Beruflich Dokumente

Kultur Dokumente

Optical Simulation Analysis of High Power LED Package Structure

Hochgeladen von

Diogo Duarte0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

29 Ansichten5 Seitena

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldena

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

29 Ansichten5 SeitenOptical Simulation Analysis of High Power LED Package Structure

Hochgeladen von

Diogo Duartea

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 5

99

Optical simulation analysis of high power LED package structure

Yinong Liu

a,b,c

Yiping Wu

a,b

Bing An

a,b,

*

a

Huazhong University of Science & Technology, Wuhan 430074, China

b

Wuhan National Laboratory for Optoelectronics, Wuhan 430074, China

c

Shenzhen Research Institute of Huazhong University of Science & Technology, Shenzhen 511816, China

*

corresponding author at: College of materials science & engineering, Huazhong University Science & Technology, Wuhan

430074, China. Tel.: +86 27 87544454; Fax: +86 27 87792402; E-mail address: anbing@mail.hust.edu.cn.

Abstract

The single LED package structure determines

the light intensity distribution and the well-

designed package structure will be conductive to

light emitting and improve its external quantum

efficiency. This paper based on the optical package

structure of high power LED, in order to analyze

the influence of the structure of LED package on

optical performance and the feasibility of the

packaging structure design, the simplified high

power LED optical models were established in

Tracepro software. The light distribution curve of

LED was obtained and the difference between

measured data and simulation result was compared.

By changing the LED optical model parameters in

the experiment, such as: the shape of reflector, lens

design and the position of phosphors to get the light

distribution curves under different parameters of

package structure and then we analyze the effect of

various packaging structures on optical

performance to find the package structure

optimization, so that it could be used in actual

production getting a higher available luminous flux

and the light extraction. Whats more, designing a

package structure which can be achieving the

specific light intensity distribution meets the

requirements of the LED light source in different

areas.

1 Introduction

Since the first red LED(Light Emitting Diode)

that was invented by Holonyak and Bevacqua in

1962[1], LED has a wide application in

illumination markets due to its advantages of high

efficiency, low power consumption, environmental

friendliness, long life, and small size. The market

for high power LEDs is growing rapidly in various

applications such as large size flat panel

backlighting, street lighting, vehicle forward lamp,

museum illumination and residential illumination

[2]. With the rapid development of compound

semiconductor technology, its luminous efficacy far

exceeds the commonly used incandescent light

bulb, fluorescent lamp and HID lamp. It has been

widely accepted that LED solid-state lighting will

be the fourth illumination source to substitute those

lamps.

As a new type of light source, its potential

value is receiving more and more attention. The

main function of LED packaging is to protect the

LED chip, enhance the light extraction and provide

a path for dissipating the generated heat [3].

Through the Secondary Optics Design to optimize

the light distribution of LED, the LED emitted light

is more reasonable to meet the requirements of all

kinds of applications. In the optical design for the

packaging, we should take how to achieve the high

luminous efficacy into consideration. However, in

LEDs, photons travel in random direction and there

are too many photon trajectories to consider making

the quantitative analysis extremely difficult. In this

paper, we used Tracepro software based on Monte

Carlo method to trace the photons, from generation

to coupling out of the lamp, statistically using

random numbers [4].

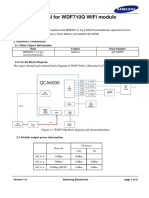

2 Optical model

The basic composition structure of the high

power LED include: LED chip, pins, gold wire,

reflecting cup, lens, phosphor, and substrate. A

cross-sectional structure of a Luxeon package is

shown in Fig.1.

2011 International Symposium on Advanced Packaging Materials (APM 2011)

978-1-4673-0149-7/11/$26.00 2011 IEEE

100

Fig. 1. A cross-sectional structure of a Luxeon package

In this paper, we mainly study the influence

of LED package structure on the light extracting

rate, whether the model structure of LED is in

accordance with the output optical light distribution

requirements. From this aspect, we could use a

simplified model ignoring the base, pins, metal

wire, substrate and focus on the position of

reflecting cup, lens type and size, phosphor. The

schematics of an LED lamp and simplified model

established in Tracepro software is shown in Fig. 2.

a

b

Fig. 2 Schematics of an LED lamp (a) and a simplified model (b)

We plan to define the material property of

epoxy resin (refractive index 1.5), surface source of

LED chip (light emitting surface of Lambertian

type, luminous flux of 1lm) and the surface

property of inner surface of the reflector (80%

reflectivity, 20% absorptivity). Using the Tracepro

software to ray tracing and get the emitted light

intensity distribution curve based on this LED

model.

