Beruflich Dokumente

Kultur Dokumente

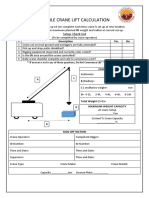

Lift Plan

Hochgeladen von

veeru280Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lift Plan

Hochgeladen von

veeru280Copyright:

Verfügbare Formate

In accordance with BS7121

1. Introduction

2. Management of lifting operations

3. Selection and duties of personnel

4. Procedures and precautions

5. Slinging and handling of loads

6. Lifting equipment

. !is" #ssessment

$. Lifting #ssessment

%. Schedule of common lifts

1&.!ecord of lifting appliances and accessories

11.'rane (eam appointment and certification

Contents

In order to pro)ide a safe s*stem of +or" and to ensure compliance +ith

current legislation this site lifting plan has ,een de)eloped and is to ,e

implemented ,* e)er* mem,er of the crane team in)ol)ed +ith this pro-ect.

#lthough not e.hausti)e the follo+ing regulations must ,e adhered to/

(he Lifting 0perations and Lifting 1quipment !egulations %$ 2L0L1!3

(he Pro)ision and 4se of 5or" 1quipment !egulations %$ 2P451!3

(he management of health and safet* regulations 1%%%

It is )ital that all lifting operations are properl* planned ,* a competent

person and that the plan is follo+ed ,* e)er*one in)ol)ed in the operation.

(his plan is to ,e read ,* all team mem,ers in)ol)ed in lifting operations6

this must ,e done prior to an* lifting ,eing carried out.

It is essential that all team mem,ers are full* competent and certified to

carr* out their indi)idual roles. 2See section 133

It is essential that all team mem,ers are confident that the* can fulfil their

duties especiall* +hen +or"s ma* need to ,e carried out at height.

INTRODUCTION

Safe s*stem of +or"

5hether the lifting operations are repetiti)e or if the* are a one off7 a safe

s*stem of +or" must ,e esta,lished and follo+ed for the operation to ,e

,oth safe and successful.

In order to pro)ide a safe s*stem of +or" the follo+ing items are to ,e

included in the lift plan 8 #ssessment/

(he selection of suita,le cranes and +or" equipment must ,e carried out.

# crane team is to ,e emplo*ed +ho are full* trained and competent and

+ho ha)e had their roles and responsi,ilities clearl* e.plained to them.

(he areas for the cranes access and rigging etc must ,e properl* planned

and properl* prepared.

# regime of maintenance7 testing and e.amination of equipment must ,e

de)ised.

#ll certification7 reports of thorough e.amination and other documents

including manufacturer9s manuals are to ,e retained and ,e a)aila,le.

It is essential that all personnel can communicate clearl* in the same

language.

Management of lifting operations

5hen appointing a crane team it is essential that all the mem,ers of that

team are full* a+are of the role and duties and that each person has

sufficient "no+ledge7 training and e.perience to carr* out their role.

!ecords of training and e.perience are to ,e )erified prior to an* ne+

mem,er -oining the crane team and their details are to ,e retained in the site

file.

(he crane team organisation chart is sho+n ,elo+ and roles and duties are

continued ,eneath.

#ppointed Person

'rane Super)isor

'rane 'o:ordinator

'rane 0perator

Slinger8Signaller

Selection and duties of personnel

Appointed Person

(he appointed person9s duties are to include the follo+ing6

;eing familiar +ith the rele)ant parts of the pro-ect <ealth and

Safet* Plan +here lifting operations are to ,e carried out on a site

+here '=M regulations appl*.

#ssess the lifting operations to pro)ide such planning7 selection of

cranes7 lifting accessories and equipment7 instruction and super)ision

as is necessar* for the tas" to ,e underta"en safel*. 2+here +or"s are

on a shared site or +here logistics ma* ,e restricti)e co:ordination

+ith others +ill ,e required3

1nsure that adequate inspection 8 e.amination and maintenance of

the equipment ha)e ,een carried out prior to its use.

1sta,lish an effecti)e procedure for reporting defects and incidents

and ta"ing necessar* correcti)e action.

