Beruflich Dokumente

Kultur Dokumente

Rotary Kiln Services 2013 Prices

Hochgeladen von

MKPashaPasha0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

211 Ansichten8 SeitenRotary Kiln Services 2013 Prices

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenRotary Kiln Services 2013 Prices

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

211 Ansichten8 SeitenRotary Kiln Services 2013 Prices

Hochgeladen von

MKPashaPashaRotary Kiln Services 2013 Prices

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 8

Address: BOSB Birlik Sanayi Sitesi 5.

Cadde No:32 34520 Beylikduzu Istanbul TURKEY

Phone: +90 212 861 09 86 Fax: +90 212 861 53 02 DIRECT: +90 533 650 09 20

URL: www.ozekmakina.com E-Mail: bilgi@ozekmakina.com

Document Nu: 20130822 Page: 1 / 8

To :

Subject : Document Nu : Sent to : Date :

Purchase department

Quote 20130822 - 22

nd

August 2013

SUBJECT:

Quotation for the works listed below.

SCOPE OF THE WORK :

FULL KILN ANALYSIS

- Basic mechanical kiln inspection.

- Horizontal and vertical axial deviations.

- Kiln slope.

- Individual tyre, roller and gear slopes.

- Tyre and 5 point roller diameters.

- Under tyre gaps, tyre relative movement.

- Roller working angles.

- Roller skew.

- Girth gear/pinion gear 10 point backlash measurement.

- Wobbling (Tyres and girth gear).

- Ovality.

- Shell deformation analysis. (Reports for full shell and individual sections for every 1 meter.)

- Full kiln analysis report presentation.

ALIGNMENT SUPERVISION (Depending on the report result.)

- Alignment (Roller Skewing) supervision of the rollers depending on the hot kiln alignment

report.

IN SITU TYRE/ROLLER/THRUST ROLLER RESURFACING (Depending on the report result.)

- Machining and grinding the supporting roller side of tyre.

- Machining and grinding the thrust roller side of tyre.

- Machining the tyre side of thrust roller.

- Machining the tyre side of supporting roller.

Address: BOSB Birlik Sanayi Sitesi 5. Cadde No:32 34520 Beylikduzu Istanbul TURKEY

Phone: +90 212 861 09 86 Fax: +90 212 861 53 02 DIRECT: +90 533 650 09 20

URL: www.ozekmakina.com E-Mail: bilgi@ozekmakina.com

Document Nu: 20130822 Page: 2 / 8

TECHNICAL SPECIFICATIONS:

All the equipments which will be used in this work will be provided by OZEK MAKINA.

220V and 380V continuous electrial power, oxygen welding, lighting and the scaffold in the rotary kiln

piers will be provided by CUSTOMER.

A room close to the working area which will be used as an office will be provided by CUSTOMER.

All the safety clothing objects will be provided by OZEK MAKINA.

CUSTOMER is responsible of securing all crew and the equipments during working period.

PAYMENT OF THE EXTRA COSTS:

DESCRIPTION COST

PAID BY

OZEK MAKINA CUSTOMER

VISA

Consultancy and embassy payments

- x -

FLIGHT TICKETS

Istanbul-Plant-Istanbul Flight tickets

for 5 people.

- x -

TOOL BOX CARGO (ISTANBUL TO PLANT)

Tool Box; Sizes: 1 x 1 x 2 m Weight: 1000 Kg

All consultancy, air cargo and customs

payments including re-import payments.

- x -

TOOL BOX CARGO (PLANT TO ISTANBUL)

Tool Box; Sizes: 1 x 1 x 2 m Weight: 1000 Kg

All consultancy, air cargo and customs

payments including import and re-export

payments.

- - x

HOTEL

For 5 people for 10 nights including

breakfast.

- - x

FOOD

Lunch, dinner and night breakfast for 5

people.(15 per meal) The team may use

plant refectory for lunch, dinner and night

breakfast for night shift.

- - x

TRANSFERS OR CAR RENTAL

10 days price for a mid class car rental.

CUSTOMER is responsible for all transfers

for airport-hotel-airport and plant-hotel-

plant.

- - x

TOTAL - - -

- Ozek Makina Works with 5 people team for resurfacing projects and 3 people team for full kiln

analysis projects.

- Tool Box is used during resurfacing projects.

- All the costs of plant side including importing the tool box and re-exporting will be paid by

CUSTOMER.

- Due to the night shift works and unplanned site visits, car rental might be a better option for all

transfers.

- The team needs an office with internet connection close to the kiln during all works.

