Beruflich Dokumente

Kultur Dokumente

Part C LearningGuide2013

Hochgeladen von

Suman SahaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Part C LearningGuide2013

Hochgeladen von

Suman SahaCopyright:

Verfügbare Formate

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 17 17 17 17

Part C Part C Part C Part C Learning Guide Learning Guide Learning Guide Learning Guide

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 18 18 18 18

Part C: Learning Guide

You are now beginning the course. Please turn to Topic 1 and work

your way through the sessions. Remember to use the chart in Part A if

you are unsure about the next activity or section of work to complete.

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 19 19 19 19

Introduction

This course develops the necessary competence and knowledge to

produce drawings for the detailing of structural steel elements of

construction in accordance with the requirements of relevant Australian

Standards and codes and industry benchmarks.

Such that at the completion of this course you will be able to:

1. Read, interpret and extract relevant information from the structural

steel project specifications.

1.1 Project specifications are correctly interpreted to determine the

requirements for the structural steel with respect to materials,

workmanship, welding, corrosion control and bolting.

1.2 Relevant information is extracted from the specification and

applied to the design drawings.

1.3 The compliance standards applicable to the project and cited in

the specification are understood and applied to the design

drawings.

2. Interpret and apply relevant codes.

2.1 AS 4100 is interpreted accurately to determine correct bolt hole

edge distances, fabrication tolerances and erection procedures.

2.2 AS are interpreted accurately and correctly with respect to

structural steel connections.

3. Draw structural steel line

3.1 Structural steel line diagrams are drawn in plan, section and

diagrams elevation.

4. Produce design drawings of various structural components in

accordance with the design specifications.

4.1 Relevant data is extracted from relevant standards.

4.2 Design drawings of various structural steel components are

prepared in accordance with the design specifications and to AS

1100.501.

4.4 Line diagrams, plans and elevations, details and sections are

correctly labelled using an appropriate member marking system.

4.5 Member schedules are included and are complete and with

correct designations.

5. Apply knowledge of weld types and requirements for field and site

welds.

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 20 20 20 20

5.1 The terminology for various types and elements of welds can

be correctly used.

5.2 Welding specifications are correctly applied to welded

connection design features.

6. Specify appropriate protective coatings

6.1 The method for selecting and specifying protective coating is

understood and applied as required.

6.2 The appropriate protective coating is selected and specified on

the drawing.

7. Detail bolted connections.

7.1 The differences between commercial and high strength bolts is

understood and applied as required.

7.2 The tightening procedures for both commercial and high

strength bolts is understood and used to inform drafting

decisions.

7.3 Bolting procedure designation is correctly applied to structural

design drawings.

7.4 Bolted connections are correctly detailed.

7.5 The Bolt schedule is included and is complete.

8. Consider other design and drafting disciplines involved in a

structural design project.

8.1 The types of design and drafting activities that make up a

major structural design project is understood and used to inform

personal work practices.

8.2 The interaction required between disciplines to ensure that all

aspects of the project are considered prior to commencing detailed

drafting is understood and used to inform personal work

practices.

8.3 Drawings from other major disciplines involved in a major

design project which need to be interpreted in order to avoid

unnecessary construction clashes is understood and used to

inform personal work practices.

Drafting in its broad sense involves the depiction of items of some

sort so that the item can be constructed, commercially manufactured

or simply created. Since these depictions or drawings are usually

distributed on paper hard copy, we can only portray in two

dimensional drawings. Therefore drafting generally involves the

portrayal of three dimensional objects into two dimensional drawings.

Structural steel design layout and/or detail drawings must clearly

show:

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 21 21 21 21

the nominal loading, fire resistance and corrosion protection

requirements

steel grades, sizes and member designations

number, size and categories of bolts and welds (including

testing if required)

connection details, joint and splice details

member camber and any construction or fabrication constraints.

Each drawing needs to provide all the information necessary for the

construction of the steel work and to ensure clarity, should omit

irrelevant details.

Drawing, section and detail references should be given to linked

drawings for individual details or associations with other components

and any included schedules.

Written descriptions on drawings need to be clear and concise. Any

special requirements relating to construction details should be noted or

referenced on the drawing to enable inclusion in construction.

Overall clarity of detailing and dimensioning is essential and always

remember:

If it is not on the drawing it wont get built!

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 22 22 22 22

Topic 1 - Design Layout Drawings Plans,

Elevations and Sections

Learning outcomes

Upon the successful completion of this topic, you will be able to:

Read, interpret and extract relevant information from the

structural steel project specifications. [LO1]

Interpret and apply relevant codes. . [LO2]

Draw structural steel line. [LO3]

Introduction to topic

Structural steel design drawings are required to provide the necessary

dimensioned setout of all the structural component of the work. The

full set of contract documents produced for construction may or may

not include a set of fully dimensioned architectural drawings.