3 Simulation results and Discussions

3.1 Reflecting Cup

A significant number of the photons coupled

out of the chip would be directed laterally and they

would be mostly reflected from the reflecting cup

[4]. Consequently the shape of the reflecting cup

has a closely relationship with beam angle. The

reflecting cup has the shape of a truncated cone,

then we keep the top surface radius and height in

constant and change the bottom surface radius, that

means changing the cup slanting angles, simulating

the LED light extraction rate and light emitting

space angle. The simulation results are shown in

Fig. 3.

Table The variable radius parameters for simulation

Bottom surface radius

(mm)

Initial luminous flux

(lm)

Emitted luminous flux

(lm)

0.5 1 0.54

0.7 1 0.56

0.9 1 0.61

a

b

c

Fig. 3 Simulation of rectangular candela distribution plot

(a) radius 0.5mm (b) 0.7mm (c) 0.9mm

2011 International Symposium on Advanced Packaging Materials (APM 2011)

978-1-4673-0149-7/11/$26.00 2011 IEEE

101

It can be seen from the figure that with the

bottom surface radius of LED reflecting cup

decreasing, the cup slanting angle becomes lager

and the LED light extraction rate increases.

Because along with the increase of the cup slanting

angle, the light emitted from the reflecting cup will

meet less reflections and the energy loss is also

substantially reduced, leading to improve the LED

light extraction rate. Meanwhile, the beam angle

increased at first and then decreased with the

reduction of bottom surface radius. The reason is

that with the further increase of the cup slanting,

the light emitting out of the chip reaches to the top

surface of the reflecting cup and total reflection

may occur in the top surface of the reflecting cup

when light propagate to air (optically thinner

medium) from epoxy resin (optically denser

medium), thus the beam angle will be decrease [5].

From the above analysis, we can see that the

reflecting cup slanting angle has an impact on the

light extraction rate and beam angle, selecting the

appropriate one is very important.

3.2 Encapsulating Lens

The encapsulating lens is normally used to

change the light distribution by the refraction of

materials and reflection on the interface; different

size and type of lens have a significant impact on

the candela distribution plot.

3.2.1 Lens Size

The sidewall cylinder radius of reflecting cup

is equal to the lens radius and we change the lens

radius without changing other parameters of LED

during the simulation. The simulation model and

results are shown in Fig.4, Fig. 5, respectively.

a b c

Fig Simplified optical model (a) radius 1mm (b) .4mm (c) 1.8mm

a b c

Fig. 5 Simulation of polar candela distribution plot (a) radius 1mm (b) 1.4mm (c) 1.8mm

The figure shows that with the increasing of

the lens radius, the normal light intensity decreases

and the light intensity is evenly distributed. Whats

more, the beam angle is gradually increased.

3.2.2 Lens Type

Next, we simulated three kinds of lens types,

the luminescence intensity space distribution are

Lambertian, Side Emitting and Batwing,

respectively. The simulation results are shown in

Fig. 6.

2011 International Symposium on Advanced Packaging Materials (APM 2011)

978-1-4673-0149-7/11/$26.00 2011 IEEE

102

a

b

c

Fig Simulation of rectangular candela distribution plot

(a) Lambertian (b) Side Emitting (c) Batwing

The figure indicates that the emergent light

through different light emitting types of lens have

distinct center intensity and beam angle. Therefore

we should choose the appropriate lens according to

different application requirements.

3.3 phosphors

Nowadays there are three general approaches

to obtaining white light LEDs. One is the mixing

light from monochromatic RGB LEDs. For the

green gap problem and the efficiencies of red,

green, and blue LEDs vary over time at different

rates, the use of RGB LED has been limited.