Address: BOSB Birlik Sanayi Sitesi 5. Cadde No:32 34520 Beylikduzu Istanbul TURKEY

Phone: +90 212 861 09 86 Fax: +90 212 861 53 02 DIRECT: +90 533 650 09 20

URL: www.ozekmakina.com E-Mail: bilgi@ozekmakina.com

Document Nu: 20130822 Page: 3 / 8

PRICING:

SUBJECT DURATION KILN SPEED AMOUNT PRICE

Full kiln analysis.

9

Days

Up To

4 rpm

1 15.000,00 USD

Alignment supervision.

4

Days

Up To

4 rpm

1 7.000,00 USD

Machining and grinding the supporting roller

side of tyre.

6

Days

Up To

3 rpm

1 20.000,00 USD

Machining and grinding the thrust roller side

of tyre. (One side only)

4

Days

Up To

3 rpm

1 16.000,00 USD

Machining the tyre side of thrust roller.

2

Days

Up To

4 rpm

1 2.500,00 USD

Machining the tyre side of supporting roller.

2

Days

Up To

5 rpm

1 3.500,00 USD

BUNDLE PRICE FOR THRUST ROLLER PIER

- Machining and grinding the supporting

roller side of tyre.

- Machining and grinding the thrust roller

side of tyre. (One side only)

- Machining the tyre side of supporting

roller.

8

Days

Up To

3 rpm

1

Set

32.000,00 USD

- Valid as a whole.

- Please see additional costs section.

- 1.500 USD /day will be added to price for alignment supervision works more than 4 days.

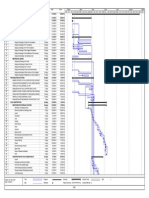

ESTIMATED TIME TABLE:

DAYS 1 2 3 4 5 6 7 8 9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

Full Kiln Analysis BI*

Roller Resurfacing 1 2 3 4 5 6

Tyre Resurfacing Pier 1 with thrust roller (Bundle) Pier 2 Pier 3

Alignment (Skew)

* BI: Basic Inspection including diameter measurements of tyres and rollers.

- Estimated durations might change due to the tyre wear and kiln conditions.

Address: BOSB Birlik Sanayi Sitesi 5. Cadde No:32 34520 Beylikduzu Istanbul TURKEY

Phone: +90 212 861 09 86 Fax: +90 212 861 53 02 DIRECT: +90 533 650 09 20

URL: www.ozekmakina.com E-Mail: bilgi@ozekmakina.com

Document Nu: 20130822 Page: 4 / 8

TERMS:

Half of the total price will be paid cash or via bank transfer when quotation signed.

Balance will be paid cash or via bank transfer at the end of the bussiness.

Please use following account info for advance payment.

ACCOUNT OWNER Ozek Makina - Hatice Ozek

BANK Akbank

BRANCH Buyukcekmece

IBAN TR510004600197001000204703

SWIFT CODE AKBKTRIS

VALIDITY:

Price offer is valid as a whole till 31.12.2013

Best Regards,

Zeki ZEK

Address: BOSB Birlik Sanayi Sitesi 5. Cadde No:32 34520 Beylikduzu Istanbul TURKEY

Phone: +90 212 861 09 86 Fax: +90 212 861 53 02 DIRECT: +90 533 650 09 20

URL: www.ozekmakina.com E-Mail: bilgi@ozekmakina.com

Document Nu: 20130822 Page: 5 / 8

APPENDIX

EQUIPMENT LIST:

All the tools listed below are packed in a w:100 X l:200 X h:100 cm closed metal box and all weights

(including the box itself) 1000 kg.

Tool box will be insured by the carrier company.

UNIT QUANTITY

(Label A,B,E) Portable lathe unit

Three types of portable lathe support moving by the power of electric motor used for mounting

and auto moving lathe tools.

1 Set

(Label C) Portable lathe leaning apparatus

A set of iron mounts which is used for installing and bending the portable machining and grinding

tool over the rotary kiln tyre.

1 Set

(Label D) Pulley carriers

Two types of pulleys which are used for carrying the PMGT by hanging the pulleys on scaffold.

3 Set

(Label F,G) Grinding motor

Two different sized electrik motor bowl grinders which are used for grinding the rotary kiln tyre.

2 Set

(Label 1,2) Tool Box : Diameter measurement tools

Electronic meaurement tools which are used for on-site measurement needs.

