Beruflich Dokumente

Kultur Dokumente

IAF1403 - Fish Farming Technology Supplement

Hochgeladen von

International Aquafeed magazineOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

IAF1403 - Fish Farming Technology Supplement

Hochgeladen von

International Aquafeed magazineCopyright:

Verfügbare Formate

SUPPL EMENT

FISH FARMING

TECHNOLOGY

SUPPL EMENT

Nets and cages

Recirculating Aquaculture Systems

- Benefits and disadvantages of

modern basic systems

A

t Boris Nets all

our fish cages are

manufactured to

the highest standard

using drawings and technical

information gathered through-

out our years of experience in

the industry.

The company works closely

with each customer so that its

cages are crafted using a mix of

traditional methods and modern

technology with great attention

to individual specifics and site

conditions. The result is a pre-

mium quality product with an

excellent reputation.

Cages are predominantly

made using knot-less nylon net-

ting. Good for its strength elastic-

ity and resistance to abrasion with

a relatively high uv resistance.

Together with the comparatively

low cost this makes it an excellent

choice for fish cage manufactur-

ing.

Nylon netting size ranges from

first feeder to larger mesh size

higher-grade netting, perfect for

offshore heavy weather condi-

tions. There is some shrinkage

but this is taken into consid-

eration during our manufacturing

process.

We have conducted large

scale trials with polyester in com-

parison to traditional nylon cages.

Although it is perceived that

the lower elasticity, decreased

shrinkage and higher UV resist-

ant properties are advantageous

it is not proven that these are

significant. Nylon remains the

preferred material of the two for

most of our customers, says the

company.

Dyneema has been widely

used in production for several

years. Although more expensive

than other materials it provides

3-4 times greater strength by

weight than traditional nylon net-

ting and retains this strength for a

longer period leading to

an increase in longevity

in the life of the cages.

Dyneema is favoured

by freshwater clients as

it is easy to handle being

light and the increased

strength offers superior

protection from preda-

tors such as otters. It

is also widely used in

cages for sea bream as they have

a tendency to chew at the cages.

Again the increase in strength

provides better resistance to this.

We have used dyneema in

the production of seawater cages.

However due to lack of elas-

ticity we would recommend an

increase of at least a 25 percent

in strength to compensate for this

and ensure that the integrity of

the cage is left uncompromised.

These specifications make the

dyneema cages approximately

half the weight in comparison to

a conventional nylon cage. Due

to the nature of dyneema it is

critical that nets are produced to

the correct size with the correct

amount of slack added evenly.

In our opinion this makes the

need for hand mounted ropes

greater to ensure the probity of

the product. There is a propen-

sity by many manufacturers due

to the raised costs and machine

mounted roping to use con-

siderably less than the amount

required to make a premium

quality cage.

More recently there's been a

significant interest in the use of

Ultra high tenacity PE.

Generally, knotted provides

the advantage of being around 20

percent stronger in comparative

weight to nylon. It has very good

abrasion resistance and is very

low stretch. These properties

make it excellent in cages where

in situ net washers are used. That

said it is difficult to obtain in sizes

below 18-20mm which could

lead to restrictions in its use.

The majority of our ropes are

made from polysteel due to its

superior abrasion resistance. We

use the traditional hand mounting

method in preference to machine

sewing as it allows for more even

strain distribution reducing future

repair needs, says the company.

In situ net washing processes

have necessitated a change in

design of cages.

The amount of slack incor-

porated into the netting for the

manufacture of the cages has

had to be reduced to allow a

firmer surface to allow the wash-

er to operate efficiently. If too

little slack is used the integrity

is comprised. The ropes will no

longer form the framework of

the cage and too much strain

will be placed on the netting

itself leading to potentially cata-

strophic results. For this reason

it is imperative that all ropes are

hand mounted to ensure even

and consistent distribution of the

netting therefore minimising the

risk of unnecessary damage.

Working closely

with customers

We work closely with our

customers to develop anti preda-

tor methods with great success.

A large number of our customers

use predator screens permanent-

ly attached to the outside of their

cages for extra protection and

allowing the net itself to be tight-

er which is also a good deterrent

.Along with weighting systems

and in particular the froya ring

support system which helps to

maintain net shape in strong cur-

rent reducing the potential loss

from seal attacks, excellent results

have been achieved and the loss

of fish has greatly reduced.

We are currently involved in

a research and development pro-

gram and have successfully trialled

a new sewing machine for use

in the manufacture of treatment

tarps on a larger scale using very

heavy duty materials .

The old and the

new makes for a

premium product

&

NETS

CAGES

02 | INTERNATIONAL AQUAFEED | Fish farming Technology

FISH FARMING TECHNOLOGY

W

&J Knox has

been making

nets for aqua-

culture since

the inception of the industry in

Scotland. Traditionally, knotless

nylon netting has been utilized

for cage nets; however in the

past year, Knox has started

to introduce cage nets to

Scotland which have been

produced from star netting, a

modified HDPE developed by

Garware-Wall Ropes of India.

