Beruflich Dokumente

Kultur Dokumente

Hot Tapping

Hochgeladen von

ghkashyap150%(2)50% fanden dieses Dokument nützlich (2 Abstimmungen)

367 Ansichten15 Seitenhot tap

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenhot tap

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

50%(2)50% fanden dieses Dokument nützlich (2 Abstimmungen)

367 Ansichten15 SeitenHot Tapping

Hochgeladen von

ghkashyap1hot tap

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 15

Title: Hot Tap and Stopple Procedure

Function: Health & Safety

BASF Corporation

Beaumont Site

Beaumont, TX

No.: BMEHS-002.016

Reviewed: 09/06 Effective: 10/01/06 Revision: New

Preparer:

Health & Safety Member

Owner:

Health & Safety Manager

Approver:

Plant Manager

Signed copy on file Signed copy on file Signed copy on file

Document Revision Change Table

Revision

Number

Revision Description Revised

By

Revision

Date

New

1:37 pm

01/31/2013

CONTROLLED DOCUMENT- 24 HRS

-- UNCONTROLLED THEREAFTER --

Title: Hot Tap and Stopple Procedure

Function: Health & Safety

BASF

Corporation

Beaumont Site

Beaumont, TX

No.: BMEHS-002.016 Page:2 of 15

Reviewed: 09/06 Effective: 10/01/06 Revision: New

1. PURPOSE

To establish a clear set of guidelines to be followed when performing Hot Tap and Stopple installations.

2. DEFINITIONS

Coupon The part of the pipe that is removed during the Hot Tap operation.

Hot Tap The method of making a mechanical tie-in by welding an attachment to the pipe that is in

service; then installing a valve and cutting a hole in the existing pipe through the new valve using a

tapping machine specifically designed for such a purpose.

Stopple The installation of a flow-blocking device in a piping system that cannot otherwise be isolated

depressurized or cleared.

Contractor the Company that supplies the Hot Tap and/or Stopple machine and its operating

personnel.

Hot Tap/Stopple Document Package A collection of documentation required to obtain Hot Tap

approval:

Weldment Calculation (if applicable)

Hot Tap Penetration Calculation

Hot Tap Checklist Form A (Sections 1 Hot Work & 2 Owner Approval)

Hot Tap Checklist Form B

Stopple Checklist Form C (If applicable)

Piping and/or Structural Stress Analysis (if applicable)

Welding Procedure

Thickness Testing Report

Dye Penetrant Testing Report (Stainless Steel tie-ins only)

Deviation Approval(s) (if applicable)

Piping Iso of tie-in (Hand sketch is acceptable)

J SA (Provided by Operations)

Approved MOC

Completion Plug - A metal plug sometimes installed in the tie-in piping after a stopple is completed, in

order to isolate the process from the tie-in entry point without the use of a valve.

Weldment A welded-in pipe fitting that connects the new tie-in piping spool to the existing piping

system (e.g. a split tee or a weld-o-let)

J ob Coordinator Person assigned by the Operations Manager to coordinate a job. This is

typically the Operations Coordinator.

1:37 pm

01/31/2013

CONTROLLED DOCUMENT- 24 HRS

-- UNCONTROLLED THEREAFTER --

Title: Hot Tap and Stopple Procedure

Function: Health & Safety

BASF

Corporation

Beaumont Site

Beaumont, TX

No.: BMEHS-002.016 Page:3 of 15

Reviewed: 09/06 Effective: 10/01/06 Revision: New

Maintenance/Construction Representative Person assigned by the TES Manager to follow a job,

depending on whether the job is part of maintenance or a capital project.

3. SCOPE

Hot Taps and Stopples shall only be installed on piping that cannot be safely cleared and/or

isolated due to operational and/or system design constraints. It must also be evaluated to see if

the Hot Tap or Stopple could be avoided by delaying the job until an upcoming planned Outage or

Turnaround. Any Hot Tap and/or Stopple must be part of an approved MOC with Hot Tap/Stopple

Document Package and shall require a PSSR prior to being put into service.

4. PROCEDURE

4.1 General

4.1.1 Hot Taps are NOT to be performed on piping containing:

a. Combustible vapor/air/oxygen mixtures with-in flammable and/or explosive ranges.

b. Hydrogen, if the equipment has operated above the Nelson Curve Limits

c. Any chemicals likely to violently decompose or become hazardous from the heat

generated by welding.

d. Strong Caustics or Acids

e. Oxygen or Ammonia

f. Any process stream containing ethylene or acetylene*

* Streams with low concentrations of ethylene/acetylene can be considered for

Hot Tapping contingent on concurrence from Corporate Process Safety.

4.1.2 Hot Tapping shall not be performed on piping under vacuum unless approved by the

TES Manager.

4.1.3 Hot Taps shall not be performed on piping that is lined, clad, or where stress relieving

is required.

4.1.4 Hot Taps made upstream of equipment and/or in-line instrumentation that are not

adequately protected by filters and cannot be isolated, shall be carefully evaluated for

safety and operational risks that could arise from a coupon or metal shavings being left

behind in the piping system. A risk analysis shall be completed and added to the

Document Package if this paragraph is applicable.

1:37 pm

01/31/2013

CONTROLLED DOCUMENT- 24 HRS

-- UNCONTROLLED THEREAFTER --

Title: Hot Tap and Stopple Procedure

Function: Health & Safety

BASF

Corporation

Beaumont Site

Beaumont, TX

No.: BMEHS-002.016 Page:4 of 15

Reviewed: 09/06 Effective: 10/01/06 Revision: New

4.1.5 Hot Tap and Stopple machinery shall be operated by authorized Contractor personnel

only. Procurement maintains a list of approved Contractors. Potential new Contractor

must go through the Sites procedure for qualifying new Vendors. It is the

responsibility of the Contractor to ensure such equipment is properly maintained and in

good working condition, and that their personnel are adequately trained.

