Beruflich Dokumente

Kultur Dokumente

Evanko Presentation

Hochgeladen von

UCSBiee0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

60 Ansichten12 SeitenResearch Review 2014

Brian Evanko Presentation

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenResearch Review 2014

Brian Evanko Presentation

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

60 Ansichten12 SeitenEvanko Presentation

Hochgeladen von

UCSBieeResearch Review 2014

Brian Evanko Presentation

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 12

University of Oregon

Sang-Eun Chun, Shannon Boettcher*

Oregon State University

Xingfeng Wang, Bao Wang, Vadivukarasi Raju, David Ji*

University of California, Santa Barbara

Brian Evanko, Nick Parker, Dave Auston, Galen Stucky*

April 29, 2014

High Power Capacitors Boosted with Both

Anolyte and Catholyte

Powered by Solutions

Electrochemical Capacitors

# High Power Density

# Low Energy Density

# Excellent Cycle

Efficiency,

Cyclability, and

Lifetime

# Referred to also as

supercapacitors,

ultracapacitors, and

EDLCs

P. Simon and Y. Gogotsi, Materials for electrochemical capacitors.,

Nat. Mater., vol. 7, no. 11, pp. 84554, Nov. 2008.

Powered by Solutions

Electrochemical Capacitors

Traditional Capacitor

Supercapacitor

P. Jampani, et al. Advancing the supercapacitor materials and technology frontier Electrochem. Soc. Interface, 2010.

-

-

-

-

+

+

+

+

d

A

!

- +

- +

- +

- +

- +

- +

Powered by Solutions

Electrochemical Capacitors

# Energy stored in a capacitor is

proportional to the area under

the charge/discharge curve.

+

"

K

+

K

+

Galvanostatic

discharge profiles (1

A/g) of devices with

KI and VOSO

4

concentrations of

!) 0.15 M and 0.1 M,

II) 0.3 M and 0.2 M,

and III) 0.75 M and

0.5 M, respectively

SO

4

2-

K

+

K

+

SO

4

2-

K

+

K

+

SO

4

2-

Electrolyte:

Aqueous K

2

SO

4

Specific Energy:

5 Wh/kg

Powered by Solutions

Redox-Active Electrolytes: Gen I Chemistry

# Redox-active ions in electrolyte

generate pseudocapacitance

# Fast kinetics without material

degradation

+

I

-

I

3

-

I

-

SO

4

2-

I

-

(+) 3I

-

! I

3

-

+ 2e

-

SO

4

2-

"

V

3+

VO

2+

K

+

VO

2+

K

+

VO

2+

(-) 2VO

2+

+ 2e

-

! 2V

3+

Electrolyte:

0.1 M VOSO

4

and 0.15 M KI

Galvanostatic

discharge profiles (1

A/g) of devices with

KI and VOSO

4

concentrations of

!) 0.15 M and 0.1 M,

II) 0.3 M and 0.2 M,

and III) 0.75 M and

0.5 M, respectively

Specific Energy:

20 Wh/kg

Powered by Solutions

Redox-Active Electrolytes: Gen II Chemistry

6

Electrolyte:

0.1 M methyl viologen, 1 M KBr

# The methyl viologen

bromide system

behaves as a capacitor

at low voltages and a

battery at higher

voltages.

# 1.5 V operating window

with Br

-

! Br

3

-

oxidation

and MV

2+

! MV

+

reduction greatly

increases specific

energy.

Powered by Solutions

Redox-Active Electrolytes: Gen II Chemistry

7

Potential

window

1.0 V 1.2 V 1.4 V

Specific capacity

(mAh/g)

8.6 18.9 36.8

Energy density

(Wh/kg)

4.6 15.1 36.6

Coulombic (%) 99.3 99.2 98.2

Energy (%) 84.2 89.1 87.0

- Se|f-d|scharge

Aer 6 h of self-dlscharge, 22

Wh]kg ls sull reserved ln 8r/Mv

* Acuve elecLrode mass-based energy denslLy

measured from Swagelok-cell

Powered by Solutions

Design of Electrochemical Cell

8

Lpoxy lnsulaung layer

separaLor (lLer paper)