Another is PC LEDs, which means using a blue

LED to pump visible light-emitting phosphors

integrated into the LED package. It generates the

white light by mixing the blue light from LED chip

with the broadband yellow light excited by

phosphor [6]. The third method is based on UV

LEDs.

The most commercially available white LEDs

are single-chip white LEDs--PC LEDs. In this

package structure, the phosphor is dispersed within

an epoxy resin that surrounds the LED die.

However, a significant portion of the light is

backscattered by the phosphor and lost within the

LED due to absorption and has a negatively

impacts on the overall efficacy of white LED. In

this case, U.S. N. Narendran Professor proposes a

new package method named scattered photon

extraction (SPE). The schematic of SPE is shown in

Fig. 7.

Fig Schematic of the SPE white LED package

In the SPE package, the phosphor is placed at

a remote location from the die. The geometry of the

optic element plays an important role: it efficiently

transfers the light exiting the GaN die to the

phosphor layer and allows most of the

backscattered light from the phosphor layer to

escape the optic [7]. The new SPE method enables

higher luminous efficacy and shows over 60

percent improvement in light output and efficacy

compared to similar commercial white LEDs [8].

Conclusions

In this paper, we built a simplified high power

LED optical models in the Tracepro software. By

changing the LED optical model parameters in the

experiment, such as: the shape of reflector, lens

design and the position of phosphors to get a clear

exposition of the general law about these factors

affecting on the LED light intensity distribution and

light extraction rate. These laws have a practical

guiding value to LED packaging manufacturing

2011 International Symposium on Advanced Packaging Materials (APM 2011)

978-1-4673-0149-7/11/$26.00 2011 IEEE

103

process and production of specific LED intensity

distribution.

Acknowledgments

I would like to thank my professors for their

support and instruction. I also wish to thank

Shenzhen Research Institute of Huazhong

University of Science and Technology for its

experiment condition.

References

1. Holonyak, J. N. and Bevacqua, S. F., "Coherent

(visible) light emission from Ga(As1-XPx)

junctions", Applied Physics Letters, Vol. 1, No.

4 (1962), pp. 82-83.

2. Craford, M. G., "LEDs for solid state lighting

and other emerging applications: Status, trends,

and challenges," 5th International Conference on

Solid State Lighting, San Diego ,CA,

August.2005, pp. 594101-594110.

3. Zongyuan.Liu, Sheng.Liu, Kai.Wang,

Xiaobing,Luo, Analysis of Factors Affecting

Color Distribution of White LEDs,

International Conference on Electronic

Packaging Technology &High Density

Packaging, Shanghai, July.2008, pp.1-8.

4. SongJae, Lee, Light-Emitting Diode Lamp

Design by Monte Carlo Photon Simulation, the

International Society for Optical Engineering,

Vol. 4278, (2001), pp. 99-108.

5. Ning, Lei, Shi, Yongsheng, Shi, Yaohua, Chen,

Yangyang, Influence of Package structure on

LED Light Extraction, Chinese Journal of

Liquid Crystals and Displays, Vol.25,

No.6(2010), pp.823-825.(in Chinese)

6. Schlotter, P., Schmidt, R. and Schneider, J,

"Luminescence conversion of blue light emitting

diodes," Applied Physics A: Materials Science

& Processing, Vol. 64, No. 4 (1997), pp. 417-

418.

7. Narendran, N, Gu,Y, Freyssinier-Nova,J.P.

Zhu,Y. Extracting phosphor-scattered photons

to improve white LED efficiency, Physica

Status Solidi (A), Applied Research, Vol. 202,

No. 6 (2005) , pp. 60-62.

8. Narendran, N, Improved Performance White

LED, 5th International Conference on Solid

State Lighting, San Diego, CA, August.2005,

pp.594145-594150.

