Beruflich Dokumente

Kultur Dokumente

14 Nicrmo13-4 PDF

Hochgeladen von

zirtaqOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

14 Nicrmo13-4 PDF

Hochgeladen von

zirtaqCopyright:

Verfügbare Formate

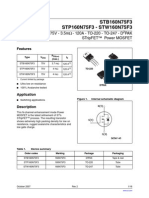

SPECIFICATIONS

European standards:

- 14NiCrMo13-4

- Numerical designation: 1.6657

AIR : 16 NCD 13

WL : 1.6657

BS : S 157

For the remelted grade:

WL : 1.6658

MECHANICAL PROPERTIES

Annealed condition: heat to 825C followed by slow cooling.

- Brinell Hardness: 217

Oil quench from 825C. Temper at 150C.

(Properties beneath the carburised layer)

- UTS: 1350 N/mm

2

- 0.2 % Yield strength: 1000 N/mm

2

- Elongation (5d): 14 %

- Impact strength KCU: 100 J/cm

2

COMPOSITION

Carbon ..............................................0.16

Nickel ................................................3.20

Chromium..........................................1.00

Molybdenum......................................0.25

APPLICATIONS

Various heavily stressed carburised

and non carburised mechanical parts.

Safety-critical parts for the aerospace industry.

CHARACTERISTICS

Carburising and heat treatable nickel-chromium-

molybdenum steel.

After carburising, quenching and tempering,

the surface hardness is around 730 HV.

Good toughness of the carburised layer.

High level of hardenability.

Good mechanical properties.

Good resistance to fatigue.

1414j

Steel

FADH

14NiCrMo13-4

Variants:

FADHW: Consumable electrode remelted grade

FADHYW: Vacuum induction melted and consumable

electrode remelted grade

HEAT TREATMENT

Carburising:

- approximately 900C.

Harden:

- Heat to 825/850C.

- Oil quench.

Temper:

- After carburising and hardening, the

steel is tempered between 140C and

200C as required.

- For use in the non carburised heat

treated condition, temper in accordance

with properties required.

PHYSICAL PROPERTIES

Density: 7.8

Mean coefficient of expansion in m/m.C:

- between 20C and 100C: 11.3 x 10

-6

- between 20C and 700C: 14.0 x 10

-6

Critical points:

- Ac 1: 690C

- Ac 3: 780C

TEMPERING CURVE

500 200 300 400 600 700

44

46

42

40

38

36

34

32

30

28

26

24

22

20

18

16

14

12

10

8

6

4

2

0

440

460

420

400

380

360

340

320

300

280

260

240

220

200

180

160

140

120

100

80

60

40

20

0

% J/cm

2

0

N/mm

2

UTS - 0.2 % YS

N/mm

2

A %: 5d

KCU: J/cm

2

UTS

0.2 % YS

A

K

2200

2300

2100

2000

1900

1800

1700

1600

1500

1400

1300

1200

1100

1000

900

800

700

600

500

400

300

200

100

FADH 1414j

Heated to 825/850C, oil quenched.

(Heat treatment on rough machined blanks)

1100/900C

FORGING

AUBERT & DUVAL

Tour Maine Montparnasse

33, avenue du Maine 75755 Cedex 15

www.aubertduval.com

The data provided in this document represent typical or average values rather than maximum or minimum guaranteed values. The applications indicated for the grades described are given as

guidance only in order to help the reader in his personal assessment. Please note that these do not constitute a guarantee whether implicit or explicit as to whether the grade selected is suited to

specific requirements. Aubert & Duvals liability shall not under any circumstances extend to product selection or to the consequences of that selection.

