Beruflich Dokumente

Kultur Dokumente

Synthesis of Ferrofluid

Hochgeladen von

Valentin-AngeloUzunov0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

253 Ansichten3 SeitenThe current report details a simple method for the synthesis of aqueous based ferrofluid. The synthesis method is based on the reaction between aqueous iron(II) and Iron(III) ions with aqueous ammonia solution, to form magnetite, Fe3O4 precipitate. The nanoparticles of magnetite produced were then mixed with a surfactant, tetramethylammonium hydroxide (CH3)4NOH, forming a colloidal suspension of the magnetite crystals. When a magnet was applied to the colloid suspension, spikes formed along the surface of the fluid, and varied in size and numbers depending on the strength of the magnetic field.

Copyright

© © All Rights Reserved

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThe current report details a simple method for the synthesis of aqueous based ferrofluid. The synthesis method is based on the reaction between aqueous iron(II) and Iron(III) ions with aqueous ammonia solution, to form magnetite, Fe3O4 precipitate. The nanoparticles of magnetite produced were then mixed with a surfactant, tetramethylammonium hydroxide (CH3)4NOH, forming a colloidal suspension of the magnetite crystals. When a magnet was applied to the colloid suspension, spikes formed along the surface of the fluid, and varied in size and numbers depending on the strength of the magnetic field.

Copyright:

© All Rights Reserved

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

253 Ansichten3 SeitenSynthesis of Ferrofluid

Hochgeladen von

Valentin-AngeloUzunovThe current report details a simple method for the synthesis of aqueous based ferrofluid. The synthesis method is based on the reaction between aqueous iron(II) and Iron(III) ions with aqueous ammonia solution, to form magnetite, Fe3O4 precipitate. The nanoparticles of magnetite produced were then mixed with a surfactant, tetramethylammonium hydroxide (CH3)4NOH, forming a colloidal suspension of the magnetite crystals. When a magnet was applied to the colloid suspension, spikes formed along the surface of the fluid, and varied in size and numbers depending on the strength of the magnetic field.

Copyright:

© All Rights Reserved

Sie sind auf Seite 1von 3

Synthesis of Ferrofluid

Valentin Uzunov (author), Tom Ronay and Hans Harshfield

PSU ID#: 964100377

CHM 229H, Lab 269

ABSTRACT

The current report details a simple method for the synthesis of aqueous based ferrofluid. The

synthesis method is based on the reaction between aqueous iron(II) and Iron(III) ions with

aqueous ammonia solution, to form magnetite, Fe

3

O

4

precipitate. The nanoparticles of magnetite

produced were then mixed with a surfactant, tetramethylammonium hydroxide (CH

3

)

4

NOH,

forming a colloidal suspension of the magnetite crystals. When a magnet was applied to the

colloid suspension, spikes formed along the surface of the fluid, and varied in size and numbers

depending on the strength of the magnetic field.

EXPERIMENTAL

Magnetite nanoparticles were synthesized by reacting 1.0 mL of 2.0 M FeCl

2

, 4.0 ml of 1.0 M

F

3

Cl

3

and 50 mL of 0.7 M aqueous ammonia solution:

2 FeCl

3

(aq) + FeCl

2

(aq) + 8 NH

3

(aq) + 4 H

2

0 Fe

3

O

4

(s) + 8 NH

4

Cl (aq)

[Rxn 1]

Ammonia was added drop wise at a rate of 5-7 drops per second using a 50 mL buret, while the

solution was constantly stirred. The precipitate formed was allowed to settle before excess liquid

was decanted. Remaining solution was further separated, using a centrifuge for 1 min at 1000

rpm. Any remaining supernatant was then decanted and the remaining magnetite precipitate was

mixed thoroughly with 8 mL 25% aqueous tetramethylammonium hydroxide (CH

3

)

4

NOH

solution. It is important that final product be not to moist or dry.

