Beruflich Dokumente

Kultur Dokumente

DGS Diagram

Hochgeladen von

Dhanasekaran RCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

DGS Diagram

Hochgeladen von

Dhanasekaran RCopyright:

Verfügbare Formate

DGS

A method using the DGS diagram ( Distance Gain Size) for experessing the high echo from a reflector in terms of the

equivalent height of a disc shaped reflector. This techniquie is one of several methods used for the sizing of effects sometimes

reffered to a DAC/AVG- method (German term)

Sizing Method

Advantage :

Simple go/no- system

Can be applied to different shapes

Disadvantage:

Requires special curves, no indication of vertical extent

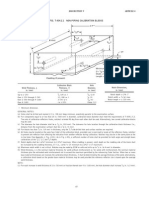

DGS diagram

The regularities of sound propagation in material have been theoretically known

for a long time and were confirmed in practice by numerous experiments. The

development of modern evaluation methods shows two ways. With the reference

block method the characteristic curve of the sound field is always determined

before carrying out an ultrasonic test, whereas in the DGS method DGS diagrams

for probes are applied for this. A DGS diagram shows the echo amplitudes of disk

shaped reflectors with different diameters and those of large, flat reflectors

(backwall) as a function of the distance Fig.1 DGS Diagram.

Procedure

To understand this better, let us start by explaining the sequences for both evaluation methods at this point.

The reference block method requires that a reference block, corresponding to the test object and

containing one or more reference reflectors, be available for the test. The distance dependence of

echo amplitudes is determined experimentally by means of drilled holes in the reference block, the

resulting curve is then transmitted to the screen display of the test instrument (DAC Distance

Amplitude Correction). This curve automatically includes all probe (sound field) and material

effects. The test object can now be scanned with the probe. An indication recording is made when an

echo reaches the DAC curve or exceeds it.

A prerequisite with the DGS method is that the corresponding DGS diagram be available for the

probe used in the test application. The reference gain of the test instrument, with which the reference

echo is at a fixed screen height (reference level), is determined for a specific reflector, i.e. the

reference reflector. After this, the instrument gain is increased by a certain value, i.e. the test

sensitivity is adjusted. If the reference reflector is a circular arc from one of the standardized

calibration blocks, then the instrument gain should be varied in accordance with the correction value

given for the angle beam probe: the amplitude correction value is adjusted. With different surface

qualities between the test object and the calibration block the transfer correction must be determined

experimentally and likewise taken into consideration. The gain difference with regard to the

reference echo is determined for the maximum echo from a detected indication. This is followed by

a graphic determination of the equivalent reflector size using the DGS diagram. If required, the

sound attenuation correction is additionally carried out. This makes it possible to assess whether the

indication is to be recorded or not. Nevertheless, by using the DGS scale it is possible to

significantly simplify evaluation with the DGS method (Fig.2).

Fig. 2 Evaluation using a DGS scale.

In this connection, the inspector uses an attachment scale for the screen of the

ultrasonic instrument. This scale contains one or several ready made recording curves.

The tiresome graphic evaluation with the DGS diagram can thus be omitted. The

inspector can directly assess flaw indications by means of the curve.

A comparison of the test sequences for the reference block method and DGS method shows the pros and

cons in this table.

Pros and cons of the DGS and reference block method

Refernce block methode DGS-method

Pros

The DAC curve contains all test-related

Influences, i.e. no time-consuming

corrections are recuired.

Easy and reliable evaluation.

No reference blocks required.

Cons

Fabrication or procurement of a

suitable reference block.

Recording of a DAC curve for every

test application

Measurement and consideration of different

individual corrections.

Graphic determination of the equivalent reflector size.