Das könnte Ihnen auch gefallen

- ABC Datasheet V DZCDokument2 SeitenABC Datasheet V DZCMartin Kratky100% (3)

- Four SeasonsDokument8 SeitenFour Seasonseli100% (1)

- EN6114Dokument14 SeitenEN6114akayirNoch keine Bewertungen

- Ep - Three Phase Medium Voltage Slipring Motors 22.03.2012 PDFDokument44 SeitenEp - Three Phase Medium Voltage Slipring Motors 22.03.2012 PDFClaudiu FatuNoch keine Bewertungen

- Catalogue Micro-Moteurs Namiki - TSADokument68 SeitenCatalogue Micro-Moteurs Namiki - TSAWilliam RoaNoch keine Bewertungen

- SM-T385 SVC MANUAL (Phonelumi - Com)Dokument145 SeitenSM-T385 SVC MANUAL (Phonelumi - Com)Rudy ATNoch keine Bewertungen

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- Marine Electrical Practice: Marine Engineering SeriesVon EverandMarine Electrical Practice: Marine Engineering SeriesBewertung: 4 von 5 Sternen4/5 (8)

- SOP EnterpreneurshipDokument2 SeitenSOP EnterpreneurshipArun Kumar100% (1)

- B207A Powerpoint - Week 1Dokument10 SeitenB207A Powerpoint - Week 1ranaNoch keine Bewertungen

- Training Market AnalysisDokument46 SeitenTraining Market AnalysisNischal UpretiNoch keine Bewertungen

- Steel GKHDokument2 SeitenSteel GKHAngel ZanottiNoch keine Bewertungen

- 34 CR Mo 4Dokument2 Seiten34 CR Mo 4fsfunbNoch keine Bewertungen

- 21CrMoV5 7Dokument2 Seiten21CrMoV5 7zamporpsNoch keine Bewertungen

- 42 Crmo 4Dokument2 Seiten42 Crmo 4Shubham GuptaNoch keine Bewertungen

- Neodymium-Iron-Boron Magnet Grades PDFDokument82 SeitenNeodymium-Iron-Boron Magnet Grades PDFzcrackNoch keine Bewertungen

- SCV GBDokument2 SeitenSCV GBGyanendraNoch keine Bewertungen

- 11 - TW Thermo-KineticsDokument14 Seiten11 - TW Thermo-Kineticsthomas_v501925Noch keine Bewertungen

- 1 2714Dokument1 Seite1 2714K Mohana PraneshNoch keine Bewertungen

- X17CrNi16 2Dokument2 SeitenX17CrNi16 2madodandembeNoch keine Bewertungen

- U1620RGDokument5 SeitenU1620RGLeonardo OuverneyNoch keine Bewertungen

- 42CrMo4 Datos Tecnicos PDFDokument2 Seiten42CrMo4 Datos Tecnicos PDFjlplazaolaNoch keine Bewertungen

- Ra6 GB 01Dokument2 SeitenRa6 GB 01Nguyen Quoc TuanNoch keine Bewertungen

- Metrode ER110S-G FillerDokument6 SeitenMetrode ER110S-G FillerBernie SimcsNoch keine Bewertungen

- Semikron SKB - 25 - 07238680Dokument3 SeitenSemikron SKB - 25 - 07238680shamkhairnarNoch keine Bewertungen

- Anixter - Teck90Dokument18 SeitenAnixter - Teck90Michele BacocchiaNoch keine Bewertungen

- SKD 30 Bridge RectifierDokument3 SeitenSKD 30 Bridge RectifierkazishahNoch keine Bewertungen

- 42 CR Mo 4Dokument2 Seiten42 CR Mo 4ElMacheteDelHuesoNoch keine Bewertungen

- 890 Resistor CI (Obsolete)Dokument4 Seiten890 Resistor CI (Obsolete)Juan Pablo AmadorNoch keine Bewertungen

- DatasheetDokument9 SeitenDatasheetloisaomNoch keine Bewertungen

- General CatalogDokument24 SeitenGeneral CatalogAravindhan ENoch keine Bewertungen

- Book PDFDokument24 SeitenBook PDFJon SnowNoch keine Bewertungen

- 102 CR 6Dokument2 Seiten102 CR 6ceca nikolicNoch keine Bewertungen

- AD8001Dokument16 SeitenAD8001sresciaNoch keine Bewertungen

- 2CDC002157D0201Dokument7 Seiten2CDC002157D0201260380sdNoch keine Bewertungen

- BL L502Dokument4 SeitenBL L502Roberto GarzonNoch keine Bewertungen

- Radaflex A XLPE Double Insulated Power Cabl1Dokument2 SeitenRadaflex A XLPE Double Insulated Power Cabl1Mark BensonNoch keine Bewertungen

