Beruflich Dokumente

Kultur Dokumente

Pel Whe MNSP

Hochgeladen von

aadhanOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Pel Whe MNSP

Hochgeladen von

aadhanCopyright:

Verfügbare Formate

Hydraulics and Hydraulic Machines

Dr. M. N. Shesha Prakash, Prof essor, J. N. N. Col l ege of Engi neeri ng, Shi moga

1

HYDRAULIC TURBINES

Introducti on:

The device which convert s hydraulic energy into mechanical energy or

vice versa is known as Hydrauli c Machines. The hydraulic machines

which convert hydraulic energy int o mechanical energy are known as

Turbines and that convert mechanical energy into hydraulic energy is

known as Pumps.

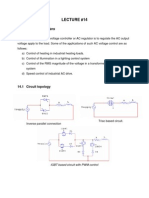

Fig. shows a general layout of a hydroelectric plant.

Animation as in the PPT

H

g

h

L

H

Penstock

Turbine

Tailrace

Headrace

Head

Race

Tail Race

H

g

H

h

L

Hydraulics and Hydraulic Machines

Dr. M. N. Shesha Prakash, Prof essor, J. N. N. Col l ege of Engi neeri ng, Shi moga

2

It consists of t he following:

1. A Dam const ruct ed across a river or a channel to store water. The

reservoir is also known as Headrace.

2. Pipes of large diamet er called Penstocks which carry wat er under

pressure from st orage reservoir to the turbines. These pipes are

usually made of st eel or reinforced concrete.

3. Turbines having different t ypes of vanes or buckets or blades

mount ed on a wheel called runner.

4. Tailrace which is a channel carrying water away from the t urbine

aft er t he wat er has worked on the turbines. The wat er surface in the

tailrace is also referred to as tailrace.

Important Terms:

Gross Head (H

g

): It is the vertical difference between headrace and

tailrace.

Net Head:(H): Net head or effective head is the actual head available

at t he inlet of the t o work on t he turbine.

H = H

g

- h

L

Where h

L

is the tot al head loss during the t ransit of wat er from the

headrace t o t ailrace which is mainly head loss due t o friction, and is

given by

d g

V L f

h

f

2

4

2

=

Where f is the coefficient of friction of penst ock depending on the

t ype of mat erial of penst ock

L is the total lengt h of penstock

V is t he mean flow velocit y of water t hrough t he penstock

D is the diamet er of penstock and

g is the accelerat ion due to gravit y

Hydraulics and Hydraulic Machines

Dr. M. N. Shesha Prakash, Prof essor, J. N. N. Col l ege of Engi neeri ng, Shi moga

3

R.P.

S.P.

=

m

TYPES OF EFFICIENCIES

Depending on the considerations of input and output, the efficiencies

can be classified as

(i) Hydraulic Efficiency

(ii) Mechanical Efficiency

(iii) Overall efficiency

(i) Hydraulic Efficiency: (

h

)

It is the ratio of the power

developed by t he runner of a

turbine t o the power supplied at the inlet

of a turbine. Since the power supplied is hydraulic, and the probable loss is between

the striking jet and vaneit is rightlycalled hydraulic efficiency.

If R.P. is the Runner Power and W.P. is the Water Power

(ii) Mechanical Efficiency: (qm)

It is the ratio of the power available at the shaft to the power developed by the

runner of a turbine. This depends on the slips and other mechanical problems that

will create a loss of energy between the runner in the annular area bet ween

the nozzle and spear, t he amount of water reduces as the spear is

pushed forward and vice-versa.

and shaft which is purely mechanical and hence mechanical

efficiency.

If S. P. is t he Shaft Power

(02)

(iii) Overall Efficiency: ( )

It is t he ratio of t he power available at t he shaft to t he power

supplied at the inlet of a turbine. As this covers overall problems of

losses in energy, it is known as overall efficiency. This depends on

both the hydraulic losses and the slips and other mechanical problems

Inlet of turbine

Turbine Runner

Shaft

W.P.

R.P.

=

h

(01)

Hydraulics and Hydraulic Machines

Dr. M. N. Shesha Prakash, Prof essor, J. N. N. Col l ege of Engi neeri ng, Shi moga

4

W.P.

S.P.

=

that will creat e a loss of energy bet ween the j et power supplied and

the power generated at the shaft available for coupling of the

generator.

(03)

From Eqs 1, 2 and 3, we have

=

h

x

m

Classificati on of Turbines

The hydraulic turbines can be classified based on t ype of energy at

the inlet , direction of flow through the vanes, head available at the

inlet , discharge through t he vanes and specific speed. They can be

arranged as per t he following table:

Turbine Type of

energy

Head Discharge

Direction

of flow

Specific

Speed Name Type

Pelton

Wheel

Impulse Kinetic

High

Head >

250m to

1000m

Low

Tangential

to runner

Low

<35 Single jet

35 60 Multiple jet

Francis

Turbine

Reaction

Turbine

Kinetic +

Pressure

Medium

60 m to

150 m

Medium

Radial flow

Medium

60 to 300

Mixed Flow

Kaplan

Turbine

Low

< 30 m

High

Axial Flow

High

300 to 1000

As can be seen from the above t able, any specific t ype can be

explained by suitable const ruction of sentences by select ing t he other

items in the t able along the row.

Hydraulics and Hydraulic Machines

Dr. M. N. Shesha Prakash, Prof essor, J. N. N. Col l ege of Engi neeri ng, Shi moga

5

Penstock

Nozzle

Wheel

Spear

PELTON WHEEL OR TURBINE

Pelton wheel, named aft er an eminent engineer, is an impulse turbine

wherein the flow is tangential to t he runner and t he available energy

at the ent rance is complet ely kinetic energy. Further, it is preferred

at a very high head and low discharges with low specific speeds. The

pressure available at the inlet and t he out let is atmospheric.

The main component s of a Pelton turbine are:

(i) Nozzl e and flow regulating arrangement :

Water is brought t o the hydroelect ric plant site through large

penstocks at the end of which t here will be a nozzle, which converts

the pressure energy complet ely int o

kinetic energy. This will convert the

liquid flow into a high-speed jet,

which st rikes the buckets or

vanes mount ed on the runner,

which in-turn rot at es the runner of

the t urbine. The amount of wat er striking the vanes is cont rolled by

the forward and backward motion of t he spear. As t he wat er is

flowing in t he annular area between the annular area between the

Animation:

(i) The water jet has to reduce

and increase as the spear is

brought forward and

backward

(ii) The wheel has to rotate as the

jet strikes

Breaking jet

Hydraulics and Hydraulic Machines

Dr. M. N. Shesha Prakash, Prof essor, J. N. N. Col l ege of Engi neeri ng, Shi moga

6

nozzle opening and the spear, the flow gets reduced as the spear

moves forward and vice-versa.

