Beruflich Dokumente

Kultur Dokumente

Data Sheet For Variable Speed Drives of Medium and Large Power

Hochgeladen von

brome2014Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Data Sheet For Variable Speed Drives of Medium and Large Power

Hochgeladen von

brome2014Copyright:

Verfügbare Formate

- IEC rating

- % Pn &

ONAF

/

DATA SHEET FOR VARIABLE SPEED DRIVES OF MEDIUM AND LARGE POWER

6

0

1

0

h

S

4

/

5

1

0

.

A

M

R

.

E

L

E

.

D

O

M

GENERAL DESIGN DATA

Tag :

Type and services of operating machine :

TYPE OF

DRIVES

REQUIRED

PERFORMANCES

OPERATING

CONDITIONS

SITE DESIGN

CONDITIONS

CONVERTER

COOLING FLUID

TRANSFORMER

ARMONIC

FILTRES

Direct current

Duty :

Rated power :

Load torque :

Rotation :

Rated speed Nn :

Range of speed variation : from

Automatic change over of supplies

System neutral :

Air temperature :

Relative humidity :

Climate :

H2S pollution :

Primary

Secondary

Closed circuit forced air

Air natural

Inlet pressure

Sweet water

Mineral oil

Insulation class

Installation :

Required

at Pn & Nn : p.f.

Max allowed :

Type of motor :

Rated power at Nn:

Rated voltage :

Insulation class :

D.O.L. starting at Un

Number of start : consecutive N

Installation :

Type of enclosure :

Degree of protection : motor encl. IP

Cooling methode : IC

Lubrification :

Type of bearing :

MAIN

MOTOR

Impressed current Impressed voltage Hyposynch. cascade

- at speed of RPM

Quadratic

Bidirection

- Max Nm

- Frequency :

- Frequency variation :

Solid Resistance earthed

Zone :

- Altitude

- at temperature of

Continental Desert

- concentrations

Open circuit forced air

Dejonized water

Sea water

- Inlet temperature

Silicon oil Dry air Cast resin

- Temp. rise oil/windings

Air Forced air

Outdoor Sheltered

Required for

Induction Synchronous

Other STD

Temperature rise

Hourly from hot

Outdoor Sheltered

Safety Ex

- Cable boxes IP

Grease

Sleeve

Noise level max : dBA at 1 m

Tropical

Indoor

Totally enclosed

Oil

P. FACTOR

IMPROOVEMENT

POWER

This document is Company property. The Company lawfully reserves all rights.

Dept.

Agip

Sheet / of Compiled Date

Doc. n

/

COMPANY

Job.

AREA

COUNTRY

PLANT

Revision

0

INTERNAL NORMALIZATION

% Nn

- to

Hz

%

- V % f

- max MVA

C m

% C

ppm

C

K

- A - Nn - cosfi

- at 0,75 Pn & 0,9 Nn cosfi

7 11 13

%

5

kV

kW

% Nn %

kV

%

MVA min.

kpA

ONAM

% % % %

kW kW

-

-

-

Continuous

Constant

Unidirection

RPM

Insulated

Rated voltage :

Outside Inside

Voltage variation :

Max combined voltage and freq. variation :

Short circuit duty on supply

Installation of motor :

Indoor

Cooling :

D.C.

Rolling

Mfr STD

This document is Company property. The Company lawfully reserves all rights.

Dept.

Agip

Sheet / of Compiled Date

Doc. n

/

COMPANY

Job.

AREA

COUNTRY

PLANT

Revision

0

INTERNAL NORMALIZATION

/

6

0

2

0

h

S

4

/

5

1

0

.

A

M

R

.

E

L

E

.