If included, the architectural drawings will show fully dimensioned

details and all applied finishes that are required for the completed

construction. It is normal practice that the architectural drawings will

also show all the structural component dimensions as well, however the

structural steel design drawings will always specify the structural

design member sizes.

Design layout drawings are required to provide all the information

necessary for the construction of the work shown and should omit

irrelevant non-structural details. Information to be shown on the

drawings shall include any required design information and such items

as are specified in the respective structural design codes, or as

instructed by the designer.

References should be given to associated drawings for particular details

or for showing the relationship with other components, and to

schedules.

The design of any structure is a progressive process, very often the

structural outlines and profile sizes will be known well in advance of

the finer details of specific connections. The design layout drawings

will be issued early in the documentation of a project so that all other

disciplines can coordinate their work. The design layout drawings are

also used to assist the design engineer to complete design and sketching

of final detail requirements.

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 23 23 23 23

Session 1.1 Framing Plans

Structural steel framing members are generally much more slender than

the outline profiles of concrete members used in reinforced concrete

construction. Whereas reinforced concrete plans and elevation

drawings show the concrete outline and then proceed to detail specific

reinforcement, because the structural steel members are much finer,

steel drawings show members as line diagrams which are then

developed to show enlarged scale connection details.

Activity 1A Read text

1. Refer to AS 4100 and read Section 1

2. Refer to AS 1100.501 and read Section 1

A typical steel building structure will incorporate columns, beams,

bracing, wall and roof cladding support members and possibly a range

of combinations of other structural configurations.

Therefore in a standard set of structural steel construction design

drawings, their will be drawings of each of these components showing

all their design requirements.

Activity 1B Read text

1. Refer to AS 1100.501 and read Section 2.

Because steel framed structures consist of a multitude of components, it

is necessary to show each of the various elements in its location relative

to the other framing members. In any typical steel structure there can

a number of levels of the structure, eg ground floor or footings support

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 24 24 24 24

the columns, there may be mezzanine or intermediate levels and then

the roof level.

Each of these will be provided with a plan layout which shows the level

of steelwork and the members used in the framing.

Activity 1C Read text and draw column setout plan

1. Refer to AS 1100.501 and read Section 3.

2. Refer to AS 1100.101 and read Section 5 Scales and

refer to Appendix B3 Scales

3. Create a new drawing directory in your home directory

area named //CIVE5568/Factory

4. Create a new drawing in your home directory area named

//CIVE5568/Factory/Column setout using an appropriate

drawing seed file.

4. Refer to Appendix C1 Column Setout Plan of this guide.

Refer also to Appendix C3 Member Schedule of this guide.

5. Create, or reuse and modify as necessary, a suitable

Levels Structure for this drawing. An example level structure

is shown for reference in Appendix C2 of this guide.

6. Using the member sizes and setout dimensions shown

(assume the ground slab is 300mm outside the grid lines all

round), draw the Column Setout Plan.

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 25 25 25 25

Activity 1D Read text and draw Roof Framing Plan

1. Create a new drawing directory in your home directory

area named //CIVE5568/Factory/Roof Framing using an

appropriate drawing seed file.

2. Refer to Appendix C4 Roof Framing Plan of this guide

and to Appendix C3 Member Schedule of this guide and

draw the roof framing plan as shown.

3. Create, or reuse and modify as necessary, a suitable

Levels Structure for this drawing. An example level structure

is shown for reference in Appendix C2 of this guide.

4. Refer to Appendix D Work Samples for example

drawings of structural steel layout plans. These are

provided as a guide and are not to be drawn.

It is important that before you start any drawing work to make sure

you read through all the Activity requirements first. This will ensure

you get a clear picture of the final activity outcome and that you

formulate your proposal of what to do along the way. The activities

shown in this course document are not necessarily designed to be a step

by step, do part 1 then move onto part 2, type of exercise. You are

expected to formulate a plan of completion and bring in all the exercises

learned from RMIT CIVE5575 CAD basic feature 2D drawing and

RMIT CIVE5576 CAD advanced extended feature 2D drawing studied

previously.

Nor are all activities completed necessarily an assessment item. Some

of the following activities are to be completed as part of your personal

folio development or are to be completed progressively as part of your

final projects.

Remember that a lot of the work in completing a drawing is not

necessarily done using a computer and software. Planning the final

result is often some of the best spent time; it can save you many hours,

false starts and restarts, particularly when you get into some more

complicated projects.

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 26 26 26 26

Once the plan has been drawn the various elevations can be produced.

Refer to CIVE5575 - CAD basic feature 2D drawings for standard

drawing scales used for structural plans and details and remember that

the relative scale of a drawing is related to the final plotted/printed text

size.

