Beruflich Dokumente

Kultur Dokumente

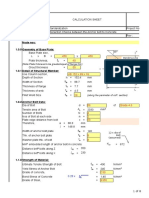

Design of Grating For Platform

Hochgeladen von

vj8584Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design of Grating For Platform

Hochgeladen von

vj8584Copyright:

Verfügbare Formate

( Rev 0 , 05.12.

10 )

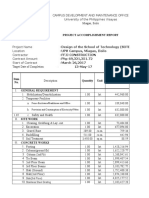

AL ROSTAMANI PEGEL L.L.C

Link Middle east Ltd , J ebel Ali , Dubai

Design of Grating Support Structure for Hanging Platform

231796391.xls.ms_office

1 . Introduction

The purpose of following calculations is as listed below;

(A) To check proposed grating support system for the platform.

(B) To check the adequacy of the grating for live load of personnel as 5 kN/m

Reference Documents and drawings ::

LME drawing # EN-1563-101 Dt. 01.12.10 - " Plan Layout for Grating ".

Reference codes::

* BS 5950 - Part 1:2000 -Structural use of steelwork in building.

* BS 8110-1997 - Structural use of concrete.

* Chemical anchor bolts - HILTI or equivalent.

2 .STAAD model and Loads

Staad model- Isometric view

3D- View

Analysis and Design of the grating has been done using Staad Pro as per BS5950 code.

Proposed Grating is Lionweld grating as below made of 30 x 3 thk flats at pitch 30x100.

231796391.xls.ms_office

900

1300

30

Main load bearing flats 30 x 3 thk ,are at 30 mm C/c.

Dead load ( DL)

self weight of steel structure is calculated by STAAD programme.

Consider Ladder load = 1 kN/m being exerted on the platform respective member.

self weight of grating members 24 kg/m = 0.24 kN/m

Live load .( LL)

Platform load- 5.0 kN/m As required by the client

Load combinations:

Design Load combinations

1.4DL+1.6LL

* Service Load combinations ( For deflection check)

1.0DL+1.0LL

3 . Analysis and Design

3.1 - Grating design

Refer grating diagram above.

Total design load = 1.4DL+1.6LL

= 1.4 x 0.24 + 1.6 x 5.0

= 8.34 kN/m

Grating length = 1300 mm

\ no. of load bearing flat bars = 1300 / 30 = 43.34

Max bending moment in the grating panel =

consider this UDL full on the grating span 8.34 x 1.3 = 11 kN/m

900

Bending moment = 11 x 0.9 / 8 = 0.11 kNm

Moment capacity = 43.34 x (1.2 py.Z) = 43.34 (1.2 x 275 x 3 x 30 / 6)

= 6.45 kNm > actual moment

Hence safe

Deflection check :

231796391.xls.ms_office

max deflection = 5 WL

4

/ 384 E I I = 67 x 3 x 30

3

/ 12 = 0.45 x 10

6

mm

4

= 5 x 11 x 900

4

/ ( 384 x 203000 x 0.45 x 10

6

)

= 1.03 mm

Allowable deflection = span / 200 = 1300 / 200 = 6.5 mm

Actual deflection < allowable deflection

Hence safe

3.2 Chemical Anchor Connection between UC 152X152X23 & concrete roof.

Fx = 6 kN

Fy = 78 kN

Fz = 1 kN

Use 152x152 x20 thk base plate for columns.

It is proposed to use 8 no. M20 HILTI chemical anchor bolts

max tension in bolt due to Fz = 25 /4 = 6.25 kN

Max shear in bolt = Fy / 8 = 78 /4 = 19.5 kN

Refer HILTI chemical anchor bolt catalogue :: HVU adhesive with HAS rod.

Tensile capacity: ( for 20 dia bolts) Refer catalogue:

N

Rd,c

= N

o

Rd,c

.f

B,N

.f

T

.f

A,N

.f

R,N

N

o

Rd,c

.= 52.4 kN

f

B,N

. = 1.16 for C40 grade concrete

\ N

Rd,c

= 52.4 * 1.16 * 1.0 * 0.68 * 1.0 f

T

.= 1.0 full recommended anchor depth

= 41.3 kN > actual tension in bolt f

A,N

.= 0.68 for 120 mm spacing

f

R,N

= 1.0 no edge distance influence

Hence safe

(egde distance > 180 mm)

Shear capacity: (for 20 dia bolts) Refer catalogue:

V

Rd,c

= V

o

Rd,c

.f

B,V

.f

AR,V

.f

b,V

V

o

Rd,c

.= 10.3 kN

min edge distance required C

min

= 85 mm f

B,V

.= 1.28 for C40 concrete grade

actual edge distance C = 200 mm f

AR,V

.= 1.89 C/C

min

= 2.35

spacing between bolts S = 120 mm S/C

min

= 1.4

\ V

Rd,c

= 10.3 * 1.28 * 1.89 *1.0 f

b,V

= 1.0

= 25 kN > actual shear in bolt

Hence safe

Combined capacity = 6.25/41.3 + 19.5 / 25 = 0.94 < 1.4

Hence safe

End plate :

max moment in end plate = 2 x 6.25 x 0.05 = 0.62kNm

Moment capacity of end plate per unit width = p

y

.t

p

/4 ..cl.6.3.4.3, BS5950-1:2000

\Moment capacity of end plate = p

y

.b.t

p

/4

= 275 x 152 x 20 /4 = 4.18 kNm > actual moment in end plate

hence safe

Hence provided 4no. M20 chemical HILTI anchor bolts/rod and the end plate are safe.

231796391.xls.ms_office

3.3 Bolted connection between main member UC 152x152x23 to secondary members CH 125x65x15.

max axial force in hanger members = 10kN

provide 2M12 through bolts, BS grade 8.8

max tension per bolt = 10/2 = 5 kN

capacity of M12 bolt in tension = 37.8 kN > actual design tension

Provide 12 thk end plate .. Hence safe

4. Conclusion :

The proposed grating made of 30 x 3 thk flat at pitch 30 mm c/c and the support system

is structurally safe.

Deflections are within allowable limit.

The proposed connections are structurally safe.

231796391.xls.ms_office

Das könnte Ihnen auch gefallen

- P 5.0.1 Loading Condition For Columns: 5.0 Analysis of ColumnDokument6 SeitenP 5.0.1 Loading Condition For Columns: 5.0 Analysis of Columnanimesh91Noch keine Bewertungen

- Design of Base PlateDokument4 SeitenDesign of Base PlateBenjun Balbin100% (5)

- Anchor Bolt & Base Plate DesignDokument6 SeitenAnchor Bolt & Base Plate DesignAzeem Suddal100% (1)

- Anchor BoltDokument93 SeitenAnchor BoltAnand.5Noch keine Bewertungen

- Structural Steelwork ConnectionsDokument4 SeitenStructural Steelwork Connectionstheunknown076Noch keine Bewertungen

- Design Calculation Steel Structure Power PlantDokument58 SeitenDesign Calculation Steel Structure Power Plantrajeshdebnath100% (2)

- Splice Design - LRFDDokument22 SeitenSplice Design - LRFDkalpanaadhiNoch keine Bewertungen

- Rafter DesignDokument12 SeitenRafter DesignsetakNoch keine Bewertungen

- Chequered Plate 1250mm-cDokument28 SeitenChequered Plate 1250mm-casvenk309100% (3)

- Insert Plate DesignDokument1 SeiteInsert Plate DesignDivya MohanNoch keine Bewertungen

- Bolted Moment Connection 2x2Dokument22 SeitenBolted Moment Connection 2x2Немања КараклајићNoch keine Bewertungen

- Design of Base Plate For BS5950Dokument2 SeitenDesign of Base Plate For BS5950dantevarias89% (19)

- Brace ConnectionDokument10 SeitenBrace ConnectionAhmed Ben HmidaNoch keine Bewertungen

- Design of Base PlateDokument161 SeitenDesign of Base PlatemaheshbandhamNoch keine Bewertungen

- ANCHOR - REINFORCEMENT (Metric)Dokument10 SeitenANCHOR - REINFORCEMENT (Metric)Tarek AbulailNoch keine Bewertungen

- Design of CHQRD PlateDokument20 SeitenDesign of CHQRD PlateRagavanNoch keine Bewertungen

- Shear Connection I-SecDokument36 SeitenShear Connection I-SecRaveendra Babu CherukuriNoch keine Bewertungen

- Design Calculation For Lifting Hook Rev00Dokument29 SeitenDesign Calculation For Lifting Hook Rev00layaljamal2Noch keine Bewertungen

- Baseplate MonorailDokument31 SeitenBaseplate Monorailmohamad chandraNoch keine Bewertungen

- Base PlateDokument12 SeitenBase PlateD SRINIVAS100% (1)