D

O

M

GENERAL DESIGN DATA

Supply voltage

CONTROL, MEASURES AND SIGNALLING

Selection Test - O - In service

Start

Speed regulation

Emergency stop

Stop

Auxiliary start and stop

Transformer primary current

Motor voltage

Absorbed active power

Windings temperature

Motor current

Transformer secondary voltage

Transformer secondary current

Motor frequency

Power factor on incoming side

Bearing temperature

Motor speed

Motor on start

Ready to start

Motor off

Auxiliary voltage on

Motor Running

Start-End of Ex-p motor purging operation

Motor Locked-out

Space heater on

Start

Speed regulation

AUXILIARIES AND ACCESSORIES

Stop

Speed measure

Stator RTD

Tachometric generator

Water flow switch

Water leakage detectors

Vibration detectors

Oil flow switch

Water valves and flanges

Foundation plates and bolts

Space heaters

Transformer accessories

Purging and pressurization control unit

Local push button station

Data aquisition and supervisory system

Serial interface with DCS

Converter by-pass device

CONTROLS ON

CONVERTER PANEL

MEASURE ON

CONVERTER PANEL

SIGNALLING ON

CONTROLS ON

LOCAL P.B. STATION

Type :

Coupling : Direct By red. gear By overgear

OPERATING MACHINE

DATA SHEET FOR VARIABLE SPEED DRIVES OF MEDIUM AND LARGE POWER

Exciter RTD

S

Bearings RTD

S

Hot air RTD

S

Water RTD

NOTES :

This document is Company property. The Company lawfully reserves all rights.

Dept.

Agip

Sheet / of Compiled Date

Doc. n

/

COMPANY

Job.

AREA

COUNTRY

PLANT

Revision

0

INTERNAL NORMALIZATION

/

6

0

3

0

h

S

4

/

5

1

0

.

A

M

R

.

E

L

E

.

D

O

M

PERFORMANCES

EFFICIENCY

AND LOSSES

Efficiency at 100% Pn & Nn - Transf./Converter/motor/total

at 75% Pn & 90% Nn: Transf./Converter/motor/total

OVERALL

POWER FACTOR

Total losses at Pn & Nn :

With capacitors

at 100% Pn & Nn - p.f.

at 75% Pn & 90% Nn - p.f.

Without capacitors

ARMONICS

TRANSFERRED

TO THE SUPPLY

NETWORK

Without filtres with filtres

5^ armonic

7^ armonic

11^ armonic

13^ armonic

at 100% Pn & Nn

at 75% Pn & 90% Nn

at 100% Pn & 105% Nn

POWER DEMAND

( kVA )

DATA SHEET FOR VARIABLE SPEED DRIVES OF MEDIUM AND LARGE POWER

With capacitors Without capacitors

kVA

kVA

kVA

kVA

kVA

kVA

NOTES:

kW

max p.u. p.u.

max p.u. p.u.

max p.u. p.u.

max p.u. p.u.

/ / /

This document is Company property. The Company lawfully reserves all rights.

Dept.

Agip

Sheet / of Compiled Date

Doc. n

/

COMPANY

Job.

AREA

COUNTRY

PLANT

Revision

0

INTERNAL NORMALIZATION

/

6

0

4

0

h

S

4

/

5

1

0

.

A

M

R

.

E

L

E

.

D

O

M

CONSTRUCTIONAL DATA

TRANSFORMER

Transformation ratio

Insulation :

Rated power natural/forced

Primary/secondary terminals N

Masses :

Windings connection

Impedance voltage Vcc

Dimensions W x D x H

Manufacturer :

Oil Dry in air Cast resin

| Vector group

- Oil - lift mass

Model

CONVERTER

UNIT

Rated power

Rated voltage incoming side

Rated voltage output side

Rated frequency incoming side

Rated frequency output side

Rated current input side

Rated current output side

Converter type

Inverter type

Cooling air demand

Cooling water demand

Demi-water demand

Masses : Total - lift mass

Cooling : oil air

REACTORS

Nominal current for armonic

- Consumption l/year

Total loss at nominal duty

Dimensions W x D x H

Masses :

CAPACITORS

Rated power/rated voltage

Masses/dimensions

DATA SHEET FOR VARIABLE SPEED DRIVES OF MEDIUM AND LARGE POWER

Dimensions (W x D x H)

POWER

MAIN MOTOR

Mfr

Overall dimensions (W x D x H)

Masses : Total

Main terminal box side (D.E.) :

