Beruflich Dokumente

Kultur Dokumente

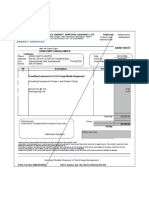

Equipment 20checking

Hochgeladen von

Joshi DhvanitOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Equipment 20checking

Hochgeladen von

Joshi DhvanitCopyright:

Verfügbare Formate

Designer

Checker

Guidelines for use:

This category of issues includes: What is it? Where is it? Do the reference documents and

the item match? Is all the correct information available and is all the available information

correct?

Safety Issues

This category of issues includes how the equipment item is going to be installed and what, if

any, it will have on the location of the equipment and/or the piping.

At the start of detailed design, a designer is assigned an an area of work by the responsible

supervisor. The supervisor then sits down with the assigned designer and reviews each item

on the list for each type of equipment contained in the area. The review can be done on a

hard copy or on an electronic copy. Between the supervisor and the designer they review the

sheet against the expected piece of equipment. Together, they place a "Y" (for yes) or a "N"

(for no) in the column marked "Applicable" for each listed item. This then becomes only the

minimum requirement for active consideration during the design process.

As the designer proceeds with the design work he (or she) shall place their initials & date in

the "Designer Confirms" column when each item has been properly satisfied or determined to

be not applicable. The completed sheet forms a part of the design development package and

stays with the area records.

The checker assigned to perform the checking or QA/QC shall use this sheet and place their

initials & date in the "Checker Confirms" column to varify that all the required items have been

properly addressed.

This category of issues includes the accessibility to areas of the equipment that require

maintenance.

This category of issues includes the question of the possibility of vendor supplied supports,

clearances, anchors, bracing or other items. It also deals with clearance accesses for pipe

routing to and from piping connections.

This category of issues includes accessibility to operational valves and instruments.

Process Plant Equipment Layout and Design Guides

This category of issues includes the requirement for relief valves, rapid and unrestricted

egress, Fireproofing, safety (personnel protection) insulation or safety showers.

Listed below are the six major issues that need to be considered as a part of the design

process for every piece of equipment. These sheets currently exist for only the most common

types of the major equipment found in Refinerys and Chemical Plants.

Engineering and Design Issues

Manufacturing and Fabrication Issues

Construction and Installation Issues

Operational Issues

Maintenance Issues

Page 1 of 18

Equipment Number :

Description of Layout consideration Source

Applicable

Y/N

Designer

Confirm

Checker

Confirm

A -- Engineering and Design Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

Key Performance Issues:

(Define)

Process Plant Equipment Layout & Design Guide

(Define)

Basic description:

Primary function:

Page 2 of 18

Equipment Number :

Description of Layout consideration Source

Applicable

Y/N

Designer

Confirm

Checker

Confirm

(Define)

B -- Manufacturing and Fabrication Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

C -- Shipping and Traffic Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

D -- Construction and Installation Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

E -- Operational Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

F -- Maintenance Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

G -- Safety Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

Safety Device (PSV, Thermal Relief, Rupture Disk) P&ID

Uninsulated skin temperature (Personnel Protection) Datasheet

Page 3 of 18

Equipment Number :

Description of Layout consideration Source

Applicable

Y/N

Designer

Confirm

Checker

Confirm

A -- Engineering and Design Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>>>>>>>>>>>>>>

System location, schematic P&ID

Equipment configuration matches P&ID P&ID & Outline

Number of units and designation P&ID/Eqp. datasheet

Physical location, horizontal & elevation LCP

Operating Pressure/Temperature Equip. Datasheet

Suction Nozzle orientation P&ID/Eqp. datasheet

Suction Nozzle data (Size, Rating, Facing) P&ID/Eqp. datasheet

Discharge Nozzle orientation P&ID/Eqp. datasheet

Discharge Nozzle data (Size, Rating, Facing) P&ID/Eqp. datasheet

Secondary Nozzles (Vents, Drains, PI,) P&ID/Eqp. datasheet

Insulation, Type, thickness, and clearances P&ID/Eqp. datasheet

Nozzle location dimensions Equip. Outline

Nozzle clearance between Suct./ Disch. pipe flg. O. D. Equip. Outline

Nozzle ID matches pipe ID (Require taper bore?) Outline & Pipe Spec

Centerline shaft/centerline base plate dimension Equip. Outline

Base plate anchor bolt Locations Equip. Outline

Base Plate Thickness given Equip. Outline

Operating weight Equip. Outline

Hydro test weight (Full of water) Equip. Outline

B -- Manufacturing and Fabrication Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>>>>>>>>>>>>>>

Vendor furnished piping located and supported Equip. Outline

Driver - Frame Type, Size, Dimensions Equip. Outline

C -- Construction and Installation Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>>>>>>>>>>>>>>

Overall Size Equip. Outline

Foundation (or Pad) overall size and elevation Struct Dwg.