(ii) Runner with buckets:

Runner is a circular disk mount ed on a shaft on the periphery of

which a number of buckets are fixed equally spaced as shown in

Fig. The bucket s are made of cast -iron cast -st eel, bronze or

stainless st eel depending upon the head at the inlet of the turbine.

The wat er jet st rikes the bucket on the splitter of the bucket and

gets deflect ed through() 160-170

0

.

(iii) Casing:

It is made of cast -iron or fabricat ed st eel plat es. The main function

of the casing is t o prevent splashing of wat er and to discharge the

wat er into t ailrace.

(iv) Breaking jet:

Even aft er the amount of wat er st riking the buckets is complet ely

stopped, the runner goes on rotat ing for a very long time due t o

inertia. To st op t he runner in a short time, a small nozzle is

provided which directs t he jet of wat er on the back of bucket with

which t he rot ation of the runner is reversed. This jet is called as

breaking j et.

Buckets

Shaft

Runner

Hydraulics and Hydraulic Machines

Dr. M. N. Shesha Prakash, Prof essor, J. N. N. Col l ege of Engi neeri ng, Shi moga

7

3 D Picture of a j et striking t he splitt er and get ting split in to two parts

and deviating.

Velocit y t riangles for the jet st riking the bucket

From t he impulse-momentum t heorem, the force with which t he j et strikes

tthe bucket along the direction of vane is given by

F

x

= rat e of change of momentum of the jet along t he direction of vane

motion

F

x

= (Mass of wat er / second) x change in velocit y along the x direction

Deflection

angle of jet

jet

Vane

u

1

Vr

1

V

1

=Vw

1

u

Deflection angle

Vr

2

u

2

Vw

2

V

f2

V

2

V

f1

=0

Hydraulics and Hydraulic Machines

Dr. M. N. Shesha Prakash, Prof essor, J. N. N. Col l ege of Engi neeri ng, Shi moga

8

, ) j

2 1 1 w w

V V V a =

j

2 1 1 w w

V V V a + =

Work done per second by t he j et on t he vane is given by t he product of

Force exert ed on t he vane and the dist ance moved by the vane in one

second

W. D. /S = F

x

x u

j u V V V a

w w 2 1 1

+ =

Input t o the jet per second = Kinetic energy of t he j et per second

3

1

2

1

V a =

Efficiency of the j et =

ond Input

ond Workdone

ond Input

ond Output

sec /

sec /

sec /

sec /

=

j

3

1 2

1

2 1 1

V a

u V V V a

w w

+

=

j

2

1

2 1

2

V

V V u

w w

+

=

From inlet velocit y t riangle, V

w1

= V

1

Assuming no shock and ignoring frictional losses through t he vane, we

haveV

r 1

= V

r 2

= (V

1

u

1

)

In case of Pelton wheel, the inlet and out let are located at t he same radial

dist ance from the centre of runner and hence u

1

= u

2

= u

From outlet velocit y triangle, we have V

w2

= V

r 2

Cos - u

2

= (V

1

u)Cos - u

, ) j u Cos u V V V a F

x

+ =

1 1 1

, ) j Cos u V V a F

x

+ = 1

1 1

Substit uting these values in the above equation for efficiency, we have

, ) j

2

1

1 1

cos 2

V

u u V V u +

=

, ) , ) j cos

2

1 1 2

1

u V u V

V

u

+ =

Hydraulics and Hydraulic Machines

Dr. M. N. Shesha Prakash, Prof essor, J. N. N. Col l ege of Engi neeri ng, Shi moga

9

, ) j cos 1

2

1 2

1

+ = u V

V

u

The above equation gives the efficiency of the j et st riking the vane in

case of Pelton wheel.

To obt ain t he maximum efficiency for a given j et velocit yand vane angle,

from maxima-minima, we have

0 =

u d

d

j , ) 0 cos 1

2

2

1 2

1

= + = u uV

u d

d

V u d

d

V

1

-2u = 0

or

2

1

V

u =

i. e. When the bucket speed is maint ained at half the velocit y of t he j et,

the efficiencyof a Pelton wheel will be maximum. Substituting we get,

, )

, ) j cos 1 2

2

2

2 max

+ = u u

u

u

j cos 1

2

1

max

+ =

From t he above it can be seen t hat more the value of cos, more will be

the efficiency. Form maximum efficiency, the value of cos should be 1

and the value of should be 0

0

. This condition makes the jet to

complet ely deviat e by 180

0

and t his, forces the j et st riking the bucket t o

strike the successive bucket on the back of it acting like a breaking j et .

Hence to avoid this situation, at least a small angle of =5

0

should be

provided.

Hydraulics and Hydraulic Machines

Dr. M. N. Shesha Prakash, Prof essor, J. N. N. Col l ege of Engi neeri ng, Shi moga

10

Dec-06/Jan07

6 a. i)Sket ch the layout of a PELTON wheel turbine showing the det ails

of nozzle, buckets and wheel whenthe t urbine axis is horizont al(04)

ii) Obt ain an expression for maximum-efficiency of an impulse t urbine.

(06)

July 06

6 (a) With a neat sket ch explain t he layout of a hydro-elect ric plant (06)

(b) With a neat sket ch explain t he parts of an Impulse turbine. (06)

Jan 06

6 (a) What Is specific speed of turbine and state Its significance. (04)

(b) Draw a neat sketch of a hydroelectric plant and mention the

function of each component . (08)

Jan 05

6 (a) Classify the turbines based on head, specific speed and hydraulic

actions. Give examples for each. (06)

(b) What is meant by Governing of t urbines? Explain with a neat sket ch

the governing of an impulse t urbine (06)

July 04

5 (a) Explain the classification of t urbines. (08)

Hydraulics and Hydraulic Machines

Dr. M. N. Shesha Prakash, Prof essor, J. N. N. Col l ege of Engi neeri ng, Shi moga

11

The head at the base of the nozzle of a Pelton wheel is 640 m. The outlet

vane angle of the bucket is 15

o

. The relative velocit y at the out let is

reduced by 15% due to friction along t he vanes. If the discharge at outlet

is without whirl find the ratio of bucket speed to the jet speed. If the j et

diamet er is 100 mm while the wheel diamet er is 1. 2 m, find the speed of

the turbine in rpm, t he force exert ed by the j et on the wheel, the Power

developed and t he hydraulic efficiency. Take C

v

=0.97.