Structural drafting utilises third angle orthographic projection to depict

the three dimensional structure as a set of two dimensional drawings.

Activity 1E Read text

1. Refer to AS 1100.101 and read Section 6 - Projections.

2. Refer to AS 1100.501 and revise Section 2 General

Applications

3. Refer to AS 1100.501 and revise Section 3.3 Structural

Steel

The structural steel layout or General Arrangement drawings are used

to show the basic framework and dimensional setout of the

construction. They show the position of the main components of the

framing and often will include the dimensional relationships. The

layout or general arrangement drawings are usually drawn full size

and then are scaled at 1:100 (or sometimes 1:50) and hard copies or

prints made to issue to other contractors and construction personnel.

The layout drawings show all the major views of the framework

including plans, elevations and relevant sections. Because structural

steelwork layout drawings depict thin slender members, the sizes of the

members are usually shown in some sort of table or member schedule.

Once the general arrangement layout drawings are completed (or at

least underway) the detailed drawings are commenced. These show

the main connection details required for the completed structure. Often

these will show typical details of the work plus any specific connection

details required by the design. These drawings are also drawn full size

and are generally scaled to 1:10 or 1:20 for printing and issue to other

contractors and to the construction personnel, other scales are used as

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 27 27 27 27

necessary if the detail is very small or complicated, these can include

1:1, 1:2 or 1:5 scales.

Activity 1F Draw framing elevations

1. Create a new drawing file in your home directory area

named //CIVE5568/Factory/Elevations 1 using an

appropriate drawing seed file.

2. Create, or reuse and modify as necessary, a suitable

Levels Structure for this drawing.

3. Refer to Appendix C5 North Elevation of this guide and

referring also to Appendix C3 Member Schedule of this

guide, draw the North Elevation as shown.

4. Refer to Appendix C6 South Elevation of this guide and

referring also to Appendix C3 Member Schedule of this

guide, draw the South Elevation as shown.

5. Refer to Appendix C7 East Elevation of this guide and

referring also to Appendix C3 Member Schedule of this

guide, draw the East Elevation as shown.

6. Refer to Appendix C8 Section A of this guide and

referring also to Appendix C3 Member Schedule of this

guide, and using the data from the previous plans and

elevations, draw a cross section (A) through the building

along grid line 2 looking towards the west. Show purlins

and girts in their correct size relationships. Draw Section A

as shown.

7. Using Appendix C9 Structural Steelwork - Notes on

page of this guide create a set of Structural Steelwork

Notes.

8. Refer to Appendix B1 Layout and Projections on page

of this guide and locate the Framing Plans, Elevations,

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 28 28 28 28

Section A and steelwork notes within a standard A3 drawing

title block. Note that you may need more than one drawing.

Summary and Outcome Checklist

Tick the box for each statement with which you agree:

At the completion of Topic 1 I can:

Read, interpret and extract relevant information from the structural

steel project specifications.

Interpret and apply relevant codes.

Draw structural steel line.

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 29 29 29 29

Topic 2 - Bolting and bolted connection selection

and detailing

Learning outcomes

Upon the successful completion of this topic, you will be able to:

Detail bolted connections. [LO7]

Three main types of metric bolt are used in structural engineering in

Australia:

Commercial bolts to AS 1111, strength grade 4.6

Medium strength or tower bolts to AS 1559, strength grade 5.6

High strength structural bolts to AS 1252, strength grade 8.8

Commercial bolts strength grade 4.6 and high strength bolts strength grade

8.8 are the two main types of bolts used in general structural steel

construction. Design provisions for these two types of structural bolts

are contained in AS 4100.

Relevant material standards referenced by AS 4100 are the current

editions of:

AS 1110 ISO metric hexagon precision bolts and screws

AS 1111 ISO metric hexagon commercial bolts and screws

AS 1112 ISO metric hexagon nuts, including thin nuts, slotted

nuts and castle nuts.

AS 1252 High strength steel bolts with associated nuts and

washers for structural engineering

AS 1275 Metric screw threads for fasteners

The strength of metric structural bolts is specified in terms of the tensile

strength of the bolt and defined according to the ISO strength grade

system which consists of two numbers separated by a point, for

example 4.6. The first number of the designation represents one

hundredth of the nominal tensile strength (MPa) and the number

following the point represents the ratio between nominal yield stress

and nominal tensile strength.