RESULTS

The final product of the synthesis was a dark black liquid, wish a viscosity somewhat similar to

that of the solvent. When a magnetic field from a strong magnet (Neodymium magnet) was

placed near the liquid, it responded by forming spikes on its surface (Figure 1).

Figure 1 shows the synthetizes product. The magnetic field from the

magnetic field passing through the fluid is causing the spike

formation

It was observed that the size of the spikes

depended on the viscosity if the liquid.

When the fluid was to wet (saturated with

water), the spikes created with the magnet were smaller and less well defined. When excess

water was removed, the spikes were bigger in size and formed well defined sharp points.

It was also observed that the distance of the magnet from the fluid had an influence on the spike

length. When the magnet was touching the weight boat the spikes were small and tightly packed.

When the magnet was withdrawn, the spiked grew in size and were less tightly packed.

DISCUSSION

The objective of the current experiment was to replicate the ferrofluid synthesis process

described by Berger et al. (1999) in the Journal of Chemical Education.

In the current experiment, the removal of ammonia, though vacuum aspiration was omitted from

the procedure. It would expected that by removing any excess ammonia from the precipitate the

ferrofluid formed would be of higher quality and and likely form large spikes [1]. Despite so, the

product synthesized, without this step was of sufficient quality to display the desired magnetic

behavior common to ferrofluids.

The magnetic properties of the synthesized fluid are due to the magnetic properties of magnetite

particles in the colloidal suspension. Ferrofluids display an interesting physical property, which

is the formation of spikes at their surface in the presence of a sufficiently strong magnetic field

(ie. from a neodymium magnet). The spike formation can be attributed to the surface instability

of the suspended particles in the fluid, causing constant small waves on the surface. When a

vertical magnetic field, strong enough to overcome the surface tension of the fluid is applied, the

amplitude of these surface waves increases along the magnetic field lines. Depending on the

strength of the interactions between the magnetite particles and the magnetic field, it will

determine the maximal size the spikes can reach [1].

Along with the quality of the fluid, an inverse relationship was observed between the number and

size of spikes and the distance of the magnet from the fluid. This observation can be explained

by the dissipating strength of the magnetic field with distance from the source.

The success of the experiment demonstrates the effectiveness of the synthesis procedure used.

The quality of the final product can be adjusted in further trials to improve the quality of the

product. One way to do so, would be to adjust the initial concentrations of the reactants, as the

product of the magnetite is sensitive to the stoichiometry between Fe2+ ions and Fe3+ ions. The

ratio and positioning between Fe2+ and Fe3+ in the magnetite crystals is important, as it

determines the net magnetization of the crystals, and in turn how well the fluid will respond to

the external magnetic field [1].

It would also be of interest to compare the difference in quality of fluid synthesized when excess

ammonia was remove from the precipitate before mixing with surfactant, as recommended by

Berger et al., compared to current results

CITATIONS

[1] Berger, Patricia; Adelman, Nicholas B; Beckman, Katie J; Campbell, Dean J; Ellis, Arthur B;

and Lisensky, George C. Preparation and Properties of an Aqueous Ferrofluid", Journal of

Chemical Education, 1999, 76(7), 943.

Das könnte Ihnen auch gefallen

- Ferro FluidDokument31 SeitenFerro FluidnanosakthivelNoch keine Bewertungen

- Potassium: Physical PropertiesDokument6 SeitenPotassium: Physical PropertiesJihad Ibrahim AYNoch keine Bewertungen

- Stability of LSD ConditionsDokument6 SeitenStability of LSD ConditionsDarioNoch keine Bewertungen

- What Is A Solar Motor?Dokument11 SeitenWhat Is A Solar Motor?D K SHARMANoch keine Bewertungen

- Bericht Mendocinomotor PDFDokument24 SeitenBericht Mendocinomotor PDFKodos666100% (1)

- Magnetic BlenderDokument5 SeitenMagnetic BlenderYa Sayyadi BilalNoch keine Bewertungen

- Beck Magnetic PulserDokument6 SeitenBeck Magnetic PulserAquila93Noch keine Bewertungen