(a"es responsi,ilit* for the organisation and control of the lifting

operation.

1nsure the crane super)isor is full* ,riefed in the contents of the lift

plan 8 method statement etc.

(he appointed person is a,le to delegate his duties to another person ,ut the

responsi,ilities still remain the appointed persons.

Crane Supervisor

(he crane super)isor role is to direct and super)ise the lifting operation and

ensure that these are carried out in accordance +ith the rele)ant method

statement 8 lift plan.

(he crane super)isor should ,e competent and suita,l* trained and must ,e

e.perienced to carr* out all rele)ant duties.

(he crane super)isor has authorit* to stop the lifting operation if he

considers it dangerous to proceed.

This role can be carried out by the appointed person or may be delegated to someone with appropriate

expertise in lifting operations.

Crane Co-ordinator

(he crane co:ordinator9s role is to plan and direct the sequence of

operations of the cranes to ensure the* do not collide +ith other cranes7

loads and other equipment and ,uildings.

This role can be carried out by a competent person with knowledge and experience in lifting operations.

Crane Operator

(he crane operator is responsi,le for the correct operation of the crane in

accordance +ith the manufacturer9s instructions and +ithin the safe s*stem

of +or".

(he crane operator is to respond to a single slinger 8 signaller at an* gi)en

time and these must ,e identifia,le to the operator.

Should an* person near a lifting operation gi)e the recognised stop signal

the operator must cease lifting operations immediatel* and confirm +hat

actions are required from the slinger 8 signaller.

(he crane operator must report an* defects to the appointed person

immediatel*. 2(he dri)er ma* report defects etc direct to the fitters etc ,ut

the appointed person must still ,e made a+are of this action3

Slinger Signaller

(he slinger 8 signaller is responsi,le for the attaching and detaching of

loads to and from the crane load lifting attachment and ensuring that the

correct accessories are used for that operation in accordance +ith the

planning of the operation.

(he slinger 8 signaller is responsi,le for the safe mo)ement of the crane and

clear direction must ,e gi)en +hether )isual or hand signals.

5here more than one slinger 8 signaller is required7 clear instruction must

,e gi)en +hen passing responsi,ilit* o)er to the ne.t slinger 8 signaller.

(he slinger 8 signaller is to store lifting accessories in a suita,le place +hen

not ,eing used and prior to re:using an accessor* he must )isuall* inspect it

,efore use.

(he slinger 8 signaller must notif* the appointed person of an* damaged

equipment immediatel*.

Procedures and Precautions

Crane Operation

5hene)er a crane is to ,e mo)ed 2e)en if not lifting3 it is to ,e dri)en ,* a

competent operator nominated ,* the appointed person.

(he crane must onl* ,e operated under a safe s*stem of +or" and +ithin

the manufacturer9s instructions.

5hen the da*s operations are completed and the crane is >par"ed? the

operator must put the crane in out of ser)ice position and set the ,loc" at

minimum radius 2mo,ile cranes37 25@ radius 2Luffing cranes37 ma.imum

radius 2Saddle -i, cranes3.2see manufacturers specifications3

(he ca,in must ,e secured at the end of the shift and +here there is a ris"

of intruders or protesters a loc"a,le trap door +ill ,e required for to+er

cranes.

!egular inspections of the crane are to ,e carried out and this must ,e

recorded +ee"l* in the site office.

Inspection and Maintenance

5here there is a requirement for a person to clim, the mast of a crane

+hilst the crane is still operational the dri)er must ,e made a+are of

someone clim,ing ,efore the* commence.

#n* tools or equipment needed to ,e used must ,e secure and free from

ris" of falling and if tools are to ,e lifted up using the crane the* must ,e

done so using equipment designed for that tas".

# regime of monitoring and e.amination is to ,e esta,lished ,* the

appointed person this must include a schedule of ser)icing for cranes and

generators etc.

In order to maintain production it ma* ,e necessar* to carr* out

maintenance outside normal +or"ing hours.

Ot!er cranes plant "uildings

5here there are other cranes on the same site and there is a ris" of

collision7 a crash radio s*stem is to ,e esta,lished and ,e used. (his +ill ,e

determined ,* the lifting assessment.

