Beruflich Dokumente

Kultur Dokumente

Excavation Trenching and Horizontal

Hochgeladen von

Raed Naim KhammashOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Excavation Trenching and Horizontal

Hochgeladen von

Raed Naim KhammashCopyright:

Verfügbare Formate

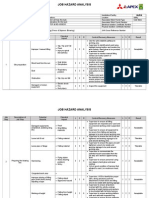

Western Power Safe Work Method Statement

Task details

Description Excavation / Trenching and Horizontal Directional Drilling

DM 10696991 Approved by Work Practices Manager

Review team SWMS Development Approval date May 2013

Qualifications/Licences required Valid Western Power Authorisations for the Task/ Network Authority Card (correct level of authorisation)

Permits required Vicinity Authority (VA) if required

Which Safety LifeSavers are required for this task?

Potential hazards associated with the task

Category Hazard Category Hazard Category Hazard

1. Working at heights

Ladders

Lifting equipment, scissors / EWP

Scaffolding

Stairs / platforms

Working at height

Working above others

Multiple work requiring EWPs

5. Pressure

Competitive pressures

Compressed gases / air

Fluid

High pressure steam

Hydraulic

Water

2. Working with electricity

Static electricity / induction

Substations / switch rooms

Underground cables

Contact with electrical equipment

Electrical cables

High voltage equipment

Overhead lines

Non-compliant earths, e.g. tagged / tested

6. Human factors

Rushing

Complacency

Fatigue

Unclear work direction

Stress / anxiety / frustration

Lack of knowledge

Poor communications

Negative attitudes

3. Radiation

Infra-red

Microwaves

Ultra-violet light, i.e. sun

X-ray

Laser

7. Using mobile plant

Traffic / pedestrian interaction / collision

Uneven terrain

Unlicensed / untrained operators

Vehicle instability

Vehicle access

10. Workplace

Asbestos

Confined space / void space

Falling objects

General access

Housekeeping

Illumination / lighting

Noise, i.e. exposure / nuisance

Poor ventilation

Protrusions

Restricted visibility

Restricted work area

Slip and trip hazards

Unauthorised personnel

Unlabelled controls

Vibration

Wet / slippery

Wind / storm activity

Fog / mist / smoke

Working in isolation

Dust / particulates

8. Manual handling

(ergonomic)

Awkward / unbalanced load

High / low reach

High force / heavy loads

Lighting

Over exertion / fatigue

Poor design / layout / surface

Repetitive movements

11. Chemical

Chemicals / reagents

Fumes / vapour / mist, e.g. SF6

Flammable gases

Handling flammable materials

Hazardous chemical exposure

Solid chemical

Splashes / burns

Spills to ground or work area

4. Mechanical

Abrasive blasting / grinding

Auto-start equipment

Conveyors

Equipment failure

Hand and power tool

Impact and crushing areas

Pinch / cutting points

Residual / stored energy

Uncontrolled movement

Unguarded moving parts

Welding or cutting

Crimping / connecting

9. Environment

Air contamination

Soil contamination

Storm water contamination

Waste, e.g. effluent / hazardous

Solid waste

12. Thermal

Cold ambient temperature

Heat ambient temperature

Hot materials / fluids

Hot surfaces

UV exposure

Western Power Safe Work Method Statement Excavation / Trenching and Horizontal Directional Drilling page 1 of 5

Western Power Safe Work Method Statement Excavation / Trenching and Horizontal Directional Drilling page 2 of 5

Steps

required to perform the task, in the

correct sequence

Hazards

for each task step

Initial

Risk

Rating

Controls

required to eliminate or minimise the risk of injury

Controlled

Risk

Rating

References

Plan and prepare

Pre-plan

Determine staff requirements

Staff skilled, trained and

competent

Plan and discuss route plans,

access and equipment needs

Locate any underground

utilities

Notify SOCC / NOCC if

Vicinity Authority (VA) is

required

Consumer / land owner

notification (if required)

Weather conditions / fire alerts

at work place

PPE requirements inspection

and testing

Inspect / check tools, material

plant and equipment

Manual handling

Vehicles and plant

Driving to work place

Notify Main Roads and local

council (if traffic management

required)

