Beruflich Dokumente

Kultur Dokumente

Featools - Caeser II Integration

Hochgeladen von

Kashif KaziOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Featools - Caeser II Integration

Hochgeladen von

Kashif KaziCopyright:

Verfügbare Formate

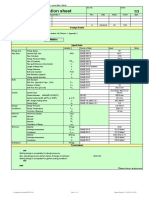

PRODUCT SHEET

BENEFITS:

Improve accuracy of designs and

analyses.

Improve analyses of components in

cyclic service.

Reduce stress on equipment.

Increase plant and equipment life.

Produce more cost-effective designs.

Reduce design changes and

iterations.

Calculate more realistic loading

conditions.

Calculate more realistic allowable

loads on nozzles.

Analyze components outside of code

limits.

FEATURES:

Incorporate FEA results into CAESAR

II model in an automated process.

Improve WRC 107/297 calculations

for loads on nozzles and attachments.

Use more accurate SIFs and k factors.

Enable FEA analysis of contoured

tees.

Support FEA analysis of bends and

tees with or without dummy-leg

supports.

Compare SIFs and k factors between

piping codes and FEA calculations.

Calculate SIFs and k factors for stan-

dard geometries.

Create tabular and graphical result

reports.

PAULIN RESEARCH GROUP

FEATOOLS

FOR CAESAR II

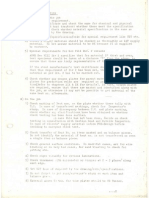

FEATools improves the quality of CAESAR II

users analysis for critical service lines

by incorporating nite element analysis (FEA) and other empirical sources into the evalu-

ation process. By using Intergraph

CAESAR II in combination with FEATools, analyzed

systems are neither over- nor under-designed, but designed with consistent safety fac-

tors, which also saves time and money.

FEATools from Paulin Research Group is available exclusively through Intergraph.

HIGHER ACCURACY, LOWER COSTS

Piping analysts know that that properly qualied FEA presents the greatest opportu-

nity to produce the most accurate analysis results. However, FEA can be extremely

time-intensive and require more technical expertise than is needed for the majority of

pipe stress problems. An ideal solution would allow FEA results to be easily and seam-

lessly incorporated within traditional code-based pipe stress analysis, so that your jobs

benet from the accuracy of FEA and the practicality of code-based analysis. CAESAR

II with FEATools provides this solution.

ADDRESSING CODE LIMITATIONS

There are well-known limitations in piping code accuracy when it comes to piping

branch connections. Performing a complete FEA of a piping system can be prohibitively

expensive. Instead, using FEA data for branch intersections is one of the most effective

and pragmatic uses of FEA technology for code-based pipe stress analysis.

FEA RESULTS AND PIPING CODES

Piping codes such as ASME B31.3 Appendix D state that, in the absence of more di-

rectly applicable data, the engineer should use the stress intensication factor (SIF) and

exibility factor (k factor) data from Appendix D of the code. FEATools uses the results

of the latest analysis, research, and testing to supply this applicable data to CAESAR

II, and it does so seamlessly and intuitively.

NOZZLES

FEATools also provides a quick way of calculating nozzle stiffness, allowable loads, and

stresses due to user-dened load sets. This more accurate nozzle exibility reduces

stress in the piping system during thermal load cases. This improves on the accuracy

of older methods used in the industry for qualifying nozzle loads such as WRC 107

and WRC 297. It addresses nozzles on heads and shells as well as radial, hillside, and

lateral nozzles.

ABOUT INTERGRAPH

Intergraph is the leading global provider of engineering and geospatial software

that enables customers to visualize complex data. Businesses and govern-

ments in more than 60 countries rely on Intergraphs industry-specic software to

organize vast amounts of data to make processes and infrastructure better, safer

and smarter. The companys software and services empower customers to build

and operate more efcient plants and ships, create intelligent maps, and protect

critical infrastructure and millions of people around the world.

Intergraph operates through two divisions: Process, Power & Marine (PP&M)

and Security, Government & Infrastructure (SG&I). Intergraph PP&M provides

enterprise engineering software for the design, construction, operation and data

management of plants, ships and offshore facilities. Intergraph SG&I provides

geospatially powered solutions, including ERDAS technologies, to the public safety

and security, defense and intelligence, government, transportation, photogrammetry,

and utilities and communications industries. Intergraph Government Solutions (IGS)

is a wholly owned subsidiary of Intergraph Corporation responsible for the SG&I U.S.

federal business.

Intergraph is part of Hexagon (Nordic exchange: HEXA B; www.hexagon.com), a

leading global provider of design, measurement, and visualization technologies that

enable customers to design, measure and position objects, and process and pres-

ent data.

For more information, visit www.intergraph.com.