Star netting is flexible

and easy to handle, weighing

approximately 25 percnet less

for the same strength as nylon.

The key benefits are that there

is less algae formation and no

antifoulant is required.

Both the structure and

the raw material make it

more suitable than nylon

for machine cleaning.

Samples of star net-

ting and further details

will be on display at

Aquaculture UK at the

Knox stand

D

aily morts

removal and

handling are part

of best practice

in fish farming and Lift Up AS

has, since 1989, supplied many

thousand morts collection

systems from it factories in

Norway and Chile.

The systems use the age-old

air-lift principle and are sim-

ple in construction and efficient

in operation. A souser-shaped

cone is lowered to the bottom

of the floating net-cage and from

there a hose allows morts to

be lifted from the bottom of the

cage to the surface by means of

compressed air introduced into

the cone at the base.

Lift Up has a wide range of

models for different species of

fish and various sizes of nets,

and exports its products to fish

farmers worldwide.

Its newest generation of col-

lection systems incorporate a

full enclosed systems to bring

morts from the bottom of

cages all the way to a cen-

tral collection point on a ser-

vice barge or onto shore for

dewatering and disposal. This

allows for all waste water to

be disposed away from the live

fish in the cages and minimises

contamination.

Lift Up AS will again be

exhibiting at this years

Aqauculture UK 2014 show in

Aviemore, Scotland, with spe-

cial focus on its newest and

fifth generation of collection

systems.

Star netting introduced to Scotland

Next generation for Lift Up

This has resulted in a com-

pany in Australia ordering and

shipping one of our largest

ever products over, with great

potential for further purchases

in the near future.

Our cages have proven a

great success in some of the

worst storms on record both

nationally and internationally

offshore. Leaving them intact

and uncompromised when

other machine sewn cages

have been destroyed with

devastating fish losses.

Changing the method in

which netting is mounted from

the usual square hanging form to

diamond style on all or part of

the net has proven very beneficial

in keeping the integrity of our

nets in bad conditions around

the world, whilst still allowing for

good aeration from water flow.

The use of gussets, chaf-

fer panels and double netting

on areas of the net that are

prone to more abrasion is

extremely effective. Together

with the hand mounted roping,

attention to specifics, excellent

design, highly skilled net mak-

ers and machinists Boris Nets

produces cages often classed

as some of the best in the

world.

Fish farming Technology | INTERNATIONAL AQUAFEED | 03

FISH FARMING TECHNOLOGY

S

eafood that is fish

from both fishing and

aquaculture - is the

most traded food com-

modity in the world and it is an

essential product for the health

of humans globally and critical

for many under developed

countries for food security.

As professionals, we all need

to be aware of issues covering

everything from food safety

to environmental sustainability,

trade barriers to fraud, etc,

are all important as we move

forward.

The aim of this association

is to network, share, educate,

communicate and promote all

activities relating to creating a

better seafood world.

There are no boundaries as

this a large and diverse industry

but our aim is not to duplicate

what others are doing and to

work with all dedicated sea-

food organisations and people.

We have created a web-

site, blogs, LinkedIn, Facebook

and Twitter (see details below)

to enable there to be a ter-

rific flow of information and

to enable us all to promote

the exchange of ideas and

information, foster interac-

tion, understanding and pro-

fessional collaboration among

individuals, organisations and

governments, disseminate

knowledge about fish, seafood

and associated products and

promote advancement of the

state-of-the-art in fish research,

development, extension and

education.

Our association does not

aim to charge for membership

as we believe that it is best to

engage as many industry peo-

ple as we can and we do not

want fees getting in the way.

We plan to create services

and opportunities for all our

members and for those ser-

vices there will be charges.

You will get to choose if you

want to sign up to the services

or not. If the services are not

what you want then you will

not have to pay for them. The

emphasis is on us to ensure the

services will be seen as being

seen to be worthwhile to you,

otherwise you will not sign up.

We can all grow and

improve ourselves and our

industry simply by learning

from each other and nature.

We use the Canadian Geese

as an example - Scientists

believe that the characteris-

tic v-shaped flock of geese

migrating serves two purposes.

First, it creates a current of air

along the lines of geese that

makes it easier for individuals

to fly. Second, it allows for bet-

ter communication and unity of

the flock while in the air.

7-11 June 2014 Association engaged in many events at

World Aquaculture Conference, Adelaide, SA, Australia

28-29 June 2014: Association assisting with EMS Forum, Thailand

1-2 July 2014: Association invited to speak at

Monaco Blue Initiative, Santiago, Chile

6-8 August 2014: Association organizing in conjunction

with VASEP the Vietfish Conference, HCMC, Vietnam

21-22 September 2014: Association invited to

speak at Aquatic China, Beijing, China

9-11 November 2014: Association organizing

SEAFEX Seafood Summit, Dubai, UAE

11-13 March 2015: Association assisting

Seafood Processing Conference at VIV

Asia, Bangkok, Thailand

U

P

-

C

O

M

I

N

G

A

C

T

I

V

I

T

I

E

S

Association of International

Professionals

C

e

rtif

c

a

tio

n

seafoodprofessionals.org

E

very fish farmer hopes to achieve

the same goal of high quality fish to

a minimum production cost.