#n* other plant 20ther cranes7 'oncrete ;ooms7 Piling !igs etc3 that ma*

,e +or"ing +ithin the radius of a crane7 their operator must ,e made a+are

of such ris"s and a s*stem must ,e put in place to control their mo)ements

2this ma* ,e )ia the crash radio or a permit to +or" s*stem3

5here e.isting ,uildings are situated +ithin the cranes radius specific

control measures must ,e put in place 2these +ill ,e determined in the ris"

assessments3

Signalling

5here a)aila,le the recognised hand signals +ill ,e adopted and a cop* of

those is attached.

5here hand signals are not suita,le radio contact is to ,e esta,lished and

implemented7 +hen using radio contact the slinger 8 signaller is to gi)e

clear7 concise directions and if unclear the dri)er is to stop all lifting

operations 2If communication is lost during a lift the dri)er is also to stop3

#n* interference on the radio s*stem is to ,e notified to the appointed

person as soon as possi,le.

(he slinger 8 signallers are to ,e identifia,le to the operators and this +ill

,e achie)ed ,* the operati)es +earing orange high )isi,ilit* )ests.

Slinging and !andling loads

It is essential that the +eight of the load to ,e lifted is "no+n to a

reasona,le accurac* and this can ,e determined a num,er of +a*s

1. 'hec" for S5L mar"ings

2. Phone the manufacturer

3. !un o)er a +eigh ,ridge

4. 'alculate

If +eights are to ,e calculated the follo+ing figures should ,e used6

Material AB8M

3

;ric" 21&&

'oncrete 24&&

1arth 16&&

Iron and Steel &&

Lead 112&&

5ater 1&&&

5ood $&&

#dditional allo+ances must ,e made if materials are +et or ha)e ,een

soa"ed this can )ar* su,stantiall*.

Lifting loads

0nce the slinger has secured a load it must ,e raised 15&mm and the load is

to ,e re:chec"ed for sta,ilit*.

0nce the slinger 8 signaler is assured of the sta,ilit* of the load he +ill gi)e

direction to the crane operator to proceed +ith the lift.

5here possi,le the direction of tra)el +ill ,e the shortest direction and +ill

,e a+a* from +here operati)e are +or"ing ,eneath. If this is not possi,le

the slinger signaler is to +arn operati)es of loads a,o)e. 0n multi:crane

sites7 this is to ,e addressed to all site +or"ers during their site induction.

Loads must ne)er ,e dragged as the cranes are onl* designed to lift in a

)ertical plane and there a possi,ilit* of damage to the crane.

#ifting $%uipment

0nl* slings and other lifting accessories for +hich a )alid report of

thorough e.amination has ,een issued +ithin the pre)ious 6 months are to

,e used.

Lifting accessories should ,e clearl* mar"ed +ith the rated capacit* and

ha)e an identification num,er for record purposes.

Lifting equipment must ,e )isuall* inspected ,efore use +ith an* defects

,eing reported immediatel*.

5hen lifting equipment is not ,eing used it should ,e stored in secure dr*

conditions7 prefera,l* ,* hanging on a rac" +here the* cannot get tangled

or contaminated.

'hain sling capa,ilities

(here is a misconception regarding the capa,ilit* of chain slings and ,elo+

is a simple guide ta"en from the Auple. ,rochure.

4sing the chains at different angles and hitching the chains results in a

reduction of the +or"ing a,ilit* of the chain sling and e.amples are sho+n

,elo+

Ris& Assessment

'a(ard Ris&s Control Measures

Plant and Machiner* In-ur* to personnel #ll plant and machiner*

to ,e inspected and

ser)iced regularl* as per

P451! and L0L1!

!egulations

# maintenance and

ser)ice schedule is to ,e

esta,lished and

implemented.

Cailure of lifting

equipment

=amage to

,uildings8equipment

and in-ur*8death to

personnel

#ll lifting equipment is

to certificated and

inspected regularl* as

per L0L1! !egulations

# cop* of certification

is to ,e retained on site

for record "eeping and

reference.