WHEN TO USE

Accurate SIFs and k factors enable pipe stress analysts to use

the built-in exibility of a piping system to reduce unnecessary

redesigns of the system, which often have design constraints or

piping code limits. This reduces interdepartmental iterations in the

design process and saves valuable time and money. FEA-derived

SIFs and k factors are typically recommended in the following pip-

ing congurations:

Systems with large diameter thin-walled pipe (D/T>50).

Systems that connect to sensitive or rotating equipment.

Systems with operating cycles anticipated to be more

than 5000.

Systems with short or stiff piping (where k factors have a

large impact).

Existing systems modeling or piping connections.

Systems that require more accurate spring hanger design.

Systems that use thin-walled welding tees.

Systems where run i-factors control the solution and d/D

ratios < 0.5.

CAESAR II INTEGRATION

FEATools supports code-based pipe, pressure vessel, and tank

design. It was developed to interact only with CAESAR II. This

means that, once calculated, branch SIFs and k factors are not

only seamlessly and automatically transferred to the CAESAR II

model, but the software retains the data for future analysis.

CAESAR II WORKFLOW

Because FEATools closely matches the way CAESAR II operates,

the current workows remain virtually unchanged. Users can con-

tinue to produce the deliverables that they have come to trust. For

time efciency, the software saves each branch FEA calculation

in a database so users can reuse those values on subsequent

jobs. If a user wants to return to the original model, the software

creates the SIF and k factor-adjusted model as a copy, keeping

the original intact.

REAL-WORLD TESTING

The original piping code SIF values for intersections were derived

from work performed in the 1940s by A. R. C. Markl. Most of

these experiments were performed on a single size piping run,

from which all other SIF values were extrapolated. The SIF values

in FEATools are based on the testing done by Markl plus many

real-world and nite element calculations performed since those

original tests. The current tests were derived from hundreds

of pipe- and branch-size test models of various material thick-

nesses. This means FEATools provides the most comprehensive

evaluation of SIFs for piping intersections to date.

RESULTS AND REPORTS

FEATools generates a log le of all of the modications performed

on the CAESAR II model. Users can produce the same reports

they have always generated with CAESAR II without having to

learn a new reporting tool.

COMPONENTS

CAESAR II FEA Translator Applies more relevant SIFs and

exibility (k) factors for branch connections automatically in the

CAESAR II input le so FEA or improved correlation methods can

be used. Includes the option for light, medium, or heavy walled

tees, laterals, and the effect of weld thickness on SIFs and k

factors.

FESIF Calculates SIFs for cylinder-to-cylinder or cylinder-to-

head connections for fabricated assemblies.

FE107 Calculates the stresses in shells or heads at nozzle

intersections, which addresses integral, pad-reinforced, radial,

hillside, and lateral nozzle congurations.

FETee Calculates SIFs for contoured welding tees for ex-

truded or B16.9 geometries.

FEBend Calculates SIFs or evaluates external loads applied

to bends with structural steel or pipe stanchions.

PRGik Instantly evaluates SIF (i) and k factors for Appendix

D branch connection components. Helps the user determine if

the system is sensitive to more applicable SIFs or k factors. Also

provides Markl, Hinnant, and ASME allowable and mean failure

curves for given piping stresses.

2013 Intergraph Corporation. All rights reserved. Intergraph is part of Hexagon. Intergraph, the Intergraph logo, and CAESAR II are registered trademarks of Intergraph Corporation or its subsidiaries in the United

States and in other countries. FEATools is a trademark of Paulin Research Group. Other brands and product names are trademarks of their respective owners. 08/13 PPM-US-0242A-ENG

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Flange Calculation ASMEVIII-Custom WNRF (Alternate Check)Dokument11 SeitenFlange Calculation ASMEVIII-Custom WNRF (Alternate Check)Kashif Kazi100% (1)

- The Impact Testing Enigma: A Review of ASME Section VIII, Division 1, Subsection C, Part UCS, Impact Testing RequirementsDokument13 SeitenThe Impact Testing Enigma: A Review of ASME Section VIII, Division 1, Subsection C, Part UCS, Impact Testing Requirementssanjaypatel25Noch keine Bewertungen

- The Impact Testing Enigma: A Review of ASME Section VIII, Division 1, Subsection C, Part UCS, Impact Testing RequirementsDokument13 SeitenThe Impact Testing Enigma: A Review of ASME Section VIII, Division 1, Subsection C, Part UCS, Impact Testing Requirementssanjaypatel25Noch keine Bewertungen

- ASME Section VIII, Division 2Dokument23 SeitenASME Section VIII, Division 2Saeed Rehman100% (1)

- Corrosion Under Insulation - Detection and Monitroing MECCOCT18-12254Dokument16 SeitenCorrosion Under Insulation - Detection and Monitroing MECCOCT18-12254Kashif KaziNoch keine Bewertungen