4.1.6 When feasible, Hot Taps should be made on the top of the pipe vs. the bottom, in

horizontal pipe runs.

4.2 Design Considerations

4.2.1 All piping components used in a Hot Tap or Stopple installation shall be in accordance

with the relevant Beaumont Site Piping Standards, with the exception of weldments

which shall be in accordance with Table 1 of this procedure Any proposed piping

component deviation will require approval from the TES Manager or designee.

4.2.2 All welding on piping components used in a Hot Tap installation shall be in accordance

with approved welding procedures.

4.2.3 Full port ball or gate valves are required for Hot Tap and Stopple installations, the Hot

Tap Contractor will supply the cutter diameter to be used for the Hot Tap and Stopple.

BASF will confirm the cutter will fit through the valve without damaging the seat.

These valves shall comply with the appropriate Beaumont Site Piping Standard.

4.2.4 The preferred method for completion of a Hot Tap and Stopple is a full port valve with

a blind. If a completion plug is to be used in the case of a Stopple, the elastomer

components shall require review and approval by the TES Group or Process

Technology Group to ensure compatibility with the process.

4.2.5 The piping and supporting structure must have an engineering review of the stress

loading from the weight of the hot tap and stopple machine. This review can be simply

good engineering judgment, or if good engineering judgment dictates, a formal stress

analysis shall be completed and included in the Hot Tap/Stopple Document Package.

4.2.6 Table 1 has been attached as a guideline for selecting the appropriate weldment. If

this table is not used, the TES Group must review and approve.

4.2.7 The location of the Hot Tap should be more that 18 away from all flanges or threaded

connections, plus more than three inches from any existing weld seam. Deviations

from these requirements must have the approval of the TES Manager or designee.

4.2.8 The design of the hot tap will allow for adequate purging after the Hot Tap and Stopple

is complete.

1:37 pm

01/31/2013

CONTROLLED DOCUMENT- 24 HRS

-- UNCONTROLLED THEREAFTER --

Title: Hot Tap and Stopple Procedure

Function: Health & Safety

BASF

Corporation

Beaumont Site

Beaumont, TX

No.: BMEHS-002.016 Page:5 of 15

Reviewed: 09/06 Effective: 10/01/06 Revision: New

4.3 Preparation

4.3.1 Operations should be appraised of any requests prior to proceeding with the

preparations for the work. It is recommended a minimum two weeks advanced notice

be provided in order for Operations to have adequate time to prepare a risk evaluation

and emergency plan associated with completing the J SA, while the Contractor

performs mechanical checks in the field.

4.3.2 The location of the Hot Tap shall allow for:

a) Adequate clearance for the machine

b) Adequate support for the machine

c) Availability of air or electric power for the machine

d) Easy and safe egress for personnel making the Hot Tap or Stopple, and easy

access for emergency personnel.

4.3.3 The Contractor shall perform measurements and calculations to verify that the cutter or

the pilot drill shall not penetrate through the opposite wall of the line being Hot Tapped.

Preferably the drill should not penetrate beyond the center of the pipe. For size-on-

size or one size smaller connections, where the drill tip will have to move further into

the pipe, measurements must ensure that the drill will not contact the inner surface of

the other side of the pipe. The Maintenance/Construction representative shall review

these measurements.

4.3.4 Thickness measurements shall be taken in the location of the Hot Tap, extending out

to either side, a minimum of 12 inches, or the diameter of the branch pipe, whichever

is greater. If any of the following conditions exist, a engineering evaluation shall be

performed by a TES engineer, to determine if a Hot Tap can be safely performed:

a) Actual thickness <3/16

b) Actual thickness >1

c) Actual thickness <Nominal thickness corrosion allowance

4.3.5 If stress cracking is possible in the service, shear wave examination of the surface of a

stainless steel pipe is required. If stress cracking exists, a qualified

engineer/technician shall determine the suitability of the existing pipe for the Hot Tap.

4.3.6 The attainable flow velocity in the line being Hot Tapped shall be verified. If the flow in

a line being hot tapped is within the following velocity ranges: Liquid: 1.5 15.0 feet

per second, Gas or vapor: 25.0 200.0 feet per second, then no engineering review is

required. For liquid or gas velocities outside these ranges, Site Engineering will review

the hot tap as per API Recommended Practice 2201 Procedures for Welding or Hot

Tapping on Equipment in Service, Latest Edition. The TES Group shall evaluate

required flow in vapor lines on a case-by-case basis.

1:37 pm

01/31/2013

CONTROLLED DOCUMENT- 24 HRS

-- UNCONTROLLED THEREAFTER --

Title: Hot Tap and Stopple Procedure

Function: Health & Safety

BASF

Corporation

Beaumont Site

Beaumont, TX

No.: BMEHS-002.016 Page:6 of 15

Reviewed: 09/06 Effective: 10/01/06 Revision: New

4.3.7 The WPS (Weld Procedure Specification) must be selected by the BASFs QA/QC

department and attached to the checklist Form A. Welding will be performed by BASF

site or Maintenance Contractor.

4.4 Hot Tap and Stopple Approval

4.4.1 Section 1 and 2 of the Hot Tap Checklist Form A shall be completely filled and

approved as noted on the form, prior to the issuance of a hot work permit for the Hot

Tap weldment.

4.4.2 In some cases several days or even weeks may elapse between the completion of the

hot work step and the actual hot tap line cutting. Prior to issuing a Safe Work Permit

for the Hot Tap, the Shift Supervisor and the Maintenance/Construction

Representative shall sign off on the Hot Tap Checklist Form B, denoting the Hot Tap

can safely commence.

4.4.3 The Hot Tap Checklist Form B shall be completed as the job progresses in the field. It

is the responsibility of the Maintenance/Construction Representative to ensure the

Contractor provides all required information and signs off in the sequential order noted.

