

Title: Long Life random vibration test

Measurement: Transfer function point n1

Trans5

Trans5_0

150.00 5.00 10.00 100.00

15.8489

0.6457

1.0000

10.0000

Frequency (Hz)

1

2

Si gnal X Y

1 Tr ans5_0 96. 4966 7. 60553

2 Tr ans5 96. 1304 8. 16215

Test report N

Date : 18/11/2013

VBN VIB 13 062 E C

Revision: A

page 19 / 28

MECHANICAL TEST REPORT T TY YP PE E T TE ES ST TS S

WARNING: The results in this test report apply only to the equipment under test.

It does not presume conformity of the whole of the products identical to the equipment under test.

It cannot be reproduced partially without written approval of the laboratory.

CURVE N 6

Axis: OX Specimen: AC3MO-038

Title: Long Life random vibration test

Measurement: Transfer function point n1

Trans5

Trans5_0

150.00 5.00 10.00 100.00

3.3113

0.5012

1.0000

Frequency (Hz)

CURVE N 7

Axis: OZ Specimen: AC3MO-038

Title: Long Life random vibration test

Measurement: Transfer function point n2

Trans2

Trans2_0

150.00 5.00 10.00 100.00

3.5481

0.8433

1.0000

Frequency (Hz)

Test report N

Date : 18/11/2013

VBN VIB 13 062 E C

Revision: A

page 20 / 28

MECHANICAL TEST REPORT T TY YP PE E T TE ES ST TS S

WARNING: The results in this test report apply only to the equipment under test.

It does not presume conformity of the whole of the products identical to the equipment under test.

It cannot be reproduced partially without written approval of the laboratory.

CURVE N 8

Axis: OY Specimen: AC3MO-038

Title: Long Life random vibration test

Measurement: Transfer function point n2

Trans6

Trans6_0

150.00 5.00 10.00 100.00

5.0119

0.7586

1.0000

Frequency (Hz)

1

2

Si gnal X Y

1 Tr ans6_0 108. 032 4. 13757

2 Tr ans6 107. 483 4. 09937

CURVE N 9

Axis: OX Specimen: AC3MO-038

Title: Long Life random vibration test

Measurement: Transfer function point n2

Trans6

Trans6_0

150.00 5.00 10.00 100.00

5.9566

0.5623

1.0000

Frequency (Hz)

1

2

Si gnal X Y

1 Tr ans6_0 39. 3677 2. 76303

2 Tr ans6 46. 875 4. 50458

Test report N

Date : 18/11/2013

VBN VIB 13 062 E C

Revision: A

page 21 / 28

MECHANICAL TEST REPORT T TY YP PE E T TE ES ST TS S

WARNING: The results in this test report apply only to the equipment under test.

It does not presume conformity of the whole of the products identical to the equipment under test.

It cannot be reproduced partially without written approval of the laboratory.

CURVE N 10

Axis: OZ Specimen: AC3MO-038

Title: Functional random vibration test

Measurement: Reference Point

profile(f)

high-alarm(f)

low-alarm(f)

control(f)

150.00 5.00 10.00 100.00

0.0016

1.26E-06

1.00E-05

0.0001

0.0010

Frequency (Hz)

(gn)/Hz

CURVE N 11

Axis: OY Specimen: AC3MO-038

Title: Functional random vibration test

Measurement: Reference Point

profile(f)

high-alarm(f)

low-alarm(f)

control(f)

150.00 5.00 10.00 100.00

0.0008

3.98E-07

1.00E-06

1.00E-05

0.0001

Frequency (Hz)

(gn)/Hz

Test report N

Date : 18/11/2013

VBN VIB 13 062 E C

Revision: A

page 22 / 28

MECHANICAL TEST REPORT T TY YP PE E T TE ES ST TS S

WARNING: The results in this test report apply only to the equipment under test.

It does not presume conformity of the whole of the products identical to the equipment under test.

It cannot be reproduced partially without written approval of the laboratory.