- ASME Joint EfficiencyDokument49 SeitenASME Joint Efficiencygateauxboy95% (39)

- The Impact Testing Enigma: A Review of ASME Section VIII, Division 1, Subsection C, Part UCS, Impact Testing RequirementsDokument13 SeitenThe Impact Testing Enigma: A Review of ASME Section VIII, Division 1, Subsection C, Part UCS, Impact Testing Requirementssanjaypatel25Noch keine Bewertungen

- ASME Joint EfficiencyDokument49 SeitenASME Joint Efficiencygateauxboy95% (39)

- Introduction MeshingDokument20 SeitenIntroduction Meshingbotan_mihaiNoch keine Bewertungen

- The Impact Testing Enigma: A Review of ASME Section VIII, Division 1, Subsection C, Part UCS, Impact Testing RequirementsDokument13 SeitenThe Impact Testing Enigma: A Review of ASME Section VIII, Division 1, Subsection C, Part UCS, Impact Testing Requirementssanjaypatel25Noch keine Bewertungen

- Nozzle Design - Codeware-Compress FAQsDokument9 SeitenNozzle Design - Codeware-Compress FAQsKashif KaziNoch keine Bewertungen

- WIS Plate Exe 05Dokument13 SeitenWIS Plate Exe 05Kashif KaziNoch keine Bewertungen

- Jump Start Shell TubeDokument14 SeitenJump Start Shell TubetrantheanNoch keine Bewertungen

- Intro DesignModelerDokument19 SeitenIntro DesignModelerAlex DanielNoch keine Bewertungen

- UT of Pressure Vessel Construction WeldsDokument30 SeitenUT of Pressure Vessel Construction WeldsKashif KaziNoch keine Bewertungen

- #3 DesignDokument92 Seiten#3 DesignKashif KaziNoch keine Bewertungen

- Weld Neck Flange DesignDokument2 SeitenWeld Neck Flange DesignKashif KaziNoch keine Bewertungen

- ASME U-Stamp Fabrication Shop Best Practices Rev 0Dokument36 SeitenASME U-Stamp Fabrication Shop Best Practices Rev 0Kashif KaziNoch keine Bewertungen

- UT of Pressure Vessel Construction WeldsDokument30 SeitenUT of Pressure Vessel Construction WeldsKashif KaziNoch keine Bewertungen

- The Impact Testing Enigma: A Review of ASME Section VIII, Division 1, Subsection C, Part UCS, Impact Testing RequirementsDokument13 SeitenThe Impact Testing Enigma: A Review of ASME Section VIII, Division 1, Subsection C, Part UCS, Impact Testing Requirementssanjaypatel25Noch keine Bewertungen

- Aws Preheat Calculations From HardnessDokument6 SeitenAws Preheat Calculations From HardnessElias KapaNoch keine Bewertungen

- Getting Started - Aspen Shell and Tube ExchangerDokument12 SeitenGetting Started - Aspen Shell and Tube ExchangerSean ChoiNoch keine Bewertungen

- Photoshop CS5 Read MeDokument11 SeitenPhotoshop CS5 Read Meali_mohammed_18Noch keine Bewertungen

- Spence SRVsDokument132 SeitenSpence SRVsKashif KaziNoch keine Bewertungen

- Asme9 Fea ReportDokument10 SeitenAsme9 Fea ReportCristian Camilo Zapata PardoNoch keine Bewertungen

- What's New - PV Elite 2018Dokument28 SeitenWhat's New - PV Elite 2018SathiyaseelanNoch keine Bewertungen

- Beams OverviewDokument18 SeitenBeams OverviewrbhavishNoch keine Bewertungen

- 51e64ae0e4b08833fb23efa5 Shkrina 1374061788922 SfbmdiagramsDokument17 Seiten51e64ae0e4b08833fb23efa5 Shkrina 1374061788922 SfbmdiagramsAiman AmirNoch keine Bewertungen

- Brochure Roll Bonded Clad Plates EDokument36 SeitenBrochure Roll Bonded Clad Plates EAries MarteNoch keine Bewertungen

- What's New - PV Elite 2018Dokument28 SeitenWhat's New - PV Elite 2018SathiyaseelanNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Uenr25330001Dokument8 SeitenUenr25330001William carlos Trujillo cruzNoch keine Bewertungen

- Chapter 16IT Controls Part IIDokument10 SeitenChapter 16IT Controls Part IIChene Soriano100% (1)

- D63983GC20 - 30 - US Oracle Hyperion Financial Reporting 11.1.2 For EssbaseDokument3 SeitenD63983GC20 - 30 - US Oracle Hyperion Financial Reporting 11.1.2 For EssbaseChinmaya MishraNoch keine Bewertungen