Unfit for work: shock, burns, injury, harm

Fatigue: injury, harm

Lack of skills or knowledge: shock, burns, injury

Site hazards slip, trip, fall, dusts: Injury, harm

Contact with live cables / lines: shock, burns,

injury

Induced voltages from overhead lines: shock,

burns

Contact with underground utilities: shock, burns

Working / driving in high fire risk areas: injury

Adverse weather lightning, wind, UV: injury

Bush and grass fires: burns, harm

Expired / damaged PPE: shock, injury, harm

Inappropriate PPE / PPC: shock, injury, harm

Damaged or faulty tools and equipment: injury

Out of test date tools and equipment: injury

Unauthorised tools and equipment: shock,

injury

Manual handling / heavy objects: strain, sprain

Unroadworthy or incorrectly set up vehicles

and plant: injury

Inadequately secured tools and equipment:

injury

Climbing / loading vehicles: strain, sprain, injury

Travelling from site to site: fatigue, injury

Weather and road conditions: injury

Vehicles, animals and pedestrians: injury

Accident / breakdown: injury, harm

Vehicles, pedestrians, unauthorised access:

injury

M

Confirm staff are fit for work

Comply with fatigue, drug and alcohol policies

Ensure staff are trained and have appropriate skills /

competencies

Confirm staff have valid Network Access Card (NAC) and

permit accreditation (if required)

Locate underground utilities contact Dial Before You Dig

(if required)

Communicate with System Operations Control Centre

(SOCC) for a Vicinity Authority (VA) if required

Check with SOCC / NOCC and local shire for weather

conditions / fire alerts

Avoid working during rain, lightning or high wind conditions

Carry approved fire fighting equipment / staff trained

Confirm staff have required safety clothing and equipment

Ensure that gloves, hats, tools and equipment are within

functional date cycle (if required)

Check that tools and equipment have been tested and

tagged (where required)

Confirm tools and equipment comply with WP standards

Use two-person lift techniques or mechanical aids to shift /

lift heavy objects

Inspect / check vehicles and plant for road worthiness

Ensure vehicles are correctly loaded and load secured

Maintain 3 points of contact when climbing

Share the driving (where possible) to avoid fatigue

Drive to suit road and weather conditions

Notify formal leader / office of daily work plan

Carry an emergency beacon or satellite phone if travelling

out of mobile phone / radio range

Engage an accredited traffic management company

Confirm site security and access requirements

Plan to access workplaces in congested areas when

vehicle or pedestrian traffic is at a minimum

L

Electrical System

Safety Rules

(ESSR) sections:

3.9, 3.10, 5.1, 5.7,

6, 7.2, 7.3

Work Practice

Manual (WPM)

sections: 2.12,

2.16, 2.21, 3, 5.10,

7.2, 7.3, 7.4, 7.10

Safety Life Savers

Fitness For Work

Standard

Main Roads Traffic

Management for

Works on Roads

Code of Practice

Western Power Safe Work Method Statement Excavation / Trenching and Horizontal Directional Drilling page 3 of 5

Steps

required to perform the task, in the

correct sequence

Hazards

for each task step

Initial

Risk

Rating

Controls

required to eliminate or minimise the risk of injury

Controlled

Risk

Rating

References

Implement a traffic management

plan (if required)

Control unauthorised access to

the workplace

Control vehicle movements

around the workplace

Vehicle and equipment movement: injury

Unprotected workplace: injury

Unauthorised access: public risk, injury

H

Maintain control of work place access at all times

L

Main Roads Traffic

Management for

Works on Roads

Code of Practice

WPM section:

2.21

Workplace set up

Correct location / apparatus

Advise landowner / consumers

(if required)

Review site plans and

drawings (if required)

Confirm location of all utilities

Complete risk assessment

include all staff

Appoint a safety observer

Site conditions / fire alerts

Emergency procedures in

place

Communicate with SOCC /

NOCC and Issuing Officer for

VA (if required)

Vehicles earthed (if required)

Daily checks and log books

Cable laying / trenching /

drilling equipment set up

Confirm cable depths (if

required)

Identify soil types and

conditions

Attach 'strike alert' lead (if

required)