- Quality 42crmo4 Chemical Composition: Technical Card Gruppo Lucefin Revision 2012 All Rights ReservedDokument2 SeitenQuality 42crmo4 Chemical Composition: Technical Card Gruppo Lucefin Revision 2012 All Rights ReservedVijayakumar SamyNoch keine Bewertungen

- 2N6027Dokument9 Seiten2N6027mariogizziNoch keine Bewertungen

- Elgacore DWA 55EDokument2 SeitenElgacore DWA 55Ecfyjdyu_684672809Noch keine Bewertungen

- EurotrodDokument76 SeitenEurotrodPedro SilvaNoch keine Bewertungen

- Metal Ferrous Metal Duplex Stainless SteelDokument2 SeitenMetal Ferrous Metal Duplex Stainless SteelTomy GeorgeNoch keine Bewertungen

- Case Hardening Steel 16MnCr5 AUSADokument3 SeitenCase Hardening Steel 16MnCr5 AUSAShubhangi ShindeNoch keine Bewertungen

- Asaab 8407 - 2MDokument11 SeitenAsaab 8407 - 2MPrabath MadusankaNoch keine Bewertungen

- LSS A286Dokument2 SeitenLSS A286anhntran4850Noch keine Bewertungen

- Ed Uccp 201501Dokument39 SeitenEd Uccp 201501XUAN CUONG PHAN0% (1)

- Sprinter XP12V2500 Battery DatasheetDokument2 SeitenSprinter XP12V2500 Battery DatasheetMuhammad azeemNoch keine Bewertungen

- Stb160N75F3 Stp160N75F3 - Stw160N75F3: N-Channel 75V - 3.5M - 120A - To-220 - To-247 - D Pak Stripfet™ Power MosfetDokument16 SeitenStb160N75F3 Stp160N75F3 - Stw160N75F3: N-Channel 75V - 3.5M - 120A - To-220 - To-247 - D Pak Stripfet™ Power MosfetmoabdolyNoch keine Bewertungen

- 8-Equipment Damage Curves ConductorsDokument5 Seiten8-Equipment Damage Curves ConductorsMoulay m'hammed LOUKILINoch keine Bewertungen

- XP12V3000 1Dokument2 SeitenXP12V3000 1mirza ateeq baigNoch keine Bewertungen

- Data Sheet Battery XP12V3000Dokument2 SeitenData Sheet Battery XP12V3000Asad NizamNoch keine Bewertungen

- Kast-O-Lite 25Dokument2 SeitenKast-O-Lite 25Abdul SabirNoch keine Bewertungen

- Af 63Dokument2 SeitenAf 63AdheyNoch keine Bewertungen

- SonnenscheinDokument1 SeiteSonnenscheinelard cardenasNoch keine Bewertungen

- Ck45 Mechanical PropertiesDokument3 SeitenCk45 Mechanical PropertiesDaniel CringusNoch keine Bewertungen

- 72.5 - 420kV Current Transformer (New)Dokument4 Seiten72.5 - 420kV Current Transformer (New)narinderNoch keine Bewertungen

- Technical Data Sheet 0.51" Single Digit SMD Displays: ELSS-505SYGWA/S530-E2Dokument8 SeitenTechnical Data Sheet 0.51" Single Digit SMD Displays: ELSS-505SYGWA/S530-E2StuxnetNoch keine Bewertungen

- Low Noise, Precision CMOS Amplifier AD8655/AD8656: Features Pin ConfigurationsDokument20 SeitenLow Noise, Precision CMOS Amplifier AD8655/AD8656: Features Pin Configurationsjeperezo_1351370Noch keine Bewertungen

- Optocoupler 6N135Dokument16 SeitenOptocoupler 6N135Lullaby summerNoch keine Bewertungen