Dry Installation Weight (Empty weight) Equip. Outline

Overhead clearance Layout

D -- Operational Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>>>>>>>>>>>>>>

Inlet and outlet piping configuration (Critical) P&ID

Inlet and Outlet block valve accessibility Design Spec

Accessibility to local Instruments (TI, PI, etc.) Designer

Visibility of local Instruments (TI, PI, etc.) Designer

Key Performance Issues: Proper sizing (head), location relationship to the suction source related equipment, correct

suction and discharge piping configuration, proper operation, and prudent maintenance.

Centrifugal Pump

Process Plant Equipment Layout & Design Guide

Centrifugal Pump (API Type)

Basic description: May be small, medium or large. Will normally be specified in pairs. May have top or end suction.

Will normally have top discharge. This version is manufactured with the shaft in the horizontal position. The driver

may be motor, turbine or engine.

Primary function: Used to transfer a liquid commodity from one point to another. May be called Charge Pumps,

Transfer Pumps, Loading Pumps or any other designation depending on function.

Page 4 of 18

Equipment Number :

Description of Layout consideration Source

Applicable

Y/N

Designer

Confirm

Checker

Confirm

Centrifugal Pump

Accessability to Elect. Start/Stop push-button station Designer

E -- Maintenance Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>>>>>>>>>>>>>>

Overhead clear for motor and pump removal Designer

Coupling and seal area clear for access Designer

F -- Safety Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>>>>>>>>>>>>>>

Safety Device (PSV, Thermal Relief, Rupture Disk) P&ID

Uninsulated skin temperature (Personnel Protection) Datasheet

Page 5 of 18

Equipment Number :

Description of Layout consideration Source

Applicable

Y/N

7

Checker

Confirm

A -- Engineering and Design Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

System location, schematic P&ID & Plot Plan

Unit, Cell, Tube Bundle configuration (P&ID Vs. Outline) P&ID & Outline

Physical location, horizontal & elevation LCP & Plot Plan

Number of (Tube) passes (Odd or Even) Equip. Datasheet

Number of Passes (odd or even) Equip. Datasheet

Requirement for sloping tubes (Free Drainage) P&ID

Location of upstream equipment relative to inlet Layout

Location of downstream equipment relative to outlet Layout

Design/Operating Temperature & Pressure Equip. Datasheet

Key column location & orientation (North Arrow) LCP

Inlet header pipe expansion Designer calc.

Cell or Unit spacing (separation for pipe supt.) Designer calc.

Inlet Nozzle count (Tube bundle inlet header) P&ID/Eqp. datasheet

Inlet Nozzle data (Size, Rating, Facing) P&ID/Eqp. datasheet

Outlet Nozzle count (Tube bundle outlet header) P&ID/Eqp. datasheet

Outlet Nozzle data (Size, Rating, Facing) P&ID/Eqp. datasheet

Inlet Nozzle Orientation Equip outline

Inlet Nozzle location dimensions Equip outline

Outlet Nozzle Orientation Equip outline

Outlet Nozzle location dimensions P&ID/Eqp. datasheet

Supplementary Heat coil Inlet data (Size, rating, Facing) P&ID & Equip outline

Heat coil Inlet location dimensions Equip outline

Supplementary Heat coil Outlet data (Size, rating, Facing) Equip outline

Key Performance Issues: Proper sizing (duty), location relationship to related equipment, correct inlet and outlet piping

configuration, clean operation, and prudent maintenance.

Fin Fan

Process Plant Equipment Layout & Design Guide

Fin Fan (Air Cooled) Type Exchanger

Basic description: Small, medium and large forced draft or induced draft Air cooled Exchangers. Forced Draft units

have the motor and the fan under the tube bundle and blow the air up past the tubes. Induced Draft units may have

the motor under the tubes or above the tubes but will have the fan above the tubes and suck the air up past the tubes.

Fin Fans will have one or two tube bundles per unit. Some installations may require ten or more units per service.

Units will normally have two Fans per unit (Small package units may have only one fan). Most Fin Fans normally have

only one inlet and one outlet per tube bundle, however some may have two inlets and two outlets per bundle. Some

are totally open-sided and some have full side panels. Some may also come with steam coils to temper the air in

fridged climates.

Primary function: Used for cooling of process or utility gas streams where Cooling water is in short supply. May be

called a Cooler or Condenser.

Page 6 of 18

Equipment Number :

Description of Layout consideration Source

Applicable

Y/N

7

Checker

Confirm

Fin Fan

Heat coil Outlet location dimensions Equip outline

Nozzle Loading Designer/Stress

Winterization Dampers (location, spacing, dimensions) Equip. Outline

Secondary Nozzles (Vents, Drains, PI, TI, Chem. Clean) P&ID/Eqp. datasheet

Nozzle projections Equip. Outline

Special Nozzle configuration (Elbow, tangential, etc.) Designer

Nozzle clearance between OD Flange & support steel Designer

Nozzle ID matches pipe ID (Require taper bore?) Outline & Pipe Spec

Establish Pipe Support reqmts Designer

Integral Pipe Supt w/ Exchanger Support structure Designer

Support Leg Locations Designer

Transverse carrier beams provided (Module design) Equip. Outline

Integral grating platforms provided (Under all units) Equip. Outline

Platform for Fan motor level Equip. Outline

Minimum head room for platform at fan motors Design criteria

Platforms w/ ladders provided to inlet header box Equip. Outline

Platforms w/ ladders provided to outlet header box Equip. Outline

Air control Louver reqmts (location, spacing, dimensions) Equip. Outline

Wind and Seismic requirements Structural

Vibration sensors required Datasheet

Shipping Stops required for Tube Bundles Vendor

Shipping Braces Required for Module or Package Units Vendor

Operating weight Equip. Outline

Hydro test weight (Full of water) Equip. Outline

B -- Manufacturing and Fabrication Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