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 30 30 30 30

For example a grade 4.6 bolt has:

Tensile strength of 400 MPa

Yield stress of 0.6 x 400 = 240 MPa

Activity 2A Read text

1. Refer to the Welding Technology Institute of Australia

website at:

http://www.wtia.com.au/ and search for Bolting procedure

for Steel Structures

2. Open the Technical Note TGN-RT-03 entitled Bolting

Procedure for Steel Structures referred to in the URL shown

above and read pages 1, 2 and 3

Activity 2B Read text

1. Refer to the Galvanizers Association of Australia website

at:

www.gaa.com.au/design3.pdf

2. Open the Technical Note design3 entitled Bolting

Galvanized Steel and read the technical document in

particular:

Bolting steel structures

Modes of force transfer in bolted joints

Bolting category system

Design for bolted structural joints

Design for high strength bolting

Tightening procedures for high strength structural

bolts

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 31 31 31 31

Activity 2C Self Help Questions

1. Name the three standard bolting categories used in

structural steelwork.

2. Describe the three standard bolting categories used in

structural steelwork

3. Name and explain the tightening procedures used for

three standard bolting categories used in structural

steelwork.

Summary and Outcome Checklist

Tick the box for each statement with which you agree:

At the completion of Topic 2 I can:

Detail bolted connections

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 32 32 32 32

Topic 3 - Welding and welded connection

selection and detailing

Learning outcomes

Upon the successful completion of this topic, you will be able to:

Apply knowledge of weld types and requirements for field and

site welds. [LO4]

The aim of welding within a structure is to provide a connection

mechanism that will maintain the specified structural performance

throughout the design life of the structure.

Electric arc welding is used as a versatile method for joining steel

components within shop fabrication and on site applications.

The main areas of application are:

Shop fabrication

Joining members together

Joining plates to form fabricated sections such as plate girders etc

Attaching stiffeners and cleat plates

Attaching end plates and temporary connections

Site work

Beam to beam or beam to column connections

Member splices

Strengthening existing structural members

Jointing plates for silos or other plated type structures

Two main types of arc welding are used in structural engineering in

Australia:

fillet welding

butt welding

Additionally there are numerous other types of weld used in fabrication

but these are the major structural types.

Design provisions for these two types of weld are contained in AS 4100.

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 33 33 33 33

Welding shall comply with AS/NZS 1554.1, AS 1554.2 or AS/NZS 1554.5, as

appropriate; welds shall be butt, fillet, and slot or plug welds, or compound

welds.

Weld quality shall be either SP or GP as specified in AS/NZS 1554.1. Weld

quality shall be specified on the design drawings.

Complete and incomplete penetration butt

welds

Complete penetration butt welda butt weld

in which fusion exists between the weld

and parent metal throughout the complete

depth of the joint.

Incomplete penetration butt welda butt

weld in which fusion exists over less than

the complete depth of the joint.

Fillet welds

The size of a fillet weld is specified by the leg lengths. The leg lengths

are the lengths of the sides lying along the legs of a triangle inscribed

within the cross-section of the weld. When the legs are of equal length,

the size is specified by a single dimension (tw).

The preferred sizes of a fillet weld less than 15 mm are3, 4, 5, 6, 8, 10

and 12 mm. (This allows single weld pass.)

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 34 34 34 34

Some relevant material standards referenced by AS 4100 are the current

editions of:

AS/NZS

1553

1553.1

Covered electrodes for welding

Part 1: Low carbon steel electrodes for manual metal-arc

welding of carbon steels and carbon-manganese steels

1554

1554.1

1554.5

Structural steel welding

Part 1: Welding of steel structures

Part 5: Welding of steel structures subject to high levels of

fatigue loading

2717

2717.1

WeldingElectrodesGas metal arc

Part 1: Ferritic steel electrodes

The strength of welding is specified in terms of the tensile strength of

the welding electrode and defined in AS 4100 and AS 1554 as the

nominal tensile strength of the weld metal.

Nominal tensile strength of weld metal (

uw

f )

Manual metal

arc electrode

(AS/NZS

1553.1)

Submerged arc (AS 1858.1)

Flux cored arc (AS 2203)

Gas metal arc (AS/NZS

2717.1)

Nominal

tensile strength

of weld metal,

uw

f MPa

E41XX W40X 410

E48XX W50X 480

Activity 3A Read text

1. Refer to the Aussie Weld website at:

www.aussieweld.com.au/arcwelding/

2. Open the Aussie Weld Introduction to Arc Welding - Basic

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 35 35 35 35

Principles of Welding - Weldability of Metals and Alloys

referred to in the URL shown above and read tutorials:

Arc welding

Various weld joints

Types of weld

Activity 3B Read text and draw symbols

1. Refer to AS 1101.3 Graphical symbols for general

engineering Part 3: Welding and non-destructive

examination

2. Read the following sections:

Section 2 Basic Principles

Section 3 Symbols For Fillet Welds

Section 4 Symbols For Butt Welds

Appendix B Design Of Standard Symbols

3. Create a new drawing file in your home directory

area named //CIVE5568/Factory/Weld Details 1

using an appropriate drawing seed file.