Soluti on:

H = 640 m; =15

o

; V

r 1

= 0. 85 V

r 2

; V

w2

= 0; d = 100 mm; D = 1. 2 m;

C

v

= 0. 97; K

u

= ?; N = ?; F

x

= ?; P = ?;

h

= ?

We know that t he absolut e velocit y of j et is given by

74 . 109 640 10 2 97 . 0 2 = = = H g C V

v

m/s

Let the bucket speed be u

Relative velocit y at inlet = V

r 1

= V

1

-u = 109. 74-u

Relative velocit y at outlet = V

r 2

= (1-0. 15)V

r 1

= 0. 85(109. 74-u)

But V

r 2

cos = u 0. 85(109. 74-u)cos15

Henceu = 49. 48 m/ s

But

60

N D

u

= and hence

u

1

Vr

1

V

1

=Vw

1

u

Deflection angle

Vr

2

u

2

Vw

2

=0

V

2

=V

f2

V

f1

=0

Hydraulics and Hydraulic Machines

Dr. M. N. Shesha Prakash, Prof essor, J. N. N. Col l ege of Engi neeri ng, Shi moga

12

5 . 787

2 . 1

48 . 49 60 60

=

= =

D

u

N rpm (Ans)

Jet ratio = m = 45 . 0

74 . 109

48 . 49

= =

V

u

Weight of wat er supplied = Q = 62 . 8 74 . 109 1 . 0

4

1000 10

2 2

=

kN/s

Force exert ed = , )

2 1 1 w w x

V V V a F =

But V

w1

= V

1

andV

w2

= 0 and hence

, ) 58 . 94 74 . 109 1 . 0

4

1000

2 2

= =

x

F kN

Work done/second = F

x

x u = 94. 58 x 49. 48 = 4679. 82 kN/ s

Kinetic Energy/ second = 189.85 5 74 . 109 1 . 0

4

1000

2

1

2

1

3 2 3

1

= =

V a kN/ s

Hydraulic Efficiency = % 17 . 90 100

85 . 5189

82 . 4679

Energy/s Kinetic

done/s Work

= = =

h

Dec 06-Jan 07

A PELTON wheel t urbine is having a mean runner diameter of 1. 0 m and

is running at 1000 rpm. The net head is 100. 0 m. If the side clearance is

20 and discharge is 0. 1 m

3

/s, find the power available at the nozzle and

hydraulic efficiency of t he turbine. (10)

Solution:

D = 1. 0 m; N = 1000 rpm; H = 100. 0 m; = 20

o

; Q = 0. 1 m

3

/s; WD/s = ?

and

h

= ?

Assume C

v

= 0. 98

We know that t he velocit y of t he j et is given by

m/s 83 . 43 1000 10 2 98 . 0 2 = = = H g C V

v

The absolut e velocit y of the vane is given by

m/s 36 . 52

60

1000 1

60

=

= =

N D

u

This situation is impracticable and hence the dat a has to be modified.

Clearly st at e t he assumption as follows:

Hydraulics and Hydraulic Machines

Dr. M. N. Shesha Prakash, Prof essor, J. N. N. Col l ege of Engi neeri ng, Shi moga

13

Assume H = 700 m (Because it is assumed that the t yping and seeing error

as 100 for 700)

Absolut e velocit y of the jet is given by

m/s 96 . 115 700 10 2 98 . 0 2 = = = H g C V

v

Power available at the nozzle is t he given bywork done per second

WD/second = Q H = g Q H = 1000x10x0. 1x700 = 700 kW

Hydraulic Efficiency is given by

, ) j , ) % 07 . 96 ) 20 cos 1 ( 36 . 52 96 . 115

96 . 115

36 . 52 2

cos 1

2

2 1 2

1

= +

= + = u V

V

u

h

July 06

A Pelt on wheel has a mean bucket speed of 10 m/s wit h a jet of wat er

flowing at the rat e of 700 lps under a head of 30 m. The buckets deflect

the jet through an angle of 160. Calculat e the power given by wat er to

the runner and t he hydraulic efficiency of the turbine. Assume the

coefficient of nozzle as 0. 98. (08)

Soluti on:

u = 10 m/s; Q = 0. 7 m

3

/s; = 180-160 = 20

o

; H = 30 m; C

v

= 0. 98;

WD/s = ? and

h

= ?

Assume g = 10m/ s

2

52.36 Vr

1

V

1

=115.96

u

Deflection angle

Vr

2

52.36 Vw

2

V

f2

V

2

20

V

f1

=0

Hydraulics and Hydraulic Machines

Dr. M. N. Shesha Prakash, Prof essor, J. N. N. Col l ege of Engi neeri ng, Shi moga

14

m/s 24 30 10 2 98 . 0 2 = = = H g C V

v

V

r 1

= V

1

-u = 24 10 = 14 m/s

Assuming no shock and frictional losses we have V

r 1

= V

r 2

= 14 m/ s

V

w2

= V

r 2

Cos - u = 14 x Cos 20 10 = 3. 16 m/s

We know that t he Work done by the j et on the vane is given by

WD/s j j

2 1 2 1 1 w w w w

V V u Q u V V V a + = + = as Q = aV

1

j 12 . 190 16 . 3 24 10 7 . 0 1000 = + = kN-m/s (Ans)

IP/s = KE/ s 201.6 24 7 . 0 1000

2

1

2

1

2

1

2 2

1

3

1

= = = = V Q V a kN-m/s

Hydraulic Efficiency = Out put/ Input = 190. 12/ 201. 6 = 94. 305%

It canalso be directly calculat ed by the derived equat ion as

, ) j , ) j 94.29% 20 cos 1 10 24

24

10 2

cos 1

2

2 1 2

1

= +

= + = u V

V

u

h

(Ans)

Jan 06

A Pelt on wheel has t o develop 13230 kW under a net head of 800 m while

running at a speed of 600 rpm. If the coefficient of Jet C

y

= 0. 97, speed

rat io | = 0. 46 and the ratio of the Jet diamet er is

1 /16 of wheel diameter. Calculat e

i) Pit ch circle diamet er ii) t he diamet er of jet

iii) t he quantit y of wat er supplied to t he wheel

10 Vr

1

V

1

=24

u

Deflection angle

Vr

2

10 Vw

2

V

f2

V

2

20

V

f1

=0

Hydraulics and Hydraulic Machines

Dr. M. N. Shesha Prakash, Prof essor, J. N. N. Col l ege of Engi neeri ng, Shi moga

15

iv) the number of Jets required.

