Beruflich Dokumente

Kultur Dokumente

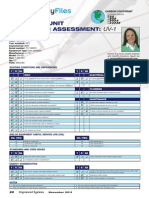

500-Ton Hospital Roof CT Assessment

Hochgeladen von

sajuhereOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

500-Ton Hospital Roof CT Assessment

Hochgeladen von

sajuhereCopyright:

Verfügbare Formate

20 Engi neer ed Syst ems August 2010

BY AMANDA MCKEW

Date: August 16, 2010

Building: Hospital

Floor: Roof

Year installed: 1996

Inspected by: AEM

Serial number: 111010293

System type: Draw-through

Manufacturer: X-Y-Z

Model: DT-111

Size: 500 tons

Hp: 40

Volts: 460/3/60

EXISTING CONDITIONS AND DEFICIENCIES

END OF EQUIPMENT USEFUL SERVICE LIFE (USL)

STANDARDS AND CODE ISSUES

ENERGY CONSERVATION

NOTES

DRAW-THROUGH

COOLING TOWER ASSESSMENT: CT-3A

TheFacilityFiles

Y N NA Y N NA

HVAC

Is there access around equipment?

Exterior enclosure in good condition?

Is unit close to roof edge requiring railings?

Is condenser air flow restricted and/or short-circuiting?

Is walking surface safe (flat roof, non-slip material, etc.)?

Are there sufficient gauges?

Is there ground-fault protection?

Are there sufficient thermometers?

Overall, unit is clean, no vibration or noise?

Are there signs of water leaks?

All ATC devices appear in good condition?

Is there condenser water overflow in distribution sump? ELECTRICAL

Is there non-toxic glycol solution in system?

Is motor a high-efficiency model?

Is unit support (steel frame, etc.) in good condition?

Is there a localized disconnect?

Are valves around unit in good condition?

Does the unit have VSD fans?

Are there valve tags and a valve chart? PLUMBING

Are drain lines piped directly to drains?

Are there localized drains to serve the unit?

Is piping insulation in good condition?

Is water makeup missing backflow preventer?

Are condenser fans in good condition? MAINTENANCE

Is there a vibration switch on unit?

System flow diagram mounted by unit?

Is tower sump clean and in good condition?

O&M manual secured at unit or on file?

Is there an OSHA ladder to top of unit?

Work order last completed?

Is there any kind of filter system adjacent to unit (sand filter, etc.)?

Is there a service contract for this unit?

Are there seismic supports/hangers?

Date of last completed predictive maintenance (vibration analysis, etc.)?

Y N NA Y N NA

Does unit meet current codes?

Does unit/system meet current energy code?

Is emergency power a requirement?

Y N NA Y N NA

End of USL, replace with higher efficient unit/fill?

Is there a chemical treatment service contract?

Can unit/system be retrofitted to meet latest energy code?

Is there a water meter on makeup line?

Consider waterside economizer?

1. Can unit be readily removed/replaced? 3. Are unit controls interactive with building ATC computer?

2. Does unit operate 24/7 year-round or seasonal? 4. Are there energy meters (fuel, Btuh, etc.)?

Year Year

14 Motor is x years old 20 USL benchmark is _

14 Controls are x years old 16 USL benchmark is _

14 Condenser fans are x years old 20 USL benchmark is _

14 Unit is x years old 20 USL benchmark is _

McKew is a senior project engineer

with InterPro Solutions. Reach her

at amckew@interprosoft.com.