- Progress in Heterocyclic Chemistry: A Critical Review of the 1994 Literature Preceded by Two Chapters on Current Heterocyclic TopicsVon EverandProgress in Heterocyclic Chemistry: A Critical Review of the 1994 Literature Preceded by Two Chapters on Current Heterocyclic TopicsNoch keine Bewertungen

- Transformers PDFDokument6 SeitenTransformers PDFVasileSpireaNoch keine Bewertungen

- The Cold Fusion ReactorDokument12 SeitenThe Cold Fusion ReactorShahid Z Ansari100% (1)

- WWW Free Energy Ws Samuel Freedman HTMLDokument3 SeitenWWW Free Energy Ws Samuel Freedman HTMLWEEGE33Noch keine Bewertungen

- Arclightshroom's 4 Aco DMT WorkDokument6 SeitenArclightshroom's 4 Aco DMT Workj.pedrogomes84Noch keine Bewertungen

- Torch ManualDokument3 SeitenTorch ManualterapeutasordoNoch keine Bewertungen

- 9 Tausends GoldDokument14 Seiten9 Tausends GoldGeorge O AmadoNoch keine Bewertungen

- Aluminium ChlorideDokument4 SeitenAluminium ChlorideIntanmieyNoch keine Bewertungen

- Applied Superconductivity - 04Dokument16 SeitenApplied Superconductivity - 04Maria Reggie GualbertoNoch keine Bewertungen

- Prentice Earth Energy TapDokument7 SeitenPrentice Earth Energy TapGeorggeNoch keine Bewertungen

- 2016 Atomic Transformation 3Dokument3 Seiten2016 Atomic Transformation 3tavd100% (1)

- How To Make Colloidal Silver at Home - Alternative Cancer TreatmentsDokument10 SeitenHow To Make Colloidal Silver at Home - Alternative Cancer TreatmentsCarl J. WilkeyNoch keine Bewertungen

- Field OrgoniteDokument2 SeitenField OrgoniteBebi BenNoch keine Bewertungen

- Human DisasterDokument173 SeitenHuman DisasterfredekzgredekNoch keine Bewertungen

- Nemescope NemeskopDokument42 SeitenNemescope NemeskopPeter Benedikt WeberNoch keine Bewertungen

- Determination of Organic Structures by Physical MethodsVon EverandDetermination of Organic Structures by Physical MethodsE. A. BraudeBewertung: 5 von 5 Sternen5/5 (1)

- Application Rates For ORMUS Precipitate in AgricultureDokument2 SeitenApplication Rates For ORMUS Precipitate in AgricultureKristina MartinezNoch keine Bewertungen

- Permanent Magnet Early HistoryDokument9 SeitenPermanent Magnet Early HistoryCarlos MarighellaNoch keine Bewertungen

- Magnetostrictive MaterialsDokument11 SeitenMagnetostrictive MaterialsrenukaceNoch keine Bewertungen

- Plasma Orbital Expansion Electrons WaterDokument138 SeitenPlasma Orbital Expansion Electrons WaterVincent J. CataldiNoch keine Bewertungen

- Geyser ReactorDokument31 SeitenGeyser Reactoradamdwaldrop100% (2)

- 3 2 PDFDokument3 Seiten3 2 PDFLeon BlažinovićNoch keine Bewertungen

- Magnetic Potential Energy of A Linear Magnetic Track GunDokument14 SeitenMagnetic Potential Energy of A Linear Magnetic Track GunNick CanningNoch keine Bewertungen

- Electrolysis Using Nano-Pulse Power SupplyDokument4 SeitenElectrolysis Using Nano-Pulse Power SupplyKaryadi DjayaNoch keine Bewertungen

- Sound Through MetalDokument3 SeitenSound Through Metalm.edwards06Noch keine Bewertungen

- Magnetic Repulsion Piston Engine PDFDokument7 SeitenMagnetic Repulsion Piston Engine PDFudayNoch keine Bewertungen

