Beruflich Dokumente

Kultur Dokumente

1.4.1 Compressor-Pump Curves

Hochgeladen von

karthipetroCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

1.4.1 Compressor-Pump Curves

Hochgeladen von

karthipetroCopyright:

Verfügbare Formate

Compressor & Pump Curves 1

1

Compressor & Pump Curves

2002 Hyprotech Ltd. - All Rights Reserved.

1.4.1 Compressor-Pump Curves.pdf

2 Compressor & Pump Curves

2

Workshop

In this module, compressor and pump curves will be used to model the

behaviour of simulated compressors and pumps. Using curves to model

these unit operations allows HYSYS to accurately simulate actual plant

equipment.

Learning Objectives

Once you have completed this module, you will be able to:

Specify and attach head and efficiency curves to compressors

Use single and multiple curves to model compressors

Attach head curves to pumps

Accurately model existing plant equipment with HYSYS

Prerequisites

Before beginning this module, you need to know how to:

Define and import a fluid package

Add streams and unit operations to the PFD

Compressor & Pump Curves 3

3

Compressor Curves

Using compressor curves in your HYSYS simulation allows you to

accurately model existing plant equipment. You can determine if an

existing compressor is able to meet the specifications of your process.

Using compressor curves allows HYSYS to calculate heads and

efficiencies that are dependant on the flow rate. If the flow rate through

the compressor is known to be constant, a single flow rate and efficiency

can be supplied. If, however, the flow rate is expected to change, using a

compressor curve will allow HYSYS to calculate new heads and

efficiencies based on the current flow rate.

This results in greater accuracy in the simulation, and allows HYSYS to

more closely model actual plant equipment.

Defining the Fluid Package

Before we begin any simulation in HYSYS, we must first define the

appropriate fluid package.

1. Start a New Case and add a Fluid Package.

2. Select the Fluid Package tab.

3. Select the Add button.

4. Select the Sour PR EOS package.

5. Select the Components tab.

6. Add a components list.

7. Add the following components: H

2

O, H

2

S, CO

2

, C1, C2, C3, i-C4, and

n-C4.

4 Compressor & Pump Curves

4

Installing a Stream

1. Add a Material Steam to the PFD with the following data:

Adding the Compressor

1. Add a Compressor to the PFD.

2. Enter the following information on the Connections page:

In This Cell... Enter...

Name Feed

Temperature 70C (160F)

Pressure 130 kPa (19 psia)

Molar Flow 500 kgmole/h (1100 lbmole/hr)

Mole Fraction [H

2

O] 0.24

Mole Fraction [H

2

S] 0.07

Mole Fraction [CO

2

] 0.06

Mole Fraction [C1] 0.04

Mole Fraction [C2] 0.11

Mole Fraction [C3] 0.25

Mole Fraction [i-C4] 0.08

Mole Fraction [n-C4] 0.15

In This Cell... Enter...

Inlet Stream Feed

Outlet Stream Outlet

Energy Stream Comp Duty

Compressor icon

Compressor & Pump Curves 5

5

3. On the Parameters page, ensure that the Polytropic and Adiabatic

efficiency boxes both read <empty>.

These values must read <empty> because the efficiencies will be

calculated from the compressor curves, and defining the same value in

two places will always result in a consistency error.

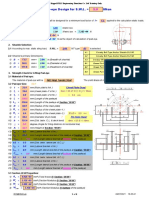

4. On the Curves page (on the Rating tab), select the Adiabatic radio

button in the Efficiency group. Click the Add Curve button, and

enter the data as shown here:

Figure 1

Figure 2

Be sure to use the correct

units for the curve.

6 Compressor & Pump Curves

6

5. Close the above view and activate Curve-1 on the Curves page.

Ensure that the Enable Curves box on the Curves page is checked.

6. The pressure of the outlet stream can be seen on the Worksheet

page, or you can choose Show Table when object-inspecting the

outlet stream on the PFD. The compressors efficiencies can be

found on the Results page.

Optional Exercise

It is desired to have an outlet pressure of 300 kPa (44 psia).