4. Create, or reuse and modify as necessary, a suitable

Levels Structure for this drawing.

5. Using AS 1101.3 Appendix B Design of Standard

Symbols, draw symbols for fillet welds and single and

double V preparation butt welds for both shop and

site locations and save the individual symbols to your

cell library.

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 36 36 36 36

Activity 3C Read text

1. Refer to AS/NZS 1554.1:2004 Structural Steel

Welding - Welding of steel structures

2. Read the following sections:

Section 1.6 Weld Categories

Section 3 Details Of Welded Connections

3.1 General

3.2 Butt Welds

3.3 Fillet Welds

Activity 3D Self Help Questions

1. Describe and compare fillet welds and butt welds as

they are used in structural steelwork connections.

2. Draw the weld symbol designation for 6mm fillet weld

all round.

3. Draw the weld symbol designation for 5mm site fillet

weld arrow side of the joint.

4. Draw the weld symbol for a double V preparation butt

weld both sides of the joint.

5. Draw the weld symbol for a single V preparation butt

weld with backing run on a single side of the joint.

Summary and Outcome Checklist

Tick the box for each statement with which you agree:

At the completion of Topic 3 I can:

Apply knowledge of weld types and requirements for field and site

welds.

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 37 37 37 37

Topic 4 - Design Detail Drawings - fabrication and

erection requirements

Learning outcomes

Upon the successful completion of this topic, you will be able to:

Interpret and apply relevant codes. [LO1]

Once the general arrangement design layout drawings are completed,

or at least underway, work can commence on the design detail

drawings.

The design detail drawings show the actual connection layouts and

geometry and provide enough information to enable shop fabrication

drawings to be produced. Shop fabrication drawings are used by the

steel fabricators to cut and shape the steel sections, to weld cleats and

plates and to provide all necessary holes and bolts for the erection

procedure.

Design detail drawings are usually drawn at a scale of 1:10 but smaller

scales such as 1:5, 1:2 and sometimes 1:1 can also be used.

Activity 4A Read text

1. Refer to AS 4100 and read Section 14 Fabrication

and Section 15 Erection.

2. Refer to the AISC (Australian Institute of Steel

Construction) Standardised Structural Steel

Connections Handbook, specifically refer to the

sections Basic Parameters, Geometrical Details and

Standard Connections).

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 38 38 38 38

Activity 4B Draw details

1. Create a new drawing file in your home directory

area named //CIVE5568/Factory/Design Details 1

using an appropriate drawing seed file.

2. Create, or reuse and modify as necessary, a suitable

Levels Structure for this drawing.

3. Refer to Appendix C10 Factory Details Sheet 1

of 5 of this guide and referring also to Appendix C3

Member Schedule of this guide, draw the typical

column cap and base detail as shown. Replace the

weld notation with the correct weld symbol(s).

4. Refer to Appendix C11 Factory Details Sheet 2

of 5 of this guide and referring also to Appendix C3

Member Schedule of this guide, draw the rb1 roof

bracing detail as shown. Replace the weld notation

with the correct weld symbol(s).

5. Refer to Appendix C12 Factory Details Sheet 3

of 5 of this guide and referring also to Appendix C3

Member Schedule of this guide, draw the typical

flybrace detail as shown. Replace the weld notation

with the correct weld symbol(s).

6. Refer to Appendix C13 Factory Details Sheet 4

of 5 of this guide and referring also to Appendix C3

Member Schedule of this guide, draw the detail

C2D/PRB4 as shown. Replace the weld notation with

the correct weld symbol(s).

7. Refer to Appendix C14 Factory Details Sheet 5

of 5 of this guide and referring also to Appendix C3

Member Schedule of this guide, draw the wall brace

detail as shown. Replace the weld notation with the

correct weld symbol(s).

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 39 39 39 39

Summary and Outcome Checklist

Tick the box for each statement with which you agree:

At the completion of Topic 4 I can:

Interpret and apply relevant codes to detail structural steel

connections

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 40 40 40 40

Topic 5 - Protective coatings

Learning outcomes

Upon the successful completion of this topic, you will be able to:

Specify appropriate protective coatings. [LO6]

Bare steel will only corrode in the presence of both oxygen and

moisture and the corrosion will be accelerated when the steel is

subjected to polluted environments or chemicals.

Steel inside a sealed building such as a multi-story structure is rarely at

risk of corrosion, similarly steelwork within factory or warehouse type

structures are at negligible risk of corrosion.

However bare steel is not exactly pretty to look at and most

owners/architects/designers require some form of protective or

decorative coating. Painting, powder coating and galvanizing are just

three of the methods used to coat and protect structural steelwork from

corrosion.