Swage|ok-type ce|| Vo|ume-||m|nng ce||

Mlnlmal amounL of elecLrode +

elecLrolyLe mass

Side

Powered by Solutions

Scaling Up

9

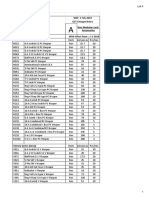

Ce|| Goa|s for 186S0 Iormat

kedox Supercapac|tor

Current Commerc|a||y

Ava||ab|e Dev|ce

L|ectro|yte Aqueous (1.3v) Crganlc (2.7v)

D|mens|ons P: 63mm , Cu: 18mm P: 43mm , Cu: 22mm

Vo|ume 16.S cm

3

17.1 cm

3

Spec|hc Lnergy z 1S Wh]kg 4.4 Wh]kg

Spec|hc ower z 2000 W]kg 7000 W]kg

1emperature -10 C Lo 60C -40C Lo 63C

Powered by Solutions

18650 Prototyping Line

# Electrodes are coated by doctor blade on

vacuum chuck with PID controlled IR lamp

drying.

# Roll press installation was completed April 10.

10

Powered by Solutions

18650 Prototyping Line

# We also have received and installed equipment

for welding, necking, and sealing 18650 cans.

# Testing is done in-house, in the remodeled MRL

Battery Lab.

11

Powered by Solutions

Questions

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- What Is Free Energy Generator - Flywheel Working - Advantages & Disadvantages of Free Energy GeneratorDokument14 SeitenWhat Is Free Energy Generator - Flywheel Working - Advantages & Disadvantages of Free Energy GeneratorPieter SteenkampNoch keine Bewertungen

- Circuit Breaker LTB D 72.5 - 170 KV FSA Spring Operating MechanismsDokument8 SeitenCircuit Breaker LTB D 72.5 - 170 KV FSA Spring Operating MechanismsRazvan Mares50% (2)

- Wiring Inspection ChecklistDokument7 SeitenWiring Inspection ChecklistJesus Bedriñana Gascon100% (2)

- Speed Control of Shunt and Separately Excited DC Motors ReportDokument8 SeitenSpeed Control of Shunt and Separately Excited DC Motors ReportMuhammad Ali HaiderNoch keine Bewertungen

- Permanent Magnet Motor: Instruction Manual and Experiment Guide For The PASCO Scientific Model SE-8658ADokument34 SeitenPermanent Magnet Motor: Instruction Manual and Experiment Guide For The PASCO Scientific Model SE-8658AAbhijeet SinhaNoch keine Bewertungen

- Jim Fiske PresentationDokument37 SeitenJim Fiske PresentationUCSBieeNoch keine Bewertungen

- Opportunities and Challenges For Photonics in Next-Generation Data Centers - Clint SchowDokument53 SeitenOpportunities and Challenges For Photonics in Next-Generation Data Centers - Clint SchowUCSBieeNoch keine Bewertungen

- Energy-Proportional Computing: A New Definition - David WoodDokument72 SeitenEnergy-Proportional Computing: A New Definition - David WoodUCSBieeNoch keine Bewertungen

- Assessing Opportunities To Exploit Stranded Power - Andrew ChienDokument21 SeitenAssessing Opportunities To Exploit Stranded Power - Andrew ChienUCSBieeNoch keine Bewertungen

- American Institute For Manufacturing Integrated Photonics: Implications For The Future - John BowersDokument55 SeitenAmerican Institute For Manufacturing Integrated Photonics: Implications For The Future - John BowersUCSBieeNoch keine Bewertungen

- Lin Zhong Seminar SlidesDokument77 SeitenLin Zhong Seminar SlidesUCSBieeNoch keine Bewertungen

- Silicon Photonics: Heterogeneous Integration For High Bandwidth, Efficient ComputingDokument34 SeitenSilicon Photonics: Heterogeneous Integration For High Bandwidth, Efficient ComputingUCSBieeNoch keine Bewertungen

- Leonard Tender SeminarDokument35 SeitenLeonard Tender SeminarUCSBieeNoch keine Bewertungen

- Shannon Boettcher SeminarDokument45 SeitenShannon Boettcher SeminarUCSBieeNoch keine Bewertungen

- Chemicals and Materials: NovelDokument15 SeitenChemicals and Materials: NovelUCSBieeNoch keine Bewertungen