Use an Adjust operation with the following information:

Figure 3

What is the Outlet Pressure of the compressor? __________________________

What is the Adiabatic Efficiency? ______________________________________

The Polytropic Efficiency?_____________________________________________

In This Cell... Enter...

Adjusted Variable Feed - Molar Flow

Target Variable Outlet - Pressure

Specified Target Value 300 kPa (44 psia)

Step Size 5 kgmole/h (10 lbmole/hr)

Iterations 50

We do not need to enter a

compressor speed because

we are only entering one

curve. However, multiple

curves with different speeds

can be used.

Compressor & Pump Curves 7

7

Multiple Curves

Typically, industrial compressors are able to run at multiple speeds

depending on the current demand. HYSYS allows users to enter multiple

compressor curves that each represent a specified speed. Once the

curves are entered, any compressor speed can be specified and the head

and efficiency are calculated automatically.

In this exercise, a Natural Gas compressor will be examined to

determine the outlet pressure of a multi-speed compressor.

1. Begin a new case and import the fluid package Nat-Gas.fpk from the

diskette provide with this course.

2. Add a new stream to the PFD with the following data:

What is the Molar Flow rate if the Outlet Pressure is set at 300 kPa (44 psia)?

____________________________________________________________________

Can you think of an easier way of doing this? __________________________

How? _______________________________________________________________

In This Cell... Enter...

Name LP Gas

Temperature 10C (50F)

Pressure 1700 kPa (245 psia)

Molar Flow Rate 1500 kgmole/h (3300 lbmole/hr)

Comp. Mole Fraction - C1 0.99

Comp. Mole Fraction - C2 0.002

Comp. Mole Fraction - C3 0.0005

Comp. Mole Fraction - N2 0.005

Comp. Mole Fraction - CO2 0.0025

Save your case!

8 Compressor & Pump Curves

8

3. Add a Compressor to the PFD with this data:

4. Delete the default Adiabatic Efficiency value on the Parameters

page. Again, the efficiency will be calculated from the compressor

curves.

5. Add the four curves shown below to the compressor. Note that the

curves have been supplied in Field units. (If you are using SI units,

you must change the Flow and Head units to those shown here

before you enter the curve data).

In This Cell... Enter...

Inlet LP Gas

Outlet HP Gas

Energy Comp Duty

Figure 4

Figure 5

Note that compressor speeds

must be entered here as

multiple curves are being

used.

Compressor & Pump Curves 9

9

6. Ensure that all of the curves are activated, and the Enable Curves

box is checked. These curves are polytropic curves, therefore the

Polytropic radio button must be checked in the Efficiency group on

the Curves page.

Figure 6

Figure 7

The plots for efficiency and

head versus flow can be seen

by pressing the Plot Curves

button on the Curves page.

Instead of entering all of the

curve data, open the HYSYS

case Comp_Shortcut.hsc on

the disk supplied with this

module, and begin on step 6.

10 Compressor & Pump Curves

10

7. On the Curves page, enter a speed of 11 000 per min.

Optional Exercise

1. Delete the specified compressor speed of 11 000 per minute.

2. Enter a pressure of 5000 kPa (725 psia) for the HP Gas stream.

3. HYSYS will automatically calculate the compressor speed needed to

meet this outlet pressure.

Figure 8

What is the pressure of the HP Gas stream? _____________________________

What is the compressor speed needed to achieve the specified outlet

pressure? ___________________________________________________________

What are the Adiabatic and Polytropic efficiencies of the compressor under

these conditions? ____________________________________________________

What is the temperature of the HP Gas? ________________________________

Save your case!

Compressor & Pump Curves 11

11

Pump Curves

As with compressor curves, pump curves are used to allow HYSYS to

accurately model existing pumps. Pump curves allow the pressure rise

across the pump to be dependent on the flow rate of liquid.

The pump curves are entered into HYSYS using a form different than the

form used for compressor curves. With pump curves the coefficients of

an expression, up to the fifth order, are entered into HYSYS rather than

the actual data points.

Defining the Fluid Package

1. Begin a new case and select the Peng Robinson EOS package.

2. Add the components n-Hexane, n-Heptane, and n-Octane.

Installing a Stream

Add a new stream to the PFD and enter the following information:

In This Cell... Enter...

