Beruflich Dokumente

Kultur Dokumente

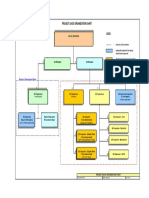

Quality Control Flow Chart

Hochgeladen von

同道文档中心100%(17)100% fanden dieses Dokument nützlich (17 Abstimmungen)

18K Ansichten1 SeiteThe quality control flow chart outlines the inspection process from receiving materials to shipping. It includes over 20 key stages of production such as inspection of incoming materials, storage of materials, assembly, testing, burn-in, and final inspection. Each stage lists the responsible department, inspection frequency, documents used, and quality records maintained. The goal is to ensure high quality through 100% inspection or statistical sampling at various stages, and documentation of all quality assurance procedures and results.

Originalbeschreibung:

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThe quality control flow chart outlines the inspection process from receiving materials to shipping. It includes over 20 key stages of production such as inspection of incoming materials, storage of materials, assembly, testing, burn-in, and final inspection. Each stage lists the responsible department, inspection frequency, documents used, and quality records maintained. The goal is to ensure high quality through 100% inspection or statistical sampling at various stages, and documentation of all quality assurance procedures and results.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

100%(17)100% fanden dieses Dokument nützlich (17 Abstimmungen)

18K Ansichten1 SeiteQuality Control Flow Chart

Hochgeladen von

同道文档中心The quality control flow chart outlines the inspection process from receiving materials to shipping. It includes over 20 key stages of production such as inspection of incoming materials, storage of materials, assembly, testing, burn-in, and final inspection. Each stage lists the responsible department, inspection frequency, documents used, and quality records maintained. The goal is to ensure high quality through 100% inspection or statistical sampling at various stages, and documentation of all quality assurance procedures and results.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

Quality Control Flow Chart(品質管制流程圖)

QUALITY CONTROL FLOW CHART

Operation Resp.

Flow Chart Insp. Frequency Documents Records

Content Dept.

Tender Tender SALES ------------ Contract review procedure Quotation, Contract review

sheet

Receiving materials PMC 100% count Receiving SOP Incoming materal list, SDR

Receiving

report, Confirmation form

IQA Insp. report, Confirm.

N

Incoming Incoming Inspection lot sampling Criteria of incoming form, CA report,

MRB Inspection QA

(MIL-STD 105E, inspection W/H audit report,

Level II, AQL=0.4) Supplier history card

Y

Warehouse PMC ------------ Warehouse management B in card, Temp&himidity record,

M'tl Warehouse

SOP W/H in-out control card, M'tl

over 6 months list

Material M'tl dispatching to PMC 100% count Material dispatching SOP Stencil in-out control sheet, M'tl

Dispatching ** SPC-1 ** SMT/SA MCR SOP dispatching sheet, MCR report

Screen printing / SMT operation SOP Attrition rate record

SMT

Pick & Place/ Reflow MFG ----------- Solder paste measure. SOP Precious component record

Vacumn packing SOP SMT self-insp. Sheet

Visual Visual Inspection MFG 100% inspection Criteria of Outgoing MFG. Daily report

Insp. Quality Control FAAR

MIL-STD 105E Criteria of Outgoing OQA insp. report, Rework

OQA

OQA (If shipped QA Level II, AQL=0.4 Quality Control trace form, CA report,

after SMT) OQA daily insp. report

Manual Insertion MFG ----------- ASS'Y control SOP MFG. Daily report

M.I. Manual insert instruction

MFG. Daily report

Wave-soldering MFG ----------- ASS'Y control SOP Wave-soldering prod. record

Wave-

soldering Wave-soldering profile sheet

Flux uniformity record

** SPC-2 ** Touch-Up MFG 100% inspection ASS'Y control SOP MFG. Daily report

Touch Up

IPQA IPQA Audit QA once every 4 hours Criteria of IPQA,Corrective IPQA audit report

Audit

&prevent action procedure CA report

Assembly Assembly MFG ----------- Assembly instruction MFG. Daily report

ASS'Y control SOP _____ daily check report

Testing ** SPC-3 ** Repair control SOP Testing daily record

Testing MFG 100% testing Testing SOP Fixture insp. Report

Daily maintenance report

Burn-In Static Burn-In MFG 32 / 500pcs Testing SOP Burn-in status report

Burn-in daily check record

Visual Inspection MFG 100% inspection Criteria of Outgoing MFG. Daily report

Visual Insp.