4.4.4 Prior to issuing a Safe Work Permit for a Stopple, the Shift Supervisor, Contractor

Representative, Maintenance/Construction Representative and J ob Coordinator shall

sign off on the Stopple Checklist Form C, denoting the Stopple work can safely

commence.

4.5 Hot Tap and Stopple Field Work

4.5.1 The J ob Coordinator together with the Maintenance/Construction Representative shall

ensure the planned location of a Hot Tap as being correct and clearly marked in the

field. The Hot Tap location shall have been cleaned as necessary to bare metal. This

includes removal of paint, insulation, and any other debris that could interfere with

potential Hot Tap operations.

4.5.2 The TES Manager, together with the Operations Manager, are responsible for

ensuring that an emergency plan has been identified and communicated appropriately.

The emergency plan must cover potential risks such as burn through during welding.

Radio communication with the control room is required while installing a Hot Tap and

while installing a Stopple.

4.5.3 All required documentation should be presented to the person issuing the hot work

permit.

4.5.4 The person issuing the hot work permit shall confirm that no unusual process

conditions exist, and the flow rate, temperature, and pressure ranges specified on the

Hot Tap Hot Work Checklist A form exist in the field.

1:37 pm

01/31/2013

CONTROLLED DOCUMENT- 24 HRS

-- UNCONTROLLED THEREAFTER --

Title: Hot Tap and Stopple Procedure

Function: Health & Safety

BASF

Corporation

Beaumont Site

Beaumont, TX

No.: BMEHS-002.016 Page:7 of 15

Reviewed: 09/06 Effective: 10/01/06 Revision: New

4.5.5 A pressure test of the installation shall be witnessed by the Maintenance/QC

representative upon completion of the Hot Tap welding. Valves utilized in conjunction

with the Hot Tap shall be pressure tested prior to installation.

4.5.6 After completion of the Hot Tap/Stopple, the Maintenance/Construction Representative

shall witness flow from the leak off valve on the Hot Tap/Stopple machine.

4.5.7 Before removing the Hot Tap/Stopple machine, the Maintenance/Construction

Representative shall have the Contractor verify that the requirements of the Hot

Tap/Stopple have been completed and have the technician sign the hot work permit

prior to the removal of the Hot Tap/Stopple machine.

4.5.8 For maintenance jobs, the Maintenance Department will retain the complete Hot Tap

Stopple documentation package on file for one month. For projects, the Project

Manager will provide a copy of the documentation package in the project job books,

upon completion.

4.5.9 The Maintenance/Construction Representative shall witness removal of the coupon. If

the coupon is lost, he/she shall immediately notify the shift coordinator and initiate an

Incident Report. The coupon shall be inspected by the J ob Coordinator and properly

disposed of, if there is nothing unusual about its condition.

5. Responsibilities

Maintenance/Construction Representative Ensure Section 1 of the Hot Tap Checklist

Form A is accurate and closely monitor Contractor activities in the field.

Job Coordinator Ensure process conditions needed to perform the job safely exist, and

ensure adequate communication occurs between the Contractor, Maintenance/Project, and

Operations. Ensure Section 2 of the Hot Tap Checklist Form B is accurate.

Contractor Provide equipment in good working order and properly trained personnel, in

additional to strictly following all safety and operations rules and procedures. Complete

Checklist Forms B and/or C if applicable.

Operations Manager Ensure there are no other alternative to performing the Hot Tap

and/or Stopple work. Evaluate potential risks associated with the job and establish an

emergency plan to cope with these risks.

TES Manager Ensure the job has been properly engineered and that all required

preparations have been carried out.

Safety Department Manager Review the job scope and set-up in the field from a safety

perspective to help ensure all identifiable precautions have been taken.

1:37 pm

01/31/2013

CONTROLLED DOCUMENT- 24 HRS

-- UNCONTROLLED THEREAFTER --

Title: Hot Tap and Stopple Procedure

Function: Health & Safety

BASF

Corporation

Beaumont Site

Beaumont, TX

No.: BMEHS-002.016 Page:8 of 15

Reviewed: 09/06 Effective: 10/01/06 Revision: New

6. RELATED DOCUMENTS

ANSI B31.3 Chemical Plant and Petroleum Refinery Piping

API Recommended Practice 2201 Procedures for Welding or Hot Tapping on Equipment in

Service

OSHA 1910.119 Process Safety Management of Highly Hazardous Chemicals

Beaumont Management of Change Procedure

Beaumont Pre-Startup Safety Review Procedure

Beaumont Hot Work Procedure

1:37 pm

01/31/2013

CONTROLLED DOCUMENT- 24 HRS

-- UNCONTROLLED THEREAFTER --

TABLE 1 - FITTING SELECTION TABLE

This table is to be used to select hot tap fittings for pipelines only. A selection from this table does

not require engineering review or mechanical calculations. NOTE: Incase of conflict with Pipe

Spec, Hot Tap Procedure will govern.

HEADER

PIPE

SIZE

BRANCH SIZE

1" 1-1/2" 2" 3" 4" 6" 8" 10" 12" 14" 16" 18" 20" 24"

1" T or

W

1-1/2" T or

W

T or

W

2" W T or

W

T or

W

3" W W T or

W

T

4" W W W T T

6" W W W T T T

8" W W W P T T T

10" W W W P P T T T

12" W W W P P T T T T

14" W W W P P T T T T T

16" W W W P P P T T T T T

18" W W W P P P T T T T T T

20" W W W P P P P T T T T T T

24" W W W P P P P T T T T T T T

SYMBOLS

W - Integrally reinforced fitting (weld-o-let).

T - Full encirclement split tee.