Name LP Mixture

Temperature 25C (77F)

Pressure 120 kPa (18 psia)

Liquid Volume Flow 500 m

3

/hr (76,000 BPD)

Comp. Mass Fraction (Hexane) 0.60

Comp. Mass Fraction (Heptane) 0.30

Comp. Mass Fraction (Octane) 0.10

The coefficients can be

obtained from a spreadsheet

program capable of nonlinear

regression, such as EXCEL,

or may be supplied by the

pumps manufacturer.

12 Compressor & Pump Curves

12

Adding the Pump

1. Add a Pump to the PFD and enter the following information:

2. On the Curves page, enter the following data:

3. Ensure that the Activate Curves box is checked.

In This Cell... Enter...

Inlet LP Mixture

Outlet HP Mixture

Energy Pump Duty

Efficiency (Parameters Page) 75%

In This Cell... Enter...

Coefficient A 3000

Coefficient B -2.0

Coefficient C -0.005

All Other Coefficients 0

Units for Head m

Flow Basis Act. Vol. Flow

Units for Flow m

3

/h

Figure 9

Pump icon

Compressor & Pump Curves 13

13

4. The pressure of the product stream can be seen on the Worksheet

tab.

What is the outlet pressure of the pump?________________________________

The pump sales representative, who supplied the curve data, guaranteed an

outlet pressure of 5000 kPa (725 psia) at the specified flow rate. Should you

fill out the purchase order? ____________________________________________

Save your case!

14 Compressor & Pump Curves

14

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Practical Thermal Design of Air-Cooled Heat ExchangersDokument151 SeitenPractical Thermal Design of Air-Cooled Heat Exchangerskarthipetro100% (13)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Natural Gas Sweetening & Effect of Decline PressureDokument29 SeitenNatural Gas Sweetening & Effect of Decline Pressureromdhan88Noch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Thickness CalculationDokument1 SeiteThickness CalculationkarthipetroNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Teg ContactorDokument4 SeitenTeg ContactorrepentinezNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Process DescriptionDokument4 SeitenProcess DescriptionkarthipetroNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Two Phase Separator SizingDokument5 SeitenTwo Phase Separator SizingNoman Abu-FarhaNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Tube Selection ChartDokument6 SeitenTube Selection ChartkarthipetroNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Flowmeter Piping RequirementsDokument11 SeitenFlowmeter Piping RequirementskarthipetroNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- PVRV Sizing Calculations - Crude Oil Stroage Tank (007486-T-01)Dokument2 SeitenPVRV Sizing Calculations - Crude Oil Stroage Tank (007486-T-01)karthipetro100% (7)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Air Cooler - DesignDokument7 SeitenAir Cooler - Designkarthipetro100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- State Bank of IndiaDokument5 SeitenState Bank of IndiakarthipetroNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Redapt Hazardous Area GuideDokument11 SeitenRedapt Hazardous Area GuidekarthipetroNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Head Loss Due To Friction: Darcy-Weisbach EquationDokument5 SeitenHead Loss Due To Friction: Darcy-Weisbach EquationkarthipetroNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Control Valve SizingDokument21 SeitenControl Valve Sizingtiwarishailendra2198Noch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Amine Sweetening Process DesignDokument12 SeitenAmine Sweetening Process Designswapnil2603100% (2)

- Calculation Acc. To Calame A. Hengst: Only For Gases Only For Low Pressure Regulator ZM-R, ZM-B and LPR, LPSDokument6 SeitenCalculation Acc. To Calame A. Hengst: Only For Gases Only For Low Pressure Regulator ZM-R, ZM-B and LPR, LPSkarthipetro100% (2)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Tied Independent Scaffolding Leg LoadsDokument14 SeitenTied Independent Scaffolding Leg LoadsjmsNoch keine Bewertungen

- Flange Dimensions PDFDokument4 SeitenFlange Dimensions PDFSRINIVASNoch keine Bewertungen

- Shovel Vs Wheel LoaderDokument22 SeitenShovel Vs Wheel LoadermanamohanroutNoch keine Bewertungen