Model

- Rotor - Lift

Right Left

V /

kVA /

at kVA

/

mm x mm x mm

kVA

mm x mm x mm

kV

kV

Hz

Hz

A

A

m/h

Kg

m/h

5 - 7

7

kW

mm

kVAR/kV

Kg/mm

Kg/mm

Kg/mm

Kg Kg Kg

l

Kg

A A - 11 A - 13 A

Kg - 7 - 11 - 13 Kg Kg Kg

5 x x

- 11 - 13 mm x x mm x x mm x x

5 kVAR/kV - 7 kVAR/kV

kVAR/kV kVAR/kV 11 - 13

- l x p x h mm x x

5 - 7

11 - 13

Kg/mm

Kg/mm

mm x mm x mm

Kg Kg Kg

%

This document is Company property. The Company lawfully reserves all rights.

Dept.

Agip

Sheet / of Compiled Date

Doc. n

/

COMPANY

Job.

AREA

COUNTRY

PLANT

Revision

0

INTERNAL NORMALIZATION

/

6

0

5

0

h

S

4

/

5

1

0

.

A

M

R

.

E

L

E

.

D

O

M

NOTES :

ANTICORROSION TREATMENTS

PAINTING

Switchboards : Cycle

TROPICALIZATION

Motor : Cycle

Switchboards :

Motor :

Std

Std

Color

Color

OTHER REQUIREMENTS

Official language : For Bid documentation :

For Project documentation :

SUPPLY LIMITS AND ESCLUSIONS

DATA SHEET FOR VARIABLE SPEED DRIVES OF MEDIUM AND LARGE POWER

This document is Company property. The Company lawfully reserves all rights.

Dept.

Agip

Sheet / of Compiled Date

Doc. n

/

COMPANY

Job.

AREA

COUNTRY

PLANT

Revision

0

INTERNAL NORMALIZATION

/

6

0

6

0

h

S

4

/

5

1

0

.

A

M

R

.

E

L

E

.

D

O

M

SPARE PARTS FOR COMMISSIONING

Material description Manufacturer Model & Mfr Code

Quantity

min. request suppl.

Aux. motor bearings

and dimension

1 Nos each type

Fuses of any type and rating,

including signalling contacts

Power diode and thyristors

each type and characteristics

Lamps, lampholder, coloured

cops, terminals of various

type and colors

Auxiliary relay of any installed

type

Push buttuons,control and

selector switches

Thermometers, manometers,

temperature and flow switches

H.V. bushings for power

Transformer silicagel

Gaskets

Oil and water valves

Capacitors

Electronic control and

regulation unit

Touch-up painting

3 Nos each type

0.1 N with min. of

2 Nos each type

0.1 N with min. of

type and voltage

2Nos of each

of 1 No installed

0.1 N with min.

optional item

NOTES: N -

Vendor shall recommend other components deemed necessary on the basis of the past experience.

1 Kg each color

DATA SHEET FOR VARIABLE SPEED DRIVES OF MEDIUM AND LARGE POWER

2 Nos each type

0.1 N with min. of

installed type

installed type

1 No of each

transformers

installed type

L.V. bushings for power

transformer

installed type

1 No of each

1 No of each

1 No of each

1 No

1 No

1 No

Quantity of components of each type and model, included in the supply.

Das könnte Ihnen auch gefallen

- ZX 130-5g - Electrical Wiring DiagramDokument13 SeitenZX 130-5g - Electrical Wiring DiagramPrudz86% (7)

- Ge Sitepro 20kvaDokument5 SeitenGe Sitepro 20kvaNilson Eduardo Torres100% (1)

- A330 200Dokument1 SeiteA330 200Rédei JánosNoch keine Bewertungen

- L and TDokument17 SeitenL and TRaja Chowdary40% (5)

- SR-103 APA System Report 103 Use of Wood Structural Panels For Energy-Heel Trusses PDFDokument12 SeitenSR-103 APA System Report 103 Use of Wood Structural Panels For Energy-Heel Trusses PDFAbdurrahman CinarNoch keine Bewertungen