Slinger 8 Signaller to

carr* out )isual

inspection prior to use

Calling Materials =amage to

,uildings8equipment

and in-ur*8death to

personnel

#ll lifts are to ,e carried

out ,* competent

trained

slinger8signallers

#ll lifts are to ,e carried

out as directed in the

lifting assessments and

schedule of common

lifts

Cree falling loads =amage to

,uildings8equipment

and in-ur*8death to

personnel

=ail* inspections and

chec"s are to ,e made

,* the crane operator to

ensure that the crane is

safe and opera,le

<ea)* loads Cailure of lifting

equipment and

machiner*

Disual assessments are

to ,e made ,*

competent personnel to

ensure the correct lifting

equipment is used for

the lift and that the

crane is a,le to lift the

+eight of the load at the

required radius

#ll lifts are to ,e carried

out as directed in the

lifting assessments and

schedule of common

lifts

<igh 5inds Insta,ilit* and loss of

control of lifting

operation

5ind speeds +ithin the

site area are to ,e

monitored and all lifting

operations are to ,e in

strict conditions of the

;eafort +ind speed

allo+ances as laid do+n

for the restrictions of

safe use of cranes in

high +ind and +ind

conditions.

4nscheduled 8 Eon

competent lifts

=amage to

,uildings8equipment

and in-ur*8death to

personnel

Eo unauthorised

persons are to carr* out

an* lifting operations7

all operati)es are to

sho+ proof of their

competenc* prior to

emplo*ment.

# lifting assessment is

to ,e carried out prior to

an* unique or special

lifts ,eing carried out.

'lose pro.imit* of

cranes8,uilding8pu,lic

amenities

1ntanglement leading to

loss of integrit* of load

# safe s*stem of +or"

is to ,e instigated

ensuring the ris" of

collision is eradicated.

(his ma* ,e a crash

radio s*stem or a

Foning s*stem fitted to

the crane.

Sleeping or dead cranes. 'ollision of cranes #s a,o)e

#SS1SS1= ;GHHHHHHHHH..=#(1HHHHHH..

IDENTIFICATION AND ASSESSMENT OF LIFTING OPERATIONS

* Change as per site requirements Issue No.:

Date:

Operation * Items to be

Lifted

Max

Weight

Crane Used Lifted From Lifted To Equipment

Used

Comments

Site SetUp offi!es We"fare

fa!i"ities

#$%t Mobi"e Crane

&'ired in(

)e"i*er+ ,ehi!"es

-On Site-

Fina" position

as per site

"a+out p"an

. "eg /0t !hains

. no$ 1t sha!2"es

Sur*e+ required of site ground

!onditions prior to !rane setup$

Crane Coordinator and

S"inger3Signa""er to be in

attendan!e$ Chains 4 sha!2"es to

be hired 5ith !rane$

6i"ing 7und"es of

8einfor!ement

8einfor!ement

!ages

#t

/$%t

9"" Cranes )e"i*er+ ,ehi!"es

Site position Fina" position

. "eg :$;t !hains

. Leg :t !hains

Cho2e 5rapped using # "egs

Lifting points to be !"ear"+ defined

in method statement $

8etaining

Wa""s

7und"es of

reinfor!ement

8$M$)

Shutters

Con!rete b+ S2ip

#t

#$%t

1t 3 :$%t

Mobi"e 3 to5er

Mobi"e 3 To5er

Mobi"e 3 To5er

)e"i*er+ ,ehi!"es

6reparation area

9reas bet5een

9reas bet5een

Fina" position

Wa"" Shutters

# "eg :t !hains

8$M$) "ifting

de*i!es and #

"eg :t !hains

<t )rop Chain

Cho2e 5rapped using # "egs

9ppro*a" required for 8 M )