PWHT (Post Weld Heat Treat) Required Equip. Outline

Code Name Plate each cell (Orientation & Location) Designer

Paint or Galvanizing Equip. Outline

Special cleaning Equip. Outline

C -- Shipping and Traffic Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

Overall size is shippable with full shop assembly Vendor & Traffic

Special shipping is required if full shop assembly Vendor & Traffic

D -- Construction and Installation Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

Overall Size Equip. Outline

Dry Installation Weight (Empty weight) Equip. Outline

Overhead clearance Layout

Lifting lugs provided Equip. Outline

Maximum Hydro test Pressure (Tubes & Header Box) Equip. Outline

Removal of Shipping Stops Equip. Outline

Page 7 of 18

Equipment Number :

Description of Layout consideration Source

Applicable

Y/N

7

Checker

Confirm

Fin Fan

Removal of Shipping Braces Equip. Outline

E -- Operational Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

Tube side design and operating conditions P&ID/Datasheet

Winterization protection Equip. Spec

Inlet and outlet piping configuration (Critical) P&ID

Inlet and Outlet block valve accessibility Design Spec

Accessibility to local Instruments (TI, PI, etc.) Designer

Visibility of local Instruments (TI, PI, etc.) Designer

Hot Air Discharge Designer

F -- Maintenance Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

Header Box cover or plug access and removal Outline & Layout

Tube rodding or cleaning Outline & Layout

Fan access and blade removal Outline & Layout

Motor access and removal Outline & Layout

G -- Safety Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

Safety Device (PSV, Thermal Relief, Rupture Disk) P&ID

Uninsulated skin temperature (Personnel Protection) Datasheet

Emergency egress OSHA & Design Spec

Grounding Lug provided Outline

Fireproofing of support structure (Verify clearance) Structural Dwgs

Water Spray/Deluges System Design Criteria

Page 8 of 18

Equipment Number :

Description of Layout consideration Source

Applicable

Y/N

7

Checker

Confirm

A -- Engineering and Design Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

System location, schematic P&ID

Shell & Channel flow pattern (P&ID matches Outline) P&ID & Outline

Physical location, horizontal & elevation LCP

Shell Stacking arrangement & placement P&ID & Datasheet

Operating Temperature Equip. Datasheet

Anchor saddle location LCP

Shell expansion (Radial and Longitudinal) Designer calc.

Sliding Saddle slot size Designer calc.

Shell Inlet Nozzle count P&ID/Eqp datasheet

Shell Inlet Nozzle data (Size, Rating, Facing) P&ID/Eqp datasheet

Shell outlet Nozzle count P&ID/Eqp datasheet

Shell outlet Nozzle data (Size, Rating, Facing) P&ID/Eqp datasheet

Shell Nozzle Orientation Equip outline

Shell Nozzle Location Equip outline

Channel Inlet Nozzle count P&ID/Eqp datasheet

Channel Inlet Nozzle data (Size, Rating, Facing) P&ID/Eqp datasheet

Channel outlet Nozzle count P&ID/Eqp datasheet

Channel outlet Nozzle data (Size, Rating, Facing) P&ID/Eqp datasheet

Channel Nozzle Orientation Equip outline

Channel Nozzle Location Equip outline

Secondary Nozzles (Vents, Drains, PI, TI, Chem. Clean) Project. Specs

Insulation, Type, thickness, and clearances P&ID/Eqp datasheet

Nozzle projections Equip. Outline

Special Nozzle configuration (Elbow, tangential, etc.) Designer

Nozzle clearance between Flange OD & Foundation Designer

Nozzle ID matches pipe ID (Require taper bore?) Outline & Pipe Spec

Integral Pipe Supt w/ Exchanger Foundation Designer

Support Locations Designer

Support/Foundation height, weidth Struct. Dwg.

Key Performance Issues: Proper sizing (duty), location relationship to related equipment, correct inlet and outlet piping

configuration, clean operation, and prudent maintenance.

S & T Exchanger

Process Plant Equipment Layout & Design Guide

Horizontal Shell And Tube Exchanger

Basic description: Large diameter outer shell of a consistent diameter with removable or non-removable tubes. Will have

one or more inlets and outlets on the shell side. Will normally have only one inlet and one outlet on the tube side. This

version is normally mounted in the horizontal position. This item may be mounted as a single item of equipment or

stacked (multiple shells) for the same service or different services.