Check equipment

Unclear instructions, job location and

communications: shock, injury, harm

Failure to locate underground utilities: shock,

injury, harm

Obstacles slip, trip and fall: injury

Incorrect manual handling: strain, sprain, injury

Insects, vermin, reptiles, animals: bites, stings

Weather rain, sun, wind, lightning: injury,

harm

Fires: burns, injury

No clear access / egress plan: injury, harm

Vehicle, plant or equipment movement: injury

Failure of load bearing surfaces: injury

Cave in or collapse of excavation / trench:

injury

Flooding of trench: injury

Contaminated soil: harm

Contact with live overhead apparatus: shock,

burns, injury

Failure to obtain permit: shock, injury, harm

Noise: harm

Hydraulic pressure: injury, harm

Flammable fuel / fires: burns, injury, harm

Unauthorised public access to workplace: injury

M

Confirm correct location and maps / plans are up to date

Communicate with land owner to determine safe entry

requirements (if required)

Confirm the location of all utilities in the workplace

Conduct a risk assessment, include adjacent structures and

apparatus

Appoint a safety observer trained in emergency procedures

Confirm safe workplace access and egress

Avoid working outdoors during extremes of weather

Ensure an emergency plan is in place and understood

Ensure fire fighting equipment is at the workplace

Ensure SOCC / NOCC are aware of the work to be done

Earth vehicles and plant (as required)

Use stabilisers, pads, wheel chocks (if required)

Inspect the condition of plant, tools and equipment

Apply correct manual handling techniques, use mechanical

aids where practicable

Drink sufficient fluids to stay hydrated

Obtain permit and ensure staff are aware of its conditions

Confirm staff are aware of the hazards from mechanical /

hydraulic equipment

Ensure correct procedures for storing, handling and using

flammable fuel are followed

Ensure no unauthorised work place access

L

ESSR sections:

3.2, 3.9, 3.10, 5.7,

6, 7.2, 7.3

WPM sections:

2.1, 2.2, 2.8, 2.10,

2.16, 2.21, 2.26, 3,

5.10, 7.2, 7.3, 7.4,

7.10

Safety Life Savers

Isolation and permits (VA if

required)

Inspect / confirm apparatus to

be worked on / near

Confirm location of all utilities

in the vicinity of work place

Failure of work team to clearly understand the

conditions of the VA and the work boundaries:

shock, injury, harm

Failure to confirm the location of all utilities:

shock, injury, harm

M

Maintain contact with SOCC / NOCC / issuing officer

Use maps, plans and test equipment to locate cables and

other utilities (if required)

Ensure all staff understand the conditions of the VA and are

aware of the boundaries of the working area

L

ESSR sections:

7.2, 7.3

Safety Life Savers

Western Power Safe Work Method Statement Excavation / Trenching and Horizontal Directional Drilling page 4 of 5

Steps

required to perform the task, in the

correct sequence

Hazards

for each task step

Initial

Risk

Rating

Controls

required to eliminate or minimise the risk of injury

Controlled

Risk

Rating

References

Communicate with SOCC or

NOCC and Issuing Officer for

VA

Confirm status of apparatus in

vicinity of work place

Work team briefed on

conditions and boundaries of

the permit

VA issued

Work team sign onto permit

Contact with live cables / overhead apparatus:

shock, burns, injury

Contact with gas line: injury, burns, harm

M

Ensure that all staff have signed on to the VA

L

Carry out the job

Excavation, trenching, drilling

Advise SOCC / NOCC (if

required)

Confirm cable depths (if

required)

Avoid any underground utilities

Awareness of overhead lines

Confirm soil type and

conditions

Carry out excavation, trenching

or horizontal drilling work as

required

Inspect work for compliance

Connect / test work (if

required)

Failure to identify / contact with underground

utilities: shock, burns, injury, harm

Contact with live overhead apparatus: shock,

burns

Slip, trip, fall, obstacles: injury

Manual handling / use of tools: strain, sprain,

injury

Vehicle, plant, equipment movement: injury

Equipment or tool failure: injury

Moving machinery (pulleys, winches): pinch,

crush, injury

Failure of load bearing surfaces / ground: injury

Cave in or collapse of excavation / trench:

injury

Flooding of trench: injury

Working in the vicinity of gas main: injury, harm

Noise: harm

Hydraulic pressure: injury, harm

Contaminated soil / hazardous substances:

harm

H

Confirm staff understand what they are to do and how to do

it

Check that the appointed safety observer knows their role

Use maps, plans, and test equipment to confirm location of

cables and other utilities (if required)

Dig potholes to locate underground utilities (if required)

Identify and alert staff of suspected contaminated soil and

hazardous substances (if required)

Have the appropriate MSDS and / or risk assessment data

Confirm that spill kits and acid soil neutralising material is

onsite and staff know how and when to use them

Conduct all excavation work in accordance with approved

methods

Confirm strike alert lead is attached (if required)

Use approved tools and equipment

Earth vehicles (if required)

Maintain Minimum Approach Distances (MAD) to all utilities

Apply correct manual handling techniques. Use mechanical

aids where possible.