- Elevation Drawing of 132 - 33KV SubstationDokument10 SeitenElevation Drawing of 132 - 33KV Substationpeekate100% (1)

- Mill OptimizationDokument45 SeitenMill OptimizationDSG100% (5)

- Ei 1585Dokument8 SeitenEi 1585Hai0% (1)

- Wabco Products CatalogDokument114 SeitenWabco Products CatalogCvita Cvitić100% (1)

- Cold Room Techno Commercial Offer PDFDokument10 SeitenCold Room Techno Commercial Offer PDFManish BarnwalNoch keine Bewertungen

- DS1000D E User's GuideDokument166 SeitenDS1000D E User's GuideRicardo de AzambujaNoch keine Bewertungen

- Turbomachinery Package Installation Guidline 1000 Rev - BDokument85 SeitenTurbomachinery Package Installation Guidline 1000 Rev - Beugenio_meza_9100% (3)

- Standard Work Process Procedure Quantity Reporting: 1.0 PurposeDokument30 SeitenStandard Work Process Procedure Quantity Reporting: 1.0 PurposeGordon Longforgan100% (1)

- 2011 WABCO Product CatalogDokument143 Seiten2011 WABCO Product Catalogrrosa_9962720% (1)

- Sustainable Business Model Archetypes For The Banking IndustryDokument20 SeitenSustainable Business Model Archetypes For The Banking IndustryLili AnaNoch keine Bewertungen

- Functional Specification: Harbours, Ships and Fixed Offshore InstallationsDokument8 SeitenFunctional Specification: Harbours, Ships and Fixed Offshore Installationsbrome2014Noch keine Bewertungen

- Liebherr R 954 C Hydraulic Excavator Service Repair Manual SN 14968 and Up PDFDokument110 SeitenLiebherr R 954 C Hydraulic Excavator Service Repair Manual SN 14968 and Up PDFjfjkskemmdm100% (1)

- ONGCDokument52 SeitenONGCChetna Khanna33% (3)

- NPK 300 Z2 DW 4006 V - R5 - General Arrangement Drawing For Dryer Cyclone (81 D 322A) FCDokument4 SeitenNPK 300 Z2 DW 4006 V - R5 - General Arrangement Drawing For Dryer Cyclone (81 D 322A) FCDangolNoch keine Bewertungen

- Companies Catalogue 2013Dokument32 SeitenCompanies Catalogue 2013Mbamali ChukwunenyeNoch keine Bewertungen

- Megger TestDokument1 SeiteMegger Testecruz_yhwhNoch keine Bewertungen

- Salt Mobile Sa 1 PDFDokument1 SeiteSalt Mobile Sa 1 PDFGh UnlockersNoch keine Bewertungen

- Data Sheet For Synchronous Generators: Company Job. Country RevisionDokument5 SeitenData Sheet For Synchronous Generators: Company Job. Country Revisionbrome2014Noch keine Bewertungen

- Inspection Data Sheet (I.D.S.) : Company Job. Country RevisionDokument2 SeitenInspection Data Sheet (I.D.S.) : Company Job. Country Revisionbrome2014Noch keine Bewertungen

- Data Shhet For Floodlighting Masts Design Data: Internal NormalizationDokument3 SeitenData Shhet For Floodlighting Masts Design Data: Internal Normalizationbrome2014Noch keine Bewertungen

- Interface Component Supplementary Record of Inspection and TestingDokument2 SeitenInterface Component Supplementary Record of Inspection and TestingaamedNoch keine Bewertungen

- Core Cat 09 Revised2009Dokument223 SeitenCore Cat 09 Revised2009eltatengueNoch keine Bewertungen

- Distributed Control System: Technical Data SheetDokument13 SeitenDistributed Control System: Technical Data Sheetbrome2014Noch keine Bewertungen

- Multilevel Six-Phase Machine Drive System Composed of Three-Level and Two-Level InvertersDokument5 SeitenMultilevel Six-Phase Machine Drive System Composed of Three-Level and Two-Level InvertersPhelipe LealNoch keine Bewertungen