Primary function: Used for heating or cooling of a process or utility gas or liquid. May be called Heater, Cooler,

Condenser, or Reboiler.

Page 9 of 18

Equipment Number :

Description of Layout consideration Source

Applicable

Y/N

7

Checker

Confirm

S & T Exchanger

Saddle projections Equip. Outline

Saddle Base Plate Thickness Equip. Outline

Location of Anchor Saddle Bolt Holes Equip. Outline

Size of Anchor Saddle Bolt Holes Equip. Outline

Location of Sliding Saddle Bolt Slots Equip. Outline

Operating weight Equip. Outline

Hydro test weight (Full of water) Equip. Outline

B -- Manufacturing and Fabrication Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

Clearance between Nozzle. Repads & Shell Welds Designer

PWHT (Post Weld Heat Treat) Required Equip. Outline

Code Name Plate (Orientation & Location) Designer

C -- Construction and Installation Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

Overall Size Equip. Outline

Dry Installation Weight (Empty weight) Equip. Outline

Overhead clearance Layout

Maximum Hydro test Pressure (Shell) Equip. Outline

Maximum Hydro test Pressure (Tubes) Equip. Outline

Minimum Hydro test Temperature (Shell) Equip. Outline

Minimum Hydro test Temperature (Tubes) Equip. Outline

Maximum Differential Hydro test Pressure (Shell/Tube) Equip. Outline

D -- Operational Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

Shell side design and operating conditions P&ID/Eqp datasheet

Tube side design and operating conditions P&ID/Eqp datasheet

Inlet and outlet piping configuration Co. Design Guide

Inlet and Outlet block valve accessibility Co. Design Guide

Accessibility to local Instruments (TI, PI, etc.) Designer

Visibility of local Instruments (TI, PI, etc.) Designer

E -- Maintenance Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

Channel removal method & clearance Project. Specs.

Channel removal Lifting Lugs Exch. outline

Shell Cover removal method & clearance Project. Specs.

Shell Cover removal Lifting Lugs Exch. outline

Tubes Fixed or Removable Datasheet

Tube Bundle removal method Project. Specs.

Tube Bundle removal space Exch. outline

Tube Bundle weight Exch. outline

Tube Bundle Pull Points (Dead Men) Project. Specs.

Stud Tentioners (Space & Access) Designer

F -- Safety Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

Safety Device (PSV, Thermal Relief, Rupture Disk) P&ID

Uninsulated skin temperature (Personnel Protection) Datasheet

Page 10 of 18

Equipment Number :

Description of Layout consideration Source

Applicable

Y/N

Designer

Confirm

Checker

Confirm

A -- Engineering and Design Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>>

System location, schematic P&ID

Shell & Channel flow pattern (P&ID matches Outline) P&ID & Outline

Physical location, horizontal & elevation LCP & P&ID

Shell weir elevation relationship P&ID & Eqp Datasht

Operating Temperature Equip. Datasheet

Anchor support location Designer Calc

Shell expansion (Radial and Longitudinal) Designer calc.

Shell Inlet Nozzle count P&ID & Eqp Datasht

Shell Inlet Nozzle data (Size, Rating, Facing) P&ID & Eqp Datasht

Shell outlet Nozzle count P&ID & Eqp Datasht

Shell outlet Nozzle data (Size, Rating, Facing) P&ID & Eqp Datasht

Shell Nozzle Orientation Equip outline

Shell Nozzle location dimensions Equip outline

Channel Inlet Nozzle configuration & orientation P&ID & Eqp Datasht

Channel Inlet Nozzle data (Size, Rating, Facing) P&ID & Eqp Datasht

Channel outlet Nozzle configuration & orientation P&ID & Eqp Datasht

Channel outlet Nozzle data (Size, Rating, Facing) P&ID & Eqp Datasht

Channel Nozzle location dimensions Equip outline

Secondary Nozzles for Vents, Drains, PI & TI Project. Specs

Secondary Nozzles for Chem. Cleaning Project. Specs

Insulation, Type, thickness, and clearances P&ID & Eqp Datasht

Nozzle projections Equip. Outline

Special Nozzle configuration (Elbow, tangential, etc.) Designer

Nozzle clearance between O. D. Flange & support Designer

Nozzle ID matches pipe ID (Require taper bore?) Outline & Pipe Spec

Integral Pipe Supt w/ Exchanger support Designer

Support saddle Locations Designer

Support saddle projections Equip. Outline

Key Performance Issues: Proper sizing (duty), location relationship to the liquid level in the tower, liquid/vapor

hydraulics, correct inlet and outlet piping configuration, clean operation, and prudent maintenance.

Kettle Type Reboiler

Process Plant Equipment Layout & Design Guide

Kettle Type Reboiler

Basic description: Large diameter outer shell with eccentric cone transition to smaller diameter removable tube

bundle. Will normally have one inlet and one outlet on the tube side. May have one or two main liquid inlet located on

the bottom of the shell side. May have one or two vapor outlets located on the top of the shell. May have multiple

level instrument connections on the shell to monitor the liquid level in the shell.