CURVE N 12

Axis: OX Specimen: AC3MO-038

Title: Functional random vibration test

Measurement: Reference Point

profile(f)

high-alarm(f)

low-alarm(f)

control(f)

150.00 5.00 10.00 100.00

0.0008

3.98E-07

1.00E-06

1.00E-05

0.0001

Frequency (Hz)

(gn)/Hz

Remark: The bad behaviour of the set constituted by the specimen and by its assembly during the random

vibrations test in this axis did not allow a correct feedback control of this test in the -6 dB slope down. The ADS

level between 5 and 20 Hz has been respected.

Test report N

Date : 18/11/2013

VBN VIB 13 062 E C

Revision: A

page 23 / 28

MECHANICAL TEST REPORT T TY YP PE E T TE ES ST TS S

WARNING: The results in this test report apply only to the equipment under test.

It does not presume conformity of the whole of the products identical to the equipment under test.

It cannot be reproduced partially without written approval of the laboratory.

CURVE N 13

Axis: OZ Specimen: AC3MO-038

Title: Positive shocks

Measurement: Reference Point

profile(t)

high-abort(t)

low-abort(t)

control(t)

input3(t)

input4(t)

0.10 -0.08 -0.06 -0.04 -0.02 0 0.02 0.04 0.06 0.08

4.2000

-1.8000

-1.6000

-1.2000

-0.8000

-0.4000

0

0.4000

0.8000

1.2000

1.6000

2.0000

2.4000

2.8000

3.2000

3.6000

Time (Seconds)

gn

y1= 0. 9000 y2= - 0. 9000 dy= - 1. 8000

CURVE N 14

Axis: OZ Specimen: AC3MO-038

Title: Negative shocks

Measurement: Reference Point

profile(t)

high-abort(t)

low-abort(t)

control(t)

input3(t)

input4(t)

0.10 -0.08 -0.06 -0.04 -0.02 0 0.02 0.04 0.06 0.08

1.8000

-4.2000

-4.0000

-3.6000

-3.2000

-2.8000

-2.4000

-2.0000

-1.6000

-1.2000

-0.8000

-0.4000

0

0.4000

0.8000

1.2000

Time (Seconds)

gn

y1= 0. 9000 y2= - 0. 9000 dy= - 1. 8000

Test report N

Date : 18/11/2013

VBN VIB 13 062 E C

Revision: A

page 24 / 28

MECHANICAL TEST REPORT T TY YP PE E T TE ES ST TS S

WARNING: The results in this test report apply only to the equipment under test.

It does not presume conformity of the whole of the products identical to the equipment under test.

It cannot be reproduced partially without written approval of the laboratory.

CURVE N 15

Axis: OY Specimen: AC3MO-038

Title: Positive shocks

Measurement: Reference Point

profile(t)

high-abort(t)

low-abort(t)

control(t)

input3(t)

input4(t)

0.10 -0.08 -0.06 -0.04 -0.02 0 0.02 0.04 0.06 0.08

6.9000

-2.8000

-2.5000

-2.0000

-1.5000

-1.0000

-0.5000

0

0.5000

1.0000

1.5000

2.0000

2.5000

3.0000

3.5000

4.0000

4.5000

5.0000

5.5000

6.0000

6.5000

Time (Seconds)

gn

y1= 1. 5000 y2= - 1. 5000 dy= - 3. 0000

CURVE N 16

Axis: OY Specimen: AC3MO-038

Title: Negative shocks

Measurement: Reference Point

profile(t)

high-abort(t)

low-abort(t)

control(t)

input3(t)

input4(t)

0.10 -0.08 -0.06 -0.04 -0.02 0 0.02 0.04 0.06 0.08

2.8000

-6.9000

-6.5000

-6.0000

-5.5000

-5.0000

-4.5000

-4.0000

-3.5000

-3.0000

-2.5000

-2.0000

-1.5000

-1.0000

-0.5000

0

0.5000

1.0000

1.5000

2.0000

2.5000

Time (Seconds)

gn

y1= 1. 5000 y2= - 1. 5000 dy= - 3. 0000

Test report N

Date : 18/11/2013

VBN VIB 13 062 E C

Revision: A

page 25 / 28

MECHANICAL TEST REPORT T TY YP PE E T TE ES ST TS S

WARNING: The results in this test report apply only to the equipment under test.

It does not presume conformity of the whole of the products identical to the equipment under test.

It cannot be reproduced partially without written approval of the laboratory.