Continually review potential hazards and control methods

L

ESSR sections:

3.2, 3.9, 3.10, 5.7,

6, 7.2, 7.3

WPM sections:

2.2, 2.8, 2.16, 3,

7.1, 7.2, 7.3, 7.4,

7.5, 7.10

Occupational

Safety and Health

Regulations (1996)

Subdivision 6

Excavations and

Earthworks

WorkSafe Code of

Practice

Excavation (2005)

PTS 703 Safe

Excavations near

WP Assets

Safety Life Savers

Complete the task

Completion of task

Confirm work is completed

Communicate with Issuing

Officer (if VA used)

Vehicle and equipment movement: injury

Uneven / slippery surfaces / obstacles: injury

Incorrect manual handling techniques: strain,

sprain, injury

H

Conduct final task and workplace inspections and tests

Contact SOCC / NOCC / Issuing Officer (if required)

All recipients understand that work is completed and to sign

off the VA (if used)

L

ESSR sections:

3.2, 3.9, 3.10, 5.7,

6, 7.2, 7.3

Western Power Safe Work Method Statement Excavation / Trenching and Horizontal Directional Drilling page 5 of 5

Steps

required to perform the task, in the

correct sequence

Hazards

for each task step

Initial

Risk

Rating

Controls

required to eliminate or minimise the risk of injury

Controlled

Risk

Rating

References

Sign off VA (if used)

Communicate with consumer /

land owner (if required)

Clean, inspect and stow tools

and equipment

Reinstate site

Remove waste material /

contaminated soil

Conduct debrief

Close off risk assessment

include all staff

Update records / documents

Unsecured loads: injury

Contaminated soil / hazardous substances:

harm

Failure to conduct debrief: missed hazards and

improvement opportunities

H

Continue to use safety observer until workplace is vacated

Use correct manual handling techniques, use mechanical

aids where possible

Maintain safe clearances from all utilities

Reinstate site remove any hazardous material

Secure any holes or hazards from unauthorised access

Correctly dispose of waste material / contaminated soil

Secure all material and equipment for transport

Involve all staff in debrief. Document suggestions.

Sign off the risk assessment and discuss any issues with

the team

L

WPM sections:

2.2, 2.8, 2.16, 3,

11.5, 11.10

Safety Life Savers

Relinquish traffic management

(if used)

Vehicle and equipment movement

Unprotected workplace: public risk of injury

Unauthorised access

M

Maintain traffic management until all personnel and

equipment have left site

Remove all signs and barriers to restore traffic flow

L

WPM section:

2.21

Das könnte Ihnen auch gefallen

- Distribution Swms Substation MaintenanceDokument5 SeitenDistribution Swms Substation MaintenanceAnonymous mNQq7ojNoch keine Bewertungen

- Replace Overhead Consumer Service CoreDokument4 SeitenReplace Overhead Consumer Service Coreryan940Noch keine Bewertungen

- Activity Hazard AnalysisDokument4 SeitenActivity Hazard AnalysisGerrard Singh100% (1)

- Pre-Job Safety Assessment: Site InformationDokument2 SeitenPre-Job Safety Assessment: Site Informationgueettaf faresNoch keine Bewertungen

- Excavation Working in Trenches Swms 10281-6Dokument17 SeitenExcavation Working in Trenches Swms 10281-6JamesNoch keine Bewertungen

- JSARA - Fire Detection System InstallationDokument13 SeitenJSARA - Fire Detection System InstallationUtku Can KılıçNoch keine Bewertungen

- JHA Maintenance Tech HVACDokument2 SeitenJHA Maintenance Tech HVACMdavaNoch keine Bewertungen

- Toolbox Talk 13 Buried ServicesDokument2 SeitenToolbox Talk 13 Buried ServicesSajid Hussain100% (1)

- Risk Assessment - PLCC Cable and GIB Testing 26DEC15 - Rev 0Dokument7 SeitenRisk Assessment - PLCC Cable and GIB Testing 26DEC15 - Rev 0NirmalKumarSelvarajNoch keine Bewertungen