Primary function: Used for heating a process liquid in the bottom section of a vertical vessel (tower). May be called

Heater or Reboiler.

Page 11 of 18

Support Base Plate Thickness Equip. Outline

Location of Anchor Saddle bolt holes Designer determine

Size of Anchor Saddle bolt holes Equip. Outline

Location of sliding saddle slots Designer determine

Size of sliding saddle slots Equip. Outline

Operating weight Equip. Outline

Hydro test weight (Full of water) Equip. Outline

B -- Manufacturing and Fabrication Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>>

Clearance between Nozzle. Repads & Shell Welds Designer

PWHT (Post Weld Heat Treat) Required Equip. Outline

Code Name Plate (Orientation & Location) Designer

C -- Construction and Installation Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>>> >>>>>>>>

Overall Size Equip. Outline

Dry Installation Weight (Empty weight) Equip. Outline

Overhead clearance Layout

Maximum Hydro test Pressure (Shell) Equip. Outline

Maximum Hydro test Pressure (Tubes) Equip. Outline

Minimum Hydro test Temperature (Shell) Equip. Outline

Minimum Hydro test Temperature (Tubes) Equip. Outline

Maximum Differential Hydro test Pressure (Shell/Tube) Equip. Outline

D -- Operational Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>>> >>>>>>>>

Shell side design and operating conditions P&ID/Datasheet

Tube side design and operating conditions P&ID/Datasheet

Inlet and outlet piping configuration Co. Design Guides

Inlet and Outlet block valve accessibility Co. Design Guides

Accessibility to local Instruments (TI, PI, etc.) Designer

Visibility of local Instruments (TI, PI, etc.) Designer

E -- Maintenance Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>>> >>>>>>>>

Channel removal method & clearance Project. Specs.

Channel removal Lifting Lugs Exch. outline

Tube Bundle removal method Project. Specs.

Tube Bundle removal space Exch. outline

Tube Bundle weight Exch. outline

Stud Tentioners (Space & Access) Designer

F -- Safety Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>>

Safety Device (PSV, Thermal Relief, Rupture Disk) P&ID

Uninsulated skin temperature (Personnel Protection) Datasheet

Page 12 of 18

Equipment Number :

Description of Layout consideration Source

Applicable

Y/N

Designer

Confirm

Checker

Confirm

A -- Engineering and Design Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

System location, schematic P&ID/Plot Plan

Shell & Channel flow pattern (P&ID matches Outline) P&ID & Outline

Physical location, horizontal & elevation LCP & P&ID

Operating Temperature Equip. Datasheet

Primary support location Designer Calc

Shell expansion (Radial and Longitudinal) Designer calc.

Shell Inlet Nozzle count P&ID/Eqp datasheet

Shell Inlet Nozzle data (Size, Rating, Facing) P&ID/Eqp datasheet

Shell outlet Nozzle count P&ID/Eqp datasheet

Shell outlet Nozzle data (Size, Rating, Facing) P&ID/Eqp datasheet

Shell Nozzle Orientation Equip outline

Shell Nozzle location dimensions Equip outline

Channel Inlet Nozzle configuration & orientation P&ID/Eqp datasheet

Channel Inlet Nozzle data (Size, Rating, Facing) P&ID/Eqp datasheet

Channel outlet Nozzle configuration & orientation P&ID/Eqp datasheet

Channel outlet Nozzle data (Size, Rating, Facing) P&ID/Eqp datasheet

Channel Nozzle location dimensions Equip outline

Channel Nozzle locations match Vessel or Tower Vess. & Equip outline

Secondary Nozzles (Vents, Drains, PI, TI, Chem. Clean) P&ID/Eqp datasheet

Insulation, Type, thickness, and clearances P&ID/Eqp datasheet

Nozzle projections Equip. Outline

Special Nozzle configuration (Elbow, tangential, etc.) Designer

Nozzle clearance between Flange OD & support Designer

Nozzle ID matches pipe ID (Require taper bore?) Outline & Pipe Spec

Integral Platform Supt w/ Exchanger support Designer

Support Lug Locations Designer

Support Lug projections Equip. Outline

Saddle Base Plate Thickness Equip. Outline

Operating weight Equip. Outline

Hydro test weight (Full of water) Equip. Outline

B -- Manufacturing and Fabrication Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

Key Performance Issues: Proper sizing (duty), location in relationship to the liquid level in the tower, liquid/vapor

hydraulics, correct inlet and outlet piping configuration, clean operation, and prudent maintenance.

Thermosyphon Reboiler

Process Plant Equipment Layout & Design Guide

Thermosyphon Reboiler (Vertical) Type Exchanger

Basic description: Large diameter outer shell with removable or non-removable tubes. Will normally have one inlet

and one outlets on the shell side. Will normally have only one inlet and one outlet on the tube side. This version is

mounted in the vertical position on the side of a vertical vessel or on supports along side a vertical vessel.

Primary function: Used for heating a process liquid in the bottom section of a vertical vessel (tower). May be called

Heater or Reboiler.