P - Reinforcement pad is required. Pad width shall equal half of branch nominal size, and

thickness shall be no less than the header pipe wall thickness.

NOTES

1. For branch diameters greater than 2", reinforcement is required - either repad or split tee

as shown in Table 1. 1/8" NPT tapped holes shall be provided in pad or tee and shall be

sealed with RTV sealer. Repads will be pneumatically tested at 15 psig. Where

pneumatic testing is not practical (hot services), the use of integrally reinforced fittings

(O-lets) will be considered, use of these fittings must be approved in advance by the

engineer.

2. All branch fittings must meet or exceed main pipe schedule.

1:37 pm

01/31/2013

CONTROLLED DOCUMENT- 24 HRS

-- UNCONTROLLED THEREAFTER --

SECTION 1 (Hot Work) Hot Tap Checklist Form A

To be completed by the Maintenance/Construction Representative Prior to Welding

Plant Section MOC No. ______________

Project No. ______________

MWO No. ______________

Existing Line To Be Hot Tapped:

Line Number: Pipe Specification: Design Pipe sch./thickness: ___________

Pipe Material: Corrosion Allowance: ___________ Actual Pipe sch./thickness: ___________

Process Fluid: ______________________________

Fluid Flow velocity: ft/s Liquid ( ) Gas/vapor ( )

Operating Pressure: psig Temperature:_____________ deg F

Test Requirements for Weldment:

NDE required ( )Root pass dye check ( )Final pass dye check ( ) Radiography ( ) Ultrasonic

( )Hydrostatic test @ psig ( )Pneumatic test @ psig ( ) Test Medium ___________

( ) Shear Wave

( ) Y ( ) N ( ) n/a Does this job fully comply with the Site Hot Tap/Stopple Procedure?

( ) Y ( ) N ( ) n/a Are approved welding procedures included with the Hot Tap/Stopple Document Package?

( ) Y ( ) N ( ) n/a Does the new installation fully comply with Site Piping Standards and/or approved deviations?

( ) Y ( ) N ( ) n/a Has the Hot Tap location been clearly marked in the field and the pipe cleaned to bare metal?

( ) Y ( ) N ( ) n/a Has the added stress loading on the existing pipe and support structure been addressed?

( ) Y ( ) N ( ) n/a Does the Hot Tap/Stopple location allow for sufficient clearance and easy access/egress?

( ) Y ( ) N ( ) n/a Have thickness and dye penetrant (per Section 4.3.3) results been reviewed and determined to be

satisfactory?

( ) Y ( ) N ( ) n/a Has the weldment been either selected from Table 1 or approved by Site Engineering?

( ) Y ( ) N ( ) n/a Has Site Engineering confirmed the required flow, and is it available for the Hot Work?

( ) Y ( ) N ( ) n/a Welder is Code Certified?; Welder's Name:

Signatures

Maintenance/Construction Representative

Print Name:

Signature: Date:

TES Manager or Designee

Print Name:

Signature: Date:

Safety Department Manager or Designee

Print Name:

Signature: Date:

A hot work permit CANNOT be issued if Sections 1 & 2 are not signed and/or there are any No answers.

1:37 pm

01/31/2013

CONTROLLED DOCUMENT- 24 HRS

-- UNCONTROLLED THEREAFTER --

SECTION 2 (Owner Approval) Hot Tap Checklist Form A

To be completed by the Job Coordinator Prior to Welding

( ) Y ( ) N ( ) n/a Has a J SA been completed and attached to this form?

( ) Y ( ) N ( ) n/a Does the J SA address the risks associated with losing a coupon or introducing metal

shavings?

( ) Y ( ) N ( ) n/a Does the J SA denote measures taken to reduce the risk of burn through, and provide

a contingency plan in the event of burn through?

( ) Y ( ) N ( ) n/a Will radio communication with the Control Room be available during the execution of

this work?

( ) Y ( ) N ( ) n/a Has a complete Hot Tap/Stopple Document Package been provided to the Operations

Manager or designee?

( ) Y ( ) N ( ) n/a If a stopple is going to be used, does the J SA address measures to be taken if the

stopple fails?

To ensure compliance with OSHA's Lockout/Tag-out Standard under 1910.147, the hot tap must be

justified. The OSHA standard, as proposed, stipulated that hot tap operations would be exempt from the

requirements of the standard if the employer could demonstrate that: (1) Continuity of service is essential;

(2) shutdown of the system is impractical; and (3) documented procedures and special equipment are

utilized which will provide effective protection for employees.

Details of Requirement for continuity of service and/or impracticality of system shutdown:

NOTE: Operation Signatures signify that the Hop Tap location and size are correctly identified, that the risks

of performing a hot tap and the alternatives to a hot tap have been reviewed, and that performing a hot tap is

necessary.

Signatures

Operations Manager or Designee

Print Name:

Signature: Date:

Job Coordinator

Print Name:

Signature: Date:

A hot work permit CANNOT be issued if Sections 1 & 2 are not signed and/or there are any No answers.

1:37 pm

01/31/2013

CONTROLLED DOCUMENT- 24 HRS

-- UNCONTROLLED THEREAFTER --

Hot Tap Checklist Form B

To be completed by the Hot Tap Contractor Prior to Drilling the Coupon

Valve Tested Before Installation? Y ( ) Name of Shop performing Test _______________________________

Pressure Test of branch weld: ( ) Hydro ( ) Pneumatic Test Pressure _________ psig ( ) Passed ( ) Failed

( ) Radiography ( ) Other __________________ ( ) Passed ( ) Failed ( ) n/a

Fluid Flow velocity: miles/hour Liquid ( ) Gas/vapor ( )

Machine support arrangement approved by the TES Engineer? ( ) Y

Machine bit rated for the maximum flow velocity of the process? ( ) Y

Dimensional Checks Completed (see machine dimension sheet)? ( ) Y

Signatures

Shift Supervisor

Print Name:

Signature: Date:

Maintenance/Construction Representative

Print Name:

Signature: Date:

Job Coordinator

Print Name:

Signature: Date:

Prior to proceeding with the Hot Tap, the above information shall be completed and confirmation of successful test

results provided, and radio communication established with the Control Room

Contractor Hot Tap Checklist:

Hot Tap Machine Used Wt lb Max Working pr psig Test date__________

Boring bar travel set at " Do-not-exceed dimension " to prevent drill through

Coupon holding pins on cutter ( ) Y ( ) N Number ______

Machine bleed off verified: ( ) Y ( ) N

Coupon Retrieved: ( ) Y ( ) N

Signatures

Hot Tap Contractor Representative

Print Name:

Signature: Date:

Maintenance/Construction Representative

Print Name:

Signature: Date:

1:37 pm

01/31/2013

CONTROLLED DOCUMENT- 24 HRS

-- UNCONTROLLED THEREAFTER --

Stopple Checklist Form C

To be completed by the Stopple Contractor Prior to Installing the Stopple

Machine support arrangement approved by the TES Engineer? ( ) Y ( ) N

Stopple o-ring material acceptable for service? ( ) Y ( ) N

Expected o-ring life at process conditions: ____________________

Stopple Machine Used Wt lb Max Working Pressure psig Test date__________

Machine support arrangement approved by the J ob Coordinator? ( ) Y ( ) N

Completion Plug to be used ( ) Y ( ) N; If yes, elastomer material: ___________________

If an existing completion plug is to be removed, the integrity of the o-rings must be verified before

starting the job.

Signatures

Shift Supervisor

Print Name:

Signature: Date:

Maintenance/Construction Representative

Print Name:

Signature: Date:

Stopple Contractor Representative

Print Name:

Signature: Date:

Job Coordinator

Print Name:

Signature: Date:

Prior to proceeding with the Stopple the above information shall be signed off, and radio

communication established with the Control Room

1:37 pm

01/31/2013

CONTROLLED DOCUMENT- 24 HRS

-- UNCONTROLLED THEREAFTER --

HOT TAP MACHINE DIMENSION & CALCULATION SHEET

BRANCH TAP

SIZE "

FLANGE

RATING lb

DIMENSION DIMENSION DIMENSION TOPAZ WEIGHT

SIZE " 'A' MAX " 'B' MIN " 'C' MIN " MODEL lbs

1 All 15 67 28 T-101 50

1-1/4

1-1/2

All 15 67 28 T-101 50

2 1-7/16 All 16 53 28 T-101 50

150 19

3 2-7/16 300 20 54 29 360

600 20

250

4

150 18 54 29 360 250

3-7/16 300 19 54 29 360 250

700 (900) 600 37 (61) 78 (102) 31 660 (760)

150 35 (59)

34 (58)

32 (56)

80 (104)

6 5-15/32 300 80 (104) 31 660 (760) 700 (900)

600 82 (106)

150 32 (56)

8 7-5/16 300 33 (57) 82 (106) 31 660 (760) 700 (900)

600 33 (57)

150 30 (54) 84 (108)

10 9-1/2 300 36 (60) 79 (103) 31 660 (760) 700 (900)

600 29 (53) 85 (109)

150 33 (57)

12 11-1/2 300 34 (58) 82 (106) 31 660 (760) 700 (900)

600 32 (56)

150 35 (59) 80 (104) 31 660 (760) 700 (900)

14 12-3/4 300 60 132 56 1200 3000

600 126 56 1200 3000

150 59 132

16 14-9/16 300 56 135 56 1200 3000

600 60 131

150 56 133

18 15-1/16 300 60 133 56 1200 3000

600 130

150 57 133

3000 20 17 300 130 56 1200

600 56 133

150 53 136

24 21 300 132 56 1200

600 132

3000

NOTES:

- These are dimensions/weights for a typical (Topaz or T D Williams) machine for planning purposes only. These

parameters may vary for a different machine.

- Values given in parentheses are for a heavier and larger machine.

1:37 pm

01/31/2013

CONTROLLED DOCUMENT- 24 HRS

-- UNCONTROLLED THEREAFTER --

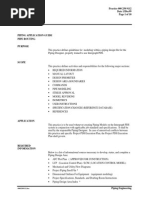

HOT TAP MACHINE

R

T

F

A B

C

E

D

Adaptor

Tapping Machine

Hot Tap Machine Used

Pipe OD to face of valve flange (A) "

Machine end to adapter flange (B) "

Machine width (C) ".

Check Clearance to operate machine ( )Y

Valve flange to plug/gate (D) "

Header pipe inside radius (R) "

Header pipe nominal thickness (T) "

Retract boring bar: adapter flange to drill tip (E) " E <D to allow valve to close ( ) Y

Drill tip projection from cutter (F) ". F<R to prevent contact with back of pipe ( )Y.

Boring bar travel - Drill to touch pipe OD (A-E) - = "

Cutter to touch pipe OD (A-E+F) - + = "

To prevent drill from going through other side of pipe:

Do not exceed (A-E+R+T) - + + = "

Only for size-on-size and one size smaller:

Do not exceed (A-E+T+2R) - + +2 X = "

Boring bar travel stops set to limit travel to "

Boring bar travel is less than Do-not-exceed dimension ? ( ) Y

1:37 pm

01/31/2013

CONTROLLED DOCUMENT- 24 HRS

-- UNCONTROLLED THEREAFTER --

Das könnte Ihnen auch gefallen

- Hottap ProcedureDokument4 SeitenHottap Procedureparas_gemilang5853100% (1)

- Hot Tap ProcedureDokument21 SeitenHot Tap ProcedureImanuel Sitepu100% (1)

- Hot Tap PipingDokument21 SeitenHot Tap PipingRachel FloresNoch keine Bewertungen