- SWMS Mobilisation of Blocks For MLT TEST RKDokument14 SeitenSWMS Mobilisation of Blocks For MLT TEST RKrakeshkhanna78100% (1)

- 13.2.11 RA SWP For Installation of Instruments and Instrument Tubing at DCLDokument17 Seiten13.2.11 RA SWP For Installation of Instruments and Instrument Tubing at DCLkeertiraj09100% (1)

- Job Safety Analysis Sheet: Arc Welding, Cutting, GrindingDokument1 SeiteJob Safety Analysis Sheet: Arc Welding, Cutting, GrindingalekyaNoch keine Bewertungen

- JSA Excavation PDFDokument6 SeitenJSA Excavation PDFmohamedamine.zemouriNoch keine Bewertungen

- JHA Blowing PressDokument5 SeitenJHA Blowing PressLuqman OsmanNoch keine Bewertungen

- JSA GC-5 Mobile ScaffoldingDokument6 SeitenJSA GC-5 Mobile Scaffoldinggrande100% (2)

- Very Very Good Risk Assessment EnvironmentDokument8 SeitenVery Very Good Risk Assessment EnvironmentSalley Bukhari100% (1)

- 8.EXACAVATION and Confined SpaceDokument16 Seiten8.EXACAVATION and Confined SpaceIhuhwa Marta TauNoch keine Bewertungen

- Activity Hazard AnalysisDokument7 SeitenActivity Hazard AnalysisAnthony MacatangayNoch keine Bewertungen

- Ra02 - Container OffloadingDokument3 SeitenRa02 - Container OffloadingSamNoch keine Bewertungen

- Safe Work Method Statement (SWMS) : Hot Work (Welding, Cutting, Grinding, Gas Cutting, in FGD-Unit#1&2)Dokument6 SeitenSafe Work Method Statement (SWMS) : Hot Work (Welding, Cutting, Grinding, Gas Cutting, in FGD-Unit#1&2)tamoor sarwarNoch keine Bewertungen

- SS JSP - 007 Excavation Work Using EquipmentDokument6 SeitenSS JSP - 007 Excavation Work Using EquipmentFarhat SetharNoch keine Bewertungen

- Tower Crane Dismantling JSA HSE ProfessionalsDokument2 SeitenTower Crane Dismantling JSA HSE ProfessionalsnabeelNoch keine Bewertungen

- SHESOP013-2 - Loading and Unloading - TLokDokument5 SeitenSHESOP013-2 - Loading and Unloading - TLokakmalul adabiNoch keine Bewertungen

- Instructions For Use: Hse-Pro-006A Asbestos Management - Minor Works SwmsDokument21 SeitenInstructions For Use: Hse-Pro-006A Asbestos Management - Minor Works SwmsWinstone AudiNoch keine Bewertungen

- JSA Working in Live AreasDokument1 SeiteJSA Working in Live Areasyc safetyNoch keine Bewertungen

- Using Hand Drill (WS)Dokument2 SeitenUsing Hand Drill (WS)John KalvinNoch keine Bewertungen

- JHA 02 Lifting and SlingingDokument4 SeitenJHA 02 Lifting and Slingingadil khanNoch keine Bewertungen

- Rebar Lifting Jha 001Dokument4 SeitenRebar Lifting Jha 001Justin JuniorNoch keine Bewertungen

- Safety Plan HSDDokument110 SeitenSafety Plan HSDvijayNoch keine Bewertungen

- JSA - Clearing Brush Chain SawDokument2 SeitenJSA - Clearing Brush Chain SawRetselisitsoeNoch keine Bewertungen

- SWMSElevated Work PlatformsDokument4 SeitenSWMSElevated Work PlatformsRay LeeNoch keine Bewertungen

- JHEA Loading and Offloading FENCEDokument13 SeitenJHEA Loading and Offloading FENCEStansilous Tatenda NyagomoNoch keine Bewertungen

- Task Risk AssesmentDokument6 SeitenTask Risk Assesmentum erNoch keine Bewertungen

- SAFETY PLAN For Pilling Work at Making AreaDokument8 SeitenSAFETY PLAN For Pilling Work at Making AreaBalogun Isaac100% (1)

- Hse JsaDokument22 SeitenHse JsaAnonymous y1pIqcNoch keine Bewertungen

- Electric Risk AssessmentDokument10 SeitenElectric Risk AssessmentThandabantu MagengeleleNoch keine Bewertungen