RAS with degassing tanks and

fixed bed up flow bio filters

In fixed bed up-flow filters with fixed sub-

strate, the water is distributed evenly throughout

the bottom of all the bio filters. This is done to

secure a low water flow speed up through the

bio filter media - in order to also remove the

smaller particles. It also reduces the amount of

solid material the bio filter has to break down

as there is settlement in the bottom of the bio

filters prior to entering the bio filter media. The

media has an open structure (media is 15%

of the volume) which helps to secure a low

water speed. This low water speed helps the

media and the bacteria that grow on them to

effectively catch the microscopic particles. In

fixed bed up-flow bio filters the whole surface

of the media is used to remove particles and

ammonia, and the result is cleaner water. Back

flush of the bio filter is a simple operation that

doesnt significantly affect the water quality. The

bio filter is separated in sections meaning that

one can be cleaned while the other sections

are still running. The cleaning intervals are 8-16

weeks depending on the amount of feeding. It is

possible to implement a semi-automatic cleaning

system to the bio filters which ease the cleaning

operation of the bio filters significantly. Efficient

removal of micro particles reduces the need for

ozone treatment to get clean and clear water. If

ozone is used, then only a small doze is needed

due to less particles in the water.

The degassing system contributes posi-

tively to the water temperature in the RAS

because the air blowers heat up the air blown

into the water and degas the CO

2

in the

water simultaneously. So in addition to the

improved water quality, heating costs are

reduced thanks to the design.

Due to the design of the bio filter, set-

tlement in the first part of the bio filter is

impossible.

The use of 2-3 bio filters gives each

bio filter less volume this will result in sig-

nificant higher water speeds in the bio filters.

High water speed makes it difficult to catch

micro particles. The cleaning of the bio filter

blocks has shown to be very time consuming

because it sometimes needs to be taken out

of bio filter for manual cleaning.

It is a known fact that the relatively large

amount of air needed for trickling filters cools

the water significant because of the evapora-

tion. This technology is actually well known in

cooling towers.

When using trickling filters for CO

2

degas-

sing, there is a need to have a high water flow

to keep the CO

2

level down as trickling filters

have lower efficiency compared to degassing

tanks.

The water enters the trickling filter just

after the drum filter and still has a lot of

organic material in the water. Organic mate-

rial creates a lot of sludge in the bio filter, the

trickling filter, drops off of old sludge that

goes back to the fish tanks as small particles

(circa 70% goes to fish tanks and circa 30% to

fixed bed filters). This design makes the water

dirty due to low cleaning efficiency. The fixed

bed bio filter has more chambers which runs

in series at 4 times the speed of the water

compared to fixed bed up-flow filters were

the water runs parallel.

Benefits Disadvantages

Low energy consumption due to one time

pumping. Best mechanical capture of particles

in the bio filter! This makes clean water. Less

oxygen consumption due to clear water = less

CO

2

production = less power consumption.

A little higher area requirement. Not full

automatic cleaning of the bio filter.

Benefits Disadvantages

Low energy consumption of the pumping of

the water due to the one-time pumping. No

cleaning of the bio filter.

Makes dirty water when running at full capacity.

Little CO

2

degassing capacity.

Benefits Disadvantages

Trickling filter does 2 jobs - CO

2

stripping and

ammonia removal.

2 times pumping gives higher power

consumption. CO

2

stripping is cooling the

system down at winter and heating it at summer.

Labor intensive to clean bio filters. Need higher

water flow to control CO

2

.

Benefits Disadvantages

Trickling filter does 2 jobs - CO

2

stripping and

ammonia removal.

2 times pumping gives higher power

consumption. CO

2

stripping is cooling the

system down at winter and heating it at summer.

Labor intensive to clean bio filters. Need higher

water flow to control CO

2

.

Benefits and disadvantages of modern basic systems

R AS

RECIRCULATING AQUACULTURE SYSTEMS

04 | INTERNATIONAL AQUAFEED | Fish farming Technology

FISH FARMING TECHNOLOGY

The trickling filter is made of bio block

systems which requires cleaning 1-2 times a

year with a high pressure cleaner.

The water is pumped 2 - 3 times which

gives higher power consumption.

The high water speed in fixed bed up- and

down-flow filters makes it difficult to remove

the micro particles. In combination with a

trickling filter this makes the water unclean.

As described before, the relatively large

amount of air needed for a trickling filter

cools the water significant because of the

evaporation.

Moving bed filters are self-cleaning

because of the air that is blown into the bio

filter medias to keep them moving. When

the layers of dead micro-organisms grow too

thick it will peel off causing dirty water. The

smallest particles that come into the mov-

ing bed filter will not be caught in the filter

but go back into the fish tanks causing very

unclear water.

Blowing air into deep water columns as it is

done in moving bed bio filters gives high super

saturation of Nitrogen which requires sig-

nificant vacuum degassing systems to remove

the super saturation of Nitrogen in the water.