CARBON FOOTPRINT

Carbon Neutral

Das könnte Ihnen auch gefallen

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsVon Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsBewertung: 4 von 5 Sternen4/5 (1)

- Switchgear Panel Details ReportDokument12 SeitenSwitchgear Panel Details Reportmuhammad nazir0% (1)

- LavDokument93 SeitenLavPamela RodriguezNoch keine Bewertungen

- Good Earthing Practices For Generator System (Presentation) PDFDokument20 SeitenGood Earthing Practices For Generator System (Presentation) PDFMokr AchourNoch keine Bewertungen

- ASHRAE Journal - Optimizing Chilled Water Plant ControlsDokument12 SeitenASHRAE Journal - Optimizing Chilled Water Plant ControlsAntonio LebrunNoch keine Bewertungen

- ASTM D3013 Epoxy Molding CompoundsDokument3 SeitenASTM D3013 Epoxy Molding CompoundsNelson RomeroNoch keine Bewertungen

- ASHRAE Journal - Tips To Reduce Chilled Water Plant Costs - TaylorDokument6 SeitenASHRAE Journal - Tips To Reduce Chilled Water Plant Costs - TaylorsajuhereNoch keine Bewertungen

- Energy Audit Quick ChecklistDokument3 SeitenEnergy Audit Quick ChecklistPrasad Kishor NaikNoch keine Bewertungen

- UltraCut Operation & Maintenance ManualDokument68 SeitenUltraCut Operation & Maintenance ManualMilko MignecoNoch keine Bewertungen

- Generator Set Installation Checklist-Open Generator SetDokument2 SeitenGenerator Set Installation Checklist-Open Generator SetHaroon ZafarNoch keine Bewertungen

- Preparation of Transformer SpecificationDokument54 SeitenPreparation of Transformer SpecificationparvezblogNoch keine Bewertungen

- Oil and Gas Pre Start Up AuditDokument16 SeitenOil and Gas Pre Start Up AuditLaw100% (1)

- ASHRAE Journal - How To Design & Control Waterside Economizers-TaylorDokument7 SeitenASHRAE Journal - How To Design & Control Waterside Economizers-TaylorsajuhereNoch keine Bewertungen

- Emergency Siren System-T 128 ManualDokument42 SeitenEmergency Siren System-T 128 ManualUsman Zouque100% (1)

- Physical separation between power and data cablesDokument16 SeitenPhysical separation between power and data cablesMouna Nj100% (1)

- Fan SurgingDokument10 SeitenFan SurgingPrashant SrivastavaNoch keine Bewertungen

- ASHRAE Symposis Degrading Delta-T-TaylorDokument13 SeitenASHRAE Symposis Degrading Delta-T-TaylormondsbaNoch keine Bewertungen

- Schneider Electric OKKEN IntroductionDokument26 SeitenSchneider Electric OKKEN IntroductionDuško TovilovićNoch keine Bewertungen

- E Booklet Feeding The ChakrasDokument20 SeitenE Booklet Feeding The ChakrasVibrating PickleNoch keine Bewertungen

- Identify Hazards and Risks in the WorkplaceDokument7 SeitenIdentify Hazards and Risks in the WorkplaceLeah Rizza CabaliwNoch keine Bewertungen

- High Dependability Switchboard for Power Distribution and Motor ControlDokument26 SeitenHigh Dependability Switchboard for Power Distribution and Motor ControlLaurentiu CatalinNoch keine Bewertungen

- ASHRAE Journal - Primary-Only Vs Primary-Secondary Variable Flow SystemsDokument5 SeitenASHRAE Journal - Primary-Only Vs Primary-Secondary Variable Flow SystemsQaz Zaq100% (1)

- 1108 The Facility FilesDokument1 Seite1108 The Facility FilessajuhereNoch keine Bewertungen

- 1105 The Facility FilesDokument1 Seite1105 The Facility FilessajuhereNoch keine Bewertungen

- The Facility Files 11 11Dokument1 SeiteThe Facility Files 11 11sajuhereNoch keine Bewertungen

- The Facility Files 8 12Dokument1 SeiteThe Facility Files 8 12sajuhereNoch keine Bewertungen

- 1102 The Facility FilesDokument1 Seite1102 The Facility FilessajuhereNoch keine Bewertungen

- VAV System AssessmentDokument1 SeiteVAV System AssessmentsajuhereNoch keine Bewertungen

- 28 The Facility Files 5 12Dokument1 Seite28 The Facility Files 5 12sajuhereNoch keine Bewertungen