Assume over all efficiency as 85%. (08)

Soluti on:

P = 13239 kW; H = 800 m; N = 600 rpm; C

v

= 0. 97; = 0. 46 (Speed ratio)

d/D = 1/16;

o

= 0. 85; D = ?; d = ?; n = ?;

Assume g = 10 m/s

2

and = 1000 kg/m

3

We know that t he overall efficiency is given by

85 . 0

800 1000 10

10 13239

3

=

= = =

Q H Q

P

Input

Output

o

HenceQ = 1. 947 m

3

/s (Ans)

Absolut e velocit y of jet is given by

m/s 696 . 122 800 10 2 97 . 0 2 = = = H g C V

v

Absolut e velocit y of vane is given by

186 . 58 800 10 2 46 . 0 2 = = = H g u m/s

The absolut e velocit y of vane is also given by

60

N D

u

= and hence

m

N

u

D 85 . 1

600

186 . 58 60 60

=

= =

(Ans)

= =

16

85 . 1

d 115. 625 mm (Ans)

Discharge per j et = 1.288 696 . 122 115625 . 0

4 4

2 2

= = =

V d q m

3

/s

No. of j ets = 2

288 . 1

947 . 1

~ = =

q

Q

n (Ans)

July 05

Design a Pelton wheel for a head of 80m. and speed of 300 RPM. The

Pelton wheel develops 110 kW. Take co-eficient of velocit y= 0. 98, speed

rat io= 0. 48 and overall efficiency = 80%. (10)

Soluti on:

H = 80 m; N = 300 rpm; P = 110 kW; C

v

= 0. 98, K

u

=0. 48;

o

= 0. 80

Hydraulics and Hydraulic Machines

Dr. M. N. Shesha Prakash, Prof essor, J. N. N. Col l ege of Engi neeri ng, Shi moga

16

Assume g = 10 m/s

2

and = 1000 kg/m

3

We know that t he overall efficiency is given by

8 . 0

80 1000 10

10 110

3

=

= = =

Q H Q

P

Input

Output

o

HenceQ = 0. 171875 m

3

/s

Absolut e velocit y of jet is given by

m/s 39.2 80 10 2 98 . 0 2 = = = H g C V

v

Absolut e velocit y of vane is given by

19.2 80 10 2 48 . 0 2 = = = H g u m/s

The absolut e velocit y of vane is also given by

60

N D

u

= and hence

m

N

u

D 22 . 1

300

19.2 60 60

=

= =

(Ans)

Singlej et Pelton t urbine is assumed

The diamet er of j et is given by the discharge continuit y equat ion

171875 . 0 2 . 39

4 4

2 2

= = d V d Q

Henced = 74. 7 mm

The design parameters are

Single j et

Pitch Diamet er = 1. 22 m

Jet diameter = 74. 7 mm

Jet Ratio = 32 . 16

0747 . 0

22 . 1

= = =

d

D

m

No. of Buckets = 0. 5xm + 15 = 24

Jan 05

It is desired to generat e 1000 kW of power and survey reveals that 450 m

of st atic head and a minimum flow of 0. 3 m

3

/s are available. Comment

whether the t ask can be accomplished by inst alling a Pelton wheel run at

1000 rpm and having an overall efficiency of 80%.

Hydraulics and Hydraulic Machines

Dr. M. N. Shesha Prakash, Prof essor, J. N. N. Col l ege of Engi neeri ng, Shi moga

17

Further, design the Pelton wheel assuming suit able dat a for coefficient of

velocit y and coefficient of drag. (08)

Soluti on:

P = 1000 kW; H = 450 m; Q = 0. 3 m

3

/s; N = 1000 rpm;

o

= 0. 8

Assume C

v

= 0. 98; K

u

=0. 45; = 1000 kg/ m

3

; g = 10 m/ s

2

74 . 0

450 3 . 0 1000 10

10 1000

3

=

= = =

H Q

P

Input

Output

o

For t he given condit ions of P, Q and H, it is not possible to achieve the

desired efficiency of 80%.

To decide whet her the task can be accomplished by a Pelton turbine

comput e the specific speedN

s

4

5

H

P N

N

s

= ;

where N is t he speed of runner, P is the power developed in kW and H is

the head available at the inlet .

25 . 15

450

1000 1000

4

5

= =

s

N <35

Hence the installation of single j et Pelt on wheel is justified.

Absolut e velocit y of jet is given by

m/s 97 . 92 450 10 2 98 . 0 2 = = = H g C V

v

Absolut e velocit y of vane is given by

19.2 80 10 2 48 . 0 2 = = = H g u m/s

The absolut e velocit y of vane is also given by

60

N D

u

= and hence

m

N

u

D 22 . 1

300

19.2 60 60

=

= =

(Ans)

Single j et Pelton t urbine is assumed

The diamet er of j et is given by the discharge continuit y equat ion

Hydraulics and Hydraulic Machines

Dr. M. N. Shesha Prakash, Prof essor, J. N. N. Col l ege of Engi neeri ng, Shi moga

18

171875 . 0 2 . 39

4 4

2 2

= = d V d Q

Henced = 74. 7 mm

The design parameters are

Single j et

Pitch Diamet er = 1. 22 m

Jet diameter = 74. 7 mm

Jet Ratio = 32 . 16

0747 . 0

22 . 1

= = =

d

D

m

No. of Buckets = 0. 5xm + 15 = 24

July04

A double j et Pelton wheel develops 895 MKW with an overall efficiency

of 82% under a head of 60m. The speed ratio = 0. 46, jet ratio = 12 and the

nozzle coefficient = 0. 97. Find t he j et diamet er, wheel diamet er and wheel

speed in RPM. (12)

Solut i on:

No. of j ets = n = 2; P = 895 kW;

o

= 0. 82; H = 60 m; K

u

= 0. 46; m = 12;

C

v

= 0. 97; D = ?; d = ?; N = ?