s+stem *ia Temp Wor2 pro!edure

C Frame$

Ensure there are no "oops or 2nots

in operating "ine$ =eep tag "ines as

short as pra!ti!ab"e$

Main Frame

Stee"5or2

Co"umns>

beams> bra!ing

?ot +et

2no5n

To be ad*ised )e"i*er+ *ehi!"es Fina" position To be !onfirmed

prior to

!ommen!ement

9"" off"oading to be !arried out

5ithin site boundaries$

IDENTIFICATION AND ASSESSMENT OF LIFTING OPERATIONS

Operation * Items to be

Lifted

Max

Weight

Crane Used Lifted From Lifted To Equipment

Used

Comments

6"ant and

ma!hiner+

Compressors

5ater bo5sers

1$0 t 9"" Cranes Site "o!ation Fina" position . "eg :$;t !hains 6"ant and ma!hiner+ to be "ifted b+

their designated "ifting points on"+$

S"inger Signa""er to be in

attendan!e$

To5er

Crane 7ase

To5er Crane

7ase

%t Mobi"e 3 To5er

Crane 3 Cra5"er

)e"i*er+ *ehi!"e Fina" position . "eg :$;t !hains Lifting points to be !"ear"+ defined

in the method statement and

appro*ed b+ 6rin!ipa" Contra!tor

7und"es of

Timber

Shoring #$%t 9"" !ranes )e"i*er+ *ehi!"e Fina" position . "eg :$;t !hains S"inger signa""er to be in

attendan!e$

Co"umns 8einfor!ed

!ages

Shuttering

Con!rete S2ip

/$%t

/t

/t @ :$%t

9"" Cranes Site Lo!ations Fina" 6osition . "eg :$;t Chains

. "eg :$;t !hains

<t drop !hain

S"inger Signa""er to be in

attendan!e

* as itemised in wors !ro"ramme Issue No.:

Date:

IDENTIFICATION AND INITIAL ASSESSMENT OF LIFTING OPERATIONS

Operation * Items to be

Lifted

Max

Weight

Crane Used Lifted From Lifted To Equipment

Used

Comments

Wa""s 8einfor!ed

!ages

Shuttering

Con!rete S2ip

/$%t

/t

/t :$%t

9"" !ranes Site "o!ations Fina" position . "eg :$;t !hains S"inger signa""er to be in

attendan!e$

Stri2ing

5a""s and

!o"umns

Shuttering /t 9"" !ranes Site "o!ations Fina" position . "eg :$; t !hains S"inger signa""er to be in

attendan!e$

Around

Wor2s

7oat s2ip . t 9"" Cranes Site "o!ations Fina" position # "egs pro*iding

the+ are of

suffi!ient

!apa!it+ or <t

drop !hain$

* as itemised in wors !ro"ramme Issue No.:

Date:

SC#ED$LE OF COMMON LIFTS

Load Met%od

Con!rete or mu!2 s2ip$ S2ip !hain <t

Ensure that an+ rope fixed to s2ip is of

singu"ar !onstru!tion and is free of a""

2nots and "oops$

7oat S2ip 38o""o*er s2ip S2ip !hain <t

7und"es of tubes> bars or other simi"ar materia"s>

e$g$$ s!affo"d tubes> bars> sma"" diameter pipes>

"engths of timber> et!$ @ w%et%er &anded or not$

. "eg :$;t !hains> "oad to be doub"e

5rapped using # "egs of the !hains

8einfor!ement 7ar Wrapped . "eg !hain s"ings$ Ensure

that bars to be "ifted are of equa"

"ength

F"+ing Tab"e 6"atforms Four "eg !hains passed through pre

prepared ho"es on top of p"atform and

5rapped around upper p"atform a"ums

or stee" supports$ Use C frame 5here

possib"e$

6a""etised materia"s$ Crane for2s 5ith !age or net$ For2 Lift

Tru!2$

Web S"ings 5i"" be used for pa""etised

materia"

Sti""ages . "eg !hain s"ings 5rapped around

!orner posts as per Auide to Safe

S"inging and Signa""ing

'eware rusted &ase. For2 Lift Tru!2$

Lorr+ t+pe rubbish s2ips$ Must be tested and !ertified if "ifting

"ugs are used or

5ith stee" box se!tions under s2ip and

spreaders

'eware o( rusted ()oors*o+er)oaded

si!s$

Wood 7und"es Wrapped 5ith . "eg !hain s"ings$

Ensure 5ood to be "ifted is of equa"