- PDF tps57 Manual DLDokument139 SeitenPDF tps57 Manual DLLisandroNoch keine Bewertungen

- Hi T VezérlésDokument56 SeitenHi T VezérlésDirt FilterNoch keine Bewertungen

- Formato IIa (L-E 5.1)Dokument1 SeiteFormato IIa (L-E 5.1)Erika AnguloNoch keine Bewertungen

- Formato Ii - A Hoja de Trabajo de Requisición: Req./OcDokument1 SeiteFormato Ii - A Hoja de Trabajo de Requisición: Req./Ocarmando0212-1Noch keine Bewertungen

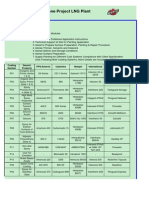

- Wheatstone Project LNG Plant: MR Number XX Title: Scope of WoDokument4 SeitenWheatstone Project LNG Plant: MR Number XX Title: Scope of WoLegend AnbuNoch keine Bewertungen

- Power Transformers Data Sheet: PaintingDokument3 SeitenPower Transformers Data Sheet: Paintingbrome2014Noch keine Bewertungen

- Spirax Sarco - FT S02 - 28Dokument2 SeitenSpirax Sarco - FT S02 - 28Marco Pacheco CallirgosNoch keine Bewertungen

- 6305ele-S1l5 - DCDokument25 Seiten6305ele-S1l5 - DCJianguo WangNoch keine Bewertungen

- NGP Door GasketingCatalogDokument52 SeitenNGP Door GasketingCatalogcoregroup1Noch keine Bewertungen

- MideaDokument74 SeitenMideaivanNoch keine Bewertungen

- Validation of Clean Rooms ForDokument53 SeitenValidation of Clean Rooms ForUsman AslamNoch keine Bewertungen

- Parts Manual (EN) : Read The Operators Manual Before Using The MachineDokument22 SeitenParts Manual (EN) : Read The Operators Manual Before Using The MachineVüsal 1Noch keine Bewertungen

- Navigation Aids Panel Data Sheet: Company Job. Country RevisionDokument3 SeitenNavigation Aids Panel Data Sheet: Company Job. Country Revisionbrome2014Noch keine Bewertungen

- MPPTDokument5 SeitenMPPTMahir Asif ShadmanNoch keine Bewertungen

- Liquid Petroleum Gas (LPG) Systems: Installation NotesDokument3 SeitenLiquid Petroleum Gas (LPG) Systems: Installation NotesSamaila Anthony MalimaNoch keine Bewertungen

- BE Engineering Guide VDC Air Cooled CondenserDokument46 SeitenBE Engineering Guide VDC Air Cooled Condensernauta007Noch keine Bewertungen

- Data Sheet For Wind Energy Generation System: Internal NormalizationDokument13 SeitenData Sheet For Wind Energy Generation System: Internal Normalizationbrome2014Noch keine Bewertungen

- Model 72400 Servo Controlled Piston Pump: Parts InformationDokument20 SeitenModel 72400 Servo Controlled Piston Pump: Parts InformationhidraulicavarginhadivulgacaoNoch keine Bewertungen

- AERO3261 Turbojet: Ass. Prof Dries VerstraeteDokument25 SeitenAERO3261 Turbojet: Ass. Prof Dries VerstraeteTuan HoangNoch keine Bewertungen

- Eht Design Summary SampleDokument1 SeiteEht Design Summary SampleHolly SmithNoch keine Bewertungen

- Electrical Power Generator - Agregati - Electrolux Macedonia - ELITE - IVECODokument2 SeitenElectrical Power Generator - Agregati - Electrolux Macedonia - ELITE - IVECOIgor MatijevićNoch keine Bewertungen

- Lekm2005 Ai Guide 3600Dokument88 SeitenLekm2005 Ai Guide 3600Jose MoralesNoch keine Bewertungen

- PAT Testing CertificateDokument4 SeitenPAT Testing CertificateD SmaleNoch keine Bewertungen

- Chart: Dehydration and Desalting System Akal J-1 Platform MPR A-51Dokument5 SeitenChart: Dehydration and Desalting System Akal J-1 Platform MPR A-51figuev2208Noch keine Bewertungen