- Veljko Milkovic - Two-Stage Mechanical Oscillator - 9 - 1 Overunity and Antigravity..Dokument26 SeitenVeljko Milkovic - Two-Stage Mechanical Oscillator - 9 - 1 Overunity and Antigravity..Erwin BlancoNoch keine Bewertungen

- Decarboxylation Wagner ADokument24 SeitenDecarboxylation Wagner AEnrico MedianoNoch keine Bewertungen

- MercuryDokument17 SeitenMercurySai Ram100% (1)

- Phonon - Data Math - Explanation.htmDokument2 SeitenPhonon - Data Math - Explanation.htmlightingfastno808Noch keine Bewertungen

- Furnace Boosting DesignDokument8 SeitenFurnace Boosting Designasitchawla100% (1)

- TPP Replication 1.0Dokument19 SeitenTPP Replication 1.0Jim BuckeyneNoch keine Bewertungen

- Is Einstein Theory of Relativity CorrecDokument3 SeitenIs Einstein Theory of Relativity CorrecJose PecinaNoch keine Bewertungen

- Experiment 4 Simple MotorDokument6 SeitenExperiment 4 Simple MotorKim HarlyNoch keine Bewertungen

- Bifilar CoilDokument2 SeitenBifilar CoilEl Zaky RizkiNoch keine Bewertungen

- The Transmutation of Base Metals Into Silver and Gold David BeutherDokument68 SeitenThe Transmutation of Base Metals Into Silver and Gold David BeutherGeorge O AmadoNoch keine Bewertungen

- Switz Russian SEG ReportDokument32 SeitenSwitz Russian SEG ReportBoris MitovNoch keine Bewertungen

- CylianiDokument3 SeitenCylianiCarlos MedinaNoch keine Bewertungen

- How To Make A Quarz FurnanceDokument12 SeitenHow To Make A Quarz FurnanceCarlos MedinaNoch keine Bewertungen

- CHEMALLOY - A New Alloy For The Science StudentDokument2 SeitenCHEMALLOY - A New Alloy For The Science StudentPeter Benedikt WeberNoch keine Bewertungen

- RLC Resonance Trainer KitDokument11 SeitenRLC Resonance Trainer Kitrohit kumarNoch keine Bewertungen

- Possibility of Transmutation To Super Heavy Element by Cold Fusion MechanismDokument8 SeitenPossibility of Transmutation To Super Heavy Element by Cold Fusion MechanismInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- An Introduction to the Chemistry of Benzenoid CompoundsVon EverandAn Introduction to the Chemistry of Benzenoid CompoundsNoch keine Bewertungen

- Necklace Hho 4Dokument55 SeitenNecklace Hho 4RuddyMartiniNoch keine Bewertungen

- Preparation of Ethanol From MolassesDokument14 SeitenPreparation of Ethanol From Molassesfajar1232697Noch keine Bewertungen

- Colloidal Gold: November 2012Dokument24 SeitenColloidal Gold: November 2012Raissa BreenzinckrNoch keine Bewertungen

- Motional EMFDokument21 SeitenMotional EMFAparna DuggiralaNoch keine Bewertungen

- Nuclear Alternative: Redesigning Our Model of the Structure of MatterVon EverandNuclear Alternative: Redesigning Our Model of the Structure of MatterNoch keine Bewertungen

- Tesla Coil ImpedanceDokument16 SeitenTesla Coil ImpedanceMagnethos100% (1)

- Who Has The Same Solid That I Have?Dokument4 SeitenWho Has The Same Solid That I Have?Valentin-AngeloUzunovNoch keine Bewertungen

- Using Conductivity To Find Equivalence PointDokument5 SeitenUsing Conductivity To Find Equivalence PointValentin-AngeloUzunov100% (2)

- Alkali Metal Carbonate Analysis ReportDokument5 SeitenAlkali Metal Carbonate Analysis ReportValentin-AngeloUzunovNoch keine Bewertungen

- Determining Concentration of Allure Red Food Coloring Dye in GatoradeDokument5 SeitenDetermining Concentration of Allure Red Food Coloring Dye in GatoradeValentin-AngeloUzunov100% (5)