- Genie E Series Slab Scissor Lift Operation PDFDokument11 SeitenGenie E Series Slab Scissor Lift Operation PDFRajesh gpNoch keine Bewertungen

- RSP Safety & InspectionDokument39 SeitenRSP Safety & InspectionSunil Panicker100% (1)

- Jsa For Site EstablishmentDokument8 SeitenJsa For Site EstablishmentBenasher IbrahimNoch keine Bewertungen

- Safety Method StatementDokument14 SeitenSafety Method StatementnayakyaNoch keine Bewertungen

- JSA-Confined Space Activity - 05Dokument4 SeitenJSA-Confined Space Activity - 05babjihanumanthuNoch keine Bewertungen

- JHA For Pipe Work-01.09Dokument3 SeitenJHA For Pipe Work-01.09Anonymous Xb3zHio100% (1)

- Job Safety Analysis - Clinker StorageDokument4 SeitenJob Safety Analysis - Clinker StorageMohammed MinhajNoch keine Bewertungen

- JSA Format Erection of Column 903-C-02,03Dokument5 SeitenJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- 1 Excavations and TrenchesDokument2 Seiten1 Excavations and TrenchesAruNoch keine Bewertungen

- Job Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentDokument6 SeitenJob Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentMoaatazz NouisriNoch keine Bewertungen

- JSA-Using A Type Ladder 2015Dokument1 SeiteJSA-Using A Type Ladder 2015nishanthNoch keine Bewertungen

- JSA For MobilizationDokument3 SeitenJSA For MobilizationHossain amjad Hossain100% (1)

- Confine Space at Water TankDokument7 SeitenConfine Space at Water TanknaraNoch keine Bewertungen

- All ChecklistsDokument0 SeitenAll Checklistsmalika_00Noch keine Bewertungen

- Brieser Construction Jobsite Survey & Behavior ObservationDokument2 SeitenBrieser Construction Jobsite Survey & Behavior ObservationRetselisitsoeNoch keine Bewertungen

- Safe Work Method StatementDokument11 SeitenSafe Work Method StatementJNoch keine Bewertungen

- JSA-Scaffolding Erection & Dismantling Works RV-00Dokument2 SeitenJSA-Scaffolding Erection & Dismantling Works RV-00abou bakarNoch keine Bewertungen

- Man Machine InterfaceDokument22 SeitenMan Machine Interfaceamdarrif3723100% (1)

- JSA M36 Hydro Testing Spool Pieces & PipeworkDokument4 SeitenJSA M36 Hydro Testing Spool Pieces & PipeworkMianNoch keine Bewertungen

- Safe Operating Procedures 03 Chainsaw OperationDokument2 SeitenSafe Operating Procedures 03 Chainsaw OperationVictorNoch keine Bewertungen

- Ra For Fire Protection Piping Installation WorksDokument7 SeitenRa For Fire Protection Piping Installation WorksprinceNoch keine Bewertungen

- JSA IndexDokument2 SeitenJSA IndexDie HArdNoch keine Bewertungen

- Conductor StringingDokument5 SeitenConductor StringingJamie JovellanosNoch keine Bewertungen

- VSL (3542)Dokument1 SeiteVSL (3542)Raed Naim KhammashNoch keine Bewertungen

- VSL (1897) PDFDokument2 SeitenVSL (1897) PDFRaed Naim KhammashNoch keine Bewertungen

- KhayatOct92012V2 PDFDokument89 SeitenKhayatOct92012V2 PDFRaed Naim KhammashNoch keine Bewertungen

- Ciria 108 Pressure AnalysisDokument4 SeitenCiria 108 Pressure AnalysisRaed Naim KhammashNoch keine Bewertungen

- Wocomplexity Analysis PDFDokument185 SeitenWocomplexity Analysis PDFRaed Naim KhammashNoch keine Bewertungen

- ProdSpecsDoc144 PDFDokument20 SeitenProdSpecsDoc144 PDFRaed Naim KhammashNoch keine Bewertungen

- P.S. Bansod, Afcons: Abstract: Construction of Marine Facilities For Standby Jetty at Dahej LNG TerminalDokument1 SeiteP.S. Bansod, Afcons: Abstract: Construction of Marine Facilities For Standby Jetty at Dahej LNG TerminalRaed Naim KhammashNoch keine Bewertungen