There is a very large selection of paint systems available for structural

steel, one of the most commonly used paints is red oxide zinc chromate

primer (ROZC) which is applied over a wire brushed steel surface

while another commonly used paint is inorganic zinc silicate primer

which is applied over class 2

1

/2 sand blasted steel surfaces. Other

finishing paint coats are then applied to the primed steel.

Galvanizing is a method of coating and protecting steel by dipping the

steel members into a molten zinc bath.

AS/NZS 2312 Guide to the protection of structural steel against

atmospheric corrosion by the use of protective coatings gives guidance

on the performance and capabilities of various paint systems.

Activity 5A Access the RMIT Australian Standards

libraries database and read text

1. Refer to AS/NZS 2312 Guide to the protection of

structural steel against atmospheric corrosion by the

use of protective coatings and read the following

sections: 1.1, 1.2, 1.5, 1.6, 2, 3.1, 3.2, 3.3, 4.1, 4.2,

5.1, 5.2, 5.3, 6.1, 6.2, 6.3, 7.1 7.6, 7.10, 9.1, 12.1,

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 41 41 41 41

12.2 and Appendix A.

Refer to the following web sites:

http://www.galvanizingasia.com/

Read technical info - Design basics for galvanizing and

Read about galvanizing Hot Dip Galvanizing

www.sewl.com.au/sewl/upload/document/95-014.1.pdf

The document contained within this web site gives a full description of

a large range of steel protective coatings. Read Section 1, 2 and 4.

Activity 5B Determine suitable coating system

1. Refer to AS/NZS 2312 Guide to the protection of

structural steel against atmospheric corrosion by the

use of protective coatings Appendix A and determine

a suitable protective coating system for the factory

building developed in topics 1 and 4.

2. Develop a suitable set of notes for the protective

coating system selected and insert into the relevant

drawings for the factory developed in topics 1 and 4.

Summary and Outcome Checklist

Tick the box for each statement with which you agree:

At the completion of Topic 5 I can:

Specify the appropriate protective coating on structural steel design

drawings

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 42 42 42 42

Topic 6 - Coordinating Work with Other People

and Disciplines

Learning outcomes

Upon the successful completion of this topic, you will be able to:

Consider other design and drafting disciplines involved in a

structural design project. [LO8]

A construction project is generally a specific one-off activity with a

precise end result, the construction of something. The project can be

divided into subprojects that must be completed and accomplished in

order to achieve the final project aims.

A construction project is a complicated exercise that requires the

subtasks to be carefully coordinated and controlled in terms of timing,

costs, precedence and performance of participating parties. Often an

individual project must be coordinated with other projects carried out

by the design office.

Most projects go through similar stages from their instigation to their

completion; this is known as the project life-cycle. The project is

commenced, a project team is setup and a work schedule is organized.

The project starts and momentum builds quickly, progress is made

rapidly, this continues until the end of the project is in sight when it

seems that all work stops or at least slows down. Often this happens

because there is a change in the resources that the project members can

commit, also because some members of the team drag their feet for

whatever reason.

In most engineering and design offices, projects undergo a similar

sequence a slowish start rapid progression through the bulk of the

work slow completion.

The coordination cycle can be almost the inverse of this process;

coordination often needs to be concentrated at the beginning of a design

project the design development stage, it can lessen off during the

production stage (there is still coordination required though) and

sometimes needs to be accentuated during the final stages of a project

when all the various discipline activities come together.

In the construction of any building works there are a large number of

disciplines and trades involved. Many of these have their own drawing

standards and methods however they all need to come together to

enable the economical and effective completion of the construction

project.

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 43 43 43 43

There has been a lot of work aimed at developing and streamlining the

effective collaboration of the various consultants and disciplines on a

project; one such view has been put forward to create an effective CAD

model. Collaborative Cad Modelling In Multidisciplinary Design

Domains. By M. A. Rosenman, J. S. Gero

Key Centre of Design Computing

Department of Architectural and Design Science, University of Sydney

NSW 2006 Australia

Activity 6A Internet Research and Read Text

1. Refer to the following URL

http://wwwpeople.arch.usyd.edu.au/~mike/PAPERS/collabC

AD.html

and read the article enclosed (in particular Sections 2 and 3)

entitled:

Collaborative Cad Modelling In Multidisciplinary

Design Domains. By M. A. Rosenman, J. S. Gero

Key Centre of Design Computing

Department of Architectural and Design Science, University

of Sydney

NSW 2006 Australia

{mike, john}@arch.usyd.edu.au

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 44 44 44 44

Activity 6B Internet Research and Definition of the

Contributors to a Project

1. Refer to the RMIT website URL:

http://www.gm.rmit.edu.au/portal/spaceinfo/ca-

all.cfm

Select the City Campus Building area

Select Building 56 at the RMIT City Campus (this

portal allows users to review the floor plans, including

floor usage, of RMIT buildings)

Examine any photographs accompanying the building

selection

Select each floor level and review the drawings

Using each floor plan, list the features you can see

which will require specialist consultants for

completion of the construction of this building.