Quality Control

Packing MFG ----------- Packing instruction MFG. Daily report

Packing

ASS'Y control SOP

OQA OQA QA MIL-STD 105E Criteria of Outgoing Daily insp. report, FAAR,

Level II,AQL=0.4 Quality Control CA report

F/G F/G Warehouse MFG ----------- F/G to warehouse SOP F/G to Warehouse report

Warehouse Bin card

OQA

OQA shipping audit QA 100% count Criteria of Outgoing Outgoing audit report

Quality Control

Shipping Shipping PMC ------------ Shipping SOP Shipping record

Das könnte Ihnen auch gefallen

- Control of Non ConformingDokument5 SeitenControl of Non ConformingNaveenkumar R100% (1)

- Quality Control Procedure SampleDokument12 SeitenQuality Control Procedure Samplepocharquitecturaromania92% (50)

- Receiving InspectionDokument5 SeitenReceiving InspectionUmair AwanNoch keine Bewertungen

- Quality Control ProcedureDokument12 SeitenQuality Control ProcedureZiya Ahmed100% (6)

- Material Receiving Inspection ProcedureDokument11 SeitenMaterial Receiving Inspection ProcedureMaheshwar polepallyNoch keine Bewertungen

- Quality Manual: Duty Party Document Ref. Quality RecordDokument1 SeiteQuality Manual: Duty Party Document Ref. Quality RecordShida ShidotNoch keine Bewertungen

- F-Qa-03 Material Inspection ReportDokument2 SeitenF-Qa-03 Material Inspection ReportHilal mohamedNoch keine Bewertungen

- Quality-Plan in Manufacturing Og Pre-Eng'Ng StructuresDokument23 SeitenQuality-Plan in Manufacturing Og Pre-Eng'Ng StructuresPageduesca Rouel100% (1)

- Material Receiving ProcedureDokument7 SeitenMaterial Receiving ProcedureRomi Abdul Rahman100% (3)

- KQP 16 Inspection & Testing Rev 04Dokument11 SeitenKQP 16 Inspection & Testing Rev 04Mohd Isa HarunNoch keine Bewertungen

- Inspection and Test Procedure and Plan Rev 0 Commented by HDECDokument16 SeitenInspection and Test Procedure and Plan Rev 0 Commented by HDECarchalys4u100% (4)

- Project-Specific Quality PlanDokument9 SeitenProject-Specific Quality PlanAlmario Sagun100% (2)

- Quality PlanDokument32 SeitenQuality PlannayumNoch keine Bewertungen

- Non Conformance ManagementDokument22 SeitenNon Conformance Managementssoni_famycare100% (1)

- Incoming Material ProcedureDokument2 SeitenIncoming Material ProcedureTridib Dey100% (6)

- Inspection Test PlanDokument7 SeitenInspection Test PlanWalha Wassim100% (1)

- QAQC Organization ChartDokument1 SeiteQAQC Organization Chartteto100% (1)

- Egatra: Quality ControlDokument6 SeitenEgatra: Quality ControlAndreas Schlager100% (3)

- Quality Assurance ProceduresDokument75 SeitenQuality Assurance Proceduresviorelu99100% (5)

- F Control of Non - Conforming Product ProcedureDokument3 SeitenF Control of Non - Conforming Product ProcedureNgonidzashe Zvarevashe100% (1)

- Inspection and Test Plan For Structure Steel Erection WorksDokument11 SeitenInspection and Test Plan For Structure Steel Erection WorksVijaya BaraniNoch keine Bewertungen

- QAP-07 Material Control Procedure PDFDokument22 SeitenQAP-07 Material Control Procedure PDFnaseema1100% (9)

- Procedure For Control of RecordsDokument3 SeitenProcedure For Control of Recordsmatrixmaze50% (2)

- Inspection ProcedureDokument6 SeitenInspection ProcedureAndreas Schlager100% (2)

- Quality Plan AuditDokument5 SeitenQuality Plan AuditRajan100% (1)

- Product Non Conformance ReportDokument2 SeitenProduct Non Conformance ReportAlaa100% (1)