- RD, 1 RD, 2 RD, 3 RD, 4 RD, 5 RD, 6 RD, 7 RD, 8: Doc. ID-Code Rev. CategoryDokument25 SeitenRD, 1 RD, 2 RD, 3 RD, 4 RD, 5 RD, 6 RD, 7 RD, 8: Doc. ID-Code Rev. CategoryHanuman Sharma83% (6)

- Here: Mat Foundation Design Spreadsheet PDFDokument2 SeitenHere: Mat Foundation Design Spreadsheet PDFbiniamNoch keine Bewertungen

- Column Base Plate DesignDokument1 SeiteColumn Base Plate DesignBunkun15Noch keine Bewertungen

- Chequered DesignDokument2 SeitenChequered DesignSaravana N100% (1)

- Sample Shear ConnectionDokument1 SeiteSample Shear ConnectionmaheshbandhamNoch keine Bewertungen

- Crane Beam Web Splice DesignDokument7 SeitenCrane Beam Web Splice DesignCrystal JaneNoch keine Bewertungen

- Breeder House FoundationDokument16 SeitenBreeder House FoundationRobbyTeresaNoch keine Bewertungen

- Sample Calculations To Australian Standard AS1170 For Design Loads For A Post To A Barrier PDFDokument24 SeitenSample Calculations To Australian Standard AS1170 For Design Loads For A Post To A Barrier PDFRommel Angelo KirongNoch keine Bewertungen

- Calculation Sheet: Anchor Bolt Design Combined Tension and Shear Code AbbreviationDokument1 SeiteCalculation Sheet: Anchor Bolt Design Combined Tension and Shear Code AbbreviationNoppolNorasriNoch keine Bewertungen

- Steel Beam Column DesignDokument4 SeitenSteel Beam Column DesignPurnima ArkalgudNoch keine Bewertungen

- Pinned Base Plate DesignDokument12 SeitenPinned Base Plate DesignvtalexNoch keine Bewertungen

- Rafter Splice DesignDokument2 SeitenRafter Splice DesignkalpanaadhiNoch keine Bewertungen

- Att-5 - End-Plate Shear ConnectionDokument7 SeitenAtt-5 - End-Plate Shear Connectioncravikumar1971100% (3)

- Anchor Bolt DesignDokument1 SeiteAnchor Bolt DesignpawanNoch keine Bewertungen

- Design of Shear KeyDokument13 SeitenDesign of Shear Keynhulugalla100% (1)

- Calculation Sheet: Base Plate & Anchor Bolt Design - Moment Connection Base Plate DataDokument1 SeiteCalculation Sheet: Base Plate & Anchor Bolt Design - Moment Connection Base Plate DataLaurence Arcon Banal0% (1)

- Moment Connection DETAIL 2Dokument5 SeitenMoment Connection DETAIL 2way2vaseemNoch keine Bewertungen

- Project Name DOC. No.: Tank Name Rev No.: Item No.Dokument4 SeitenProject Name DOC. No.: Tank Name Rev No.: Item No.AnggaNoch keine Bewertungen

- Design of Anchor Bolt - Rev.ADokument8 SeitenDesign of Anchor Bolt - Rev.AcivilaskarNoch keine Bewertungen

- Design of Plate GirdersDokument30 SeitenDesign of Plate GirdersTHULASI MNoch keine Bewertungen

- 8224 Grating No HeaderDokument69 Seiten8224 Grating No HeadervishalnalwarNoch keine Bewertungen

- Design of Base PlateDokument4 SeitenDesign of Base PlatesanggythaNoch keine Bewertungen

- SX019a-Example Column Base Connection Under Axial Compression PDFDokument5 SeitenSX019a-Example Column Base Connection Under Axial Compression PDFdvelchev100% (1)

- Column Properties:-: Due To UplitDokument2 SeitenColumn Properties:-: Due To UplitRohit SinghNoch keine Bewertungen

- 4 stiffened-WH500X400X12X25-WH500X400X12X25Dokument7 Seiten4 stiffened-WH500X400X12X25-WH500X400X12X25phanikrishnabNoch keine Bewertungen

- Biaxial Base Plate2Dokument3 SeitenBiaxial Base Plate2abdul kareeNoch keine Bewertungen

- Crane Beam DesignDokument7 SeitenCrane Beam DesignTharanga Pradeep100% (2)

- Anchor Bolt and Base Plate Design CheckDokument48 SeitenAnchor Bolt and Base Plate Design CheckmaheshbandhamNoch keine Bewertungen