Eg. Structural engineer

Architect

Interior designer

Mechanical HVAC Heating Ventilation Air-Conditioning

etc.

2. Using the internet portal from item 1. above, select

Building 57 at the RMIT City Campus (this portal

allows users to review the floor plans, including floor

usage, of RMIT buildings)

Examine any photographs accompanying the building

selection

Select each floor level and review the drawings

Using each floor plan, list the features you can see

which will require specialist consultants for

completion of the construction of this building.

Eg. Structural engineer

Architect

Interior designer

Mechanical HVAC Heating Ventilation Air-Conditioning

etc.

School of Engineering (TAFE)

V2-2013

CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare CIVE 5663 Prepare Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings Structural Steel Design Drawings 45 45 45 45

Summary and Outcome Checklist

Tick the box for each statement with which you agree:

At the completion of Topic 6 I can:

Consider other design and drafting disciplines involved in a

structural design project.

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- GCNSDokument10 SeitenGCNSSuman SahaNoch keine Bewertungen

- Qut EN50 27746 Dom Cms UnitDokument3 SeitenQut EN50 27746 Dom Cms UnitSuman SahaNoch keine Bewertungen

- Class Routine (30 & 31 August 2014) : AdviceDokument1 SeiteClass Routine (30 & 31 August 2014) : AdviceSuman SahaNoch keine Bewertungen

- Engineering Science #16 Handout - 2013 Sem 1Dokument8 SeitenEngineering Science #16 Handout - 2013 Sem 1Suman SahaNoch keine Bewertungen

- Class Routine (12, 13, 14 & 15 Aug 2014) : AdviceDokument1 SeiteClass Routine (12, 13, 14 & 15 Aug 2014) : AdviceSuman SahaNoch keine Bewertungen

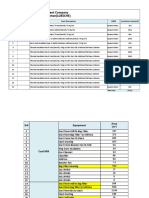

- 2014-15 Postgraduate Tuition Fees For School of The Built Environment ProgrammesDokument6 Seiten2014-15 Postgraduate Tuition Fees For School of The Built Environment ProgrammesSuman SahaNoch keine Bewertungen

- Class Routine (19, 20, 21 & 22 Aug 2014) : AdviceDokument1 SeiteClass Routine (19, 20, 21 & 22 Aug 2014) : AdviceSuman SahaNoch keine Bewertungen

- Class Routine (29, 30, 31 July & 01 Aug 2014) : AdviceDokument1 SeiteClass Routine (29, 30, 31 July & 01 Aug 2014) : AdviceSuman SahaNoch keine Bewertungen

- Class Routine (16 & 17 August 2014) : AdviceDokument1 SeiteClass Routine (16 & 17 August 2014) : AdviceSuman SahaNoch keine Bewertungen

- Class Routine (02 & 03 August 2014) : AdviceDokument1 SeiteClass Routine (02 & 03 August 2014) : AdviceSuman SahaNoch keine Bewertungen

- Class Routine (02 & 03 August 2014) : AdviceDokument1 SeiteClass Routine (02 & 03 August 2014) : AdviceSuman SahaNoch keine Bewertungen

- Revit Structure 2012 FundamentalsDokument11 SeitenRevit Structure 2012 FundamentalsSuman SahaNoch keine Bewertungen

- Faq Sts and SterDokument7 SeitenFaq Sts and SterSuman SahaNoch keine Bewertungen

- Application For A Student VisaDokument27 SeitenApplication For A Student VisaSuman SahaNoch keine Bewertungen

- LAB 1: Steps For Analysis & Design of Beam in SAP2000Dokument16 SeitenLAB 1: Steps For Analysis & Design of Beam in SAP2000Suman SahaNoch keine Bewertungen

- 1499 Bridge NReqDokument12 Seiten1499 Bridge NReqSuman SahaNoch keine Bewertungen

- Design of Steel Structures TocDokument6 SeitenDesign of Steel Structures TocSuman Saha0% (1)

- Civ1501 Engineering Statics Semester 2, 2002: Solution To Assignment 2Dokument2 SeitenCiv1501 Engineering Statics Semester 2, 2002: Solution To Assignment 2Suman SahaNoch keine Bewertungen

- Publications Order Form TEMPLATEDokument1 SeitePublications Order Form TEMPLATESuman SahaNoch keine Bewertungen

- 2004 Engineering Studies Notes OhmzDokument6 Seiten2004 Engineering Studies Notes OhmzSuman SahaNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Dr. Kirti Chandra Sahu Department of Chemical Engineering IIT HyderabadDokument15 SeitenDr. Kirti Chandra Sahu Department of Chemical Engineering IIT HyderabadAnonymous P7J7V4Noch keine Bewertungen