- Control System Cabinet AccDokument295 SeitenControl System Cabinet Accan doNoch keine Bewertungen

- Collar Pivot 38 MMDokument1 SeiteCollar Pivot 38 MMPreetam KumarNoch keine Bewertungen

- T WREX Maintenance Sched 1Dokument2 SeitenT WREX Maintenance Sched 1rezkyfebri.sunandaNoch keine Bewertungen

- NFPA 14-2000 Installation of Standpipe and Hose SystemsDokument2 SeitenNFPA 14-2000 Installation of Standpipe and Hose SystemsMuslim AliNoch keine Bewertungen

- Formato IIIa (L-E 5.1)Dokument2 SeitenFormato IIIa (L-E 5.1)Erika AnguloNoch keine Bewertungen

- Clean Air: TechnologyDokument22 SeitenClean Air: Technologyproposals vertexNoch keine Bewertungen

- Cancontrol List 2022-07-27 enDokument115 SeitenCancontrol List 2022-07-27 enAndrés Felipe Matamala QuezadaNoch keine Bewertungen

- 3kva 48Vdc Solar Home Inverter Spec 2013 2kw PanelDokument2 Seiten3kva 48Vdc Solar Home Inverter Spec 2013 2kw PanelnagendrabnpNoch keine Bewertungen

- Section 8 Designing The Input Supply: Figure 8-1. Rectification SchemesDokument6 SeitenSection 8 Designing The Input Supply: Figure 8-1. Rectification Schemescmvb123Noch keine Bewertungen

- Dixon Kodiak Series 2008-2009 Parts ManualDokument40 SeitenDixon Kodiak Series 2008-2009 Parts ManualPaul AllansonNoch keine Bewertungen

- G3616 Gas Engine Electrical System: Mids AdvisorDokument2 SeitenG3616 Gas Engine Electrical System: Mids AdvisorDiego Ruben PalavecinoNoch keine Bewertungen

- Liebherr R 954 C Hydraulic Excavator Service Repair Manual SN 14968 and Up PDF PDF FreeDokument110 SeitenLiebherr R 954 C Hydraulic Excavator Service Repair Manual SN 14968 and Up PDF PDF FreeAndré WeillerNoch keine Bewertungen

- Citizen CL-S700 Parts ListDokument71 SeitenCitizen CL-S700 Parts ListKlema HanisNoch keine Bewertungen

- Inverter Air/Water Heat Pump Chillers With Axial Fans User'S and Installer'S Manuals Pre Series ModelsDokument56 SeitenInverter Air/Water Heat Pump Chillers With Axial Fans User'S and Installer'S Manuals Pre Series ModelsDirt FilterNoch keine Bewertungen

- Power Electronics CircuitsDokument1 SeitePower Electronics CircuitsNandish IonNoch keine Bewertungen

- GSYuasa LIM30H 8ADokument2 SeitenGSYuasa LIM30H 8Abrome2014Noch keine Bewertungen

- Fiberoptic Color GuideDokument1 SeiteFiberoptic Color Guidebrome2014Noch keine Bewertungen

- Abb Acs2000Dokument20 SeitenAbb Acs2000brome2014Noch keine Bewertungen

- Functional Specification: Fixed Offshore Platforms and ShipsDokument8 SeitenFunctional Specification: Fixed Offshore Platforms and Shipsbrome2014Noch keine Bewertungen

- Data Sheet For Wind Energy Generation System: Internal NormalizationDokument13 SeitenData Sheet For Wind Energy Generation System: Internal Normalizationbrome2014Noch keine Bewertungen

- Power Transformers Data Sheet: PaintingDokument3 SeitenPower Transformers Data Sheet: Paintingbrome2014Noch keine Bewertungen

- Precommissioning Checks and Tests For Electric Cables Having Less Uo/U Than 8.7/15 KVDokument1 SeitePrecommissioning Checks and Tests For Electric Cables Having Less Uo/U Than 8.7/15 KVbrome2014Noch keine Bewertungen