CURVE N 17

Axis: OX Specimen: AC3MO-038

Title: Positive shocks

Measurement: Reference Point

profile(t)

high-abort(t)

low-abort(t)

control(t)

input3(t)

input4(t)

0.10 -0.08 -0.06 -0.04 -0.02 0 0.02 0.04 0.06 0.08

6.9000

-2.8000

-2.5000

-2.0000

-1.5000

-1.0000

-0.5000

0

0.5000

1.0000

1.5000

2.0000

2.5000

3.0000

3.5000

4.0000

4.5000

5.0000

5.5000

6.0000

6.5000

Time (Seconds)

gn

y1= 1. 5000 y2= - 1. 5000 dy= - 3. 0000

CURVE N 18

Axis: OX Specimen: AC3MO-038

Title: Negative shocks

Measurement: Reference Point

profile(t)

high-abort(t)

low-abort(t)

control(t)

input3(t)

input4(t)

0.10 -0.08 -0.06 -0.04 -0.02 0 0.02 0.04 0.06 0.08

2.8000

-6.9000

-6.5000

-6.0000

-5.5000

-5.0000

-4.5000

-4.0000

-3.5000

-3.0000

-2.5000

-2.0000

-1.5000

-1.0000

-0.5000

0

0.5000

1.0000

1.5000

2.0000

2.5000

Time (Seconds)

gn

y1= 1. 5000 y2= - 1. 5000 dy= - 3. 0000

Test report N

Date : 18/11/2013

VBN VIB 13 062 E C

Revision: A

page 26 / 28

MECHANICAL TEST REPORT T TY YP PE E T TE ES ST TS S

WARNING: The results in this test report apply only to the equipment under test.

It does not presume conformity of the whole of the products identical to the equipment under test.

It cannot be reproduced partially without written approval of the laboratory.

7 APPENDIX A: REFERENCES OF USED MAIN TEST EQUIPMENTS

Definition

Chanel

input

Reference

constructor

ID

Constructor Validity

Sensibility

(mV/g)

Reference point 2

2

ACC-302 356A15 PCB 10/2013

OX: 101,6

3 OY: 100,5

4 OZ: 97,94

Reference point 1 1 ACC-114 352A21 PCB 06/2014 102,8

Response point 1 5 ACC-115 352A21 PCB 06/2014 9,128

Response point 2 6 ACC-116 352A21 PCB 06/2014 9,194

VIBRATION / SHOCKS

Equipment Manufacturer / Type Identification Validity

Electro-dynamic excitator

Type V850440 LPT 600 C combo

LINK DYNAMIC

SYSTEM

VIB 001 09/2014

Power amplifier - SPA 30 K

LINK DYNAMIC

SYSTEM

VIB 001 09/2014

Shaker control unit DACTRON LASER

USB

LINK DYNAMIC

SYSTEM

VIB 002 09/2014

Shaker control unit DACTRON LASER

USB SLAVE

LINK DYNAMIC

SYSTEM

VIB 002 09/2014

P.C. DELL INTEL CELERON 2.8 Ghz

LINK DYNAMIC

SYSTEM

/ /

Shaker Control

Version 5.82

LINK DYNAMIC

SYSTEM

LOG 011 09/2014

Bracket assembly ATIS 3 /

Key Dynamometer FACOM CDY 001 10/2014

Key Dynamometer FACOM CDY 003 10/2014

Test report N

Date : 18/11/2013

VBN VIB 13 062 E C

Revision: A

page 27 / 28

MECHANICAL TEST REPORT T TY YP PE E T TE ES ST TS S

WARNING: The results in this test report apply only to the equipment under test.

It does not presume conformity of the whole of the products identical to the equipment under test.

It cannot be reproduced partially without written approval of the laboratory.

8 APPENDIX B: GLOSSARY

B.T. : Battery

EUT : Equipment Under Test

H.F. : High Frequency

hPa : Hecto Pascal

IEC : International Electrotechnical Commission

ISM : Industrial, Scientific and Medical

I/O : Input / Output

ITE : Information Technology Equipment

R.H. : Relative humidity

Un : Nominal voltage

L : Longitudinal

T : Transversal

V : Vertical

Simulated Long Life Random Vibration: This test is aimed at establishing the mechanical integrity of the

equipment at increased service levels. It is not necessary to demonstrate ability to function under these

conditions.