- How Much Sugar Is in A Can of Coke?Dokument3 SeitenHow Much Sugar Is in A Can of Coke?Valentin-AngeloUzunovNoch keine Bewertungen

- Using Hess Law To Determining the ΔHfo for Magnesium OxideDokument7 SeitenUsing Hess Law To Determining the ΔHfo for Magnesium OxideValentin-AngeloUzunovNoch keine Bewertungen

- A Cycle of Copper ReactionsDokument6 SeitenA Cycle of Copper ReactionsValentin-AngeloUzunovNoch keine Bewertungen

- Determining The Rate Law For A Reaction Between Iron (III) and Iodide IonDokument4 SeitenDetermining The Rate Law For A Reaction Between Iron (III) and Iodide IonValentin-AngeloUzunov100% (12)

- Experimental Investigation of Charles and Avogadro's Gas LawsDokument10 SeitenExperimental Investigation of Charles and Avogadro's Gas LawsValentin-AngeloUzunovNoch keine Bewertungen

- Vapor Pressure and Heat of VaporizationDokument8 SeitenVapor Pressure and Heat of VaporizationValentin-AngeloUzunovNoch keine Bewertungen

- Determining Molar Mass Using CryosDokument6 SeitenDetermining Molar Mass Using CryosValentin-AngeloUzunovNoch keine Bewertungen

- Finding The Equilibrium Constant For A ReactionDokument4 SeitenFinding The Equilibrium Constant For A ReactionValentin-AngeloUzunovNoch keine Bewertungen

- Enthalpy Change of Reaction Between Phosphoric Acid (H3PO4) and Sodium Hydroxide (NaOH) Using Coffee-Cup CalorimetryDokument6 SeitenEnthalpy Change of Reaction Between Phosphoric Acid (H3PO4) and Sodium Hydroxide (NaOH) Using Coffee-Cup CalorimetryValentin-AngeloUzunov80% (5)

- Potentiometric Titration of Cerium SolutionDokument4 SeitenPotentiometric Titration of Cerium SolutionValentin-AngeloUzunov100% (1)

- Acid Base Chemistry of A Common BufferDokument5 SeitenAcid Base Chemistry of A Common BufferValentin-AngeloUzunovNoch keine Bewertungen

- Visualizing and Understanding of Bonding in Simple Molecules Using Computational ChemistryDokument3 SeitenVisualizing and Understanding of Bonding in Simple Molecules Using Computational ChemistryValentin-AngeloUzunovNoch keine Bewertungen

- Using KSP For The Dissolution of Borax in Water To Determine: G°, H° and S°Dokument4 SeitenUsing KSP For The Dissolution of Borax in Water To Determine: G°, H° and S°Valentin-AngeloUzunov100% (18)

- Construction of Ag - AgCl Reference Electrode and ApplicationDokument3 SeitenConstruction of Ag - AgCl Reference Electrode and ApplicationValentin-AngeloUzunovNoch keine Bewertungen

- Construction of Quantum-Dot Sensitized Solar CellDokument6 SeitenConstruction of Quantum-Dot Sensitized Solar CellValentin-AngeloUzunovNoch keine Bewertungen

- PI Metal Detector Hammerhead PDFDokument15 SeitenPI Metal Detector Hammerhead PDFAlvaro Garcia100% (1)

- Design of Two - Storey Cultural Center Localizing Bubble Deck SystemDokument279 SeitenDesign of Two - Storey Cultural Center Localizing Bubble Deck Systemமாறன் செங்கேணிNoch keine Bewertungen

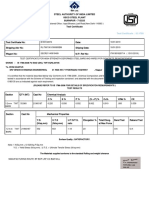

- Test Certificate 12mmDokument1 SeiteTest Certificate 12mmSabyasachi Bangal67% (9)

- Danfoss Thermostat KPS79 060L310366Dokument3 SeitenDanfoss Thermostat KPS79 060L310366vasu hassanNoch keine Bewertungen