- The Files: FacilityDokument1 SeiteThe Files: FacilitysajuhereNoch keine Bewertungen

- The Files: FacilityDokument1 SeiteThe Files: FacilitysajuhereNoch keine Bewertungen

- 0807 HVACDesigner TipsDokument1 Seite0807 HVACDesigner TipspereramjpNoch keine Bewertungen

- Educational Facilities ESDokument1 SeiteEducational Facilities ESsajuhereNoch keine Bewertungen

- C03 - HVSG 11Dokument20 SeitenC03 - HVSG 11princensikan23Noch keine Bewertungen

- Conductor Bar Quoting GuideDokument1 SeiteConductor Bar Quoting Guideventas1Noch keine Bewertungen

- Netxtend PPC Series BrochureDokument12 SeitenNetxtend PPC Series BrochureCristi GrosuNoch keine Bewertungen

- Simoprime Catalog English Aug2010Dokument16 SeitenSimoprime Catalog English Aug2010muktivarNoch keine Bewertungen

- Arteche CT Trafcomhv enDokument8 SeitenArteche CT Trafcomhv enHood RobimNoch keine Bewertungen

- Hotel Motel Dorm DBDokument1 SeiteHotel Motel Dorm DBsajuhereNoch keine Bewertungen

- Easypact MVS: CatalogueDokument96 SeitenEasypact MVS: Catalogueanant7388Noch keine Bewertungen

- AHU Replacement DR ESDokument1 SeiteAHU Replacement DR ESsajuhereNoch keine Bewertungen

- CPV10 enDokument68 SeitenCPV10 enThomas HaböckNoch keine Bewertungen

- Clch-svx01b-En 0801 Energy Wheels For T-Series IomDokument28 SeitenClch-svx01b-En 0801 Energy Wheels For T-Series Iomh2odavidNoch keine Bewertungen

- Technical Schedule - Power, Chemicals & UtilitiesDokument12 SeitenTechnical Schedule - Power, Chemicals & UtilitiesChandresh YadavNoch keine Bewertungen

- NoteDokument6 SeitenNoteLienu PrinceNoch keine Bewertungen

- Medium voltage switchgear for marine and offshore applicationsDokument20 SeitenMedium voltage switchgear for marine and offshore applicationsnicholasleeNoch keine Bewertungen

- Washing Machine Training (SPLENDIDE)Dokument68 SeitenWashing Machine Training (SPLENDIDE)Doru Razvan100% (2)

- HV Circuit Breaker Dead Tank TypeDokument4 SeitenHV Circuit Breaker Dead Tank TypeEsproNoch keine Bewertungen

- Operational Manual Air Cooled Screw Nov 2010Dokument20 SeitenOperational Manual Air Cooled Screw Nov 2010Chinh Viet HoangNoch keine Bewertungen

- Parking Cooler System Nitecool Tcc-100: Installation and Service InstructionsDokument12 SeitenParking Cooler System Nitecool Tcc-100: Installation and Service Instructionsebuk123Noch keine Bewertungen

- Rana TahirDokument35 SeitenRana TahirIrfan UllahNoch keine Bewertungen

- Sandwichplattenanker 2016 enDokument40 SeitenSandwichplattenanker 2016 enmixi1978Noch keine Bewertungen

- GA Catalogue CA 500 GB 0501Dokument36 SeitenGA Catalogue CA 500 GB 0501adst34Noch keine Bewertungen

- Section J - Wedge PDFDokument33 SeitenSection J - Wedge PDFOtto AcnNoch keine Bewertungen

- Catalog Okken enDokument26 SeitenCatalog Okken enSaid BelhaimerNoch keine Bewertungen

- Elastimold SwitchgearDokument24 SeitenElastimold SwitchgearSofiDanielaCruzNoch keine Bewertungen

- TW500A Linear Amplifier - Operator and Technical ManualDokument33 SeitenTW500A Linear Amplifier - Operator and Technical ManualAlexander J Rokowetz100% (2)