"ength and bites are in p"a!e$

Co"umn shutters Chain to be atta!hed to "ifting e+es

and ensure that the "ifting operation is

!ondu!ted 5ithin safe 5ind speeds as

per L$O$L$E$8 8EAS$

SC#ED$LE OF COMMON LIFTS

Load Met%od

Sma"" p"ant ie !ompressors> bo5sers et! Chains to be atta!hed to !ertified

"ifting e+es on"+ <t drop !hain$

6refab 8e 7ar Cages Chains to be atta!hed to doub"e tied

remo*ab"e thi!2ened re bar spe!ia"

!are must be ta2en to ensure integrit+

of the "oad$

Issue No.: /

Date:

Re,ord o( )i(tin" a!!)ian,es and a,,essories

Li(tin" A!!)ian,es -e.".

Cranes.

)es!ription I) ?o$ Supp"ierB Test Cert$

Expir+ )ateB

/# Month"+

Thorough

Examination

Expir+ )ateB

Used for "ifting personsC

D3?$

&If so> : Month"+

Thorough ExamEnC(

Wee2"+

Inspe!tions

!arried out b+B

Li(tin" A,,essories -e.". )i(tin" "ear.

)es!ription I) ?o$ O5ner S$W$L &t( Test Certifi!ate

D3?

: Month"+ Thorough Examination D3?C

Expir+ )ate

Issue No.:/0

Date:

Crane team a!!ointment and ,erti(i,ation

Position Name Date A!!ointed

A!!ointed Person*

-Li(tin" O!erations.

De!ut1 a!!ointed

Person

Crane Co2ordinator

Crane O!erators*

Si"na))ers*S)in"ers*

* Must ho"d appropriate C6CS Cards

Issue

No.:

/0

Date:

Das könnte Ihnen auch gefallen

- Lift Plan 2Dokument26 SeitenLift Plan 2Mukesh Katarnavare100% (1)

- Lift PlanDokument25 SeitenLift Plansea_man100% (1)

- Safe Use of Cranes: Site Lifting PlanDokument25 SeitenSafe Use of Cranes: Site Lifting PlanDimitar Levski100% (2)

- Safe Use of Cranes: Site Lifting PlanDokument26 SeitenSafe Use of Cranes: Site Lifting PlanMuhammad BabarNoch keine Bewertungen

- Heavy LiftingDokument8 SeitenHeavy LiftingEncik AhmadNoch keine Bewertungen

- Non Complex Method Statement For OffloadingDokument5 SeitenNon Complex Method Statement For OffloadingDaniel Cryer100% (1)

- Lifting and Supporting Loads, Mobile Equipment Awareness: Ashaka 16Mw CPP Project NigeriaDokument100 SeitenLifting and Supporting Loads, Mobile Equipment Awareness: Ashaka 16Mw CPP Project NigeriaPhilip AdewunmiNoch keine Bewertungen

- LOLER Guidance For Mgr.Dokument16 SeitenLOLER Guidance For Mgr.Cris Suyam100% (1)

- New Microsoft Word DocumentDokument20 SeitenNew Microsoft Word Documentsudeesh kumarNoch keine Bewertungen

- Lift PlanDokument26 SeitenLift PlanVenkadesh PeriathambiNoch keine Bewertungen

- Qcs 2010 Section 11 Part 2.3.10 She Procedures - The Safe Use of CranDokument26 SeitenQcs 2010 Section 11 Part 2.3.10 She Procedures - The Safe Use of Cranbryanpastor106100% (7)

- Guidebook For Lifting Supervisors PDFDokument13 SeitenGuidebook For Lifting Supervisors PDFBeste Ardıç Arslan100% (1)

- Mobile Elevating Work Platforms: AUGUST 2014Dokument64 SeitenMobile Elevating Work Platforms: AUGUST 2014Parmod RanaNoch keine Bewertungen

- Safe Unloading of Cut and BentDokument16 SeitenSafe Unloading of Cut and BentAbhinav SinhaNoch keine Bewertungen

- Rigging and Slinging TechniquesDokument15 SeitenRigging and Slinging TechniquesShiraz Najat100% (2)