- Connector SectionDokument28 SeitenConnector SectionRamesh ShindeNoch keine Bewertungen

- Transmission T-7336 PsDokument186 SeitenTransmission T-7336 PsAhmed Dessie Mohammed100% (6)

- M.tech Ise (2021-23) - List of Topics For PresentationDokument2 SeitenM.tech Ise (2021-23) - List of Topics For PresentationAmarnath Reddy RagipindiNoch keine Bewertungen

- Polylite TDSDokument3 SeitenPolylite TDSRAZA MEHDINoch keine Bewertungen

- Pipe WeldingDokument13 SeitenPipe WeldingFord Katim100% (4)

- Aluminium Alloy 6061Dokument3 SeitenAluminium Alloy 6061choobyNoch keine Bewertungen

- SSPC Paint 20Dokument6 SeitenSSPC Paint 20Juan Carlos Contreras CherresNoch keine Bewertungen

- Service ManUal - Error CodesDokument13 SeitenService ManUal - Error CodesStefanoViganóNoch keine Bewertungen

- ALPS Application Note - Leak Testing Injection Blow Molded BottlesDokument5 SeitenALPS Application Note - Leak Testing Injection Blow Molded BottlesgovindNoch keine Bewertungen

- MIL-F-5509D - Fittings, Flared Tube, Fluid ConnectionDokument18 SeitenMIL-F-5509D - Fittings, Flared Tube, Fluid ConnectionthomasNoch keine Bewertungen

- Study of Prefabrication in IndiaDokument6 SeitenStudy of Prefabrication in IndiaSayed WafiNoch keine Bewertungen

- Ieema Member's Directory Listing FormDokument12 SeitenIeema Member's Directory Listing Formsudhakarrrrrr0% (1)

- 2D Numerical Analysis of Hydraulic Fracturing in Heterogeneous Geo-Materials - 2009 - c49 PDFDokument11 Seiten2D Numerical Analysis of Hydraulic Fracturing in Heterogeneous Geo-Materials - 2009 - c49 PDFMoataz Hesham SolimanNoch keine Bewertungen

- DSFDokument3 SeitenDSFJose Maria SantosNoch keine Bewertungen

- Danfoss - Compressor Case StudiesDokument5 SeitenDanfoss - Compressor Case Studiesgpax42Noch keine Bewertungen

- ROB StaircaseDokument21 SeitenROB StaircaseSambhav PoddarNoch keine Bewertungen

- Thermax Single Effect Hot Water Driven ChillerDokument12 SeitenThermax Single Effect Hot Water Driven ChillerKetan ChandravadiyaNoch keine Bewertungen

- FYP Allocation AY 2012-2013 Sem 1Dokument7 SeitenFYP Allocation AY 2012-2013 Sem 1Yandi LayadiNoch keine Bewertungen

- Product Range: Typical ValuesDokument32 SeitenProduct Range: Typical ValuesRodrigoMachadoNoch keine Bewertungen

- ADTECH Petroplastic Technical Downhole InformationDokument12 SeitenADTECH Petroplastic Technical Downhole InformationBOUZAIDANoch keine Bewertungen

- Buckling H BeamDokument2 SeitenBuckling H BeamНемања КараклајићNoch keine Bewertungen

- Sample Science LessonDokument3 SeitenSample Science LessonMelissa BehrendtNoch keine Bewertungen

- Biomechanics Design Lab Presentation FINALDokument27 SeitenBiomechanics Design Lab Presentation FINALLinh PhanNoch keine Bewertungen

- Ce04014 QaDokument49 SeitenCe04014 QaekaamfNoch keine Bewertungen

- Successful PlasteringDokument13 SeitenSuccessful PlasteringCoulis UtaumireNoch keine Bewertungen

- Om The Laboratory To Ton Scale in Continuous FlowDokument3 SeitenOm The Laboratory To Ton Scale in Continuous FlowAaron Troy SmallNoch keine Bewertungen