2 Set

(Label 3) Tool Box : Safety clothing sets

Safety gloves, safety glasses, dust masks, earplugs

20 Set

(Label 4) Tool Box : Repair tools, bolts, wrencehs, lathers

Wrench sets, screwdrivers, bolts, lathe cutting tools

1 Set

(Label 5) Tool Box : Hammers, screwdrivers, wrenchs, allen

Hammers, allen wrenches, wrench sets

1 Set

(Label 6) Tool Box : Extension cords, switchers, lights

Extension cords, plug multiplexers, switchers

1 Set

(Label 7) Tool Box : Electricity supply units

Electricity suppliers

1 Set

(Label 8) Tool Box : Grinders

Handy Grinder power tools and spare disc grinders.

1 Set

(Label 9) Tool Box : Mini welder and electrode

Portable welding machine and spare elctrodes.

1 Set

(Label 10) Tool Box : Tea Set

Water boiler, tea cups, tea, coffee, sugar

1 Set

(Label 11) Tool Box : Bowl Grinders

Spare bowl grinders

1 Set

Apart from this tool box,

- Oxygen cutting set

- 4 industrial type, middle size climating fans

- For the scaffold; (4 pieces) 3,5 meters long scaffold masts, (8 pieces) 3,5 m long scaffold pipes

and (8 pieces) 1,2 meters short scaffold pipes. If it is clamp style we will also need clamps.

- 220 and 380 V continuous electric energy

- 200mm U style 3 meters long iron.

- 120 mm L style bracket iron 2 pieces 6 meters long

- A crane or high-up to lift the tool box nearby the pier.

will be provided by CUSTOMER.

Address: BOSB Birlik Sanayi Sitesi 5. Cadde No:32 34520 Beylikduzu Istanbul TURKEY

Phone: +90 212 861 09 86 Fax: +90 212 861 53 02 DIRECT: +90 533 650 09 20

URL: www.ozekmakina.com E-Mail: bilgi@ozekmakina.com

Document Nu: 20130822 Page: 6 / 8

PRECONDITIONS:

We may require for a 5 minutes shut down for a short preparation. Apart from it, we do not ask for any

shut down or slow down up to 3,5 rpm during our work.

It is also recommended to clean around the pier, prepare the equipments which will be provided by the

company before starting.

QUALITY ASSURANCE:

We use special equipments developed by Ozek Makina team for all measurement needs during resurfacing

works and hot kiln alignment services. The presicion for diametral measurements is 0,1 mm and it is 1 mm

for our hot kiln alignment services.

Our team works coordinated with rotary kiln crew and gets regular information about serviced unit. All

shifts observes the unit and reports the situation to technical manager who is responsible of deciding the

procedure.

OHS MANAGEMENT:

Rotary kiln tyre resurfacing work is done on site during the regular conditions of kiln. A portable lathe unit

is installed on the side of tyre and crew stays over a 3 meter high scaffold during all working time. The

scaffold has stairs, seat and barrier for safety needs. The seat side is climated by 3 or 4 industrial type fans

to regulate the temperature caused by kiln. Scaffold is also covered by filet type canvas to avoid any

accident and the dust outside. Several heat shields are used for the kiln heat.

All crew uses safety clothes, helmet, safety gloves, safety glasses, dust mask and hearing protection

equipments during all working time on site.

All crew have been educated about personal protection safety rules regularly at the beginning of all site

works.

All team members are medically examined by occupational healt clinics for heavy industry standarts every

6 months. All clinic reports are stored by Ozek Makina. Name, blood type and citizenship numbers are also

written on all crews helmet.

All team members are insured by Turkish government social security foundation. All insurance costs are

monthly paid by Ozek Makina.

Ozek Makine uses in-factory clinic and ambulance for accidents and Zeki Ozek is responsible for OHS

management on site.

DURATION EXCEED:

Although it is not possible to estimate the duration before starting the work, we give 10 days as an average

working time for typical tyre problems. We are pricing the works as a whole independent from duration.

Several reasons like rotation speed, kiln shut down or tyre wobbling can cause a difference on duration.

We do not charge the delays caused by the customer up to 3 days. Delays over that period are charged 500

USD per day.

We can machine and grind the surface at rotation speeds up to 3,5 rpm and do not request any shut down

or slown down during working time. Slower rotation speed might cause duration exceeds depending on

Address: BOSB Birlik Sanayi Sitesi 5. Cadde No:32 34520 Beylikduzu Istanbul TURKEY

Phone: +90 212 861 09 86 Fax: +90 212 861 53 02 DIRECT: +90 533 650 09 20

URL: www.ozekmakina.com E-Mail: bilgi@ozekmakina.com

Document Nu: 20130822 Page: 7 / 8

the wear level. We do not charge or accept any penalty for duration exceed caused by rotation speed and

wear level.