- QA QC ManualDokument25 SeitenQA QC ManualWaldo At100% (1)

- INSPECTION AND TEST PLAN (ITP) FOR TEST TANK PDM T-1001 A Rev B PDFDokument7 SeitenINSPECTION AND TEST PLAN (ITP) FOR TEST TANK PDM T-1001 A Rev B PDFgst ajah100% (4)

- Internal Audit Check Sheet Ok 2016Dokument11 SeitenInternal Audit Check Sheet Ok 2016manttupandeyNoch keine Bewertungen

- Product Audit FormatDokument2 SeitenProduct Audit FormatSUBODHH50% (2)

- 4 Types of Quality InspectionDokument6 Seiten4 Types of Quality InspectionashrafbookNoch keine Bewertungen

- Dd0250 Material Receiving and Inspection ReportDokument1 SeiteDd0250 Material Receiving and Inspection ReportBelajar MONoch keine Bewertungen

- Qa Inspection and Test PlanDokument1 SeiteQa Inspection and Test Planit4scribdNoch keine Bewertungen

- Inprocess Inspection ReportDokument8 SeitenInprocess Inspection Reportpardeep kumarNoch keine Bewertungen

- Checklist of ISO 9001 2015Dokument4 SeitenChecklist of ISO 9001 2015Charles J KunjumonNoch keine Bewertungen

- Supplier Audit Check SheetDokument33 SeitenSupplier Audit Check SheetMotive PostNoch keine Bewertungen

- QIR-105-Material Receiving Inspection ReportDokument2 SeitenQIR-105-Material Receiving Inspection ReportSamer Bayati50% (2)

- Flow Chart - QCDokument2 SeitenFlow Chart - QCKarthikeyan Shanmugavel100% (1)

- NCR ProcedureDokument10 SeitenNCR ProcedureLilian RobertsonNoch keine Bewertungen

- IMSP 01 Control of DocumentsDokument8 SeitenIMSP 01 Control of Documentsemeka20120% (1)

- Boeing-Tasl: Strategic AlliancesDokument16 SeitenBoeing-Tasl: Strategic AlliancesSanchit JainNoch keine Bewertungen

- C4 Turtle Diagram Process Design ProcessDokument1 SeiteC4 Turtle Diagram Process Design Processcao thanh quocNoch keine Bewertungen

- QUALITY CONTROL PLAN-Rev-CDokument10 SeitenQUALITY CONTROL PLAN-Rev-Csivagnanam s100% (1)

- NCR ProcedureDokument18 SeitenNCR ProcedureFerdie OS100% (5)

- Inspection and Test ProcedureDokument8 SeitenInspection and Test Proceduregaehdd1100% (1)

- Quality Control ProcedureDokument29 SeitenQuality Control Procedurekj_mekanikal33% (3)

- Iso 9001 2008 Document Kit PDFDokument8 SeitenIso 9001 2008 Document Kit PDFsytrelle100% (1)

- 7 Product Realization RequirementsDokument10 Seiten7 Product Realization RequirementsArman Ul Nasar0% (1)

- (A) Dimensions: (D) Cupping TestDokument5 Seiten(A) Dimensions: (D) Cupping Testanon_115606397100% (7)

- SOP - 01 - Structure Organization ChartDokument10 SeitenSOP - 01 - Structure Organization ChartSuci YatiningtiyasNoch keine Bewertungen

- Quality Control ManualDokument78 SeitenQuality Control ManualRajeshSekar100% (3)

- QC Sample Manual GenericDokument34 SeitenQC Sample Manual GenericIan Stewart PorterNoch keine Bewertungen

- Guiding Principles For Plant Quality - 20140708Dokument4 SeitenGuiding Principles For Plant Quality - 20140708didik dadtNoch keine Bewertungen

- 品质英语Dokument6 Seiten品质英语Dennis LiNoch keine Bewertungen

- Magnetic Level Gauge: DOC NO. QR/QC/F/14Dokument1 SeiteMagnetic Level Gauge: DOC NO. QR/QC/F/14sunshine dreamNoch keine Bewertungen

- GM 1927 16 Process Control Plan Audit PCPADokument7 SeitenGM 1927 16 Process Control Plan Audit PCPAMostafa Abd ElalemNoch keine Bewertungen