- Bottom LugDokument7 SeitenBottom LugAjiri IvoviNoch keine Bewertungen

- Anchor Bolt DesignDokument1 SeiteAnchor Bolt Designnishant131Noch keine Bewertungen

- Grating DesignDokument1 SeiteGrating DesigngaratetaNoch keine Bewertungen

- Base Plate Design Excel DesignDokument120 SeitenBase Plate Design Excel DesignOmPrakash33% (3)

- Is 800-1984-Wsd-Load CombinationsDokument30 SeitenIs 800-1984-Wsd-Load CombinationsRajesh KumarNoch keine Bewertungen

- Beam - Column Steel SpliceDokument20 SeitenBeam - Column Steel SpliceAnsh SharmaNoch keine Bewertungen

- Design of Grating For PlatformDokument5 SeitenDesign of Grating For PlatformKho C AhlNoch keine Bewertungen

- Design SheetsDokument18 SeitenDesign SheetsMuraleedharanNoch keine Bewertungen

- Design Calculation of Louvers-1Dokument7 SeitenDesign Calculation of Louvers-1vj8584Noch keine Bewertungen

- Louvers 1Dokument7 SeitenLouvers 1alex robinNoch keine Bewertungen

- Beam Ledge DesignDokument2 SeitenBeam Ledge Designauatipu100% (1)

- Anchor Bolt and Shear Key DesignDokument3 SeitenAnchor Bolt and Shear Key DesignsvgkraoNoch keine Bewertungen

- Maintenance, Inspection and Rehabilitation of Bridges: by Sri A.Nagendra Joint Secretary (RTD) Karnataka PWD BangaloreDokument145 SeitenMaintenance, Inspection and Rehabilitation of Bridges: by Sri A.Nagendra Joint Secretary (RTD) Karnataka PWD Bangalorevj8584100% (1)

- Architectural Fins - Rev 2-5 (1) .9.08Dokument15 SeitenArchitectural Fins - Rev 2-5 (1) .9.08vj8584100% (1)

- Rig 2Dokument54 SeitenRig 2toepaNoch keine Bewertungen

- National Building Code 2005Dokument1.161 SeitenNational Building Code 2005api-2617216889% (47)

- BASEPLT9Dokument27 SeitenBASEPLT9Homero Silva100% (3)

- Client Name: Prepared By: Date: A Project Name: Location: DescriptionDokument1 SeiteClient Name: Prepared By: Date: A Project Name: Location: Descriptionvj8584Noch keine Bewertungen

- 10ravens 3D 004 Modern Tables 01Dokument16 Seiten10ravens 3D 004 Modern Tables 01Naassom VazNoch keine Bewertungen

- Client Name: Prepared By: Date: A Project Name: Location: DescriptionDokument1 SeiteClient Name: Prepared By: Date: A Project Name: Location: Descriptionvj8584Noch keine Bewertungen

- 8 M PoleDokument1 Seite8 M Polevj85840% (2)

- AnchorDokument7 SeitenAnchorvj8584Noch keine Bewertungen

- Internal Glazing PDFDokument1 SeiteInternal Glazing PDFvj8584Noch keine Bewertungen

- Design of 6 Storey Building in EtabsDokument51 SeitenDesign of 6 Storey Building in EtabsMisqal A Iqbal100% (2)

- Design Calculation of Louvers-1Dokument7 SeitenDesign Calculation of Louvers-1vj8584Noch keine Bewertungen

- Cooling Tank Support StructureDokument44 SeitenCooling Tank Support Structurevj8584100% (1)

- Sound Power, Sound Pressure, and Octave Bands Explained: 39 Series Engineering GuidelinesDokument3 SeitenSound Power, Sound Pressure, and Octave Bands Explained: 39 Series Engineering Guidelinesvj8584Noch keine Bewertungen

- Ode 45Dokument2 SeitenOde 45Allas JonyNoch keine Bewertungen

- Pull-Out Strength of Self Tapping Fasteners in Aluminum Screw Slot ConnectionsDokument3 SeitenPull-Out Strength of Self Tapping Fasteners in Aluminum Screw Slot Connectionsvj8584Noch keine Bewertungen

- The Use of Glass in Floors and StairsDokument4 SeitenThe Use of Glass in Floors and Stairsvj8584Noch keine Bewertungen

- IntroCS BookDokument104 SeitenIntroCS BookKayemba IsmaelNoch keine Bewertungen

- Guidelines On Use of Glass in BuildingsDokument34 SeitenGuidelines On Use of Glass in Buildingsqatarstructz30Noch keine Bewertungen