- Critical Lift Plan - ChecklistDokument4 SeitenCritical Lift Plan - ChecklistDelia HarsanNoch keine Bewertungen

- Rigging and Lifting ProcedureDokument16 SeitenRigging and Lifting ProcedureGhazi Kallel67% (3)

- Pengenalan CranesDokument55 SeitenPengenalan CranesekoimampNoch keine Bewertungen

- JSA-RHI-ARZ-0-004 ASU - Lifting Works Rev01 - ArzewDokument6 SeitenJSA-RHI-ARZ-0-004 ASU - Lifting Works Rev01 - ArzewUmit KaymakNoch keine Bewertungen

- LIFTING PLAN FOR Foundation and Miscelanious Items Using Telehandler - AUHJ460Dokument16 SeitenLIFTING PLAN FOR Foundation and Miscelanious Items Using Telehandler - AUHJ460Balram Kumar PandeyNoch keine Bewertungen

- Critical Lift Plan For Pile Load Test-2Dokument14 SeitenCritical Lift Plan For Pile Load Test-2sivakumarNoch keine Bewertungen

- TBT Rigging SafetyDokument1 SeiteTBT Rigging SafetyRajendraNoch keine Bewertungen

- Work Method Statement: Wms Rev. NoDokument5 SeitenWork Method Statement: Wms Rev. NoKarthik babu100% (1)

- Sample Lifting Plan 300909Dokument5 SeitenSample Lifting Plan 300909sugiyantoNoch keine Bewertungen

- WMSRA For Loading Unloading of Office Containers and Installation of Office ContainersDokument30 SeitenWMSRA For Loading Unloading of Office Containers and Installation of Office ContainersFurqan AfzalNoch keine Bewertungen

- Lifting Plan For Erection of 2nd To 6th Rev.3Dokument11 SeitenLifting Plan For Erection of 2nd To 6th Rev.3Rhannie GarciaNoch keine Bewertungen

- Lifting Plan: Lifting Appointed Person / Supervisor Site InspectionDokument4 SeitenLifting Plan: Lifting Appointed Person / Supervisor Site Inspectionkhaled redaNoch keine Bewertungen

- ARK JSA Manual Excavation A 3Dokument9 SeitenARK JSA Manual Excavation A 3REMYANoch keine Bewertungen

- Document No: Date: 17-03-12: Method Statement For The Lifting of E & I RoomDokument3 SeitenDocument No: Date: 17-03-12: Method Statement For The Lifting of E & I RoomShaikh Mohd QaisarNoch keine Bewertungen

- Planned Critical Lift Crane PermitDokument5 SeitenPlanned Critical Lift Crane PermitsurnaikNoch keine Bewertungen

- Critical Lift Plan For Overhead Cranes: (Net Load)Dokument6 SeitenCritical Lift Plan For Overhead Cranes: (Net Load)Alex Sandro Borges PereiraNoch keine Bewertungen

- LEEADokument12 SeitenLEEAAmeerUlHaqNoch keine Bewertungen

- HSE-OCP-35 REV 1. Lifting ProcedureDokument7 SeitenHSE-OCP-35 REV 1. Lifting ProcedureibrahimNoch keine Bewertungen

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Dokument3 SeitenKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNoch keine Bewertungen

- Crane Assembly and Dismantling and ModificationDokument1 SeiteCrane Assembly and Dismantling and Modificationsrinibas mohapatraNoch keine Bewertungen

- Sample Lift PlanDokument4 SeitenSample Lift Planikponmwonsa100% (1)

- TBT RiggingDokument2 SeitenTBT RiggingAl DubNoch keine Bewertungen

- Flagman TrainingDokument40 SeitenFlagman TrainingHSE1 SHAMNET100% (1)

- Risk Assessment Lifting OperationsDokument5 SeitenRisk Assessment Lifting OperationsHưng Hoàng Duy100% (1)

- Crane and Lifting TrainingDokument1 SeiteCrane and Lifting TrainingLeonardo RoncettiNoch keine Bewertungen

- Appointed Person: Planning and Regulatory RequirementsDokument6 SeitenAppointed Person: Planning and Regulatory RequirementssamNoch keine Bewertungen