- Actulux Manual SVM 24V 5A 8A Control Panel PDFDokument11 SeitenActulux Manual SVM 24V 5A 8A Control Panel PDFAna Carolina SantosNoch keine Bewertungen

- Edwards 280 Heats Heat DetectorDokument2 SeitenEdwards 280 Heats Heat Detectorbriguy4uNoch keine Bewertungen

- Tuty Court Genset ESTIMATES NewDokument42 SeitenTuty Court Genset ESTIMATES NewRajaDurai RamakrishnanNoch keine Bewertungen

- Apts Q e 2023.024.ers Nasugbu Hospital Modern Fuji MRL - Hospelev 6 Floors 6Dokument7 SeitenApts Q e 2023.024.ers Nasugbu Hospital Modern Fuji MRL - Hospelev 6 Floors 6Carlo ApilaNoch keine Bewertungen

- Catalogue-8bt1 - en Ovo Je U ProjektuDokument16 SeitenCatalogue-8bt1 - en Ovo Je U ProjektuAnonymous mcCJYBoNoch keine Bewertungen

- III Pandey GAIL 3 PDFDokument59 SeitenIII Pandey GAIL 3 PDFisukuruNoch keine Bewertungen

- Baudouin_Generator_Catalogue_ENGDokument12 SeitenBaudouin_Generator_Catalogue_ENGaec.kazakhstanNoch keine Bewertungen

- Festo Szelepsziget TYP10-G - ENDokument64 SeitenFesto Szelepsziget TYP10-G - ENEde HeimNoch keine Bewertungen

- TD1007 Water To Air DatasheetDokument3 SeitenTD1007 Water To Air DatasheetMustapha AlaouiNoch keine Bewertungen

- WHP Nema Iec Cont ActorsDokument4 SeitenWHP Nema Iec Cont ActorsJimmy Tacca ApazaNoch keine Bewertungen

- WPP ProtectionDokument24 SeitenWPP Protectionkrish18_scribdNoch keine Bewertungen

- Sizing Exhaust System For Refrigerating Machinery Rooms - Seidl, TaylorDokument13 SeitenSizing Exhaust System For Refrigerating Machinery Rooms - Seidl, Taylorforevertay2000Noch keine Bewertungen

- ASHRAE Journal - VAV Box Duct Design - TaylorDokument8 SeitenASHRAE Journal - VAV Box Duct Design - TaylorsajuhereNoch keine Bewertungen

- SandBookInterior r1Dokument16 SeitenSandBookInterior r1sajuhereNoch keine Bewertungen

- Chapter 07Dokument39 SeitenChapter 07kevinmathew27Noch keine Bewertungen

- ASHRAE Journal - Underfloor Lessons Learned-DalyDokument4 SeitenASHRAE Journal - Underfloor Lessons Learned-DalysajuhereNoch keine Bewertungen

- ASHRAE-Symposium WSE in Data Centers SteinDokument9 SeitenASHRAE-Symposium WSE in Data Centers SteinDiego CMNoch keine Bewertungen

- HPAC Operable Windows - Daly PDFDokument8 SeitenHPAC Operable Windows - Daly PDFsajuhereNoch keine Bewertungen

- Seidl NCBC08 Paper TR CorrectedDokument10 SeitenSeidl NCBC08 Paper TR CorrectedsajuhereNoch keine Bewertungen

- CoolTools ProjectggDokument24 SeitenCoolTools ProjectggdaveleyconsNoch keine Bewertungen

- ASHRAE Symposium SE 99-16-3 Kammerud & Hydeman CB Analysis UncertaintyDokument10 SeitenASHRAE Symposium SE 99-16-3 Kammerud & Hydeman CB Analysis UncertaintysajuhereNoch keine Bewertungen

- HPAC A Fresh Look at Fans-FinalDokument10 SeitenHPAC A Fresh Look at Fans-FinalsajuhereNoch keine Bewertungen

- HPAC Article On Specifying VAV BoxesDokument4 SeitenHPAC Article On Specifying VAV Boxesjoejex123Noch keine Bewertungen