Page 13 of 18

Equipment Number :

Description of Layout consideration Source

Applicable

Y/N

Designer

Confirm

Checker

Confirm

Thermosyphon Reboiler

Clearance between Nozzle. Repads & Shell Welds Designer

PWHT (Post Weld Heat Treat) Required Equip. Outline

Code Name Plate (Orientation & Location) Designer

C -- Construction and Installation Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

Overall Size Equip. Outline

Dry Installation Weight (Empty weight) Equip. Outline

Overhead clearance Layout

Maximum Hydro test Pressure (Shell) Equip. Outline

Maximum Hydro test Pressure (Tubes) Equip. Outline

Minimum Hydro test Temperature (Shell) Equip. Outline

Minimum Hydro test Temperature (Tubes) Equip. Outline

Maximum Differential Hydro test Pressure (Shell/Tube) Equip. Outline

D -- Operational Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

Shell side design and operating conditions P&ID/Eqp datasheet

Tube side design and operating conditions P&ID/Eqp datasheet

Inlet and outlet piping configuration Co. Design Guides

Inlet and Outlet block valve accessibility Co. Design Guides

Accessibility to local Instruments (TI, PI, etc.) Designer

Visibility of local Instruments (TI, PI, etc.) Designer

E -- Maintenance Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

Channel removal method & clearance Project. Specs.

Channel removal Lifting Lugs Exch. outline

Shell Cover removal method & clearance Project. Specs.

Shell Cover removal Lifting Lugs Exch. outline

Tubes Fixed or Removable Datasheet

Tube Bundle removal method Project. Specs.

Tube Bundle removal space Exch. outline

Tube Bundle weight Exch. outline

Stud Tentioners (Space & Access) Designer

F -- Safety Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

Safety Device (PSV, Thermal Relief, Rupture Disk) P&ID

Uninsulated skin temperature (Personnel Protection) Datasheet

Page 14 of 18

Equipment Number :

Description of Layout consideration Source

Applicable

Y/N

Designer

Confirm

Checker

Confirm

A -- Engineering and Design Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>>

System location, schematic P&ID

Vessel size and shape (P&ID matches Outline) P&ID & Outline

Physical location, horizontal & elevation P&ID and LCP

Plant orientation noted on vess. (North/South/East/West) LCP

Operating Temperature (Use Temp of inlet line) Equip. Datasheet

Vessel shell expansion (Radial and Longitudinal) Designer calc.

Anchor saddle location LCP

Saddle projections Equip. Outline

Saddle Base Plate Thickness Equip. Outline

Location of Anchor Saddle Bolt Holes Equip. Outline

Size of Anchor Saddle Bolt Holes Equip. Outline

Location of Sliding Saddle Bolt Slots Equip. Outline

Sliding Saddle slot size Designer calc.

Vessel Nozzle count P&ID/Eqp. datasheet

Vessel nozzle designations and purpose P&ID/Eqp. datasheet

Nozzle data (Size, Rating, Facing) P&ID/Eqp. datasheet

Nozzle projections Equip. Outline

Manhole count criteria Proj. & Vess Spec.

Manhole size Proj. & Vess Spec.

Manhole cover handling criteria (Davit, hinge, etc.) Proj. & Vess Spec.

Manhole locations Equip. Outline

Boot size (Diameter & length) Equip. Outline

Boot location Equip. Outline

Vessel internals defined Equip. Outline

Vortex breaker defined Equip. Outline

Insulation, Type, thickness, and clearances P&ID/Eqp. datasheet

Top nozzle require extention to clear platform Designer

Platform clips required & Defined Designer

Special Nozzle configuration (Elbow, tangential, etc.) Designer

Nozzle clearance between Flange OD & Foundation Designer

Key Performance Issues: Proper sizing (Volume), location relationship to related equipment, correct inlet and outlet

nozzle locations, correct inlet and outlet piping configuration, proper instrument location and proper operation.

Horizontal Vessel

Process Plant Equipment Layout & Design Guide

Horizontal Vessel (Accumulator)

Basic description: Medium to large diameter horizontal vessel with or without a boot. Will normally have one primary

inlet. May have multiple liquid and vapor outlets. Will have multiple nozzles for level, pressure, and temperature

instrumentation along with one or more nozzles for vents, drains and relief valves. These vessels will also have one

or more manholes and steam-out connections.

Primary function: Used as a holding and seperation point in a process or utility stream. May be called Accumulator,

Receiver, or Surge Drum.