- Hot TappingDokument21 SeitenHot TappingnayakyaNoch keine Bewertungen

- Hot Tapping PDFDokument32 SeitenHot Tapping PDFSreenivas Kamachi Chettiar100% (1)

- Hot TapDokument4 SeitenHot TapmiteshNoch keine Bewertungen

- Replacement of Isolation Valves by Hot Tap WorksDokument88 SeitenReplacement of Isolation Valves by Hot Tap WorksAlexis Pacheco100% (1)

- Quality Control Procedure for Hot Tap Tie-inDokument9 SeitenQuality Control Procedure for Hot Tap Tie-inarockiyathassNoch keine Bewertungen

- How to Safely Modify Pipelines and Piping While in OperationDokument28 SeitenHow to Safely Modify Pipelines and Piping While in Operationk dharmaNoch keine Bewertungen

- Msog-M1402-P-Rp-006 Rev 1Dokument44 SeitenMsog-M1402-P-Rp-006 Rev 1Mohd Nazir NorlanNoch keine Bewertungen

- STOPPLE / HOT TAPPING Method of StatementDokument9 SeitenSTOPPLE / HOT TAPPING Method of StatementLoaloat Shat AlarabNoch keine Bewertungen

- Psp-Koti-19 - Hot Tapping Procedure - Rev 0Dokument14 SeitenPsp-Koti-19 - Hot Tapping Procedure - Rev 0cheehoong82Noch keine Bewertungen

- Hot Tapping GuideDokument3 SeitenHot Tapping GuidegshdavidNoch keine Bewertungen

- PDVSA Engineering Guide for Hot TappingDokument13 SeitenPDVSA Engineering Guide for Hot TappingJosmag JatemNoch keine Bewertungen

- 35 Hot TappingDokument5 Seiten35 Hot TappingS Anantha Prasanna Venkatesh83% (6)

- SAUDI ARAMCO WELDING PROCEDURE SPECIFICATIONS FOR HOT TAP PIPINGDokument3 SeitenSAUDI ARAMCO WELDING PROCEDURE SPECIFICATIONS FOR HOT TAP PIPINGarockiyathass100% (10)

- 008 - Field Hydrotest ProcedureDokument17 Seiten008 - Field Hydrotest Procedurekaruna346100% (2)

- Hot Tapping '08Dokument85 SeitenHot Tapping '08Mariela Carrillo100% (4)

- Natural Gas Hot Tap Connections Reduce LossesDokument12 SeitenNatural Gas Hot Tap Connections Reduce LossesSmith JasonNoch keine Bewertungen

- Hydratight Hot Tap ProcedureDokument39 SeitenHydratight Hot Tap Proceduremitesh0% (1)

- Hot Tapping CalculationsDokument19 SeitenHot Tapping Calculationsna270791dia100% (1)

- Hot Tap OperationDokument23 SeitenHot Tap OperationAmresh Kumar100% (1)

- Pipeline Welding SpecificationDokument31 SeitenPipeline Welding SpecificationAnonymous hBBam1nNoch keine Bewertungen

- Method Statement For Hot Tapping Rev 0Dokument9 SeitenMethod Statement For Hot Tapping Rev 0Thomas100% (4)

- Hottap - SPC (Specification For Hot Tapping)Dokument14 SeitenHottap - SPC (Specification For Hot Tapping)Hector MejiaNoch keine Bewertungen

- Hydrotest ProcedureDokument3 SeitenHydrotest Procedureaman131100% (2)

- Welding Procedure Specification for Hot Tap WeldingDokument6 SeitenWelding Procedure Specification for Hot Tap WeldingOgbonde100% (1)

- Hot Taps & Line Stops: Industrial ServicesDokument18 SeitenHot Taps & Line Stops: Industrial Servicespapinayak5698100% (1)

- Test Pack Table of ContentsDokument1 SeiteTest Pack Table of ContentsRavindra S. JivaniNoch keine Bewertungen

- Execution Procedure For Pipe Connection Tie in and Hot TapzDokument7 SeitenExecution Procedure For Pipe Connection Tie in and Hot TapzyuwantoniNoch keine Bewertungen

- How To Proceed For A Hot TapDokument16 SeitenHow To Proceed For A Hot TapThamaraikani ManiNoch keine Bewertungen

- Hot Tap ProcedureDokument6 SeitenHot Tap ProcedureNatarajan MurugesanNoch keine Bewertungen

- ASME Temporary Repairs 101410-1Dokument41 SeitenASME Temporary Repairs 101410-1khanz88_rulz1039Noch keine Bewertungen

- Hot Tap Tool ManualDokument23 SeitenHot Tap Tool ManualEliseo Porcel HuayraNoch keine Bewertungen

- Procedure - Hot TappingDokument6 SeitenProcedure - Hot Tappingmanimaran_ratnam100% (4)

- PIPING PNEUMATIC TEST PROCEDUREDokument2 SeitenPIPING PNEUMATIC TEST PROCEDUREruzla67% (3)

- Hot Taps Reduce EmissionsDokument17 SeitenHot Taps Reduce EmissionsJose Maluenda100% (1)

- Fire Protection Pipes Method Statement PDFDokument16 SeitenFire Protection Pipes Method Statement PDFفاعل خيرNoch keine Bewertungen

- Hot Tapping Scope of WorkDokument3 SeitenHot Tapping Scope of WorkSukhen Das50% (2)

- Erection of Piping Method StatementDokument11 SeitenErection of Piping Method StatementMalik Riaz50% (2)

- Sample Hot Tap Construction Schedule PDFDokument1 SeiteSample Hot Tap Construction Schedule PDFrajkamal eshwarNoch keine Bewertungen

- FInal QAP HDPE WeldingDokument2 SeitenFInal QAP HDPE Weldingkannagi198Noch keine Bewertungen