- Contracting Business Magazine - Taking Controls in-House-FriedmanDokument2 SeitenContracting Business Magazine - Taking Controls in-House-FriedmanBasil OguakaNoch keine Bewertungen

- ASHRAE Symposium HI-02!18!2 Symposium Hydeman & Webb New Chiller ModelDokument10 SeitenASHRAE Symposium HI-02!18!2 Symposium Hydeman & Webb New Chiller ModelsajuhereNoch keine Bewertungen

- ASHRAE Journal - Select & Control Economizer Dampers in VAV Systems - TaylorDokument7 SeitenASHRAE Journal - Select & Control Economizer Dampers in VAV Systems - Taylorsajuhere100% (1)

- ASHRAE Journal - Return Air Systems - TaylorDokument4 SeitenASHRAE Journal - Return Air Systems - TaylorKadiri Olanrewaju100% (1)

- ASHRAE Journal - Return Fans in VAV Systems - TaylorDokument6 SeitenASHRAE Journal - Return Fans in VAV Systems - TaylorAntonio LebrunNoch keine Bewertungen

- ASHRAE Journal - Stauffer Case StudyDokument5 SeitenASHRAE Journal - Stauffer Case StudysajuhereNoch keine Bewertungen

- ASHRAE Journal - Staying OnlineDokument6 SeitenASHRAE Journal - Staying OnlinesajuhereNoch keine Bewertungen

- ASHRAE Journal - Series Fan-Powered Boxes-Taylor PDFDokument0 SeitenASHRAE Journal - Series Fan-Powered Boxes-Taylor PDFsajuhereNoch keine Bewertungen

- ASHRAE Journal - Retrofitting DDC Controls ASHRAE Journal June 2004Dokument7 SeitenASHRAE Journal - Retrofitting DDC Controls ASHRAE Journal June 2004sajuhereNoch keine Bewertungen

- 2014 ASHRAE - Restroom Exhaust Design PDFDokument4 Seiten2014 ASHRAE - Restroom Exhaust Design PDFAntonio LebrunNoch keine Bewertungen

- ASHRAE Journal - Humidity Controls in Data CentersDokument8 SeitenASHRAE Journal - Humidity Controls in Data CentersAntonio LebrunNoch keine Bewertungen

- ASHRAE Journal - LEED and Standard 62.1-TaylorDokument4 SeitenASHRAE Journal - LEED and Standard 62.1-TaylorNg Khanh100% (1)

- Performance Based Evaluation of Industrial Grade Resins Duolite ARA-9366 and Duolite A-368Dokument8 SeitenPerformance Based Evaluation of Industrial Grade Resins Duolite ARA-9366 and Duolite A-368misterno2Noch keine Bewertungen

- Water WastewaterDokument20 SeitenWater WastewaterterryjoseeNoch keine Bewertungen

- MD - Ziaul AlamDokument2 SeitenMD - Ziaul AlamAvijit DasNoch keine Bewertungen

- Onions: Vegetable Crops Production Guide For The Atlantic ProvincesDokument8 SeitenOnions: Vegetable Crops Production Guide For The Atlantic ProvincesEglNoch keine Bewertungen

- Epoxidation of Castor Oil With Peracetic Acid Formed in Situ in The Presence of An Ion Exchange ResinDokument8 SeitenEpoxidation of Castor Oil With Peracetic Acid Formed in Situ in The Presence of An Ion Exchange ResinSölangs QüntellaNoch keine Bewertungen

- Oil Debate Chromatography PPT 2Dokument17 SeitenOil Debate Chromatography PPT 2Eridha TriwardhaniNoch keine Bewertungen

- Journal of Environmental ManagementDokument12 SeitenJournal of Environmental ManagementAjeng FadillahNoch keine Bewertungen

- Avantor Chemical Price List 2019-2020-J.T.BAKERDokument54 SeitenAvantor Chemical Price List 2019-2020-J.T.BAKERVikki PatelNoch keine Bewertungen