Page 15 of 18

Equipment Number :

Description of Layout consideration Source

Applicable

Y/N

Designer

Confirm

Checker

Confirm

Horizontal Vessel

Nozzle ID matches pipe ID (Require taper bore?) Outline & Pipe Spec

Integral Pipe Supt w/ Vessel Foundation Designer

Vessel Support Locations Designer

Aessel Support/Pier Size, Location, Height

Operating weight Equip. Outline

Hydrotest weight (Full of water) Equip. Outline

B -- Manufacturing and Fabrication Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>>>>>>>>>>>>>>

Clearance between Nozz. Repads & Shell Welds Designer

PWHT (Post Weld Heat Treat) Required Equip. Outline

Code Name Plate (Orientation & Location) Designer

C -- Construction and Installation Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>>>>>>>>>>>>>>

Overall Size Equip. Outline

Dry Installation Weight (Empty weight) Equip. Outline

Overhead clearance Layout

Maximum Hydrotest Pressure Equip. Outline

D -- Operational Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>>>>>>>>>>>>>>

Normal design and operating conditions P&ID/Datasheet

Inlet and outlet piping configuration Co. Design Guides

Inlet and Outlet block valve accessibility Co. Design Guides

Accessibility to local Instruments (TI, PI, etc.) Designer

Visibility of local Instruments (TI, PI, etc.) Designer

E -- Maintenance Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>>>>>>>>>>>>>>

Manhole access Co. Design Guides

Internal access (internal ladder required?) Co. Design Guides

F -- Safety Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>>>>>>>>>>>>>>

Safety Device (PSV, Rupture Disk) P&ID

Uninsulated skin temperature (Personnel Protection) Datasheet

Page 16 of 18

Equipment Number :

Description of Layout consideration Source

Applicable

Y/N

Designer

Confirm

Checker

Confirm

A -- Engineering and Design Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

System location, schematic P&ID

Vessel size and shape (P&ID matches Outline) P&ID & Outline

Physical location, horizontal & elevation P&ID and LCP

Vessel Foundation (Location, Top of Grout) Structural Drawing

Compass orient noted on vessel. head (North, South, etc.) LCP

Vessel Design & Operating Temperature Equip. Datasheet

Number of Trays P&ID/Eqp. Datasheet

Number of Tray passes P&ID/Eqp. Datasheet

Type of Trays P&ID/Eqp. Datasheet

Tray Spacing P&ID/datasheet

Operating Temperature of connected lines Line List

Vessel shell expansion (Radial and Longitudinal) Designer calc.

Vessel Nozzle count matches P&ID P&ID/Eqp. Datasheet

Vessel nozzle designations and purpose P&ID/Eqp. Datasheet

Nozzle data (Size, Rating, Facing) P&ID/Eqp. Datasheet

Nozzle projections Equip. Outline

Manhole count and criteria Proj. & Vessel Spec.

Manhole size Proj. & Vessel Spec.

Manhole cover handling criteria (Davit, hinge, etc.) Proj. & Vessel Spec.

Manhole locations Equip. Outline

Liquid level criteria defined (LLL, LLN, LLH, etc.) P&ID/Eqp. Datasheet

PI, TI Criteria defined P&ID/Eqp. Datasheet

Vessel internals defined Equip. Outline

Vortex breaker defined Equip. Outline

Insulation, Type, thickness, and clearances P&ID/datasheet

Top nozzle require extension to clear platform Designer

Platform clips required? (Defined) Designer

Special Nozzle configuration (Elbow, tangential, etc.) Designer

Key Performance Issues: Proper sizing (Volume), number & type of trays, location relationship to related equipment,

correct inlet and outlet nozzle to tray locations, correct inlet and outlet piping configuration, proper instrument location

and proper operation.

Vertical Vessel

Process Plant Equipment Layout & Design Guide

Vertical Trayed Vessel (Fractionation Column or Tower)

Basic description: Medium to large diameter vertical vessel with tray type internals. Will normally have one primary

feed nozzle. The line attached to this nozzle will be liquid or mixed phase flow. Will normally have only one vapor

outlet located on the top vessel head or on the shell near the top. This vessel will normally have only one primary or

main feed inlet. This vessel will normally operate at a high temperature and therefore will expand vertically in

perportion to the operation temp. and the materials of construction. This type of equipment will have many piping

lines that connect to it and therefore will travel up and down the vessel sides. These lines will also need supports and

guides.

Primary function: Separation of one or more products from the primary feed stream. .

Page 17 of 18

Equipment Number :

Description of Layout consideration Source

Applicable

Y/N

Designer

Confirm

Checker

Confirm

Vertical Vessel

Nozzle clearance between O. D. Flange Platform Designer

Nozzle ID matches pipe ID (Require taper bore?) Outline & Pipe Spec

Pipe Support sized and located for all lines Designer

Pipe Guides sized and located for all lines Designer

Platform cut-outs sized and located for all lines Designer

Base Plate "Chair" height Equip. Outline

Platforms defined (width, orient., elevation, I. D.) Designer

Ladders defined (I. D., location, length, cage) Designer

Davit defined (Height, capacity, location, etc.) Designer

Operating weight Equip. Outline

Hydro test weight (Full of water) Equip. Outline

B -- Manufacturing and Fabrication Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

Clearance between Nozzle. Reinforcing pads & Shell Welds Designer

PWHT (Post Weld Heat Treat) Required Equip. Outline

Code Name Plate (Orientation & Location) Designer

C -- Construction and Installation Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