We know that t he absolut e velocit y of j et is given by

6 . 33 60 10 2 97 . 0 2 = = = H g C V

v

m/s

The absolut e velocit y of vane is given by

93 . 15 60 10 2 46 . 0 2 = = = H g K u

u

m/s

Overall efficiency is given by

H Q

P

o

= and hence 819 . 1

60 82 . 0 10 10

10 895

3

3

=

= =

H

P

Q

m

3

/s

Discharge per j et = 9095 . 0

2

819 . 1

= = =

n

Q

q m

3

/s

From discharge cont inuit y equation, discharge per j et is also given by

m d

d

V

d

q

186 . 0

9095 . 0 6 . 33

4 4

2 2

=

= =

Hydraulics and Hydraulic Machines

Dr. M. N. Shesha Prakash, Prof essor, J. N. N. Col l ege of Engi neeri ng, Shi moga

19

Further, the j et ratio

d

D

m = =12

HenceD = 2. 232 m

Also

60

N D

u

= and hence 136

232 . 2

93 . 15 60 60

=

= =

D

u

N rpm

Not e: Design a Pelton wheel: Widt h of bucket = 5d and depth of bucket is

1. 2d

The following dat a is relat ed t o a Pelton wheel:

Head at the base of the nozzle = 80m; Diamet er of the jet = 100 mm;

Discharge of t he nozzle = 0. 3m

3

/s; Power at the shaft = 206 kW; Power

absorbed in mechanical resist ance = 4. 5 kW. Det ermine (i) Power lost in

the nozzle and (ii) Power lost due to hydraulic resist ance in t he runner.

Soluti on:

H = 80 m; d = 0. 1m; a = d

2

= 0. 007854 m

2

; Q = 0. 3 m

3

/ s; SP = 206

kW; Power absorbed in mechani cal resist ance = 4. 5 kW.

From discharge conti nuit y equation, we have,

Q = a x V = 0. 007854 x V 0. 3

V = 38. 197 m/ s

Power at the base of the nozzl e = g Q H

= 1000 x 10 x 0. 3 x 80 = 240 kW

Power correspondi ng t o t he ki net ic energy of the jet = a V

3

= 218. 85 kW

(i) Power at the base of the nozzle = Power of the jet + Power lost in the nozzle

Power lost in the nozzle= 240 218.85 = 21.15 kW (Ans)

(ii) Power at the base of the nozzle = Power at the shaft + Power lost in the

(nozzle + runner + due to mechanical

resistance)

Power lost in the runner = 240 (206 + 21.15 + 4.5) = 5.35 kW (Ans)

Hydraulics and Hydraulic Machines

Dr. M. N. Shesha Prakash, Prof essor, J. N. N. Col l ege of Engi neeri ng, Shi moga

20

The water available for a Pelton wheel is 4 m

3

/s and the total head from reservoir

to the nozzle is 250 m. The turbine has two runners with two jets per runner. All

the four jets have the same diameters. The pipeline is 3000 m long. The

efficiency if power transmission through the pipeline and the nozzle is 91% and

efficiency of each runner is 90%. The velocity coefficient of each nozzle is 0.975

and coefficient of friction4f for the pipe is 0.0045. Determine:

(i) The power developed by the turbine; (ii) The diameter of the jet and (iii) The

diameter of the pipeline.

Solution:

Q = 4 m

3

/s; H

g

= 250 m; No. of jets = n = 2 x 2 = 4; Length of pipe = l = 3000 m;

Efficiency of the pipeline and the nozzle = 0.91 and Efficiency of the runner =

h

= 0.9; C

v

= 0.975; 4f = 0.0045

Efficiency of power transmission through pipelines and nozzle =

250

250

91 . 0

f

g

f g

h

H

h H

=

=

Henceh

f

= 22.5 m

Net head on the turbine = H = H

g

h

f

= 227.5 m

Velocity of jet = m/s 65.77 5 . 227 10 2 975 . 0 2

1

= = = H g C V

v

(i) Power at inlet of the turbine = WP = Kinetic energy/second = a V

3

WP = x 4 x 65. 77

2

= 8651. 39 kW

9 . 0

8651.39

by turbine developed Power

WP

by turbine developed Power

= =

h

Hence power developed by turbi ne = 0. 9 x 8651. 39 = 7786. 25 kW (Ans)

(ii ) Discharge per j et = /s m 0 . 1

4

0 . 4

jets of No.

discharge Total

3

= = = q

But 77 . 65

4

0 . 1

4

2

1

2

= = d V d q

Diamet er of jet = d = 0. 14 m (Ans)

(iii ) If D i s the di amet er of the pipeli ne, t hen t he head l oss through t he

pipe is given by = h

f

Hydraulics and Hydraulic Machines

Dr. M. N. Shesha Prakash, Prof essor, J. N. N. Col l ege of Engi neeri ng, Shi moga

21

5

2 2

3 2

4

D

Q L f

D g

V L f

h

f

= = (From Q=aV)

5 . 22

3

4 3000 0045 . 0

5

2

=

D

h

f

Hence D = 0. 956 m (Ans)

The three jet Pelton wheel i s requi red to generate 10, 000 kW under a net

head of 400 m. The blade at out let is 15

o

and the reducti on in the rel ati ve

vel oci t y whil e passi ng over the bl ade is 5%. If the overall effi ci ency of

the wheel is 80%, C

v

= 0. 98 and the speed ratio = 0. 46, then find: (i) t he

diamet er of the j et, (ii ) tot al flow (ii i) t he force exerted by a j et on t he

buckets (iv) The speed of the runner.

Soluti on:

No of j ets = 3; Tot al Power P = 10, 000 kW; Net head H = 400 m; Bl ade

angle = = 15

o

; Vr

2

= 0. 95 Vr

1

; Overall effi ci ency =

o

= 0. 8; C

v

= 0. 98;

Speed ratio = K

u

= 0. 45; Frequency = f = 50 Hz/s.