- 02 Heubach No 00181 ZPA RZ Epoxy Dispersion WDokument2 Seiten02 Heubach No 00181 ZPA RZ Epoxy Dispersion WnanoNoch keine Bewertungen

- Chemical, Physical, and Baking Properties of Apple FiberDokument4 SeitenChemical, Physical, and Baking Properties of Apple FiberHector FloresNoch keine Bewertungen

- Toxic Substances and Disease Registry MRLs for March 2016Dokument16 SeitenToxic Substances and Disease Registry MRLs for March 2016KodeChandrshaekharNoch keine Bewertungen

- Thermoplastics and Thermosetting PlasticDokument24 SeitenThermoplastics and Thermosetting PlasticKAPIL SINGHNoch keine Bewertungen

- Omeprazole: by Jennica Mae V. CuicoDokument7 SeitenOmeprazole: by Jennica Mae V. Cuicoジェンニカ メイNoch keine Bewertungen

- Ceilcote 242 Flakeline coating specification for concreteDokument2 SeitenCeilcote 242 Flakeline coating specification for concretenoto.sugiartoNoch keine Bewertungen

- Biopolymers - Sustainability For The Automotive Value-Added ChainDokument4 SeitenBiopolymers - Sustainability For The Automotive Value-Added ChainDiana LondoñoNoch keine Bewertungen

- Low Temp Refrigeration Oil DataDokument1 SeiteLow Temp Refrigeration Oil DataGeorgiana DumitruNoch keine Bewertungen

- Steps in Balancing Redox ReactionsDokument28 SeitenSteps in Balancing Redox ReactionsRUZCHEMISTRYNoch keine Bewertungen

- Cape Chemistry Unit Ii Module I Alkanes and Alkenes Worksheet and Revision GuideDokument5 SeitenCape Chemistry Unit Ii Module I Alkanes and Alkenes Worksheet and Revision GuideDestinee SullivanNoch keine Bewertungen

- Aldehyde, Ketones and Carboxylic AcidDokument18 SeitenAldehyde, Ketones and Carboxylic AcidPRADEEP CNoch keine Bewertungen

- 2020-Intrinsic and tunable ferromagnetism in Bi0.5Na0.5TiO3 through CaFeO3-δ modification-Scientific Reports (10), 6189 (2020)Dokument15 Seiten2020-Intrinsic and tunable ferromagnetism in Bi0.5Na0.5TiO3 through CaFeO3-δ modification-Scientific Reports (10), 6189 (2020)Lương Hữu Bắc100% (1)

- Rition Feeaing: Ruminant AnatomyDokument30 SeitenRition Feeaing: Ruminant AnatomySMP SeriesNoch keine Bewertungen

- Determination of % Available Chlorine in Bleaching PowderDokument10 SeitenDetermination of % Available Chlorine in Bleaching PowderABHILASHA MISHRA0% (1)

- Gnaser H., Huber B., Ziegler C. - Nanocrystalline TiO2 For Photocatalysis (2004) PDFDokument32 SeitenGnaser H., Huber B., Ziegler C. - Nanocrystalline TiO2 For Photocatalysis (2004) PDFoscuraNoch keine Bewertungen

- P-X-Y Diagram For Benzene (1) /ethylbenzene (2) at 363.15KDokument2 SeitenP-X-Y Diagram For Benzene (1) /ethylbenzene (2) at 363.15Ksiti azilaNoch keine Bewertungen

- A STUDY ON THE ECOFRIENDLY DYES EXTRACTED FROM THREE DIFFERENT SPECIES OF Curcuma LDokument3 SeitenA STUDY ON THE ECOFRIENDLY DYES EXTRACTED FROM THREE DIFFERENT SPECIES OF Curcuma Lanon_285184956Noch keine Bewertungen

- Mineral-rich Bilimbi fruit analysisDokument3 SeitenMineral-rich Bilimbi fruit analysisveronica francisNoch keine Bewertungen

- New Australian Curriculum Senior Secondary ChemistryDokument44 SeitenNew Australian Curriculum Senior Secondary Chemistryapi-252350138Noch keine Bewertungen