Electronic DGS evaluation

The use of microprocessor controlled ultrasonic instruments considerably simplifies both evaluation

methods, resulting in saving of time and higher test reliability. The DGS evaluation now becomes

particularly easy in an ultrasonic instrument like the USN 50 by an optional evaluation program (Fig.3):

Fig.3 The ultrasonic flaw detector USN 50 with DGS display

There are DGS diagrams for 13 standard probes stored in the instrument. However, other

probes can also be programmed on the basis of their parameters and filed in one of the 30 data

sets. A flat bottom hole (disk shaped reflector), side drilled hole or backwall can be selected as reference

reflectors. Owing to the operational concept, the use of the DGS method in the USN 50 is especially easy

and reliable, operating errors by the inspector are largely excluded due to the display of warning messages

on the screen. After the input of all parameters necessary for the flaw evaluation, the corresponding

recording curve is electronically displayed on the instrument screen (Fig.4).

Fig.4 Display contents of the USN 50 with active DGS function

The evaluation program ensures a direct evaluation of a detected indication. All the necessary

corrections are taken into consideration in this respect: exceeding of the recording threshold, i.e. the dB

value by which the flaw indication exceeds the preset recording curve, is directly displayed on the screen.

This type of evaluation meets the practical requirements specified in most of the testing guidelines. For

example, these do not only include e.g. the widely known HP 5/3, DIN 54 125, SEL 072, etc., but also all

other specifications requiring flat bottom holes as reference reflectors.

Das könnte Ihnen auch gefallen

- Calibration Methods and Reference Standards in Ultrasonic TestingDokument4 SeitenCalibration Methods and Reference Standards in Ultrasonic TestingKevin HuangNoch keine Bewertungen

- 8.5 Curved Surface Correction (CSC) - Olympus IMSDokument4 Seiten8.5 Curved Surface Correction (CSC) - Olympus IMSTHIRU.SNoch keine Bewertungen

- 05 Ultrasonic Test Procedure 500405Dokument11 Seiten05 Ultrasonic Test Procedure 500405Sefa KasapogluNoch keine Bewertungen

- High Temperature Ultrasonic ScanningDokument7 SeitenHigh Temperature Ultrasonic ScanningscribdmustaphaNoch keine Bewertungen

- Ultrasonic Testing: NDT Training & CertificationDokument21 SeitenUltrasonic Testing: NDT Training & CertificationMidhun K ChandraboseNoch keine Bewertungen

- Circ-it configured Environmental SpecificationsDokument2 SeitenCirc-it configured Environmental SpecificationsMarcos Kaian Moraes RodriguesNoch keine Bewertungen

- TOFD Interpretation Guide for Flaw Detection and SizingDokument18 SeitenTOFD Interpretation Guide for Flaw Detection and Sizingdaniel20181100% (2)

- MX2 Training Program 09 Displaying DataDokument34 SeitenMX2 Training Program 09 Displaying DataVictor Antonio Diaz FaundezNoch keine Bewertungen

- PA Probe Catalog en 201308Dokument24 SeitenPA Probe Catalog en 201308Alvaro Alexis Mendoza PradaNoch keine Bewertungen

- API UT21 ThicknessProcedure 20190304Dokument7 SeitenAPI UT21 ThicknessProcedure 20190304michaelNoch keine Bewertungen

- ASME Code Case 2600 PDFDokument2 SeitenASME Code Case 2600 PDFrotero_pujolNoch keine Bewertungen

- Lesson 3 - IsO 9712Dokument13 SeitenLesson 3 - IsO 9712Abdelaziz AbdoNoch keine Bewertungen

- Example Report TOFD 2 INT-GP1186!09!70Dokument1 SeiteExample Report TOFD 2 INT-GP1186!09!70EMTC EMTC100% (1)

- Radiograph Interpretation GuideDokument36 SeitenRadiograph Interpretation GuideMaverikbjNoch keine Bewertungen

- Calculate HVL Material Attenuation CoefficientDokument4 SeitenCalculate HVL Material Attenuation CoefficientdanemsalNoch keine Bewertungen

- Corrosion MappingDokument17 SeitenCorrosion MappingJuliog100% (1)

- UTDokument17 SeitenUTArputharaj Maria Louis100% (2)

- 09a-Calibration StepsDokument30 Seiten09a-Calibration StepsLương Hồ Vũ100% (1)

- PA Technical Guidelines Extract - enDokument10 SeitenPA Technical Guidelines Extract - enRizwan Jamil0% (1)