- Ti Alkadur p82 136 enDokument2 SeitenTi Alkadur p82 136 enKelvinNoch keine Bewertungen

- Camion 789DDokument14 SeitenCamion 789Ddinny blanco rojasNoch keine Bewertungen

- CT20 80Dokument3 SeitenCT20 80Andres VargazNoch keine Bewertungen

- EasyShrink® 20 OPERATING INSTRUCTIONS SHRINKFITDokument62 SeitenEasyShrink® 20 OPERATING INSTRUCTIONS SHRINKFITBasarabeanu50% (2)

- XRAY NT18 Engine Instruction & Safety ManualDokument26 SeitenXRAY NT18 Engine Instruction & Safety ManualAsierReloopNoch keine Bewertungen

- Bending ProcedureDokument4 SeitenBending Procedurekalpesh parmarNoch keine Bewertungen

- Lenovo V370 Hardware Maintenance Manual (English)Dokument84 SeitenLenovo V370 Hardware Maintenance Manual (English)dantzy72Noch keine Bewertungen

- API RP 2A 21st 2000 Vs 2007-FatigueDokument16 SeitenAPI RP 2A 21st 2000 Vs 2007-Fatiguesm8575Noch keine Bewertungen

- UFGS Section 09 97 13.27Dokument42 SeitenUFGS Section 09 97 13.27crcltcNoch keine Bewertungen

- SCH VsdSpeedstar2000 UmDokument93 SeitenSCH VsdSpeedstar2000 Umyasser_nasef5399Noch keine Bewertungen

- Spot Learning (Autosaved) (Autosaved) PDFDokument159 SeitenSpot Learning (Autosaved) (Autosaved) PDFaraz_1985Noch keine Bewertungen

- Silicon Wafer Wetability On Metal Thin Film MorphologyDokument8 SeitenSilicon Wafer Wetability On Metal Thin Film MorphologyLee chong looNoch keine Bewertungen

- Oil Piping Flushing: G Nuovo PignoneDokument14 SeitenOil Piping Flushing: G Nuovo Pignonecvg ertdNoch keine Bewertungen

- Viscosity ReportDokument12 SeitenViscosity ReportBF3nobelNoch keine Bewertungen

- IndexDokument50 SeitenIndexSonja Stojaković100% (1)

- 4325e Contoil VzoDokument28 Seiten4325e Contoil VzoChristian Believers' Assembly BorivaliNoch keine Bewertungen

- Bosch Go 3601JH21E0Dokument171 SeitenBosch Go 3601JH21E0william uribeNoch keine Bewertungen

- Insulation BOQ Area Wise (Square MTR.)Dokument11 SeitenInsulation BOQ Area Wise (Square MTR.)Atiq Ur RehmanNoch keine Bewertungen

- Eaton Internormen Mobile Coolant and Lubricant Service UnitDokument4 SeitenEaton Internormen Mobile Coolant and Lubricant Service UnitMiguel AlejandroNoch keine Bewertungen

- INN-QC-FR-15 Painting RecordDokument1 SeiteINN-QC-FR-15 Painting RecordchandraNoch keine Bewertungen

- K71000 Operation ManualDokument42 SeitenK71000 Operation ManualkerimtuncaNoch keine Bewertungen

- Lecture On Water Treatment Plant: M/S Jindal Power Limited (4X250 MW) Opjstpp, Tamnar, RaigarhDokument41 SeitenLecture On Water Treatment Plant: M/S Jindal Power Limited (4X250 MW) Opjstpp, Tamnar, RaigarhPrudhvi RajNoch keine Bewertungen

- Chapter 1: Overview of Apple Inc 1.1. Introduction To General Information of Apple IncDokument8 SeitenChapter 1: Overview of Apple Inc 1.1. Introduction To General Information of Apple IncLinh LêNoch keine Bewertungen

- Aquaplus - PRINSDokument18 SeitenAquaplus - PRINSمحمود الديبNoch keine Bewertungen

- Sikagrout 214-11 PdsDokument2 SeitenSikagrout 214-11 PdscharlessimoNoch keine Bewertungen

- Global Industry Classification StandardDokument54 SeitenGlobal Industry Classification StandardGeorge GeorgeNoch keine Bewertungen

- 6687 18462 1 PBDokument9 Seiten6687 18462 1 PBBimmo Dwi HartonoNoch keine Bewertungen

- Glossário CaterpillarDokument92 SeitenGlossário Caterpillarjsouza431100% (1)

- Metrics That Matter - Uncovering KPIs That Justify Operational ImprovementsDokument43 SeitenMetrics That Matter - Uncovering KPIs That Justify Operational ImprovementsOscar NilaNoch keine Bewertungen