2011 International Symposium on Advanced Packaging Materials (APM 2011)

978-1-4673-0149-7/11/$26.00 2011 IEEE

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Dell XPS L501 L502 CM6CDokument57 SeitenDell XPS L501 L502 CM6CZulfiqar Ali100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Manual Terratest 3000Dokument59 SeitenManual Terratest 3000salpacheNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- EPAgro CombiDokument2 SeitenEPAgro CombimolinacarlosfNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Training Systems Pneumatics 11 2017Dokument156 SeitenTraining Systems Pneumatics 11 2017adaptive4u4527Noch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Sss Module: Transformer Tapping OptionsDokument2 SeitenSss Module: Transformer Tapping OptionsMuhammad Akif NaeemNoch keine Bewertungen

- Dynamic Logic CircuitsDokument61 SeitenDynamic Logic Circuitsbirla_sNoch keine Bewertungen

- Manoj Updated CVDokument5 SeitenManoj Updated CVArun TiwariNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- New Horizon College of Engineering, Bangalore: 19CSE33 USNDokument12 SeitenNew Horizon College of Engineering, Bangalore: 19CSE33 USNAhmad RazaNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Surge Protection 1-Port Poe Injector: Pt-Pse106Gw-ArDokument16 SeitenSurge Protection 1-Port Poe Injector: Pt-Pse106Gw-ArNuman AminNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Jem ZR33 Hi MassDokument2 SeitenJem ZR33 Hi MassPatrick BarnesNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Users Manual 2061259Dokument5 SeitenUsers Manual 2061259Pablo Gustavo RendonNoch keine Bewertungen

- ProLight 2000 DOS ManualDokument256 SeitenProLight 2000 DOS ManualmegclayNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Large Horizontal Machining Center: HM 1000 HM 1250 HM 1250WDokument20 SeitenLarge Horizontal Machining Center: HM 1000 HM 1250 HM 1250WRAJIV GandhiNoch keine Bewertungen

- Manual Smart Inverter SamsungDokument2 SeitenManual Smart Inverter SamsungIgor BarrosoNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- APEF Electrochem MC Ans PDFDokument2 SeitenAPEF Electrochem MC Ans PDFFirdausia Rahma PutriNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- 1fujitsu Service ASU9RLS2Dokument75 Seiten1fujitsu Service ASU9RLS2Osmar Franco Pires100% (1)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elektor 14-15 (Julio-Agosto 1981)Dokument105 SeitenElektor 14-15 (Julio-Agosto 1981)Jorge RiosNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Pine Labs Q2 ManualDokument10 SeitenPine Labs Q2 ManualAli WarsiNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Reset Sony HCD-GR8Dokument1 SeiteReset Sony HCD-GR8pepitito22Noch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Fundamentals of Microprocessor 8085: Multiple Choice QuestionsDokument21 SeitenFundamentals of Microprocessor 8085: Multiple Choice Questionsraghavrocks89Noch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Automation ConDokument11 SeitenAutomation CondarshangoshNoch keine Bewertungen

- CET Power - AGIL Tri-Mono Datasheet v1.3Dokument2 SeitenCET Power - AGIL Tri-Mono Datasheet v1.3jokotsNoch keine Bewertungen

- Meteorological Instruments: MODEL 05108Dokument11 SeitenMeteorological Instruments: MODEL 05108Lac TranNoch keine Bewertungen

- Smartphone - And.pocket - Pc.magazie - June JulyDokument96 SeitenSmartphone - And.pocket - Pc.magazie - June Julyanderson4leeNoch keine Bewertungen

- LG Krowm000576943Dokument44 SeitenLG Krowm000576943vishnusarNoch keine Bewertungen

- IEEE - 219 1975 - Recommended Practice For Loudspeaker Measurements PDFDokument21 SeitenIEEE - 219 1975 - Recommended Practice For Loudspeaker Measurements PDFGreg TsaiNoch keine Bewertungen

- SX 36 ManualDokument16 SeitenSX 36 ManualAndreyna BreaNoch keine Bewertungen

- Informatics in The Health Care Professions Hardware, Software, and Roles of Support PersonnelDokument8 SeitenInformatics in The Health Care Professions Hardware, Software, and Roles of Support PersonnelMarcus, RN80% (5)

- Radar Arduino ProjectDokument17 SeitenRadar Arduino ProjectDARSHAN KUDACHENoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- PAG 09.1 - Investigating Charging and Discharging of CapacitorsDokument4 SeitenPAG 09.1 - Investigating Charging and Discharging of CapacitorsjmsonlNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)