- Itp For Field Erected Tank Rev A PDF FreeDokument9 SeitenItp For Field Erected Tank Rev A PDF FreeMahmoud GaberNoch keine Bewertungen

- Inspection & Test Plan Advance Valves Butterfly ValvesDokument2 SeitenInspection & Test Plan Advance Valves Butterfly Valvessyed jafarNoch keine Bewertungen

- Detailed Requirement SheetDokument53 SeitenDetailed Requirement SheetRohit QualityNoch keine Bewertungen

- M-Almite Sealer (E)Dokument2 SeitenM-Almite Sealer (E)同道文档中心Noch keine Bewertungen

- Gartner Market Research PrimerDokument97 SeitenGartner Market Research PrimerSurya Kiran RaiNoch keine Bewertungen

- Conferences 2001Dokument7 SeitenConferences 2001同道文档中心Noch keine Bewertungen

- Miranol C2M AADokument2 SeitenMiranol C2M AA同道文档中心100% (1)

- Corfin Ind Leadfree ProbsDokument39 SeitenCorfin Ind Leadfree Probs同道文档中心Noch keine Bewertungen

- Orion Aplus: Advanced Conductivity MetersDokument54 SeitenOrion Aplus: Advanced Conductivity Meters同道文档中心75% (8)

- CMI200USDokument2 SeitenCMI200US同道文档中心Noch keine Bewertungen

- Case 5Dokument3 SeitenCase 5同道文档中心Noch keine Bewertungen

- CBM Connector: Bridging The Gap Between Failure Prediction and Asset ManagementDokument16 SeitenCBM Connector: Bridging The Gap Between Failure Prediction and Asset Management同道文档中心Noch keine Bewertungen

- CMI100USDokument2 SeitenCMI100US同道文档中心Noch keine Bewertungen

- 6000 Thickness Testing SystemDokument6 Seiten6000 Thickness Testing System同道文档中心100% (1)

- CMI700USDokument2 SeitenCMI700US同道文档中心Noch keine Bewertungen

- Case 1Dokument4 SeitenCase 1同道文档中心Noch keine Bewertungen

- CE Analytics: Your Surface Analysis and Materials Properties ResourceDokument5 SeitenCE Analytics: Your Surface Analysis and Materials Properties Resource同道文档中心100% (1)

- Asia News 6Dokument4 SeitenAsia News 6同道文档中心100% (1)

- Abs MTG 204&abs 0604Dokument1 SeiteAbs MTG 204&abs 0604同道文档中心100% (1)

- 5.0 Adobe Acrobat: New Feature HighlightsDokument7 Seiten5.0 Adobe Acrobat: New Feature Highlights同道文档中心100% (2)

- Long-Term Performance of Cadmium AlternativesDokument8 SeitenLong-Term Performance of Cadmium Alternatives同道文档中心100% (2)

- Alkaline Cleaning GuideDokument3 SeitenAlkaline Cleaning Guide同道文档中心100% (3)

- How Vci WorkDokument21 SeitenHow Vci Work同道文档中心100% (1)

- Repositioning Taiwan's Industry: A Service-Added Manufacturing IndustryDokument26 SeitenRepositioning Taiwan's Industry: A Service-Added Manufacturing Industry同道文档中心Noch keine Bewertungen

- Evaluating Cortec Vpci-126 Blue Film With Requirements Listed On Performance Specification Mil-Prf-22019DDokument5 SeitenEvaluating Cortec Vpci-126 Blue Film With Requirements Listed On Performance Specification Mil-Prf-22019D同道文档中心100% (2)

- Department of Defense Test Method Standard: Dod Preferred Methods For Acceptance of ProductDokument33 SeitenDepartment of Defense Test Method Standard: Dod Preferred Methods For Acceptance of ProductVladimir AquinoNoch keine Bewertungen

- Ee Roadinfra Tend 01Dokument3 SeitenEe Roadinfra Tend 01Prasanna VswamyNoch keine Bewertungen

- Kiruna Iron Drilling SuccessDokument12 SeitenKiruna Iron Drilling SuccessHannans Reward LtdNoch keine Bewertungen