- Ultrasonic Testing Instruction for Butt WeldsDokument4 SeitenUltrasonic Testing Instruction for Butt WeldsIkeNoch keine Bewertungen

- Calibration BlocksDokument3 SeitenCalibration BlocksvenkatNoch keine Bewertungen

- PA Probe Catalog en 201304Dokument24 SeitenPA Probe Catalog en 201304Durgamadhaba Mishra100% (2)

- Tofd Development: TechniqueDokument32 SeitenTofd Development: TechniqueLương Hồ VũNoch keine Bewertungen

- Astm Reference Block For MetalDokument10 SeitenAstm Reference Block For MetalrupamNoch keine Bewertungen

- Application of Phased Array For Corrosion Resistant Alloy (CRA) WeldsDokument6 SeitenApplication of Phased Array For Corrosion Resistant Alloy (CRA) WeldsKevin HuangNoch keine Bewertungen

- TOFD Technique Guide: Time of Flight DiffractionDokument77 SeitenTOFD Technique Guide: Time of Flight DiffractionNDTInstructorNoch keine Bewertungen

- Phased Array - GeneralDokument192 SeitenPhased Array - GeneralAndy MariscalNoch keine Bewertungen

- 16 TOFD Evaluation GuidelineDokument17 Seiten16 TOFD Evaluation GuidelineMohamed Ibrahim100% (1)

- Certification and personnel qualification for ultrasonic testing of steel plateDokument8 SeitenCertification and personnel qualification for ultrasonic testing of steel plateNooruddin SheikNoch keine Bewertungen

- PA Probe Catalog EN 201608 Web PDFDokument32 SeitenPA Probe Catalog EN 201608 Web PDFDennis Chai100% (1)

- Inspection Report Bifab Ut On Duplex Stainless Steel Piping PDFDokument11 SeitenInspection Report Bifab Ut On Duplex Stainless Steel Piping PDFquiron2014Noch keine Bewertungen

- Dac & DGSDokument14 SeitenDac & DGSAhmad Daniel100% (1)

- UT Chapter 11Dokument70 SeitenUT Chapter 11knizam1971100% (1)

- TOFD Technique for Weld InspectionDokument31 SeitenTOFD Technique for Weld Inspectionvenkat100% (1)

- DS 324 ManualDokument44 SeitenDS 324 ManualAshish Srivastava100% (1)

- BLOQUEDokument1 SeiteBLOQUEAlvaro Alexis Mendoza PradaNoch keine Bewertungen

- General DNV Qualification Applus RTD Rotoscan AUT System - 2009-4129 - Rev.03 - SignedDokument60 SeitenGeneral DNV Qualification Applus RTD Rotoscan AUT System - 2009-4129 - Rev.03 - SignedfayyazdnvNoch keine Bewertungen

- En 14096-1 Final DraftDokument11 SeitenEn 14096-1 Final Draftrizwankhanzhi100% (1)

- MX2 Training Program 07 UT ConfigurationDokument44 SeitenMX2 Training Program 07 UT ConfigurationVictor Antonio Diaz FaundezNoch keine Bewertungen

- Ultrasonic Testing: NDT Training & CertificationDokument29 SeitenUltrasonic Testing: NDT Training & CertificationMidhun K Chandrabose100% (1)

- E1936-97 Evaluating Digitization SystemsDokument4 SeitenE1936-97 Evaluating Digitization SystemsNDT Div, MedequipNoch keine Bewertungen

- Rms Auto Ut Corrosion Mapping PDFDokument6 SeitenRms Auto Ut Corrosion Mapping PDFSangeeth Kavil PNoch keine Bewertungen

- Evaluation of Flaw Acceptance Ratios According to ASME Section VIII CodeDokument3 SeitenEvaluation of Flaw Acceptance Ratios According to ASME Section VIII CodeWoodrow FoxNoch keine Bewertungen

- OmniScan MX2 P2 PA32128 LatestDokument8 SeitenOmniScan MX2 P2 PA32128 LatestGhaithNoch keine Bewertungen