- Piping Fabrication ProcedureDokument11 SeitenPiping Fabrication ProcedureMohammed Elsaid Yousef Harhera100% (2)

- Replacing a Needle Valve with a Globe ValveDokument7 SeitenReplacing a Needle Valve with a Globe ValveKamarularifin Kamel100% (2)

- WPS-PQR For Split TeeDokument9 SeitenWPS-PQR For Split TeemaheshmalaichamyNoch keine Bewertungen

- 002 016 1 PDFDokument15 Seiten002 016 1 PDFaepriyadiNoch keine Bewertungen

- RCCE Hot Tapping ProcedureDokument13 SeitenRCCE Hot Tapping ProcedureMSNoch keine Bewertungen

- Safety Information Bulletin: Sb05-02 Subject: Putting Public Safety FirstDokument3 SeitenSafety Information Bulletin: Sb05-02 Subject: Putting Public Safety FirstMSNoch keine Bewertungen

- 029 Hot Tap Procedure 0011Dokument5 Seiten029 Hot Tap Procedure 0011Fadlul Akbar HerfiantoNoch keine Bewertungen

- Hot Tap Form Proposed SignatoriesDokument43 SeitenHot Tap Form Proposed SignatoriesSongAn BuiNoch keine Bewertungen

- Page:3 of 15: 12/29/2018 Controlled Document-24 Hrs - Uncontrolled ThereafterDokument1 SeitePage:3 of 15: 12/29/2018 Controlled Document-24 Hrs - Uncontrolled ThereafterestudiemosNoch keine Bewertungen

- Pressure Testing of Pipelines: CR Asia GroupDokument7 SeitenPressure Testing of Pipelines: CR Asia Groupvishal bailurNoch keine Bewertungen

- Requirements in Executing A Hot Tap - ION PRODokument25 SeitenRequirements in Executing A Hot Tap - ION PROHous BoukadoNoch keine Bewertungen

- Taping and Chilled Water Pipe InstallationDokument13 SeitenTaping and Chilled Water Pipe InstallationProject enghvacNoch keine Bewertungen

- Pec WP SWP 0006r0 Hot Tap PolicyDokument5 SeitenPec WP SWP 0006r0 Hot Tap PolicyvuongNoch keine Bewertungen

- Page:2 of 15: 12/29/2018 Controlled Document-24 Hrs - Uncontrolled ThereafterDokument1 SeitePage:2 of 15: 12/29/2018 Controlled Document-24 Hrs - Uncontrolled ThereafterestudiemosNoch keine Bewertungen

- Hydro TestDokument12 SeitenHydro TestEndika Alfan100% (2)

- Method Statement For Hot TappingDokument13 SeitenMethod Statement For Hot TappingAmb Patrick OghateNoch keine Bewertungen

- Work Instruction On Tube ExpansionDokument40 SeitenWork Instruction On Tube Expansionjayaarnav100% (1)

- Race To 5GDokument16 SeitenRace To 5Gghkashyap1Noch keine Bewertungen

- AP Feasibility StudyDokument176 SeitenAP Feasibility Studyghkashyap1Noch keine Bewertungen

- AppBreweryCornellNotesTemplate PDFDokument2 SeitenAppBreweryCornellNotesTemplate PDFghkashyap1Noch keine Bewertungen

- AVEVA Everything3D: The Most Advanced and Powerful 3D Design SolutionDokument8 SeitenAVEVA Everything3D: The Most Advanced and Powerful 3D Design SolutionQUALITY12Noch keine Bewertungen

- Water Hammer Effect - Caesar II Case StudyDokument35 SeitenWater Hammer Effect - Caesar II Case Studyghkashyap1Noch keine Bewertungen

- Advanced Kanban Overview: Top 5 TopicsDokument26 SeitenAdvanced Kanban Overview: Top 5 Topicsghkashyap1Noch keine Bewertungen

- ConflictDokument6 SeitenConflictapi-306437258Noch keine Bewertungen

- AP Feasibility StudyDokument176 SeitenAP Feasibility Studyghkashyap1Noch keine Bewertungen

- Stress SystemsDokument1 SeiteStress Systemsghkashyap1Noch keine Bewertungen

- KPMGDokument6 SeitenKPMGghkashyap1Noch keine Bewertungen

- WRC 107, WRC 297 Co MP PDFDokument11 SeitenWRC 107, WRC 297 Co MP PDFkarthickmectr100% (2)

- Skylite Vesta TruePrice EstimateDokument2 SeitenSkylite Vesta TruePrice Estimateghkashyap1Noch keine Bewertungen

- CompressorDokument194 SeitenCompressorghkashyap1100% (1)

- Energize Your Career with MBA in Oil & GasDokument2 SeitenEnergize Your Career with MBA in Oil & Gasghkashyap1Noch keine Bewertungen

- GRP Piping - Stress AnalysisDokument5 SeitenGRP Piping - Stress Analysisghkashyap1Noch keine Bewertungen

- Eaajeevan Sampatti Plus BrochureDokument16 SeitenEaajeevan Sampatti Plus Brochureghkashyap1Noch keine Bewertungen

- Steam Tracing Excel 2007Dokument74 SeitenSteam Tracing Excel 2007mani170487Noch keine Bewertungen

- Pipe RoutDokument10 SeitenPipe Routghkashyap1Noch keine Bewertungen

- Engineering TalkDokument19 SeitenEngineering Talkghkashyap1Noch keine Bewertungen

- Pipe RoutDokument10 SeitenPipe Routghkashyap1Noch keine Bewertungen

- Pipe Stress Analysis Information For FRPDokument10 SeitenPipe Stress Analysis Information For FRPchemy5Noch keine Bewertungen