- WEDDING RATE - Felfest UI - 2019 PDFDokument2 SeitenWEDDING RATE - Felfest UI - 2019 PDFNurulWardhani11Noch keine Bewertungen

- Who Trs 937-Annex4Dokument72 SeitenWho Trs 937-Annex4Reza Jafari100% (1)

- Design TransferDokument5 SeitenDesign Transferazamyn100% (2)

- Keerthi Rohit Seelamsetty HCM ProfileDokument7 SeitenKeerthi Rohit Seelamsetty HCM ProfilekrishnaNoch keine Bewertungen

- Goods and Service Design: David A. Collier and James R. EvansDokument46 SeitenGoods and Service Design: David A. Collier and James R. EvansHoàng OanhNoch keine Bewertungen

- Sulphuric Acid DataDokument19 SeitenSulphuric Acid Datamartinjw100% (1)

- Internship Report of PELDokument53 SeitenInternship Report of PELRehan Aqeel100% (3)

- Fiat IndiaDokument30 SeitenFiat IndiaParagNoch keine Bewertungen

- Evaluating TransportationDokument5 SeitenEvaluating TransportationAntoNoch keine Bewertungen

- Cardiff University International ProspectusDokument48 SeitenCardiff University International ProspectusEric SunwayNoch keine Bewertungen

- Steel Fibers For Fiber-Reinforced ConcreteDokument4 SeitenSteel Fibers For Fiber-Reinforced ConcreteIvan TapiaNoch keine Bewertungen

- 3 Nelson - Up, Up, and Away! - AnswersDokument3 Seiten3 Nelson - Up, Up, and Away! - Answersdmccloy28Noch keine Bewertungen

- Batch Data Communication (BDC) and Legacy System Migration Workbench (LSMW)Dokument3 SeitenBatch Data Communication (BDC) and Legacy System Migration Workbench (LSMW)amitkeleNoch keine Bewertungen

- iiiiiiSIL 2013-02-02 PDFDokument7 SeiteniiiiiiSIL 2013-02-02 PDFdieego001Noch keine Bewertungen

- Enhancements List RVT 2015 UR5 ForR2Dokument6 SeitenEnhancements List RVT 2015 UR5 ForR2Luca BrandiNoch keine Bewertungen

- Agro Process Flowchart CG and Seed - May 17 - FinalDokument26 SeitenAgro Process Flowchart CG and Seed - May 17 - FinalMarkandeya SatyanarayanaNoch keine Bewertungen

- Norflow Controls: Gate Valves, Globe Valves, NON Return ValvesDokument5 SeitenNorflow Controls: Gate Valves, Globe Valves, NON Return ValvesnorflowvalvesNoch keine Bewertungen

- Regulations 1 December 2009 1406, 1407, 1408, 1409 and 1410Dokument163 SeitenRegulations 1 December 2009 1406, 1407, 1408, 1409 and 1410Lelethu NgwenaNoch keine Bewertungen

- 17MA20006 18ME10029: Day 3.1 OffersDokument7 Seiten17MA20006 18ME10029: Day 3.1 OffersSiddharth DhingraNoch keine Bewertungen

- Suggested Improvements For Your Mercedes W113 Pagoda SL PDFDokument3 SeitenSuggested Improvements For Your Mercedes W113 Pagoda SL PDFwhorne24Noch keine Bewertungen

- Db-Manual WPM ExtractDokument43 SeitenDb-Manual WPM ExtractSamuel MatiasNoch keine Bewertungen

- Catalog YorkDokument91 SeitenCatalog YorkedenNoch keine Bewertungen

- AS400 Job SchedulerDokument183 SeitenAS400 Job Schedulerapi-27605687Noch keine Bewertungen

- Pro Railing 2017Dokument90 SeitenPro Railing 2017Peter DavidsonNoch keine Bewertungen

- KV Chan Set 4 QPDokument6 SeitenKV Chan Set 4 QPdeepaNoch keine Bewertungen

- NIBA Belt Line December 2016Dokument12 SeitenNIBA Belt Line December 2016NIBA- The Belting AssociationNoch keine Bewertungen

- Masdar City: The World'S Greenest City?: InshareDokument7 SeitenMasdar City: The World'S Greenest City?: InshareMohd HazaziNoch keine Bewertungen