Overall Size Equip. Outline

Dry Installation Weight (Empty weight) Equip. Outline

Overhead clearance Layout

Maximum Hydro test Pressure Equip. Outline

Type, size, and location of top lifting lugs Equip. Outline

Type, size, and location of tail lifting lugs Equip. Outline

D -- Operational Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

Normal design and operating conditions P&ID/Datasheet

Inlet and outlet piping configuration Co. Design Guides

Inlet and Outlet block valve accessibility Co. Design Guides

Accessibility to local Instruments (TI, PI, etc.) Designer

Visibility of local Instruments (TI, PI, etc.) Designer

E -- Maintenance Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

Manhole access Co. Design Guides

Internal access (internal ladder required?) Co. Design Guides

F -- Safety Issues >>>>>>>>>>>>>> >>>>>>>> >>>>>>> >>>>>>>

Safety Device (PSV, Rupture Disk) P&ID

Uninsulated skin temperature (Personnel Protection) Datasheet

Page 18 of 18

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Appointment Letter FormatDokument7 SeitenAppointment Letter FormatAdv Kunal KapoorNoch keine Bewertungen

- Jim Meyer LPG Expansion Joints White PaperDokument7 SeitenJim Meyer LPG Expansion Joints White PaperJoshi DhvanitNoch keine Bewertungen

- Siemens Basics of PLCDokument89 SeitenSiemens Basics of PLCAlejandro Cortes Bolados100% (1)

- ANNEXURE-7.pdf BHEL PDFDokument10 SeitenANNEXURE-7.pdf BHEL PDFSuleman KhanNoch keine Bewertungen

- Schneider NS800Dokument64 SeitenSchneider NS800Anonymous Lh3Yh8basINoch keine Bewertungen

- Appointment Letter FormatDokument7 SeitenAppointment Letter FormatAdv Kunal KapoorNoch keine Bewertungen

- ASME B31.3 InterpretationDokument743 SeitenASME B31.3 Interpretationiangregorrustria100% (3)

- GPCB GuidelinesDokument24 SeitenGPCB GuidelinesdurgamadhabaNoch keine Bewertungen

- Transforming India PDFDokument160 SeitenTransforming India PDFShantanu NandaNoch keine Bewertungen

- Haripura - Analysis Sheet 15-07-15Dokument58 SeitenHaripura - Analysis Sheet 15-07-15Joshi DhvanitNoch keine Bewertungen

- Conclusion & RecommendationDokument4 SeitenConclusion & RecommendationJoshi DhvanitNoch keine Bewertungen

- 144 BDokument14 Seiten144 BJoshi DhvanitNoch keine Bewertungen

- 14 - 8 - 15 FinalDokument118 Seiten14 - 8 - 15 FinalJoshi DhvanitNoch keine Bewertungen

- Lec37 PDFDokument35 SeitenLec37 PDFAli AlengineerNoch keine Bewertungen

- 144 ADokument14 Seiten144 AJoshi DhvanitNoch keine Bewertungen

- 2011 C FnodeDokument1 Seite2011 C FnodeJoshi DhvanitNoch keine Bewertungen

- Control of Moisture Content in Bagasse by Using Bagasse DryerDokument3 SeitenControl of Moisture Content in Bagasse by Using Bagasse DryerseventhsensegroupNoch keine Bewertungen

- Calculating Our Carbon FootprintDokument1 SeiteCalculating Our Carbon FootprintJoshi DhvanitNoch keine Bewertungen

- Savings Calculation: Overall Chiller SPC TR Saved Power Savings Can Be Achieved Energy SavingsDokument2 SeitenSavings Calculation: Overall Chiller SPC TR Saved Power Savings Can Be Achieved Energy SavingsJoshi DhvanitNoch keine Bewertungen

- JJDokument5 SeitenJJJoshi DhvanitNoch keine Bewertungen

- Thermopac BlowerDokument2 SeitenThermopac BlowerJoshi DhvanitNoch keine Bewertungen

- 142 ADokument16 Seiten142 AJoshi DhvanitNoch keine Bewertungen

- Coal CombustionDokument73 SeitenCoal Combustionsaliheren100% (1)

- SR - NO 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23Dokument2 SeitenSR - NO 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23Joshi DhvanitNoch keine Bewertungen

- Urban AreaDokument2 SeitenUrban AreaJoshi DhvanitNoch keine Bewertungen

- Savings Calculation: Overall Chiller SPC TR Saved Power Savings Can Be Achieved Energy SavingsDokument2 SeitenSavings Calculation: Overall Chiller SPC TR Saved Power Savings Can Be Achieved Energy SavingsJoshi DhvanitNoch keine Bewertungen

- Darcy FrictionDokument1 SeiteDarcy FrictionJoshi DhvanitNoch keine Bewertungen

- Equipment 20checkingDokument18 SeitenEquipment 20checkingJoshi DhvanitNoch keine Bewertungen

- H LookDokument1 SeiteH LookJoshi DhvanitNoch keine Bewertungen

- Energy Efficient Compressed Air Systems: GPG385 Good Practice GuideDokument40 SeitenEnergy Efficient Compressed Air Systems: GPG385 Good Practice GuideDerek White100% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)