- Mde 3802SDokument38 SeitenMde 3802SHeber Cari100% (1)

- F7400 Vs BHT8048Dokument1 SeiteF7400 Vs BHT8048Arief RahardjoNoch keine Bewertungen

- Sencore SA 1454 Manual V1.0Dokument76 SeitenSencore SA 1454 Manual V1.0scribbderNoch keine Bewertungen

- Vitruvian Principles - The Interdependancy of Firmitas, Utilitas and Venustas in Architecture and Design Pui's Blog PDFDokument7 SeitenVitruvian Principles - The Interdependancy of Firmitas, Utilitas and Venustas in Architecture and Design Pui's Blog PDFChristelle Joy EusebioNoch keine Bewertungen

- Power BI ArchitectureDokument47 SeitenPower BI ArchitectureMadhavan Eyunni100% (1)

- Project 1914198Dokument30 SeitenProject 1914198abhishek malhotraNoch keine Bewertungen

- Techniques To Reduce Timing Violations Using Clock Tree Optimizations in Synopsys ICC2Dokument10 SeitenTechniques To Reduce Timing Violations Using Clock Tree Optimizations in Synopsys ICC2Pardhasaradhi Damarla100% (1)

- Optimization of Shovel-Truck System For Surface MiningDokument8 SeitenOptimization of Shovel-Truck System For Surface MiningWilkhen ChuraNoch keine Bewertungen

- C++ Practicle FileDokument39 SeitenC++ Practicle Filekhushi birlaNoch keine Bewertungen

- Delcam - ArtCAM 2010 Insignia TrainingCourse EN - 2010Dokument134 SeitenDelcam - ArtCAM 2010 Insignia TrainingCourse EN - 2010akaki leqvinadzeNoch keine Bewertungen

- NGSPICE Manual-Devices and Circuits LabDokument15 SeitenNGSPICE Manual-Devices and Circuits LabShreya R HNoch keine Bewertungen

- From The Chair A Blog by Richard ArthursDokument4 SeitenFrom The Chair A Blog by Richard ArthursMohit DhandNoch keine Bewertungen

- Setup and Deployment in Visual Basic 2010Dokument15 SeitenSetup and Deployment in Visual Basic 2010meongkuNoch keine Bewertungen

- Introduction To Correlation and Regression Analysis PDFDokument6 SeitenIntroduction To Correlation and Regression Analysis PDFAzra MuftiNoch keine Bewertungen

- JR & Associates ProfileDokument16 SeitenJR & Associates ProfileGODFREY JATHONoch keine Bewertungen

- Booster Unit Auto Backwash FilterDokument5 SeitenBooster Unit Auto Backwash FilterFardin NawazNoch keine Bewertungen

- MST is-WiFi Tag Datasheet USDokument2 SeitenMST is-WiFi Tag Datasheet USedgarNoch keine Bewertungen

- Dynamics 365 Enterprise Edition Licensing GuideDokument52 SeitenDynamics 365 Enterprise Edition Licensing Guidefran.obando1332Noch keine Bewertungen

- A Conceptual Model For Electronic Document and Records Management System Adoption in Malaysian Public SectorDokument8 SeitenA Conceptual Model For Electronic Document and Records Management System Adoption in Malaysian Public SectorAronza LeeNoch keine Bewertungen

- FLTMC Instances OutputDokument2 SeitenFLTMC Instances OutputΓεώργιος ΝάσταςNoch keine Bewertungen

- Process Owner Manager Difference PDFDokument2 SeitenProcess Owner Manager Difference PDFNikolay DilanovNoch keine Bewertungen

- Itutor Prospectus 2013-2015 - FEB 16 - Itutor Fee StructureDokument3 SeitenItutor Prospectus 2013-2015 - FEB 16 - Itutor Fee StructureAnshuman DashNoch keine Bewertungen

- VPLS Autodiscovery BGP Based-CiscoDokument34 SeitenVPLS Autodiscovery BGP Based-Ciscokirantbhat19834099Noch keine Bewertungen

- Details Linux Based Pax S80 ARM ProcesorDokument2 SeitenDetails Linux Based Pax S80 ARM Procesorkakyo29433Noch keine Bewertungen

- +12V, 30ma Flash Memory Programming Supply: Evaluation Kit Manual Follows Data SheetDokument6 Seiten+12V, 30ma Flash Memory Programming Supply: Evaluation Kit Manual Follows Data SheetJuan Carlos TellezNoch keine Bewertungen

- Jubail Management Procedure: 090101 Subject Safety Tagging PurposeDokument9 SeitenJubail Management Procedure: 090101 Subject Safety Tagging PurposeAbdalrahman AntariNoch keine Bewertungen