Dirty water in the fish tanks creates a

significant higher oxygen consumption and

CO

2

production of up to 50% which requires

up to 50% more electricity consumption for

oxygen injection and CO

2

removal as well as

50% more oxygen purchase.

Fish farming Technology | INTERNATIONAL AQUAFEED | 05

FISH FARMING TECHNOLOGY

BOC is a leading end-to-end supplier to fish farms, offering:

gas supply, specialist oxygenation and control equipment,

installation and consulting services.

The BOC SOLVOX range

Better conditions for fish, cost efficiencies for fish

farmers.

Contact us

UK www.BOConline.co.uk/aquaculture, Tel 0800 111 333

IE www.BOConline.ie/aquaculture, Tel 1890 355 255

Key Benefits

Reduced feed conversion rate

Reduced fish mortality

Improved growth rate

Higher stock densities

Visit us at

A

Q

U

A

CU

LTU

RE U

K 2014

stand 35

507955-MPG Aquaculture Landscape 216mm x 303mm Advert 02.indd 1 30/04/2014 11:09

T

wo key companies to the aqua-

culture sector have entered into

a distribution agreement that will

benefit fish farming operators

when it comes to combining fish health with

fish nutrition.

By signing a distribution agreement with

the German ingredient manufacturer, Leiber

GmbH, Pharmaq AS teams up with a very

competent partner in the interesting segment

of yeast products and immune stimulation for

its global aquaculture customer base.

Pharmaq is very happy to add the quality

products of Leiber GmbH to its portfolio.

It will make a basis for early entry into new

geographies and species, as well as strength-

ening the relationship with customers in our

present markets," says Jan Oppen Berntsen,

Director Feed Products and Equipment in

Pharmaq AS.

For 60 years, Leiber GmbH, located in

Bramsche in Lower Saxony, Germany, has

been

one of the

leading manufac-

turers of specialist yeast

products. The natural raw material of

brewers' yeast is processed using an innova-

tive biotechnological method to form high-

quality products which are used in the areas

of animal nutrition, food, food supplements

and biotechnology.

Our customers are found in the salmonid,

tilapia, pangasius, sea bass/bream as well as

the shrimp segments of the global aquaculture

industry.

By adding a high-quality beta-glucan man-

ufactured by Leiber to our Pharmaq product

portfolio, we will support unspecific immunity

to products administered by the oral route,

says Jan Oppen Berntsen.

Pharmaq AS provides environmentally

sound, safe and efficacious health products

for the global fish farming industry. Besides a

range of therapeutic products, the company's

core products are fish vaccines with a broad

portfolio of 25 different vaccines for various

markets.

06 | INTERNATIONAL AQUAFEED | Fish farming Technology

FISH FARMING TECHNOLOGY

Pharmaq in holistic

distribution deal with

Leiber to expand its global

product portfolio

Interview - Pharmaq

International Aquafeed interviewed Jan

Oppen Berntsen, Director - Feed Products

and Equipment based in Pharmaqs Oslo

office, Norway, who answered questions

with interesting insights and depth.

How will Leibers products

benefit Pharmaqs customers?

Traditionally, Pharmaq AS has had its main

focus on vaccines for farmed fish. And as

such our vaccines are specific products,

meaning one component in any given vac-

cine is designed to solve one specific disease

in one specific specie.

A vaccine can contain many different

components and thus solve many disease

problems in one injection. The most com-

monly used injection vaccine in Norwegian

salmon farming today contains six differ-

ent antigens and protects against as many

pathognes.

Leiber's products are delivered through

feed and their basic ingredient is beta-glucan.

Beta-glucans boost the animals unspecific

immune system and as such is a more

general way of helping animals overcome

general stress periods.

Feeds containing immune stimulating

substances such as beta-glucan are often

recommended during stress periods caused

by for example change in temperature,

change in feeding regime, before handling

such as sorting and vaccination.

At what stage is it now and

what is the long-term goal

of the agreement? Is this

a world-wide agreement

or for specific regions?

Leiber wanted to strengthen their presence

in the aquaculture segment and chose to do

so through the collaboration with Pharmaq

AS.

Pharmaq AS is recognised as the world's

leading pharmaceutical company specialising

in aquaculture. We provide environmentally

sound, safe and efficacious health products

to the global aquaculture industry through

targeted research and the commitment of

dedicated people.

The agreement gives Pharmaq access

to Leiber's products exclusively to

aquaculture in a few selected markets

(Greece and Spain) and as our own

branded products to aquaculture on a

global basis.

Leiber's brands are BioLex MB40 and

Beta-S. Pharmaq's corresponding brands are

Vetregard and ALPHA Beta 80. The latter

products (Beta-S and AB 80) are purified

and with a very high content (> 80%) of

Beta-glucan.

The long term goal is to build a stronger

presence in the feed additive segment for a

product portfolio that fits our business idea.

(Pharmaq provides environmentally sound,

safe and efficacious health products to the

global aquaculture industry.) Leiber products

fit this perfectly.