- Pipe RoutDokument10 SeitenPipe Routghkashyap1Noch keine Bewertungen

- API 582 The Welding Solution PDFDokument21 SeitenAPI 582 The Welding Solution PDFRemmy Torres Vega75% (8)

- HmuDokument7 SeitenHmughkashyap1Noch keine Bewertungen

- API 582 The Welding Solution PDFDokument21 SeitenAPI 582 The Welding Solution PDFRemmy Torres Vega75% (8)

- Distillation Column PipingDokument57 SeitenDistillation Column PipingKaran Singh92% (13)

- Techincal JournalDokument20 SeitenTechincal Journalghkashyap1100% (1)

- Load CasesDokument8 SeitenLoad Casestebodin_319100% (1)

- Water Treatment Table Effectiveness GuideDokument2 SeitenWater Treatment Table Effectiveness Guideghkashyap1Noch keine Bewertungen

- Higuey, Dom Rep Mdpc/Puj: .Eff.23.MayDokument5 SeitenHiguey, Dom Rep Mdpc/Puj: .Eff.23.MayVanessa Yumayusa0% (1)

- Effects of Climate Change and Global WarmingDokument14 SeitenEffects of Climate Change and Global WarmingSwetal SosaNoch keine Bewertungen

- Quickscan™ Lite Qw2100: Multi-Purpose Uses For Different ApplicationsDokument2 SeitenQuickscan™ Lite Qw2100: Multi-Purpose Uses For Different ApplicationsHaythem BchirNoch keine Bewertungen

- Transactional Analysis (TA)Dokument21 SeitenTransactional Analysis (TA)Rohan TandonNoch keine Bewertungen

- RICKETSDokument23 SeitenRICKETSDewi SofyanaNoch keine Bewertungen

- ABS and Air Conditioner Wiring DiagramDokument207 SeitenABS and Air Conditioner Wiring Diagramservice_00783% (30)

- Modified Micro Marsupialization in Pediatric Patients: A Minimally Invasive TechniqueDokument4 SeitenModified Micro Marsupialization in Pediatric Patients: A Minimally Invasive TechniquerinahpsNoch keine Bewertungen

- Pub - New Directions in Progressive Relaxation TrainingDokument176 SeitenPub - New Directions in Progressive Relaxation TrainingRafael Bagus100% (1)

- Krisbow KW06-291 PDFDokument1 SeiteKrisbow KW06-291 PDFBoyke WinterbergNoch keine Bewertungen

- Solarizer Value, Spring & UltraDokument4 SeitenSolarizer Value, Spring & UltraEmmvee SolarNoch keine Bewertungen

- Data SheetDokument15 SeitenData SheetLucian Sorin BortosuNoch keine Bewertungen

- Govt Schemes - 1 MWCD MOSJEDokument36 SeitenGovt Schemes - 1 MWCD MOSJEshaheen razaNoch keine Bewertungen

- Certificate of Analysis: Ship Date: Port of Discharge: Carrier: Vessel: Voyage: Quantity (MT) : Us GallonsDokument1 SeiteCertificate of Analysis: Ship Date: Port of Discharge: Carrier: Vessel: Voyage: Quantity (MT) : Us GallonsMercadeo BelaraviNoch keine Bewertungen

- Pronunciation Pairs Unit 2-6 Answer KeyDokument5 SeitenPronunciation Pairs Unit 2-6 Answer KeyChloe Liu50% (2)

- 1 s2.0 S2667345222000104 MainDokument19 Seiten1 s2.0 S2667345222000104 MainJosiah MwashitaNoch keine Bewertungen

- Energy Certification of Buildings and Nearly Zero-Energy BuildingsDokument70 SeitenEnergy Certification of Buildings and Nearly Zero-Energy BuildingsOgnjen BobicicNoch keine Bewertungen

- Manufacturing ProcessDokument6 SeitenManufacturing Processbro nawalibmatNoch keine Bewertungen

- Mr. Tieu Dat's English Academy Practice TestDokument16 SeitenMr. Tieu Dat's English Academy Practice TestĐỗ Nhật QuangNoch keine Bewertungen

- Distance Protection SchemesDokument10 SeitenDistance Protection SchemesdebasishNoch keine Bewertungen

- A7V Variable Displacement PumpDokument22 SeitenA7V Variable Displacement PumpEduardo CramerNoch keine Bewertungen

- Redraw Rod For Multiwire DrawingDokument6 SeitenRedraw Rod For Multiwire DrawingWajeeh BitarNoch keine Bewertungen

- HawkeyeDokument12 SeitenHawkeyeJanardhanam VaratharajanNoch keine Bewertungen

- Geoheritage of Labuan Island: Bulletin of The Geological Society of Malaysia December 2016Dokument14 SeitenGeoheritage of Labuan Island: Bulletin of The Geological Society of Malaysia December 2016songkkNoch keine Bewertungen

- Proposed Rule: Airworthiness Directives: Bell Helicopter Textron CanadaDokument3 SeitenProposed Rule: Airworthiness Directives: Bell Helicopter Textron CanadaJustia.comNoch keine Bewertungen

- Usos HummusDokument36 SeitenUsos HummusAlisson FernandaNoch keine Bewertungen

- Chemical Equation CalculationsDokument6 SeitenChemical Equation CalculationsHera RiegoNoch keine Bewertungen

- Effects of Climate ChangeDokument10 SeitenEffects of Climate ChangeJan100% (1)

- Ten Laws of BoundariesDokument17 SeitenTen Laws of Boundariesstjohn30067% (3)

- Postnatal Care, Complaints & AbnormalitiesDokument38 SeitenPostnatal Care, Complaints & AbnormalitiesBernice GyapongNoch keine Bewertungen

- 7220 Instrucciones de Intalacion PDFDokument2 Seiten7220 Instrucciones de Intalacion PDFAttackDenied123Noch keine Bewertungen