We know that

400 10 1000

10 000 , 10

8 . 0

3

= =

Q H Q g

P

o

Q = 3. 125 m

3

/s (Ans)

Discharge through one nozzle = /s m 042 . 1

3

125 . 3

3

= = =

n

Q

q

Vel ocit y of the j et = /s m 65 . 87 400 10 2 98 . 0 2

3

1

= = = H g C V

v

But 65 . 87

4

042 . 1

4

2

1

2

= = d V d q

d = 123 mm (Ans)

Vel ocit y of the Vane = /s m 14 . 41 400 10 2 46 . 0 2

3

= = = H g K u

u

Vr

1

= (V

1

u

1

)=87. 6541. 14 = 46. 51 m/s

Vr

2

= 0. 95 Vr

1

= 0. 95 x 46. 51 = 44. 18 m/ s

V

w1

= V

1

= 87. 65 m/s

V

w2

= Vr

2

cos u

2

= 44. 18 cos 1541. 14 = 1. 53 m/s

Force exert ed by the jet on t he buckets = F

x

= q(Vw

1

+Vw

2

)

Hydraulics and Hydraulic Machines

Dr. M. N. Shesha Prakash, Prof essor, J. N. N. Col l ege of Engi neeri ng, Shi moga

22

F

x

= 1000 x 1. 042 (87. 65+1. 53) = 92. 926 kN (Ans)

Jet ratio = (Assumed) 10 =

d

D

m

D = 1. 23 m

60

N D

u

=

Hence

23 . 1

14 . 41 60 60

= =

D

u

N =638. 8 rpm (Ans)

Das könnte Ihnen auch gefallen

- Buck Converter Circuit AnalysisDokument5 SeitenBuck Converter Circuit AnalysisselageaalinNoch keine Bewertungen

- Sect2-3 PDFDokument10 SeitenSect2-3 PDFBlaiseNoch keine Bewertungen

- Thyristor ReportDokument9 SeitenThyristor ReportDhaval GamiNoch keine Bewertungen

- Electrical Circuit Lab ManualDokument38 SeitenElectrical Circuit Lab Manualecessec67% (3)

- STATIC SHUNTDokument13 SeitenSTATIC SHUNTDeptiranjan MohapatraNoch keine Bewertungen

- Petersen Coils - Principle and ApplicationDokument2 SeitenPetersen Coils - Principle and ApplicationadauNoch keine Bewertungen

- Presentation About HVDC GeneratorDokument22 SeitenPresentation About HVDC GeneratorFarhan Bukhari100% (1)

- Lecture #14: AC Voltage ControllersDokument14 SeitenLecture #14: AC Voltage ControllersMat SahNoch keine Bewertungen

- Example 3.1 Finding The Performance Parameters of A Full-Wave Rectifier With A Center-Tapped TransformerDokument4 SeitenExample 3.1 Finding The Performance Parameters of A Full-Wave Rectifier With A Center-Tapped TransformersoberNoch keine Bewertungen

- Experiment No.3Dokument6 SeitenExperiment No.3justinepunzalan250% (1)

- MATLAB Simulation of Controlled and Uncontrolled RectifiersDokument32 SeitenMATLAB Simulation of Controlled and Uncontrolled RectifiersAnime XNoch keine Bewertungen

- Fault analysis and sequence networks of power systemsDokument7 SeitenFault analysis and sequence networks of power systemsDenish Gupta0% (1)

- Typical Rod Gap ArresterDokument11 SeitenTypical Rod Gap ArresterMuhammad Asif Iqbal100% (1)

- Delta ConnectionDokument5 SeitenDelta ConnectionJewel MaritheNoch keine Bewertungen

- Transformer PPT For First YearDokument42 SeitenTransformer PPT For First YearDhairya PathakNoch keine Bewertungen

- Voltage Source InverterDokument77 SeitenVoltage Source InverterSaied Aly SalamahNoch keine Bewertungen

- HV Engineering: Generation of High Frequency Ac High Voltage Using Tesla CoilDokument6 SeitenHV Engineering: Generation of High Frequency Ac High Voltage Using Tesla CoilAdnan AliNoch keine Bewertungen

- Course Pack For: B20EEP E11Dokument4 SeitenCourse Pack For: B20EEP E11Bhargavi KmNoch keine Bewertungen

- Chapter 1c (RECTIFIER)Dokument15 SeitenChapter 1c (RECTIFIER)Akmal Amyrul Aizat100% (1)

- Three Phase Transformer ConnectionsDokument42 SeitenThree Phase Transformer ConnectionsabhinavNoch keine Bewertungen

- Frog Leg WindingDokument9 SeitenFrog Leg WindingAbhijeet RedekarNoch keine Bewertungen

- Comparison of Copper Volume in AC and DC Transmission SystemsDokument5 SeitenComparison of Copper Volume in AC and DC Transmission SystemsRohan100% (1)

- Calculating Induced Voltage in Parallel CablesDokument51 SeitenCalculating Induced Voltage in Parallel CablesAhmed Sabri0% (1)

- Effect of Source InductanceDokument25 SeitenEffect of Source InductanceSriram Anil Kumar Gandham100% (1)

- Static Series Compensation TechniquesDokument9 SeitenStatic Series Compensation Techniqueshaseeb khanNoch keine Bewertungen

- Tut - PsocDokument2 SeitenTut - Psocfews100% (1)

- What Is R.M.S (Root Mean Square) ?Dokument5 SeitenWhat Is R.M.S (Root Mean Square) ?Muhammad UmairNoch keine Bewertungen

- Corona, Sag and Conductor Vibration: Batch IXDokument15 SeitenCorona, Sag and Conductor Vibration: Batch IXShyamala Chettiraj100% (1)

- HV Engineering: Impulse Current GenerationDokument14 SeitenHV Engineering: Impulse Current GenerationsaiNoch keine Bewertungen

- DC Generator Principles ExplainedDokument15 SeitenDC Generator Principles ExplainedAjay Talajiya0% (1)

- Electrical 4Dokument2 SeitenElectrical 4Puran Singh LabanaNoch keine Bewertungen

- EE296 Lightning Overvoltage Simulation of Wind FarmDokument30 SeitenEE296 Lightning Overvoltage Simulation of Wind FarmPaolo Josemari ZafraNoch keine Bewertungen

- 1 Basic Principles: 1.1 Power in Single-Phase AC CircuitsDokument9 Seiten1 Basic Principles: 1.1 Power in Single-Phase AC CircuitsDharamNoch keine Bewertungen

- EE309 Notes 07 PDFDokument4 SeitenEE309 Notes 07 PDFbals123456100% (1)

- EEE 465 - PPT - 3Dokument12 SeitenEEE 465 - PPT - 3Md IbtidaNoch keine Bewertungen

- 5.AC Phase Control Using SCRDokument8 Seiten5.AC Phase Control Using SCRabcdefgNoch keine Bewertungen

- Analysis of 6 Pulse ConverterDokument27 SeitenAnalysis of 6 Pulse ConverterSowjanya BhamidipatiNoch keine Bewertungen