- Lifting Plan For UnloadingDokument5 SeitenLifting Plan For Unloadingkhaled redaNoch keine Bewertungen

- Rigging JSA RiggerDokument12 SeitenRigging JSA RiggeraQiLGunawanNoch keine Bewertungen

- Procedure For Lifting Operations Over Live Process Are AsDokument11 SeitenProcedure For Lifting Operations Over Live Process Are Aszam110Noch keine Bewertungen

- Lift Plan Drawing GCC - Tandem LiftDokument1 SeiteLift Plan Drawing GCC - Tandem LiftBrijesh 'Robin'0% (1)

- Pre Crane Lift ChecklistDokument1 SeitePre Crane Lift ChecklistmiaicarbaNoch keine Bewertungen

- Crane Lifting Calculation SheetDokument1 SeiteCrane Lifting Calculation SheetAkbar Dawood100% (1)

- Lifting Procedure: 1.0 GeneralDokument4 SeitenLifting Procedure: 1.0 GeneralMagdy BakryNoch keine Bewertungen

- Safe Work Method Statement WorksheetDokument5 SeitenSafe Work Method Statement Worksheetgoodspeed_phNoch keine Bewertungen

- Lifting Plan Rev.01: Load Less Than 10 TonDokument19 SeitenLifting Plan Rev.01: Load Less Than 10 Tonsajin100% (1)

- Tips Critical Crane LiftDokument5 SeitenTips Critical Crane LiftSteve John PolandNoch keine Bewertungen

- Rigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Dokument3 SeitenRigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Cleiciane FrancoNoch keine Bewertungen

- HSA MEWPs GuidanceDokument20 SeitenHSA MEWPs GuidancemadmossyNoch keine Bewertungen

- Job Safety Analysis - Civil WorksDokument7 SeitenJob Safety Analysis - Civil WorksMoaatazz Nouisri67% (3)

- JSA For Crawler Crane Installation FormDokument3 SeitenJSA For Crawler Crane Installation FormHu Man88% (8)

- Liting PlansDokument28 SeitenLiting PlansFirdaus Ismail Jr.Noch keine Bewertungen

- Banksman ResponsibilitiesDokument2 SeitenBanksman ResponsibilitiesAnil CNoch keine Bewertungen

- Lift PlanDokument26 SeitenLift Planvinodhyper89% (9)

- Sop LiftingDokument5 SeitenSop LiftingShaiful AnnuarNoch keine Bewertungen

- PMG HouseholdBudget1Dokument1 SeitePMG HouseholdBudget1Fred AlmaNoch keine Bewertungen

- Family Budget (Monthly) 1Dokument11 SeitenFamily Budget (Monthly) 1Fred Alma20% (10)

- Statistics Paper 1: Answer: (A) ..Dokument7 SeitenStatistics Paper 1: Answer: (A) ..P.m. KaruNoch keine Bewertungen

- Physics Trial Papers: NameDokument1 SeitePhysics Trial Papers: NameFred AlmaNoch keine Bewertungen

- Health and Safety Unit Liverpool John Moores University Health and Safety CommitteeDokument7 SeitenHealth and Safety Unit Liverpool John Moores University Health and Safety CommitteeFred AlmaNoch keine Bewertungen

- PHSeptember 2012 Minutes - FinalDokument7 SeitenPHSeptember 2012 Minutes - FinalFred AlmaNoch keine Bewertungen

- February 2011 Minutes-FinalDokument5 SeitenFebruary 2011 Minutes-FinalFred AlmaNoch keine Bewertungen

- February 2010-MinDokument5 SeitenFebruary 2010-MinFred AlmaNoch keine Bewertungen

- DEE EHU-03!5!1 Health and Safety Committee Meeting MinutesDokument2 SeitenDEE EHU-03!5!1 Health and Safety Committee Meeting MinutesFred AlmaNoch keine Bewertungen

- Safety Committee Minutes February 28, 2007 PresentDokument4 SeitenSafety Committee Minutes February 28, 2007 PresentFred AlmaNoch keine Bewertungen