Functional Random vibration: The functional random test levels are the minimum test levels to be applied on

order to demonstrate that the equipment under test is capable of functioning when subjected to conditions

which are likely to occur in service, on railway vehicles. The functional tests are not intended to be a full

performance evaluation under simulated service conditions.

Test report N

Date : 18/11/2013

VBN VIB 13 062 E C

Revision: A

page 28 / 28

MECHANICAL TEST REPORT T TY YP PE E T TE ES ST TS S

WARNING: The results in this test report apply only to the equipment under test.

It does not presume conformity of the whole of the products identical to the equipment under test.

It cannot be reproduced partially without written approval of the laboratory.

9 APPENDIX C: TESTS SHEET

9.1.1 Random vibration

Tests carried out were complied with the standard EN 60068-2-64 requirement.

Random vibrations transmitted with Gaussian distribution of instantaneous values with a clipping factor of 3,

are defined by their Power Spectral Density of acceleration G(f) and their frequency bandwidth f=f2-f1. The

number of degrees of freedom used is 120.

RMS acceleration is worked out using the equation:

=

2

1

2

). (

f

f

df f G with G(f) in g/Hz and f in Hz

Control is made on the average of 2 reference sensors located close to the specimen fixations.

Measurement accuracy of each accelerometric channels is of 4.21 % with a k factor =2 (frequencies range

5-500Hz).

9.1.2 Shocks test

Tests carried out were complied with the standard EN 60068-2-27 requirement.

Half sine shocks are defined bY their acceleration peak in g and their duration D in ms as shown on the

following scheme.

Control is made on the filtered signal of one reference sensor located close to the specimens fixations.

Das könnte Ihnen auch gefallen

- Mouser PDFDokument2.054 SeitenMouser PDFamicoadrianoNoch keine Bewertungen

- Dell Latitude E4300 JAL10 Compal LA-4151P SchematicsDokument57 SeitenDell Latitude E4300 JAL10 Compal LA-4151P SchematicsMuhammad MajidNoch keine Bewertungen

- SBC8360VEA: Socket 370 Embedded SBC With Multi-Media & Mechanical Backward Compatible SolutionsDokument1 SeiteSBC8360VEA: Socket 370 Embedded SBC With Multi-Media & Mechanical Backward Compatible SolutionsSATBRAINNoch keine Bewertungen

- 1208 - EN - Brief Operating Instructions - DIC-4-002 To DIC-4-110Dokument60 Seiten1208 - EN - Brief Operating Instructions - DIC-4-002 To DIC-4-110Cristiano AlvesNoch keine Bewertungen

- Semikron Datasheet Skiip 25ac126v1 25230090Dokument4 SeitenSemikron Datasheet Skiip 25ac126v1 25230090elias100% (1)

- Eaton UpsDokument2 SeitenEaton UpsririnNoch keine Bewertungen

- 3adw000195r0301 Dcs800 Service Manual e CDokument128 Seiten3adw000195r0301 Dcs800 Service Manual e CCharoon SuriyawichitwongNoch keine Bewertungen

- Weg Cfw700 Manual UsuarioDokument248 SeitenWeg Cfw700 Manual UsuarioAnonymous dyT6AgjSxSNoch keine Bewertungen

- Samhop MOSFETs Production Selection Guide - Version 2014Dokument14 SeitenSamhop MOSFETs Production Selection Guide - Version 2014goguNoch keine Bewertungen

- Manuali - Eltex.biz Manuali Siei ARTDriveG-EVDokument214 SeitenManuali - Eltex.biz Manuali Siei ARTDriveG-EVRoxana NegoitaNoch keine Bewertungen

- PL Ga800 01 PDFDokument50 SeitenPL Ga800 01 PDFBock DharmaNoch keine Bewertungen

- DC Panel OperationDokument30 SeitenDC Panel Operationnguyễn hùngNoch keine Bewertungen

- 5.2. Operation Manual - Starter-EngDokument26 Seiten5.2. Operation Manual - Starter-EngBelal Ameen100% (1)