- Difference Between Active and Reactive PowerDokument2 SeitenDifference Between Active and Reactive PowerDada Khalandar ShaikNoch keine Bewertungen

- Transformer - NT PDFDokument108 SeitenTransformer - NT PDFReshab Sahoo100% (1)

- Chap 11 Frequency - ResponseDokument173 SeitenChap 11 Frequency - ResponseyashNoch keine Bewertungen

- PUT Experiment EditedDokument9 SeitenPUT Experiment EditedReineirDuranNoch keine Bewertungen

- Syllabus in Electrical Equipment DevicesDokument15 SeitenSyllabus in Electrical Equipment Devicesrare machineNoch keine Bewertungen

- NIRMA Univ Electrical Power Sys Symmetrical FaultsDokument39 SeitenNIRMA Univ Electrical Power Sys Symmetrical FaultsGunjan lalakiya100% (2)

- AC CircuitsDokument20 SeitenAC CircuitsNikhil GobhilNoch keine Bewertungen

- Power System Parameters and EquationsDokument29 SeitenPower System Parameters and EquationsCatrina FedericoNoch keine Bewertungen

- High Voltage AC GenerationDokument4 SeitenHigh Voltage AC GenerationsaravananvietwNoch keine Bewertungen

- Single Phase Current Transformer LabDokument6 SeitenSingle Phase Current Transformer LabHumayun ArshadNoch keine Bewertungen

- Three-Phase Transformer BasicsDokument26 SeitenThree-Phase Transformer BasicsElardZPNoch keine Bewertungen

- Experiment No.02 To Observe The Characteristics of A Half Wave RectifierDokument4 SeitenExperiment No.02 To Observe The Characteristics of A Half Wave RectifierWaqas MughalNoch keine Bewertungen

- ICL8038 Linear Sweep Function Generator CCTDokument2 SeitenICL8038 Linear Sweep Function Generator CCTian_new100% (1)

- Introduction To Power Systems (Eceg-3176) : Addis Ababa University Addis Ababa Institute of Technology (Aait)Dokument38 SeitenIntroduction To Power Systems (Eceg-3176) : Addis Ababa University Addis Ababa Institute of Technology (Aait)DANIEL ABERANoch keine Bewertungen

- Exp11.Three Phase Full Wave Controlled ConvertersDokument4 SeitenExp11.Three Phase Full Wave Controlled ConvertersJawad Rasheed SheikhNoch keine Bewertungen

- Full Wave Rectifier Guide: Circuit, Theory & UsesDokument7 SeitenFull Wave Rectifier Guide: Circuit, Theory & UsesArun PratapNoch keine Bewertungen

- Hydraulic TurbinesDokument18 SeitenHydraulic TurbinesdagemNoch keine Bewertungen

- 16 Mechanical FM IIDokument91 Seiten16 Mechanical FM IIAamir ArainNoch keine Bewertungen

- Hydraulic Turbines Explained: Types, Components & EfficienciesDokument17 SeitenHydraulic Turbines Explained: Types, Components & Efficiencieszakaria masud sonyNoch keine Bewertungen

- HM Assingment 02Dokument7 SeitenHM Assingment 02PradneshNoch keine Bewertungen

- Hydraulic TurbinesDokument43 SeitenHydraulic TurbinesKarim SayedNoch keine Bewertungen

- 278 - BE8253 Basic Electrical and Electronics and Instrumentation Engineering - 16 MarksDokument13 Seiten278 - BE8253 Basic Electrical and Electronics and Instrumentation Engineering - 16 MarksSundara MoorthyNoch keine Bewertungen

- MT MLMDokument17 SeitenMT MLMSundara MoorthyNoch keine Bewertungen

- MagnetisationDokument1 SeiteMagnetisationSundara MoorthyNoch keine Bewertungen

- Determine The Diameter of A Shaft Which Carries 2 Pulleys Each Weight 2KNDokument2 SeitenDetermine The Diameter of A Shaft Which Carries 2 Pulleys Each Weight 2KNSundara MoorthyNoch keine Bewertungen

- Section PropertiesDokument2 SeitenSection PropertiesSundara MoorthyNoch keine Bewertungen

- ME6513 Lab MeasurementsDokument2 SeitenME6513 Lab MeasurementsSundara MoorthyNoch keine Bewertungen

- Question of DmeDokument1 SeiteQuestion of DmeSundara MoorthyNoch keine Bewertungen

- MT MLMDokument17 SeitenMT MLMSundara MoorthyNoch keine Bewertungen

- Master Attendance: Reg. No. Name of The StudentDokument3 SeitenMaster Attendance: Reg. No. Name of The StudentSundara MoorthyNoch keine Bewertungen

- Define ShaftDokument1 SeiteDefine ShaftSundara MoorthyNoch keine Bewertungen

- MT 1 Manufacturing TechDokument7 SeitenMT 1 Manufacturing TechSundara MoorthyNoch keine Bewertungen

- Dme Unit 2Dokument1 SeiteDme Unit 2Sundara MoorthyNoch keine Bewertungen

- ReferencesDokument47 SeitenReferencesSundara MoorthyNoch keine Bewertungen

- QuestionsDokument11 SeitenQuestionsSundara MoorthyNoch keine Bewertungen

- Powr PlantDokument1 SeitePowr PlantSundara MoorthyNoch keine Bewertungen

- TQM 16 MarksDokument3 SeitenTQM 16 MarksSundara MoorthyNoch keine Bewertungen

- ScheduleDokument2 SeitenScheduleSundara MoorthyNoch keine Bewertungen

- Dme 1Dokument1 SeiteDme 1Sundara MoorthyNoch keine Bewertungen

- CIM Chapter 9 Material Handling Systems Robots GuideDokument17 SeitenCIM Chapter 9 Material Handling Systems Robots GuideSundara MoorthyNoch keine Bewertungen

- Sl. No. Name of The Programme Faculty of Civil Engineering: Regulations 2013Dokument2 SeitenSl. No. Name of The Programme Faculty of Civil Engineering: Regulations 2013Sundara MoorthyNoch keine Bewertungen

- PART - A (5x2 10 Marks) Answer All Questions: Issue No:01Dokument2 SeitenPART - A (5x2 10 Marks) Answer All Questions: Issue No:01Sundara MoorthyNoch keine Bewertungen

- Instructions for AuthorsDokument3 SeitenInstructions for AuthorsSundara MoorthyNoch keine Bewertungen