Has there been a history of

working with fish farmers

that use Leiber products

anyway? Has it been a

naturally, gradual process?

No, we have a small product portfolio in

selected markets in this segment. Some

of our present customers will naturally be

interested in the Leiber products.

Fish farming Technology | INTERNATIONAL AQUAFEED | 07

FISH FARMING TECHNOLOGY

Interview - Leiber

I

nternational Aquafeed

interviewed Karen

Mrler, Marketing -

Animal Nutrition at

Leiber GmbH in Bramsche in

Lower Saxony, Germany who

also answered question about

the agreement in detail.

How will Leibers

products benefit

Pharmaqs customers?

Leibers high quality made in

Germany products for aqua-

culture include the highly puri-

fied 1.3-1.6--D-glucan Leiber

Beta-S and the yeast cell wall

product Biolex MB40, which

are both delivered through the

feed.

The famous phrase pre-

vention is better than cure

gains more and more impor-

tance in todays aquatic ani-

mal husbandry. Following this

approach, the overall aim and

result of these prophylactically

administered products is to

boost the immune and health

status of fish and shellfish in

order to increase their resist-

ance against the variety of

stress factors that occur during

the production cycles in inten-

sive aquaculture.

As a result, the efficiency

and profitability of the aquacul-

ture farms is improved, mainly

but not exclusively through a

reduction in mortality rates.

How important is the

health of fish to Leibers

current customers, and

does Leiber's immune

stimulation products

match well for fish

farmers with Pharmaqs

products and expertise

in fish vaccination

and fish health?

The health status of fish

and shellfish is the decisive

factor in why Leibers cus-

tomers are using the health

promoting products Leiber

Beta-S and Leiber Biolex

MB40.

In todays intensive aqua-

culture fish and shellfish are

often subjected to a plethora

of various stress factors in

their living environment. A

chronic stress response is gen-

erally believed to suppress or

dysregulate immune functions

and makes the organism more

susceptible to pathogens with

the eventual risk of causing

diseases.

Among others one fre-

quently occurring stress factor

is handling, and this is where

Leibers and Pharmaq's prod-

ucts complement each other

perfectly.

Especially Leibers -glucan

product Leiber Beta-S pre-

pares the fish to better over-

come the stress of a vaccina-

tion procedure and, in addi-

tion, subsequently improves

the effect of the vaccination

through its proven, adjuvant

effect.

What links will this

distribution partnership

bring, are there

long-term goals?

Leiber wants to further

strengthen its presence in

aquaculture and Pharmaq as

the market leader in aquacul-

ture pharmaceuticals, with a

direct link to the farmers, is

an ideal partner.

The combination of both

companies products will

generate a more holistic

approach to the improve-

ment of fish health and ulti-

mately to the profitability

of aquaculture operations

for the farmers benefit in a

sound, safe and sustainable

way.

08 | INTERNATIONAL AQUAFEED | Fish farming Technology

FISH FARMING TECHNOLOGY

A

n ever increasingly crowed ocean

where increasing demands are being

made by various activity groups is

putting unnecessary pressure on the

fishing and aquaculture industries.

Thats the message delegated attending the

inaugural Seafood Summit event which was part of

the Seafex Seafood Exhibition (which in itself was

part of a massive program covering all activities sea-

food related from world hospitality competitions

through to various trade shows and meetings), at

Dubai World Trade Centre earlier this year.

The Association of International Seafood

Professionals (AISP) was engaged to put together

the Summit program.

The opening of the Summit included a message

from Carl-Christian Schmidt, Head of Fisheries

Policies Division at OECD with a video which

sets the scene for the challenges ahead for what is

describes as the Green Growth Period.

Starting proceedings with a session Corporate

Ocean Responsibility: Regional Ocean Industry

Collaboration was Paul Holthus from the World

Ocean Council (WOC). Mr Holthus highlighted

how complex and challenging it is when we are

dealing with an ever increasingly crowded ocean

with everyone demanding their needs should get

priority.

The WOC session brought together repre-

sentatives from shipping, desalination and fisheries/

aquaculture and much was learned about the chal-

lenges and opportunities in each sector.

Captain Anshuman Singh, a legal expert in

shipping matters, explained that at the moment

many shipping companies were economically chal-

lenged and this has seen many vessels simply left an

anchor, that is, dumped. Captain Singh also spoke

about water ballast issues and action plans in case

of oil spillages these can both have incredible

impacts on fisheries/aquaculture.

Prathapchandra Shetty, Emirates Star Fisheries,

commented that in addition to fisheries, aquacul-

ture, shipping and desalination, these same waters

host an increasing level of many other economic

activities - oil and gas, ports, dredging, coastal devel-

opment, tourism and their ocean uses - which

collectively create challenges to maintaining marine

ecosystem health and productivity in the region.

Felix Dent, FAO Globefish, gave an excellent

presentation on Status and Trends of Global

Fisheries & Aquaculture and gave some basic

information on FAO and Globefish roles.