TERMS AND CONDITIONS:

Our resurfacing services consist of machining and grinding the surface by the help of a portable lathe

equipment. Ozek Makina, accepts the work as a predecided part of a sollution and does not claim that

resurfacing will solve the ongoing problems on kiln.

Ozek Makina is responsible of shaping the tyre and/or roller to the minimum diametral cylinder with N12

roghness standarts and after acceptance of work by the help of any measurements taken by the customer,

Ozek Makina does not guarantee for any term for its services which may be worn due to the wrong usages

or other problems.

TERMINATION:

This offer is valid as a whole for 6 months. Ozek Makina keeps its rights reserved to terminate the contract

in case of the conditions which do not let to work like high security problems, natural disasters and long

therm shut downs for over 15 days. If the contract is terminated by CUSTOMER during the working time,

Ozek Makina accepts the work is done and may claim to charge the full invoice price and additional costs.

Address: BOSB Birlik Sanayi Sitesi 5. Cadde No:32 34520 Beylikduzu Istanbul TURKEY

Phone: +90 212 861 09 86 Fax: +90 212 861 53 02 DIRECT: +90 533 650 09 20

URL: www.ozekmakina.com E-Mail: bilgi@ozekmakina.com

Document Nu: 20130822 Page: 8 / 8

REFERENCES

OVER 100 ROTARY KILN SERVICES AT 60 PLANTS ACROSS 8 COUNTRIES SINCE 1968

www.rotarykiln.eu

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Creating A BudgetDokument131 SeitenCreating A BudgetMKPashaPashaNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- AfdkjfaldjDokument53 SeitenAfdkjfaldjSam Chu100% (3)

- Resorts and Great Hotels Magazine 2005 PDFDokument456 SeitenResorts and Great Hotels Magazine 2005 PDFBuliga Alexandra ElenaNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- 04 MillingDokument21 Seiten04 MillingMKPashaPasha100% (1)

- Drafting For Finance LawyersDokument2 SeitenDrafting For Finance LawyersMark OmugaNoch keine Bewertungen

- 07 EnvironmentDokument14 Seiten07 EnvironmentMKPashaPashaNoch keine Bewertungen

- POwise Monthly Trend-205206207Dokument1 SeitePOwise Monthly Trend-205206207MKPashaPashaNoch keine Bewertungen

- Pyro ProcessingDokument29 SeitenPyro ProcessingMKPashaPasha100% (2)

- Pyro ProcessingDokument29 SeitenPyro ProcessingMKPashaPasha100% (2)

- 441 GC & EspDokument6 Seiten441 GC & EspMKPashaPashaNoch keine Bewertungen

- Fast Meals Less Bills (A Feasibility Study)Dokument57 SeitenFast Meals Less Bills (A Feasibility Study)Carl Justin Ballerta100% (1)

- 117 - DWP Difficult Solid Fuel Burning 191207 - RDB&YJBDokument10 Seiten117 - DWP Difficult Solid Fuel Burning 191207 - RDB&YJBMKPashaPashaNoch keine Bewertungen

- Process GuidlinesDokument20 SeitenProcess GuidlinesMKPashaPasha100% (4)

- 05 CombustionDokument15 Seiten05 CombustionMKPashaPasha100% (1)

- Chris Cool TEEN Agent Sereis #5 Heads You LoseDokument175 SeitenChris Cool TEEN Agent Sereis #5 Heads You LosePastPresentFuture100% (1)

- Filtration: Fiber FilterDokument20 SeitenFiltration: Fiber FilterTamer Farouk KhalifaNoch keine Bewertungen

- Samba Cantina EbDokument2 SeitenSamba Cantina EbGustavo HuntNoch keine Bewertungen

- POwise Monthly Trend-812Dokument1 SeitePOwise Monthly Trend-812MKPashaPashaNoch keine Bewertungen

- Mechanical Properties For Steel FastenersDokument7 SeitenMechanical Properties For Steel FastenersepriyonoNoch keine Bewertungen

- POwise Monthly Trend-153Dokument1 SeitePOwise Monthly Trend-153MKPashaPashaNoch keine Bewertungen

- POwise Monthly Trend-812Dokument1 SeitePOwise Monthly Trend-812MKPashaPashaNoch keine Bewertungen

- POwise Monthly Trend-405406407Dokument1 SeitePOwise Monthly Trend-405406407MKPashaPashaNoch keine Bewertungen