- Management - Inventing and Delivering Its FutureDokument324 SeitenManagement - Inventing and Delivering Its FutureMadasamy Murugaboobathi100% (1)

- Difference Between Creativity and InnovationDokument3 SeitenDifference Between Creativity and InnovationAll RecordsNoch keine Bewertungen

- Equity ProjectDokument52 SeitenEquity ProjectSimon Muteke100% (1)

- Glass Cutting CatalogDokument39 SeitenGlass Cutting CatalogAgustin SsJjNoch keine Bewertungen

- HANNA General Catalog v28 Chapter0 IntroductionDokument16 SeitenHANNA General Catalog v28 Chapter0 IntroductionOrtomet_SANoch keine Bewertungen

- Wazir Ahmad PM Week 2 PDFDokument5 SeitenWazir Ahmad PM Week 2 PDFWazeeer AhmadNoch keine Bewertungen

- Design Thinking Is Not EnoughDokument24 SeitenDesign Thinking Is Not EnoughTushar_kanavalliNoch keine Bewertungen

- Entrepreneurship DevelopmentDokument9 SeitenEntrepreneurship Developmentrc_prabirNoch keine Bewertungen

- QwertyDokument116 SeitenQwertyRyan Reyes100% (1)

- Business PlanDokument28 SeitenBusiness PlanNirajan SharmaNoch keine Bewertungen

- The Carlyle Group Corporate Citizenship ReportDokument36 SeitenThe Carlyle Group Corporate Citizenship ReportDan PrimackNoch keine Bewertungen

- Abs 1Dokument230 SeitenAbs 1Likhith0% (1)

- Approved Revised Guidelines of TBI 2Dokument22 SeitenApproved Revised Guidelines of TBI 2crsarinNoch keine Bewertungen

- Chief Technology Officer Program BrochureDokument17 SeitenChief Technology Officer Program BrochureVishwa ThothathriNoch keine Bewertungen

- Knowledge Architecture Framework Based On ZachmanDokument4 SeitenKnowledge Architecture Framework Based On ZachmanEditor IJRITCCNoch keine Bewertungen

- JGC IT Grand Plan 2030 PDFDokument10 SeitenJGC IT Grand Plan 2030 PDFriswandyandy80Noch keine Bewertungen

- Sustainability 10 04846 PDFDokument22 SeitenSustainability 10 04846 PDFNik saslizaNoch keine Bewertungen

- Group - 4 FinalDokument16 SeitenGroup - 4 Finalpericharla ravivarmaNoch keine Bewertungen

- WWW Toptal Com Finance Venture Capital Consultants Venture CDokument37 SeitenWWW Toptal Com Finance Venture Capital Consultants Venture CAbdulazizNoch keine Bewertungen

- Las TNCT CN Sa Q4W3-4Dokument9 SeitenLas TNCT CN Sa Q4W3-4Tristan Paul Pagalanan75% (4)

- Managing Digital Innovation A Knowledge Perspectiv... - (1 The Changing Context of Work Implications For Knowledge and Innovati... )Dokument20 SeitenManaging Digital Innovation A Knowledge Perspectiv... - (1 The Changing Context of Work Implications For Knowledge and Innovati... )Joseph Justeen LavarinthanNoch keine Bewertungen

- Port Management Prog Digitalisation-2021Dokument11 SeitenPort Management Prog Digitalisation-2021Dihan RamadhanNoch keine Bewertungen

- Adoption and Spread of Innovation in The NHS: This Content Relates To The Following TopicsDokument4 SeitenAdoption and Spread of Innovation in The NHS: This Content Relates To The Following Topicszeze_13Noch keine Bewertungen

- HBR500Dokument11 SeitenHBR500Harsh kapilaNoch keine Bewertungen

- Operations ManagementDokument4 SeitenOperations ManagementJoey Wong100% (2)

- Science Comes From The Latin Word Scientia, MeaningDokument44 SeitenScience Comes From The Latin Word Scientia, MeaningMaurice Jane Eunice AyogNoch keine Bewertungen