- Driver L7 OMRON PDFDokument299 SeitenDriver L7 OMRON PDFmuaadhNoch keine Bewertungen

- Tutorial Can PicDokument24 SeitenTutorial Can Picjass1304100% (1)

- Iskra Merni InstrumentiDokument108 SeitenIskra Merni InstrumentiБаба ЏајаNoch keine Bewertungen

- LC2005 BA Lift ControlDokument40 SeitenLC2005 BA Lift ControlFERNSNoch keine Bewertungen

- DS 720 SDokument2 SeitenDS 720 SIvan DumontNoch keine Bewertungen

- SVX9000 ManualDokument84 SeitenSVX9000 ManualekoNoch keine Bewertungen

- Omron CJ1M Motion IntroductionDokument76 SeitenOmron CJ1M Motion IntroductionMahadzir Bin Mat Rabi'Noch keine Bewertungen

- Electrolux Service Manual EnglezaDokument56 SeitenElectrolux Service Manual EnglezaNegru P. PlantatieNoch keine Bewertungen

- Gearless Xaf: Installation and MaintenanceDokument44 SeitenGearless Xaf: Installation and MaintenanceyounesNoch keine Bewertungen

- Gear Pump MKU-MKF-MKL Assembly InstructionsDokument102 SeitenGear Pump MKU-MKF-MKL Assembly InstructionssunhuynhNoch keine Bewertungen

- User Manual CAC ControllerDokument18 SeitenUser Manual CAC ControllerJuanita Pardo MirandaNoch keine Bewertungen

- B43876S9478M 1 - Ed5Dokument3 SeitenB43876S9478M 1 - Ed5Mauricio BaronNoch keine Bewertungen

- Siemens Micromaster Eco ManualDokument181 SeitenSiemens Micromaster Eco ManualMohammad Imtiaz ChowdhuryNoch keine Bewertungen

- A1000 Spindle OrientationDokument36 SeitenA1000 Spindle OrientationcoronaqcNoch keine Bewertungen

- SC200 PLCDokument180 SeitenSC200 PLCKostasGNoch keine Bewertungen

- RT4F 110V W1704a PDFDokument6 SeitenRT4F 110V W1704a PDFOmar Orlando Rincon FigueroaNoch keine Bewertungen

- Fermator Czesci Zamienne PDFDokument106 SeitenFermator Czesci Zamienne PDFRafał SxiNoch keine Bewertungen

- Dynamic Braking Resistor Chopper CircuitDokument5 SeitenDynamic Braking Resistor Chopper CircuitAri SutejoNoch keine Bewertungen

- Ecobrake EngDokument3 SeitenEcobrake EngbmonaandaNoch keine Bewertungen

- Vega PliusDokument4 SeitenVega PliusMatas DoviltisNoch keine Bewertungen

- Almega Manual 1Dokument63 SeitenAlmega Manual 1Tecwyn WebsterNoch keine Bewertungen

- Wolf CGB-K-11!20!24 Montage-Und Wartungsanleitung 3061344 0609Dokument76 SeitenWolf CGB-K-11!20!24 Montage-Und Wartungsanleitung 3061344 0609MatoNoch keine Bewertungen

- EM11 User's Manual 2014Dokument94 SeitenEM11 User's Manual 2014nikola gNoch keine Bewertungen

- Treadmill 93t Service Manual - TTD Serial NumberDokument201 SeitenTreadmill 93t Service Manual - TTD Serial NumberpowerliftermiloNoch keine Bewertungen

- Kollmorgen AKD PDMM Fault Card en Rev KDokument29 SeitenKollmorgen AKD PDMM Fault Card en Rev KNaveen RastogiNoch keine Bewertungen

- Hcs02.1e W0054 Indra Drive C Rexroth ManualDokument358 SeitenHcs02.1e W0054 Indra Drive C Rexroth ManualKen Lim100% (1)

- Hoistway Top: SR NO Part Name Part No. Photo Remark Gen2 Nova Mrl-Ultra Drive-401Dokument3 SeitenHoistway Top: SR NO Part Name Part No. Photo Remark Gen2 Nova Mrl-Ultra Drive-401Ashok jiyaniNoch keine Bewertungen