- Sheet-Metal-Op N Bmberations-131023053838-Phpapp02Dokument40 SeitenSheet-Metal-Op N Bmberations-131023053838-Phpapp02sbs271187Noch keine Bewertungen

- Management ToolsDokument39 SeitenManagement ToolsAbid AliNoch keine Bewertungen

- CE6304 Surveying IDokument12 SeitenCE6304 Surveying ISundara MoorthyNoch keine Bewertungen

- Work in Fluid SystemsDokument14 SeitenWork in Fluid SystemselgherianyNoch keine Bewertungen

- Projectionsofsolids 111202014535 Phpapp02Dokument58 SeitenProjectionsofsolids 111202014535 Phpapp02Priyanka RamanNoch keine Bewertungen

- Hydraulic Machinery 1Dokument60 SeitenHydraulic Machinery 1Sundara MoorthyNoch keine Bewertungen

- EngineeringDokument41 SeitenEngineeringSundara MoorthyNoch keine Bewertungen

- Golden Harvest ProductsDokument20 SeitenGolden Harvest ProductsTyson BostonNoch keine Bewertungen

- The Agricultural Implements of Byzantine PeasantsDokument14 SeitenThe Agricultural Implements of Byzantine PeasantsKyriakos D. PapadopoulosNoch keine Bewertungen

- LOGAN 2 Series 10 OvershotDokument4 SeitenLOGAN 2 Series 10 OvershotDiego ChanatasigNoch keine Bewertungen

- Renewable Energy Project For Kids: Power From Water: Problem: How Can Hydropower Be Used To Lift An Object?Dokument4 SeitenRenewable Energy Project For Kids: Power From Water: Problem: How Can Hydropower Be Used To Lift An Object?Anh Nguyen100% (1)

- 2 - 1 - Civil Works - Guidelines For Layout of Small Hydro PlantsDokument24 Seiten2 - 1 - Civil Works - Guidelines For Layout of Small Hydro PlantsjmiguelmenaNoch keine Bewertungen

- BUSM7082 (Spring 2022) Risk Management & Decision Making - Assessment 3Dokument6 SeitenBUSM7082 (Spring 2022) Risk Management & Decision Making - Assessment 3Enkhdavaa PNoch keine Bewertungen

- 08.Cpt 5 Design For Civil StructuresDokument33 Seiten08.Cpt 5 Design For Civil StructuresGneis Setia Graha100% (1)

- Waterwheels Lesson PlanDokument4 SeitenWaterwheels Lesson Planapi-490177257Noch keine Bewertungen

- A120 Series 70 150 Overshot Manual PDFDokument48 SeitenA120 Series 70 150 Overshot Manual PDFNikhil Barshettiwar0% (1)

- The History of Transformers by RKL A DrogaDokument21 SeitenThe History of Transformers by RKL A DrogaSenhas SitesNoch keine Bewertungen

- UB Internship Report UpdateDokument55 SeitenUB Internship Report UpdatepaulaNoch keine Bewertungen

- Gearing in The Ancient WorldDokument6 SeitenGearing in The Ancient Worldbd5450% (2)

- Water Wheel DesignDokument9 SeitenWater Wheel DesignPeyjann Ninie100% (1)

- Hydro 1Dokument48 SeitenHydro 1Rens Bakker100% (2)

- HP-I, Chapter - Five, Conveyance StructuresDokument174 SeitenHP-I, Chapter - Five, Conveyance StructuresNatnael SitotaNoch keine Bewertungen

- LECTURE-1-Hydropower Basics PDFDokument30 SeitenLECTURE-1-Hydropower Basics PDFAfsar Ullah WazirNoch keine Bewertungen

- Jean Gimpel - The Medieval Machine - The Industrial Revolution of The Middle Ages (1976, Holt, Rinehart and Winston)Dokument289 SeitenJean Gimpel - The Medieval Machine - The Industrial Revolution of The Middle Ages (1976, Holt, Rinehart and Winston)Leah Fauber100% (2)

- Fishing Tools Guide Overshot Types FunctionsDokument50 SeitenFishing Tools Guide Overshot Types FunctionsShaikh Sabir HussainNoch keine Bewertungen

- Hist/Engr 108 Final Study GuideDokument20 SeitenHist/Engr 108 Final Study GuideKuzameNoch keine Bewertungen

- The Barsha Pump: Technical Specifications and ApplicationsDokument9 SeitenThe Barsha Pump: Technical Specifications and ApplicationsAndrés PerezNoch keine Bewertungen

- Ancient Warfare Mod GuideDokument59 SeitenAncient Warfare Mod GuideAdrian Ciemienga0% (1)

- Bowen Wide Catch OvershotDokument8 SeitenBowen Wide Catch OvershotJavier Luzuriaga EscuderoNoch keine Bewertungen

- 93 Palmstrom&Broch On Design Unlined Hydropower Tunnels PDFDokument9 Seiten93 Palmstrom&Broch On Design Unlined Hydropower Tunnels PDFpggopal_85Noch keine Bewertungen

- Chameliya Hydroelectric Project Underground Excavations Case StudyDokument77 SeitenChameliya Hydroelectric Project Underground Excavations Case StudySaphal LamichhaneNoch keine Bewertungen

- MHP Training ManualDokument94 SeitenMHP Training ManualAnonymous M0tjyWNoch keine Bewertungen

- Hydropower Projects of KPKDokument16 SeitenHydropower Projects of KPKZeeshan KhanNoch keine Bewertungen

- Roughness evaluation of shotcrete-lined water tunnels with invert concreteDokument18 SeitenRoughness evaluation of shotcrete-lined water tunnels with invert concreteAhsan MurtazaNoch keine Bewertungen

- Kent. 1913. The Mechanical Engineers' Pocket-Book. A Reference-Book of Rules, Tables, Data, and Formulæ, For The Use of Engineers, Mechanics, and StudentsDokument1.505 SeitenKent. 1913. The Mechanical Engineers' Pocket-Book. A Reference-Book of Rules, Tables, Data, and Formulæ, For The Use of Engineers, Mechanics, and StudentsDougKneNoch keine Bewertungen

- Water Wheel ReportDokument16 SeitenWater Wheel ReportCat MaNoch keine Bewertungen

- Kilkenny's untapped hydro power potentialDokument54 SeitenKilkenny's untapped hydro power potentialmachinejigNoch keine Bewertungen