- Navigation Aids Panel Data Sheet: Company Job. Country RevisionDokument3 SeitenNavigation Aids Panel Data Sheet: Company Job. Country Revisionbrome2014Noch keine Bewertungen

- Distributed Control System: Technical Data SheetDokument13 SeitenDistributed Control System: Technical Data Sheetbrome2014Noch keine Bewertungen

- Data Sheet: Company Country Area PlantDokument3 SeitenData Sheet: Company Country Area Plantbrome2014Noch keine Bewertungen

- Data Sheet: Company Country Area PlantDokument2 SeitenData Sheet: Company Country Area Plantbrome2014Noch keine Bewertungen

- Data Sheet: Company Country Area PlantDokument2 SeitenData Sheet: Company Country Area Plantbrome2014Noch keine Bewertungen

- Data Sheet: Company Country Area PlantDokument2 SeitenData Sheet: Company Country Area Plantbrome2014Noch keine Bewertungen

- 20046E01Dokument18 Seiten20046E01brome2014Noch keine Bewertungen

- A Commodity Report On Brent Crude OilDokument8 SeitenA Commodity Report On Brent Crude OilgauravmandawawalaNoch keine Bewertungen

- Plant-Inspection Midterm ExamsDokument5 SeitenPlant-Inspection Midterm ExamsClarence Jay AcaylarNoch keine Bewertungen

- Ultima X Series EC Declaration of ConformityDokument8 SeitenUltima X Series EC Declaration of ConformityRahul DevaNoch keine Bewertungen

- World Wind Energy Report 2008Dokument16 SeitenWorld Wind Energy Report 2008Dimitris KapoiosNoch keine Bewertungen

- Causes of Boiler Slagging and FoulingDokument9 SeitenCauses of Boiler Slagging and FoulingAshiqNoch keine Bewertungen

- Sustainability 12 00327 v2Dokument19 SeitenSustainability 12 00327 v2vladimirelizalderiosNoch keine Bewertungen

- Assignment For MBA BADokument2 SeitenAssignment For MBA BAsrishti kharbandaNoch keine Bewertungen

- Maersk DelivererDokument10 SeitenMaersk DelivererMike RossNoch keine Bewertungen

- 5.quotation Condition (Arch. & Metal Work)Dokument4 Seiten5.quotation Condition (Arch. & Metal Work)Andy YuliantoNoch keine Bewertungen

- PROYMECADokument15 SeitenPROYMECAShidgounNoch keine Bewertungen

- Low Voltage Motors Report 3 Vols 2014 PDFDokument232 SeitenLow Voltage Motors Report 3 Vols 2014 PDFAnonymous 3XrBlzUtK0% (1)

- Productsheet Diesel Particulate Filter CleaningDokument2 SeitenProductsheet Diesel Particulate Filter CleaningEhtıram SeyıdovNoch keine Bewertungen

- Basic Pressure SafetyDokument25 SeitenBasic Pressure SafetyfawnNoch keine Bewertungen

- The Great Nuclear Fizzle at Old BabcockDokument7 SeitenThe Great Nuclear Fizzle at Old Babcockdsager45Noch keine Bewertungen

- Globaldieselginsetmarket 180130053303Dokument24 SeitenGlobaldieselginsetmarket 180130053303Muntasir Alam EmsonNoch keine Bewertungen

- Tekken Corporation: Company GuideDokument9 SeitenTekken Corporation: Company Guidehout rothanaNoch keine Bewertungen

- Experiment No. 9: To Study Construction Features and Working of A Cross Tube Vertical Cradely Boiler and Babcock and Wilcox BoilerDokument4 SeitenExperiment No. 9: To Study Construction Features and Working of A Cross Tube Vertical Cradely Boiler and Babcock and Wilcox BoilerhloNoch keine Bewertungen

- Roland 700 Hiprint Advanced Features Data Sheet enDokument2 SeitenRoland 700 Hiprint Advanced Features Data Sheet enKibunNoch keine Bewertungen

- Quality Standards PDFDokument20 SeitenQuality Standards PDFmudassarhussainNoch keine Bewertungen