Certification Benefits beyond the Demands

was a presentation by Peter Redmond, Global

Aquaculture Alliance. Through the development

of its Best Aquaculture Practices certification stand-

ards, GAA has become the leading standards-

setting organisation for aquaculture seafood.

Trading seafood in MENA, especially the

Middle East is an important activity that people do

not know enough about. Sadaf Murad, an AISP

member based in UAE, gave her views on Import,

Consumption and Re-Export business.

Sadaf highlighted that the area has become a

large re-processing hub for the MENA area.

Sadaf gave information on import patterns

(species, sources and connections); the spectrum

of seafood products (the top echelon, masses,

bottom of the pyramid consumption, species

and movements, etc.); inter trade and cross trade

(re-processing, re-export, etc.). The presentation

created a taste for the next subject Fishing &

Aquaculture including Financing and Investing in the

Arab Region led by Izzat Feidi, Fisheries Consultant

based in Egypt and a panel of people he had

engaged.

The panel consisted Salih Salem Bahawini,

Al-Qalzam (Sea Global Co, Saudi Arabia);

Professor Jean-Yves Mevel, UAE University, UAE;

Prathapchandra Shetty, Emirates Star Fisheries,

Yemen/UAE and Max Goulden, MacAlister-Elliott

Partners Ltd, UK.

We learnt that whilst the overall resources of

the Arab region in general constitute a small part

in the international fisheries scene they are consid-

ered a very important economic activity especially

in the traditional, artisanal communities in these

countries where it provides employment, food

and a source of income from the various activities

associated with the fisheries industry.

With this background, and in order to increase

the benefits of a largely low level industry in terms

of returns of the industry to the various national

economies as well as to the various sectors of

the industry including the fishermen communities,

there is a significant need for more attention and

prospective of development in the region in order

to raise the potential of food security.

Major investments will need to be injected

in the sector to increase the future benefits of

aquaculture in these countries of the region, com-

mented Izzat.

A successful day one was wrapped up with

a presentation on Aquaculture without Frontiers,

highlighting the issues regarding the alleviation of

hunger and poverty and the activities of the AwF.

Day Two at SEAFEX was focused on how to

make money from our oceans/water responsibly.

Dr Jed Brown, of the MASDAR Institute, gave

us an insight into Integrated Seawater Aquaculture/

Agriculture Project for Bioenergy Production in

UAE.

The importance of seafood as it relates to

individuals health was a GILLS presentation. The

catch cry is that everyone knows the importance of

seafood and health but if that was true then surely

we would not be getting anti-seafood activities

and surely every country would address their food

security needs as far as seafood is concerned.

Importantly, we would not have eating disor-

ders as we have with both hunger and obesity

around the world and seafood would be given

priority in areas relating to space/access. We know

that is not the case so we need to continue to find

new ways to spread the message globally.

Roger Gilbert, International Aquafeed, just

returning from an important Chinese Nutrition

Conference which focused on aquaculture feeds,

etc., gave an excellent presentation on the chal-

lenges we face on how to feed a growing popula-

tion in the future.

He stressed that aquatic organisms like fish,

have an advantage in efficiency (very effective feed

converters) compared to land animals which is

due to their advantage of having ambient body

temperature,and requiring less energy for keeping

body in balance, as they live in water. As feed

resources become scarce and more expensive this

advantage will become stronger he believed.

Despite these facts, there is a perception,

mainly outside the aquaculture society, that feed

is a major sustainability issue for aquaculture. Most

concern is related to the use of fish as feed for

fish but he believed that as long as there is good

management of fisheries ensuring that fish harvest

is sustainable, due to the efficiency benefits of fish,

aquafeed is the best allocation for fishmeal and oil.

However, he pointed out that the industry has

invested in substantial knowledge allowing use to

reduce fishmeal input in diets with many feed com-

panies reducing the inclusion of marine ingredients

by 50 percent over the last 10 years, and clearly

had more gains to make.

Marketing and Lessons in Fishing & Aquaculture

was presented by Professor Jose Fernandez

Polanco, Universidad de Cantabria, who has a

wealth of experience in these areas stressed that

marketing is an imperative in driving the industry

from being commodity driven to consumer driven.

Through various case studies which he has

completed over the years he highlighted that mar-

keting was still an important issue to be overcome.

Dr Farshad Shishehchian from Blue Aqua,

Thailand, spoke about Making Profit in Aquaculture

and attracted a good audience.

The IASP launched its website (http://seafood-

professionals.org/) highlighting that its aims were to

create a professional association representing all indi-

viduals from all sectors of the global seafood industry

community enabling interaction, understanding and

collaboration; disseminating knowledge about fish,

seafood and associated products; lifting values by

promoting advancement in seafood research, devel-

opment, extension, education and standards that will

lead to a professional accredited industry.

The event closed with the International

Premiere showing of Drawing the Line, an

80 minute movie, a concept of Bruce Davey, a

Northern Territorian Spanish Mackerel fisherman

who was keen to get some factual issues on record

about the previous Australian Governments push

for Marine Parks and with the added value of

explaining the Super trawler issue as it unfolded

in Australia.