- Life Cycle Impacts: NovelDokument15 SeitenLife Cycle Impacts: NovelUCSBieeNoch keine Bewertungen

- Kiessling Overhead Power Lines Planning Design ConstructionDokument396 SeitenKiessling Overhead Power Lines Planning Design ConstructionSead Saric100% (14)

- Blue 8x8x8 LED Cube Kit - PCB VersionDokument6 SeitenBlue 8x8x8 LED Cube Kit - PCB VersionsiogNoch keine Bewertungen

- DC MotorsDokument7 SeitenDC MotorsKelvin LiewNoch keine Bewertungen

- Emech Exp-1Dokument13 SeitenEmech Exp-1ATCNoch keine Bewertungen

- Agente Limpio & Diluvio 4010ESDokument8 SeitenAgente Limpio & Diluvio 4010ESData Clean Sac ChisanNoch keine Bewertungen

- Spark/Arc Detection System From Scanning Devices, Inc.: 110 Series Plug in AmplifiersDokument1 SeiteSpark/Arc Detection System From Scanning Devices, Inc.: 110 Series Plug in AmplifiersOmkar MajinbuuNoch keine Bewertungen

- Inverter Systems: For Gen 3 Drives of HEIDENHAIN ControlsDokument59 SeitenInverter Systems: For Gen 3 Drives of HEIDENHAIN ControlsSir StigaNoch keine Bewertungen

- Hosper List - Feb 2019 - ADokument4 SeitenHosper List - Feb 2019 - ANikhil GoelNoch keine Bewertungen

- Eee 1003 VitDokument71 SeitenEee 1003 VitAlok100% (1)

- Optimal Performance Tesla TransformerDokument5 SeitenOptimal Performance Tesla TransformercrazybuttfulNoch keine Bewertungen

- WMS Supplementary Protectors: Product Specification Features and BenefitsDokument7 SeitenWMS Supplementary Protectors: Product Specification Features and BenefitsWilfredo MolinaNoch keine Bewertungen

- Kohler DatasheetDokument3 SeitenKohler DatasheetAsif MehmoodNoch keine Bewertungen

- BALIMODokument3 SeitenBALIMOExcelNoch keine Bewertungen

- 74HC14 PDFDokument8 Seiten74HC14 PDFNielsy R. Aparicio QuirogaNoch keine Bewertungen

- Relay With Hysteresis & Dead Zone, Saturations / Coulomb Friction & BackslashDokument12 SeitenRelay With Hysteresis & Dead Zone, Saturations / Coulomb Friction & Backslashfarah haniNoch keine Bewertungen

- Act.3 Esw2 1 2Dokument12 SeitenAct.3 Esw2 1 2Kazuha MinatoNoch keine Bewertungen

- The Model D1029: Installing, Operating and MaintainingDokument89 SeitenThe Model D1029: Installing, Operating and MaintainingWashington MazziniNoch keine Bewertungen

- Aikido Cascade & 300B Power BoostedDokument17 SeitenAikido Cascade & 300B Power Boostedandree wNoch keine Bewertungen

- Explanation of RoutineTests For FATs On Current Transformers According To IEC 60044Dokument6 SeitenExplanation of RoutineTests For FATs On Current Transformers According To IEC 60044Hung VuNoch keine Bewertungen

- Compact NS - 630A - 30783Dokument3 SeitenCompact NS - 630A - 30783R TNoch keine Bewertungen

- CoolBLUE Inductive Absorbers PresentationDokument49 SeitenCoolBLUE Inductive Absorbers PresentationmauriciojjNoch keine Bewertungen

- 5B Accessories 5D Test Blocks MiCOM P991, P992 & P993Dokument8 Seiten5B Accessories 5D Test Blocks MiCOM P991, P992 & P993jckrishnahNoch keine Bewertungen

- FR A520 PDFDokument257 SeitenFR A520 PDFNguyen LuongNoch keine Bewertungen

- TPC8116 HDokument7 SeitenTPC8116 HCristina NistorNoch keine Bewertungen

- Experiment 3 (No Load Blocked Rotor Test On Single Phase Im)Dokument5 SeitenExperiment 3 (No Load Blocked Rotor Test On Single Phase Im)Adarsh SinghNoch keine Bewertungen