- User'S Manual: Lift ApplicationDokument63 SeitenUser'S Manual: Lift ApplicationyounesNoch keine Bewertungen

- PLC WegDokument26 SeitenPLC WegLeonardo Andres MagiNoch keine Bewertungen

- Micelect Technical Manual LM3D STD Din Ver 01.2004Dokument1 SeiteMicelect Technical Manual LM3D STD Din Ver 01.2004Armando100% (1)

- Manual of PI9100 Vector Contorl Inverter V5Dokument240 SeitenManual of PI9100 Vector Contorl Inverter V5Juan Carlos CosmeNoch keine Bewertungen

- Emerson TD3200 ManualDokument107 SeitenEmerson TD3200 ManualEri Wanto SihombingNoch keine Bewertungen

- Linear Encoder For ElevatorsDokument8 SeitenLinear Encoder For ElevatorsFERNSNoch keine Bewertungen

- Enviando Variador CT2000V - English - Ver 1.36Dokument160 SeitenEnviando Variador CT2000V - English - Ver 1.36Ariel Alexis Pinto PintoNoch keine Bewertungen

- Prostar PR7000Dokument67 SeitenProstar PR7000Amir ZeidabadiNoch keine Bewertungen

- Quick Operational Manual-Gd300lDokument17 SeitenQuick Operational Manual-Gd300lNikhil SonarNoch keine Bewertungen

- AGC 200 Operators Manual 4189340607 UK - 2013.08.29Dokument21 SeitenAGC 200 Operators Manual 4189340607 UK - 2013.08.29Ricardo Nunes Pereira JuniorNoch keine Bewertungen

- Zxk-Can3200c-2012 Wee LRDokument2 SeitenZxk-Can3200c-2012 Wee LRjose moralesNoch keine Bewertungen

- PLC OMRON CPM SeriesDokument187 SeitenPLC OMRON CPM Seriestengon_ungNoch keine Bewertungen

- Manual ACS 500Dokument49 SeitenManual ACS 500JoseNoch keine Bewertungen

- Encoder WDG 100H PDFDokument12 SeitenEncoder WDG 100H PDFAlex GonzalezNoch keine Bewertungen

- Treinamento STEC-360A (NC Program) E PDFDokument107 SeitenTreinamento STEC-360A (NC Program) E PDFArmando Rivera100% (2)

- Safety of Household and Similar Electrical Appliances Part 2-29: Particular Requirements For Battery ChargersDokument158 SeitenSafety of Household and Similar Electrical Appliances Part 2-29: Particular Requirements For Battery ChargersFemko CorporationNoch keine Bewertungen

- Test Report: External Device Server UDS1100Dokument102 SeitenTest Report: External Device Server UDS1100Arith KrishnanandanNoch keine Bewertungen

- 109080-q Smart Cell - Bilge - ManualDokument29 Seiten109080-q Smart Cell - Bilge - Manualabuzer1981Noch keine Bewertungen

- Quo Test User ManualDokument36 SeitenQuo Test User ManualBình SêNê-GalNoch keine Bewertungen

- Dokumen - Tips - Test Report Iecen 60 335 2 64 Part 2 64 Particular 1 of 109 Test Report IssuedDokument109 SeitenDokumen - Tips - Test Report Iecen 60 335 2 64 Part 2 64 Particular 1 of 109 Test Report IssuedLamber LiNoch keine Bewertungen

- SETPOINT Machinery Protection System Overview Data SheetDokument32 SeitenSETPOINT Machinery Protection System Overview Data SheetBrickvilleNoch keine Bewertungen

- Repair Station Capability L Station Id Ld7r612j RCD CHG Added Rockwell Collins CockpitDokument20 SeitenRepair Station Capability L Station Id Ld7r612j RCD CHG Added Rockwell Collins CockpitAdel KhelifiNoch keine Bewertungen

- A High Speed, Low Voltage To High Voltage Level Shifter in Standard 1.2V 0.13 M CmosDokument4 SeitenA High Speed, Low Voltage To High Voltage Level Shifter in Standard 1.2V 0.13 M CmosaramshishmanyanNoch keine Bewertungen