- Unified Facilities Criteria - Piers and WharvesDokument175 SeitenUnified Facilities Criteria - Piers and WharvesRoda CadizNoch keine Bewertungen

- PM1561Dokument4 SeitenPM1561Raed Naim KhammashNoch keine Bewertungen

- Design of Water Retaining Structures To ECDokument44 SeitenDesign of Water Retaining Structures To ECVincent Teng100% (4)

- Master Thesis-Andreas Winge PDFDokument86 SeitenMaster Thesis-Andreas Winge PDFRaed Naim KhammashNoch keine Bewertungen

- Fosroc Nitocote PE135: Constructive SolutionsDokument2 SeitenFosroc Nitocote PE135: Constructive SolutionsRaed Naim KhammashNoch keine Bewertungen

- Sti) M R: Lai Ai - 4 0Dokument3 SeitenSti) M R: Lai Ai - 4 0Raed Naim KhammashNoch keine Bewertungen

- Epc PDFDokument20 SeitenEpc PDFAnu Mali50% (2)

- TECHNICAL NOTE 013 Steel Sheet Piling - Drivability Vs SPT-N Values - Vibrations and Noise LevelDokument3 SeitenTECHNICAL NOTE 013 Steel Sheet Piling - Drivability Vs SPT-N Values - Vibrations and Noise LevelRaed Naim Khammash100% (1)

- Design of Concrete TanksDokument198 SeitenDesign of Concrete Tankssuman33100% (1)

- RS Means Estimating Cost Ch4Dokument33 SeitenRS Means Estimating Cost Ch4Krish DoodnauthNoch keine Bewertungen

- Understanding of Meteorology For Handling LNG at Ports - Sanjay GuptaDokument40 SeitenUnderstanding of Meteorology For Handling LNG at Ports - Sanjay GuptajomaferreiroNoch keine Bewertungen

- Bontang Future 3rd LNG-LPG - A Design Which Achieves Very High Levels of Flexibility, Safety and ReliabilityDokument25 SeitenBontang Future 3rd LNG-LPG - A Design Which Achieves Very High Levels of Flexibility, Safety and Reliabilitywebwormcpt100% (1)

- AFCONS DahejDokument37 SeitenAFCONS DahejRaed Naim KhammashNoch keine Bewertungen

- Annex 1 HDDDokument6 SeitenAnnex 1 HDDRaed Naim KhammashNoch keine Bewertungen

- Trust BoringDokument8 SeitenTrust BoringazamshafiqNoch keine Bewertungen

- Nitocote AP35: Constructive SolutionsDokument44 SeitenNitocote AP35: Constructive SolutionsRaed Naim KhammashNoch keine Bewertungen

- LNG Import Terminal Cost and Schedule BasicsDokument23 SeitenLNG Import Terminal Cost and Schedule Basicsjomafeba100% (3)

- 1 GasTankersAdvanceCourseDokument105 Seiten1 GasTankersAdvanceCourseValerian Strat100% (1)

- Willington C Gas Pipeline Environmental Statement Volume 2A Chapter 3 - Appendix 3.4 Generic HDD Crossing Method StatementDokument17 SeitenWillington C Gas Pipeline Environmental Statement Volume 2A Chapter 3 - Appendix 3.4 Generic HDD Crossing Method StatementRaed Naim KhammashNoch keine Bewertungen

- QGX and QCSDokument41 SeitenQGX and QCSRaed Naim KhammashNoch keine Bewertungen

- 2Dokument66 Seiten2Raed Naim KhammashNoch keine Bewertungen

- Willington C Gas Pipeline Environmental Statement Volume 2A Chapter 3 - Appendix 3.4 Generic HDD Crossing Method StatementDokument17 SeitenWillington C Gas Pipeline Environmental Statement Volume 2A Chapter 3 - Appendix 3.4 Generic HDD Crossing Method StatementRaed Naim KhammashNoch keine Bewertungen

- Construction Method StatementDokument35 SeitenConstruction Method StatementRaed Naim KhammashNoch keine Bewertungen

- m07srt Lesson KmarlinkDokument3 Seitenm07srt Lesson Kmarlinkapi-515106812Noch keine Bewertungen

- The King's Avatar - Chapter 696 - Guild Feature - Gravity TalesDokument5 SeitenThe King's Avatar - Chapter 696 - Guild Feature - Gravity TalesMayhaaaNoch keine Bewertungen