SEAFEX Middle

East/North Africa

Seafood Summit

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- FISH FARMING TECHNOLOGY: The Use of Feed in Recirculating Aquaculture Systems (RAS)Dokument4 SeitenFISH FARMING TECHNOLOGY: The Use of Feed in Recirculating Aquaculture Systems (RAS)International Aquafeed magazineNoch keine Bewertungen

- FISH FARMING TECHNOLOGY: The Faivre Equipped Trout Farms of AbbevilleDokument4 SeitenFISH FARMING TECHNOLOGY: The Faivre Equipped Trout Farms of AbbevilleInternational Aquafeed magazine100% (1)

- International Aquafeed - May - June 2016 FULL EDITIONDokument80 SeitenInternational Aquafeed - May - June 2016 FULL EDITIONInternational Aquafeed magazineNoch keine Bewertungen

- Potential For European Lobster MaricultureDokument4 SeitenPotential For European Lobster MaricultureInternational Aquafeed magazineNoch keine Bewertungen

- Innovation Nation - How New Developments in Aquaculture Are Boosting The Scottish EconomyDokument4 SeitenInnovation Nation - How New Developments in Aquaculture Are Boosting The Scottish EconomyInternational Aquafeed magazineNoch keine Bewertungen

- Potential Abounds in MexicoDokument4 SeitenPotential Abounds in MexicoInternational Aquafeed magazineNoch keine Bewertungen

- Mud Carab Farming in IndiaDokument4 SeitenMud Carab Farming in IndiaInternational Aquafeed magazine67% (3)

- FISH FARMING TECHNOLOGY - Efficient and Reliable Feed System For Fish Farming Operations - AKVA Group Feed BargesDokument3 SeitenFISH FARMING TECHNOLOGY - Efficient and Reliable Feed System For Fish Farming Operations - AKVA Group Feed BargesInternational Aquafeed magazineNoch keine Bewertungen

- International Aquafeed Jan - Feb 2016 - FULL EDITIONDokument72 SeitenInternational Aquafeed Jan - Feb 2016 - FULL EDITIONInternational Aquafeed magazine100% (1)

- International Aquafeed - March - April 2016 FULL EDITIONDokument72 SeitenInternational Aquafeed - March - April 2016 FULL EDITIONInternational Aquafeed magazineNoch keine Bewertungen

- Brewers' Yeast ProductsDokument4 SeitenBrewers' Yeast ProductsInternational Aquafeed magazine100% (1)

- FISH FARMING TECHNOLOGY - Light Emitting Diode (LED) Lighting Systems For Early Stage AquacultureDokument3 SeitenFISH FARMING TECHNOLOGY - Light Emitting Diode (LED) Lighting Systems For Early Stage AquacultureInternational Aquafeed magazineNoch keine Bewertungen

- Wavemaster AC850 PanoramaDokument8 SeitenWavemaster AC850 PanoramaInternational Aquafeed magazineNoch keine Bewertungen

- International Aquafeed Industry Profiles 2015/16Dokument2 SeitenInternational Aquafeed Industry Profiles 2015/16International Aquafeed magazineNoch keine Bewertungen

- Dinnissen Celebrates 25 Years of The Pegasus® Vacuum CoaterDokument2 SeitenDinnissen Celebrates 25 Years of The Pegasus® Vacuum CoaterInternational Aquafeed magazineNoch keine Bewertungen

- Gut Health in 4 (Easy) StepsDokument2 SeitenGut Health in 4 (Easy) StepsInternational Aquafeed magazineNoch keine Bewertungen

- More Than A Mycotoxin Binder - Anta®Ferm MT FlavoMaxDokument2 SeitenMore Than A Mycotoxin Binder - Anta®Ferm MT FlavoMaxInternational Aquafeed magazineNoch keine Bewertungen

- Extrusion, Essential Oils and Fish Feed Optimisation - Advanced Microencapsulation Improves Delivery of Phytogenic Feed AdditivesDokument2 SeitenExtrusion, Essential Oils and Fish Feed Optimisation - Advanced Microencapsulation Improves Delivery of Phytogenic Feed AdditivesInternational Aquafeed magazineNoch keine Bewertungen

- Acidifier Concepts in Aquafeed - High Quality Feed AdditivesDokument5 SeitenAcidifier Concepts in Aquafeed - High Quality Feed AdditivesInternational Aquafeed magazineNoch keine Bewertungen

- The Ginger Shrimp - Metapenaeus Kutchensis: A Promising Species For Shrimp Aquaculture in Coastal Gujarat State, IndiaDokument2 SeitenThe Ginger Shrimp - Metapenaeus Kutchensis: A Promising Species For Shrimp Aquaculture in Coastal Gujarat State, IndiaInternational Aquafeed magazineNoch keine Bewertungen

- Duckweed: A Sustainable Protein Supplement For The FutureDokument6 SeitenDuckweed: A Sustainable Protein Supplement For The FutureInternational Aquafeed magazine100% (1)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Fin e 59 2016Dokument10 SeitenFin e 59 2016Brooks OrtizNoch keine Bewertungen