- An Introduction To 8085 MicroprocessorDokument95 SeitenAn Introduction To 8085 MicroprocessorAshwini kumarNoch keine Bewertungen

- Fan-Out Wafer Level PackagingDokument2 SeitenFan-Out Wafer Level PackagingTom BlattnerNoch keine Bewertungen

- sg300 PDFDokument341 Seitensg300 PDFalex mirelesNoch keine Bewertungen

- Fundamental of Electrical Power Systems (Ee 270) : Chapter 4 (II) Basic PrinciplesDokument39 SeitenFundamental of Electrical Power Systems (Ee 270) : Chapter 4 (II) Basic PrinciplesJohn PetersNoch keine Bewertungen

- Calculation - Method - ULF Unbalanced Load Flow ETAP PDFDokument8 SeitenCalculation - Method - ULF Unbalanced Load Flow ETAP PDFZulqibalNoch keine Bewertungen

- ADPlaylistEditor3 (Network Version)Dokument42 SeitenADPlaylistEditor3 (Network Version)Dramane BonkoungouNoch keine Bewertungen

- Design Methodology For Graphene Tunable Filters at The Sub-Millimeter-Wave FrequenciesDokument18 SeitenDesign Methodology For Graphene Tunable Filters at The Sub-Millimeter-Wave FrequencieszahraNoch keine Bewertungen

- Imac Mid2011 Ug PDFDokument88 SeitenImac Mid2011 Ug PDFidscribdgmailNoch keine Bewertungen

- USBSync Board User ManualDokument18 SeitenUSBSync Board User ManualDavid JacquesNoch keine Bewertungen

- Moving Coil Instruments: L I B N FDokument31 SeitenMoving Coil Instruments: L I B N Faurellia moNoch keine Bewertungen

- Mini Intern 2022Dokument36 SeitenMini Intern 2022M AreebNoch keine Bewertungen

- IS40/Triton System: Installation ManualDokument19 SeitenIS40/Triton System: Installation ManualJITHESH KNoch keine Bewertungen

- BraktoothDokument16 SeitenBraktoothSivakumar SelvamNoch keine Bewertungen

- Product Specification: Product Mode Abbreviation Client Customer Audit SupplierDokument9 SeitenProduct Specification: Product Mode Abbreviation Client Customer Audit SupplierMartin huntNoch keine Bewertungen

- Origin AND ATA Standards: by Er - Swarnpreet SinghDokument17 SeitenOrigin AND ATA Standards: by Er - Swarnpreet SinghNupur GumberNoch keine Bewertungen

- Ibas MsanDokument53 SeitenIbas MsanOle LukoeNoch keine Bewertungen

- NptelDokument61 SeitenNptelRenuka LokaNoch keine Bewertungen

- SAED Digital Standard Cell Library - Rev1!4!20Dokument100 SeitenSAED Digital Standard Cell Library - Rev1!4!20Jordan JohnsonNoch keine Bewertungen

- Digital Modulation Techniques PDFDokument34 SeitenDigital Modulation Techniques PDFParas RastogiNoch keine Bewertungen

- Dragonwave Product GuideDokument8 SeitenDragonwave Product GuidejlmompriveNoch keine Bewertungen

- Slide01 Capacitor - Extra Examples SolutionsDokument3 SeitenSlide01 Capacitor - Extra Examples Solutions王施甯Noch keine Bewertungen

- Tellabs 8102Dokument4 SeitenTellabs 8102Pedro R MejiasNoch keine Bewertungen

- Brochure Aces MobilityDokument2 SeitenBrochure Aces Mobilitynaveenkumar MNoch keine Bewertungen

- LP 650 LP 650: User's GuideDokument47 SeitenLP 650 LP 650: User's Guidew7jesusdoNoch keine Bewertungen

- MJ 11032 G Hyundai BlowerDokument4 SeitenMJ 11032 G Hyundai BlowerDragan LugonićNoch keine Bewertungen

- Automatic Over Temperature Detection and AlertDokument5 SeitenAutomatic Over Temperature Detection and Alertsmartxdigital marketNoch keine Bewertungen

- Catalogo C29 Beneito FaureDokument106 SeitenCatalogo C29 Beneito FaurePedro FernandezNoch keine Bewertungen