- Catalog KlaussDokument5 SeitenCatalog Klaussmalboro111Noch keine Bewertungen

- Installation Instructions: MazdaDokument3 SeitenInstallation Instructions: MazdaMickael FernánNoch keine Bewertungen

- F AdaptersDokument122 SeitenF Adaptersxuanphuong2710Noch keine Bewertungen

- DENSO Robotics Datasheet VS-G Series PDFDokument2 SeitenDENSO Robotics Datasheet VS-G Series PDFjohnNoch keine Bewertungen

- Nouvelle Brochure BTTDokument28 SeitenNouvelle Brochure BTTskirubananthNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- CurveDokument19 SeitenCurveSheryll de GuzmanNoch keine Bewertungen

- H. K. Moffatt and Tadashi Tokieda - Celt Reversals: A Prototype of Chiral DynamicsDokument8 SeitenH. K. Moffatt and Tadashi Tokieda - Celt Reversals: A Prototype of Chiral DynamicsVortices3443Noch keine Bewertungen

- Work Method Statement FOR Kentledge Maintained Load TestDokument5 SeitenWork Method Statement FOR Kentledge Maintained Load TestLynn MailNoch keine Bewertungen

- D SADFNDJSFGVVDFDokument27 SeitenD SADFNDJSFGVVDFFahmi AzisNoch keine Bewertungen

- The Gas Laws: Cortez Vince Robert Linghon QuishaDokument10 SeitenThe Gas Laws: Cortez Vince Robert Linghon QuishaZ ACERNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Sec DPSDokument542 SeitenSec DPSganeshakceNoch keine Bewertungen

- Science Unit-Wheels and LeversDokument11 SeitenScience Unit-Wheels and Leversapi-535552931Noch keine Bewertungen

- 4328224R1 - N9 and N10 Engine Operation and Maintenance ManualDokument102 Seiten4328224R1 - N9 and N10 Engine Operation and Maintenance ManualJonathan Luiz PolezaNoch keine Bewertungen

- Öhlins Ka049 Zxr750r 91-94Dokument2 SeitenÖhlins Ka049 Zxr750r 91-94sasaNoch keine Bewertungen

- 1K 2K Service Manual 4th GenDokument305 Seiten1K 2K Service Manual 4th GenElectronica coetc100% (1)

- SWL 25 MT Padeye at Crosby G-2130 - Extg - MS - 9mm (Hole - Gap - 7mm) (Side - Gap - 9mm) (For 500T GC & AHII)Dokument2 SeitenSWL 25 MT Padeye at Crosby G-2130 - Extg - MS - 9mm (Hole - Gap - 7mm) (Side - Gap - 9mm) (For 500T GC & AHII)Paulo MoreiraNoch keine Bewertungen

- Parker IPS Catalog 1816-3Dokument256 SeitenParker IPS Catalog 1816-3Mario DuranNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- TorsionDokument14 SeitenTorsionProninaNoch keine Bewertungen

- Mark Scheme - Results Summer 2013: GCE Physics 6PH01 Paper 01R: Physics On The GoDokument18 SeitenMark Scheme - Results Summer 2013: GCE Physics 6PH01 Paper 01R: Physics On The GoAli SajjadNoch keine Bewertungen

- Brake SystemDokument42 SeitenBrake SystemeduamaNoch keine Bewertungen

- Part 2 Pressure Vessel DesignDokument281 SeitenPart 2 Pressure Vessel DesignSyedZainAli100% (1)

- MTO Indowater 2019Dokument5 SeitenMTO Indowater 2019Muhammad Ilham Al FaizNoch keine Bewertungen

- Midas Civil WebinarDokument51 SeitenMidas Civil WebinarCHarlesghylonNoch keine Bewertungen

- Old Oil Barrel GeneratorDokument15 SeitenOld Oil Barrel GeneratorAlbert NewhearthNoch keine Bewertungen

- Biddle - VRVDokument31 SeitenBiddle - VRVutzu_yooNoch keine Bewertungen

- ColumnsDokument37 SeitenColumnsSeventh SkyNoch keine Bewertungen

- Electrical Equipment: Passenger Compartment Connection UnitDokument233 SeitenElectrical Equipment: Passenger Compartment Connection UnitEeeps100% (2)