- Assignment Group OSHADokument10 SeitenAssignment Group OSHAariffikriismailNoch keine Bewertungen

- SOP For Operation & Calibration of PH Meter - QualityGuidancesDokument9 SeitenSOP For Operation & Calibration of PH Meter - QualityGuidancesfawaz khalilNoch keine Bewertungen

- Individual Reflection ScribdDokument4 SeitenIndividual Reflection ScribdJamie Chan JieminNoch keine Bewertungen

- Cinnamon RollDokument1 SeiteCinnamon RollMaria Manoa GantalaNoch keine Bewertungen

- Police Cranston School Committee Member Stole PTO FundsDokument1 SeitePolice Cranston School Committee Member Stole PTO FundsashaydelineNoch keine Bewertungen

- PROP CASES OUTLINE 7 - Right of Way - Light & ViewDokument108 SeitenPROP CASES OUTLINE 7 - Right of Way - Light & ViewKringle Lim - DansalNoch keine Bewertungen

- Loan Agreement: Acceleration ClauseDokument2 SeitenLoan Agreement: Acceleration ClauseSomething SuspiciousNoch keine Bewertungen

- Education Programme: The School of Concrete TechnologyDokument28 SeitenEducation Programme: The School of Concrete TechnologyThabiso Jacob MokwenaNoch keine Bewertungen

- Certain Application of Photovo PDFDokument235 SeitenCertain Application of Photovo PDFaun_nustNoch keine Bewertungen

- Mech VibrationDokument14 SeitenMech VibrationSquakx BescilNoch keine Bewertungen

- José Guadalupe PosadaDokument19 SeitenJosé Guadalupe PosadaJudy Baca100% (1)

- College Invitation Letter - Managedia 2023Dokument2 SeitenCollege Invitation Letter - Managedia 2023Sandeep DeyNoch keine Bewertungen

- FE 208 Lab #4 - Profile Leveling: CrewDokument4 SeitenFE 208 Lab #4 - Profile Leveling: CrewJefferson Himson0% (1)

- Essential Study SkillsDokument86 SeitenEssential Study SkillsFady NgunyuNoch keine Bewertungen

- Sbi Afi 2012Dokument48 SeitenSbi Afi 2012Moneylife FoundationNoch keine Bewertungen

- L15 PDFDokument15 SeitenL15 PDFlesNoch keine Bewertungen

- Fall 20122Dokument98 SeitenFall 20122DobarCovek67% (3)

- Towards A Brighter Ecological Future: Group 2Dokument24 SeitenTowards A Brighter Ecological Future: Group 2As YangNoch keine Bewertungen

- JAMB Syllabus For BiologyDokument27 SeitenJAMB Syllabus For BiologyOluebube UchennaNoch keine Bewertungen

- Proposed 4way D54 Proposed 2way D56: Issue Date DescriptionDokument3 SeitenProposed 4way D54 Proposed 2way D56: Issue Date DescriptionADIL BASHIRNoch keine Bewertungen

- The Incidence of COVID-19 Along The ThaiCambodian Border Using Geographic Information System (GIS), Sa Kaeo Province, Thailand PDFDokument5 SeitenThe Incidence of COVID-19 Along The ThaiCambodian Border Using Geographic Information System (GIS), Sa Kaeo Province, Thailand PDFInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- NCP81205Dokument1 SeiteNCP81205Tom TomNoch keine Bewertungen

- Unseen Passage 2Dokument6 SeitenUnseen Passage 2Vinay OjhaNoch keine Bewertungen

- Catphan®604 ManualDokument34 SeitenCatphan®604 ManualTold Told LeungNoch keine Bewertungen

- File 1) GRE 2009 From - Nov - 18 PDFDokument84 SeitenFile 1) GRE 2009 From - Nov - 18 PDFhuyly34Noch keine Bewertungen

- Sample Spec For AWWA HDPE Pipe Fittings 6.02revDokument6 SeitenSample Spec For AWWA HDPE Pipe Fittings 6.02revmg4myNoch keine Bewertungen

- Lesson Plan Wid Awt Method 2Dokument7 SeitenLesson Plan Wid Awt Method 2Yan LianNoch keine Bewertungen

- Luyện nghe Tiếng Anh có đáp án: I/ Listen and complete the textDokument3 SeitenLuyện nghe Tiếng Anh có đáp án: I/ Listen and complete the textVN LenaNoch keine Bewertungen