- Ecv 203Dokument2 SeitenEcv 203Civil EngineeringNoch keine Bewertungen

- Structural Design of High Rise Buildings PDFDokument142 SeitenStructural Design of High Rise Buildings PDFvineet jain100% (1)

- A Word For SCRDokument5 SeitenA Word For SCRJulius BatiloNoch keine Bewertungen

- Building Materials and AssembliesDokument25 SeitenBuilding Materials and AssembliesChristian EspinolaNoch keine Bewertungen

- Composite Steel-Concrete StructuresDokument35 SeitenComposite Steel-Concrete Structuresmishu01Noch keine Bewertungen

- Concrete Cube TestDokument6 SeitenConcrete Cube TestMd. Mynul HossainNoch keine Bewertungen

- Skewed and Curved Steel I-Girder Bridge Fit: Technical ResourceDokument4 SeitenSkewed and Curved Steel I-Girder Bridge Fit: Technical ResourceMario Guevara Ubidia- IngenieroCivilNoch keine Bewertungen

- PSD Task 2 NotesDokument16 SeitenPSD Task 2 Notesmuhfil MuhfilNoch keine Bewertungen

- Lee Shoemaker CompressedDokument78 SeitenLee Shoemaker CompressedczapatachueNoch keine Bewertungen

- Module 3 Steel Design Batch 4Dokument197 SeitenModule 3 Steel Design Batch 4Aileen PornelaNoch keine Bewertungen

- Loadings - NSCP 2015 - 2 Storey Residential Concrete Structure1Dokument52 SeitenLoadings - NSCP 2015 - 2 Storey Residential Concrete Structure1Renvil PedernalNoch keine Bewertungen

- 9Dokument20 Seiten9api-3696315100% (1)

- Dan Brown - Ldoep (Dokument31 SeitenDan Brown - Ldoep (VapaVapaNoch keine Bewertungen

- Knobloch Et Al. - 2020 - Structural Member Stability Verification in The Ne - PART 2Dokument15 SeitenKnobloch Et Al. - 2020 - Structural Member Stability Verification in The Ne - PART 2Noah NorbergNoch keine Bewertungen

- Iso 14963 en PDFDokument11 SeitenIso 14963 en PDFImane KhammouriNoch keine Bewertungen

- Femap-154 508Dokument388 SeitenFemap-154 508acupatee100% (1)

- Chapter 3 Example Set 5Dokument4 SeitenChapter 3 Example Set 5alaa altaeeNoch keine Bewertungen

- Section 9 - Brickwork and BlockworkDokument6 SeitenSection 9 - Brickwork and BlockworkShing Faat WongNoch keine Bewertungen

- A Review in High Early Strength Concrete and Local PDFDokument10 SeitenA Review in High Early Strength Concrete and Local PDFAgikx ChabeNoch keine Bewertungen

- FLAT BAR DesignDokument8 SeitenFLAT BAR DesignTerry CheukNoch keine Bewertungen

- S CurveDokument121 SeitenS CurveJohn ChristopherNoch keine Bewertungen

- DMG 01Dokument57 SeitenDMG 01Mateusz SobieszyńskiNoch keine Bewertungen

- Earthquake LectureDokument210 SeitenEarthquake LectureJeff DatinguinooNoch keine Bewertungen

- DSI Underground Systems Trusses Slings US 01Dokument6 SeitenDSI Underground Systems Trusses Slings US 01Alper OztekinNoch keine Bewertungen

- MortarDokument26 SeitenMortarLyka Isabel TanNoch keine Bewertungen

- L12 Bolt Connection 2Dokument17 SeitenL12 Bolt Connection 2Kidus KidaneNoch keine Bewertungen

- L Shaped Reatining WAll With HORZONTAL Bach FillDokument29 SeitenL Shaped Reatining WAll With HORZONTAL Bach Fillsarveshfdk48100% (2)

- DK Kzy Iapk R Lfefr Uksgj Ftyk GuqekuxDokument5 SeitenDK Kzy Iapk R Lfefr Uksgj Ftyk GuqekuxJulfikar KhanNoch keine Bewertungen

- Progress Report: Large-Scale Tests of A Low-Rise Unreinforced Masonry Building SystemDokument330 SeitenProgress Report: Large-Scale Tests of A Low-Rise Unreinforced Masonry Building SystemJalal KeNoch keine Bewertungen

- Hibbeler Structural AnalysisDokument1 SeiteHibbeler Structural AnalysisLaurentNoch keine Bewertungen