- National Step Tablet Vs Step Wedge Comparision FilmDokument4 SeitenNational Step Tablet Vs Step Wedge Comparision FilmManivannanMudhaliarNoch keine Bewertungen

- Ultrasonic Thickness Measurement Procedure for Tank BottomsDokument7 SeitenUltrasonic Thickness Measurement Procedure for Tank BottomsShreekanthKannathNoch keine Bewertungen

- HTHA - Relatório SGS PDFDokument231 SeitenHTHA - Relatório SGS PDFlgustavocoelhoNoch keine Bewertungen

- MX2 Training Program 14C Phased Array Analysis-Length SizingDokument10 SeitenMX2 Training Program 14C Phased Array Analysis-Length SizingmushruffNoch keine Bewertungen

- SEC VIII-Div 2 UT FLAW ACCEPTANCE CRITERIA in Lieu of RTDokument2 SeitenSEC VIII-Div 2 UT FLAW ACCEPTANCE CRITERIA in Lieu of RTChandrashekhar ThiramdasuNoch keine Bewertungen

- Astm E1065 E1065m 20Dokument10 SeitenAstm E1065 E1065m 20Mohamed AboelkhierNoch keine Bewertungen

- ASME SEC-I NDE Procedure SummaryDokument21 SeitenASME SEC-I NDE Procedure SummaryuaiphonNoch keine Bewertungen

- EN 15317 AnglaisDokument25 SeitenEN 15317 Anglaisbarbier100% (1)

- MX2 Training Program 4E Beam FormingDokument23 SeitenMX2 Training Program 4E Beam Formingsrgoku100% (1)

- Industrial radiography A Complete Guide - 2019 EditionVon EverandIndustrial radiography A Complete Guide - 2019 EditionNoch keine Bewertungen

- Sizing Method Advantage:: Fig.1 DGS DiagramDokument3 SeitenSizing Method Advantage:: Fig.1 DGS Diagrammangalraj900Noch keine Bewertungen

- Quick Flaw Evaluation in Ultrasonic Testing Using Microprocessor Assisted MethodsDokument4 SeitenQuick Flaw Evaluation in Ultrasonic Testing Using Microprocessor Assisted MethodsGustavo Shaw0% (1)

- UT Testing Add01a Equipment CalibrationsDokument97 SeitenUT Testing Add01a Equipment CalibrationsdebduttamallikNoch keine Bewertungen

- Thëvāram Pathigam - Song 7.048 ("Thiru-Pāndi-Kodu-Mudi") : Sundarar-Mūrthi Swāmigal's (Sundarar)Dokument16 SeitenThëvāram Pathigam - Song 7.048 ("Thiru-Pāndi-Kodu-Mudi") : Sundarar-Mūrthi Swāmigal's (Sundarar)Dhanasekaran RNoch keine Bewertungen

- Train Timing 2019 1 PDFDokument1 SeiteTrain Timing 2019 1 PDFVishal kumarNoch keine Bewertungen

- இந்து திருமண பதிவு விண்ணப்ப படிவம்Dokument6 Seitenஇந்து திருமண பதிவு விண்ணப்ப படிவம்Bakrudeen Ali AhamedNoch keine Bewertungen

- Business Visa Checklist: RemarksDokument1 SeiteBusiness Visa Checklist: RemarksDhanasekaran RNoch keine Bewertungen

- 3UT14p527 PDFDokument1 Seite3UT14p527 PDFDhanasekaran RNoch keine Bewertungen

- Camera Lens CompatibilityDokument444 SeitenCamera Lens CompatibilityDhanasekaran RNoch keine Bewertungen

- Madras High Court - Gratuity JudgementDokument3 SeitenMadras High Court - Gratuity Judgementhiteshv100% (11)

- Hoisting Rigging FundamentalsDokument89 SeitenHoisting Rigging FundamentalsRoger Loomis100% (2)

- MaterialDokument2 SeitenMaterialDhanasekaran RNoch keine Bewertungen

- Equipment Cal CentresDokument1 SeiteEquipment Cal CentresDhanasekaran RNoch keine Bewertungen