- POwise Monthly Trend-102Dokument1 SeitePOwise Monthly Trend-102MKPashaPashaNoch keine Bewertungen

- AIS-Mechanical Maintenance ModuleDokument3 SeitenAIS-Mechanical Maintenance ModuleMKPashaPashaNoch keine Bewertungen

- 01 - IP SOW Template v3.0Dokument26 Seiten01 - IP SOW Template v3.0MKPashaPashaNoch keine Bewertungen

- GCCL ManualDokument26 SeitenGCCL ManualMKPashaPashaNoch keine Bewertungen

- Excel Formulas FunctionsDokument2 SeitenExcel Formulas FunctionsMKPashaPashaNoch keine Bewertungen

- The Marketing Environment and Competitor Analysis: - SWOT Analysis - PEST Analysis - Five Forces AnalysisDokument10 SeitenThe Marketing Environment and Competitor Analysis: - SWOT Analysis - PEST Analysis - Five Forces AnalysisMKPashaPashaNoch keine Bewertungen

- Antico PizzaDokument1 SeiteAntico PizzamurielvegaNoch keine Bewertungen

- Red Cow MenuDokument2 SeitenRed Cow Menuebest4301Noch keine Bewertungen

- ExamDokument4 SeitenExamYeiser yair Hernández MartínezNoch keine Bewertungen

- Chocolate Substitution ChartDokument4 SeitenChocolate Substitution ChartHipsipila CrisálidaNoch keine Bewertungen

- Mid Bing KLS XiDokument7 SeitenMid Bing KLS Xireni yusmitaNoch keine Bewertungen

- The DrunktionaryDokument239 SeitenThe DrunktionaryRed Rex 2015Noch keine Bewertungen

- Puja Committee & President MessagesDokument7 SeitenPuja Committee & President Messagesdesikudi9000Noch keine Bewertungen

- Planos de Cascanueces de Madera Redondo.Dokument9 SeitenPlanos de Cascanueces de Madera Redondo.kevineliNoch keine Bewertungen

- 3 Successful Entrepreneurs in Our CountryDokument2 Seiten3 Successful Entrepreneurs in Our CountryWei Ren HersheyNoch keine Bewertungen

- Life at MICADokument2 SeitenLife at MICApooja sharmaNoch keine Bewertungen

- Cabouge Quebec A2 AppDokument4 SeitenCabouge Quebec A2 AppDavidAnibalNoch keine Bewertungen

- Elementary (French)Dokument52 SeitenElementary (French)Cesar Messi100% (1)

- CVJ Kiddie Party 2023Dokument3 SeitenCVJ Kiddie Party 2023ayelNoch keine Bewertungen

- Waiter Servicing: LESSON 1: Duties & Responsibilities of WaiterDokument27 SeitenWaiter Servicing: LESSON 1: Duties & Responsibilities of WaiterChryz SantosNoch keine Bewertungen

- The Province of Naga IN Bicol: Tourism Management 101Dokument22 SeitenThe Province of Naga IN Bicol: Tourism Management 101Imelda Arreglo-AgripaNoch keine Bewertungen

- Market Research Ketchup IndustryDokument8 SeitenMarket Research Ketchup Industrypuneet.glenn100% (1)

- Dukan Diet Food ListDokument2 SeitenDukan Diet Food ListprogramgrabberNoch keine Bewertungen

- Reinforcement Worksheet 1: PhotocopiableDokument4 SeitenReinforcement Worksheet 1: PhotocopiableSusana GarciaNoch keine Bewertungen

- Gordon Ramsay BiographyDokument2 SeitenGordon Ramsay BiographyRik TorresNoch keine Bewertungen

- Indian Delights - Fine Dining Restaurant in Gurgaon - Take Away - Home DeliveryDokument9 SeitenIndian Delights - Fine Dining Restaurant in Gurgaon - Take Away - Home DeliveryGauravNoch keine Bewertungen

- Ragnarok M Eternal Love SEA Cooking RecipesDokument20 SeitenRagnarok M Eternal Love SEA Cooking RecipesLaboratory Plant 7Noch keine Bewertungen

- Classified2018 10 10742022 PDFDokument5 SeitenClassified2018 10 10742022 PDFKrishnaNoch keine Bewertungen

- A Touch of KutchDokument2 SeitenA Touch of KutchsahibatrivediNoch keine Bewertungen

- Recipes Chicken Teriyaki MeatballsDokument3 SeitenRecipes Chicken Teriyaki MeatballsHexen Ong Chang ZhuangNoch keine Bewertungen