- Cooling SistemadeRefrigeracion RefroidissementDokument124 SeitenCooling SistemadeRefrigeracion RefroidissementPacoNoch keine Bewertungen

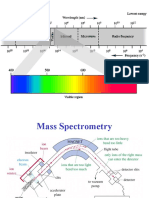

- Mass SpectrometryDokument49 SeitenMass SpectrometryUbaid ShabirNoch keine Bewertungen

- 2008 NOHC - JPHDSupplementDokument62 Seiten2008 NOHC - JPHDSupplementEliza DNNoch keine Bewertungen

- G.f.roof Beam & Slab DetailDokument1 SeiteG.f.roof Beam & Slab Detailahmad anasNoch keine Bewertungen

- RISK MANAGEMENT - Imo Multilingual Glossary On Risk Management (Secretariat)Dokument17 SeitenRISK MANAGEMENT - Imo Multilingual Glossary On Risk Management (Secretariat)Martin NiNoch keine Bewertungen

- Drug AbuseDokument33 SeitenDrug AbuseharshulnmimsNoch keine Bewertungen

- EngineCleaningAndVolcanicAsh InternDokument69 SeitenEngineCleaningAndVolcanicAsh InternLucio Portuguez AlmanzaNoch keine Bewertungen

- SSN Melaka SMK Seri Kota 2021 Annual Training Plan: Athletes Name Training ObjectivesDokument2 SeitenSSN Melaka SMK Seri Kota 2021 Annual Training Plan: Athletes Name Training Objectivessiapa kahNoch keine Bewertungen

- Qualification of Analytical Instruments For Use in Pharmaceutical Industry-A Scientific ApproachDokument23 SeitenQualification of Analytical Instruments For Use in Pharmaceutical Industry-A Scientific Approachmicrobioasturias100% (4)

- Sports MedicineDokument2 SeitenSports MedicineShelby HooklynNoch keine Bewertungen

- DSM-5 Personality Disorders PDFDokument2 SeitenDSM-5 Personality Disorders PDFIqbal Baryar0% (1)

- UIP ResumeDokument1 SeiteUIP ResumeannabellauwinezaNoch keine Bewertungen

- Private Standard: Shahram GhanbarichelaresiDokument2 SeitenPrivate Standard: Shahram Ghanbarichelaresiarian tejaratNoch keine Bewertungen

- Refrigerator: Service ManualDokument119 SeitenRefrigerator: Service ManualMihaela CaciumarciucNoch keine Bewertungen

- The Power of PositivityDokument5 SeitenThe Power of PositivityYorlenis PintoNoch keine Bewertungen

- Harmonized Household Profiling ToolDokument2 SeitenHarmonized Household Profiling ToolJessa Mae89% (9)

- Current and Voltage Controls 3-Phase AC Max. Current Control Type S 178Dokument3 SeitenCurrent and Voltage Controls 3-Phase AC Max. Current Control Type S 178Felipe FarfanNoch keine Bewertungen

- PD 984Dokument38 SeitenPD 984mav3riick100% (2)

- Api 579-2 - 4.4Dokument22 SeitenApi 579-2 - 4.4Robiansah Tri AchbarNoch keine Bewertungen

- Rediscovering Alginate Wound DressingsDokument4 SeitenRediscovering Alginate Wound DressingstanveerhusseinNoch keine Bewertungen

- Wago PCB Terminal Blocks and Connectors Catalog 7Dokument105 SeitenWago PCB Terminal Blocks and Connectors Catalog 7alinupNoch keine Bewertungen

- 2017 THE BLUE WAY Visual PDFDokument54 Seiten2017 THE BLUE WAY Visual PDFAlex KappelNoch keine Bewertungen

- German Specification BGR181 (English Version) - Acceptance Criteria For Floorings R Rating As Per DIN 51130Dokument26 SeitenGerman Specification BGR181 (English Version) - Acceptance Criteria For Floorings R Rating As Per DIN 51130Ankur Singh ANULAB100% (2)

- Posi LokDokument24 SeitenPosi LokMarcel Baque100% (1)

- Virtual or Face To Face Classes Ecuadorian University Students' Perceptions During The Pandemic by Julia Sevy-BiloonDokument1 SeiteVirtual or Face To Face Classes Ecuadorian University Students' Perceptions During The Pandemic by Julia Sevy-BiloonPlay Dos ChipeadaNoch keine Bewertungen

- Rar Vol11 Nro3Dokument21 SeitenRar Vol11 Nro3Valentine WijayaNoch keine Bewertungen

- 2 Effective Manufacturing ERP MESDokument17 Seiten2 Effective Manufacturing ERP MESm_trang2005100% (2)

- Narrative ReporDokument3 SeitenNarrative ReporMARK LUKE ULITNoch keine Bewertungen

- Poisoned NeedleDokument147 SeitenPoisoned NeedleMark Cooper100% (3)