- FormulaDokument1 SeiteFormulaDhanasekaran RNoch keine Bewertungen

- Income Tax Calculator FY 2015 16Dokument5 SeitenIncome Tax Calculator FY 2015 16freekybaby007Noch keine Bewertungen

- CDR Pdfs Indexed 1759 1Dokument8 SeitenCDR Pdfs Indexed 1759 1Dhanasekaran RNoch keine Bewertungen

- Piping and Non-Piping Calculation GuideDokument1 SeitePiping and Non-Piping Calculation GuideDhanasekaran RNoch keine Bewertungen

- Excel Gantt Chart Template: Make Impressive Powerpoint Gantt Charts For Important MeetingsDokument20 SeitenExcel Gantt Chart Template: Make Impressive Powerpoint Gantt Charts For Important MeetingsAmin MarwanNoch keine Bewertungen

- Thermal ImagingDokument5 SeitenThermal ImagingDhanasekaran RNoch keine Bewertungen

- FormDokument1 SeiteFormDhanasekaran RNoch keine Bewertungen

- InstructionsDokument1 SeiteInstructionsDhanasekaran RNoch keine Bewertungen

- PRDokument14 SeitenPRDhanasekaran RNoch keine Bewertungen

- Duplicate Bill: 2015 Maharashtra State Electricity Distribution Company LimitedDokument1 SeiteDuplicate Bill: 2015 Maharashtra State Electricity Distribution Company LimitedDhanasekaran RNoch keine Bewertungen

- SoftLicense activation date 9/20/2015Dokument1 SeiteSoftLicense activation date 9/20/2015Dhanasekaran RNoch keine Bewertungen

- Letter To Accept A ResignationDokument1 SeiteLetter To Accept A ResignationJeseu Yeomsu JaliNoch keine Bewertungen

- Panel 1Dokument440 SeitenPanel 1Dhanasekaran RNoch keine Bewertungen

- Infrared Thermos Canning Sample ReportDokument16 SeitenInfrared Thermos Canning Sample ReportKarna2504Noch keine Bewertungen

- 3 November 2015Dokument1 Seite3 November 2015Dhanasekaran RNoch keine Bewertungen

- Ect Probe 2Dokument1 SeiteEct Probe 2Dhanasekaran RNoch keine Bewertungen

- Applications For Fixed Mounted Infrared Camera SystemsDokument12 SeitenApplications For Fixed Mounted Infrared Camera SystemsDhanasekaran RNoch keine Bewertungen

- Collapsible ProbeDokument2 SeitenCollapsible ProbeDhanasekaran RNoch keine Bewertungen

- Casting Defects and Design Issues PDFDokument39 SeitenCasting Defects and Design Issues PDFPANKAJ kUMARNoch keine Bewertungen

- A Large-Capacity Pressurized-Fluidized-Bed-Combustion-Boiler Combined-Cycle Power PlantDokument5 SeitenA Large-Capacity Pressurized-Fluidized-Bed-Combustion-Boiler Combined-Cycle Power PlantDhanasekaran RNoch keine Bewertungen

- MatrixDokument37 SeitenMatrixmssurajNoch keine Bewertungen

- Gesture Controlled Animatronic Robotic HandDokument12 SeitenGesture Controlled Animatronic Robotic HandRahul GowthamNoch keine Bewertungen

- I Semester 2020-2021: Textile FibresDokument7 SeitenI Semester 2020-2021: Textile FibresNikunj SharmaNoch keine Bewertungen

- HTML Questions Answers to Front-end Job Interview QuestionsDokument7 SeitenHTML Questions Answers to Front-end Job Interview Questionsmcn37803Noch keine Bewertungen

- Customer Portal - User Manual 2021-07Dokument58 SeitenCustomer Portal - User Manual 2021-07Nurul HidayatNoch keine Bewertungen

- CAT NOH10N NOH10NH ERROR TABLEDokument9 SeitenCAT NOH10N NOH10NH ERROR TABLEcristian faundesNoch keine Bewertungen

- TX93 94 95Dokument1 SeiteTX93 94 95AnasNoch keine Bewertungen

- AVCCDokument3 SeitenAVCCTanya WilkersonNoch keine Bewertungen

- Catalogue MidlandDokument94 SeitenCatalogue MidlandzffryfvxNoch keine Bewertungen

- Sony+hvr-Hd1000 Service ManualDokument426 SeitenSony+hvr-Hd1000 Service ManualLeandroGoulartNoch keine Bewertungen

- Form Emsd Ee Ct2B: Fresh Water Cooling Towers Scheme Notification of Completion of Cooling Tower InstallationDokument3 SeitenForm Emsd Ee Ct2B: Fresh Water Cooling Towers Scheme Notification of Completion of Cooling Tower InstallationSimoncarter LawNoch keine Bewertungen

- 1/3-Inch 1.2Mp CMOS Digital Image Sensor With Global ShutterDokument123 Seiten1/3-Inch 1.2Mp CMOS Digital Image Sensor With Global ShutteralkrajoNoch keine Bewertungen

- CNS-9101 SM PDFDokument70 SeitenCNS-9101 SM PDFhadiiir pal100% (1)

- Application of The Rain-Flow Counting Method in Fatigue: Guojun Liu Dahuan Wang and Zeyou HuDokument5 SeitenApplication of The Rain-Flow Counting Method in Fatigue: Guojun Liu Dahuan Wang and Zeyou HuMuhammad FaizNoch keine Bewertungen

- 14a03 tc358870 ProdbriefDokument2 Seiten14a03 tc358870 ProdbriefrahulNoch keine Bewertungen

- SMALL, LIGHTWEIGHT AND AMAZINGLY SILENT AC MASTER POWER INVERTERSDokument2 SeitenSMALL, LIGHTWEIGHT AND AMAZINGLY SILENT AC MASTER POWER INVERTERSJimy HendrixNoch keine Bewertungen

- Transient Performance of CVTsDokument3 SeitenTransient Performance of CVTsajaysitaula8478Noch keine Bewertungen

- Newtec NOP1760 MDM6000 High Speed SystemDokument4 SeitenNewtec NOP1760 MDM6000 High Speed SystemmiltonzxNoch keine Bewertungen

- Computer Basics: TroubleshootingDokument8 SeitenComputer Basics: TroubleshootingSer Crz JyNoch keine Bewertungen

- 90852A+ Aoyue Hot Air Station en PDFDokument10 Seiten90852A+ Aoyue Hot Air Station en PDFMatthieuNoch keine Bewertungen

- Ricoh FW780Dokument6 SeitenRicoh FW780D_moneyNoch keine Bewertungen

- Tracy' Set #1 - Lynda End of Chapter QuestionsDokument38 SeitenTracy' Set #1 - Lynda End of Chapter QuestionsKofiBNoch keine Bewertungen

- Christensen CS3001Dokument2 SeitenChristensen CS3001Julio Jesus Quijano VargasNoch keine Bewertungen

- THERM - QuickStart (Software Calcul Punti Termice)Dokument16 SeitenTHERM - QuickStart (Software Calcul Punti Termice)Ciprian AndreiNoch keine Bewertungen

- Insert Report From - Read Report Into - Delete ReportDokument2 SeitenInsert Report From - Read Report Into - Delete ReportDairo LozanoNoch keine Bewertungen

- FILO - Student Ambassador ProgramDokument5 SeitenFILO - Student Ambassador ProgramVansh ChoudharyNoch keine Bewertungen

- 2004 05 Product Catalog Eltek PDFDokument72 Seiten2004 05 Product Catalog Eltek PDFwolfdeniroNoch keine Bewertungen

- Introduction To Computing Applied Business Tools and TechnologiesDokument9 SeitenIntroduction To Computing Applied Business Tools and TechnologiesClaire CarpioNoch keine Bewertungen

- Precios MayoDokument230 SeitenPrecios Mayoeuronet_seNoch keine Bewertungen

- DC G240 eDokument14 SeitenDC G240 eHany Mohamed100% (11)