Beruflich Dokumente

Kultur Dokumente

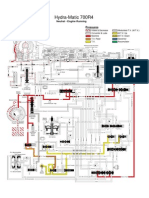

700 R4 Transmission Evolution

Hochgeladen von

Transmisiones Automáticas ChepeOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

700 R4 Transmission Evolution

Hochgeladen von

Transmisiones Automáticas ChepeCopyright:

Verfügbare Formate

700 R4 Transmission - Overdrive Evolution

For 25 Years, GM's 700-R4 And Its 4L60 Descendents Have Shifted Most Of The General's RWD

Cars. Here's How An Econo Trans Spawned In The Dark Days Of The Energy Crisis Evolved Into

A Rugged And Reliable Unit.

By Marlan Davis, Photography by B&M, General Motors, Marlan Davis, TCI

Hot Rod Magazine, February, 2009

GM's TH700-R4 four-speed automatic-overdrive transmission and its derivatives have nearly

become the universal favorite of hot rodders. Properly built, a good 700 is capable of

withstanding at least 450 lb-ft of torque. But that hasn't always been the case. With the help of

the experts at B&M and TCI, we traced the 700's initially checkered past and bring you up to

date on some of the countless improvements incorporated over the years as GM continually

refined the basic design to keep up with the increasing output of the engines it was installed

behind.

In the Beginning

The 700-R4 was first introduced in the '82 Corvette. On paper, its specs looked pretty good:

The trans had lower First and Second gears (3.06 and 1.63, respectively) than other

automatics, its lockup torque converter offered potential fuel-mileage gains, and the 0.7

overdrive decreased the overall drive ratio by 30 percent. But the original design was not

considered a strong transmission, with failures behind even a mild 350 not uncommon. The

trans was so weak that in its original setup, GM deliberately calibrated it to kick out of lockup

and high gear under full-throttle, top-end conditions to avoid burning it up.

The original versions had only downsized, 27-spline input shafts, one of many possible and

common failure points. By 1984, 700-R4s intended for use behind small-block Chevy V-8s

began to receive beefy, 30-spline input shafts similar to those found on classic TH350 and

TH400 transmissions. From 1984 to 1987, the most failure-prone internal parts, from the ring-

gear to the oil-pump housing, were upgraded.

An auxiliary valvebody was added in October 1986. Finally, on performance cars like the

Corvette, additional internal lubrication improvements permitted the trans to survive in high-

gear, full-throttle, top-end conditions. Many of the improvements can be retrofitted into the

earlier, weak transmissions, but the 27-spline versions need so many new parts that it's more

cost-effective to swap in a later core. However, it is worthwhile to upgrade the later 30-spline

versions to Corvette/IROC-level internals, if they're not already so equipped.

GM's 700-R4 trans and its descendents have become the hot rodder's favorite street

automatic trans. Early problems have been fixed, and overdrive lets you run steep rear gears

and still cruise down the highway. The call-out numbers in this photo correspond to the

sidebars on the following pages.

GM's 700-R4 trans and its descendents have become the hot rodder's favorite street automat

The 700-R4/4L60 uses a TV cable that attaches to the right rear of the case's passenger side

(A). The TV cable is eliminated on the 4L60E and its derivatives. A large hole for a multiprong

computer connector is now located in the same relative location (B). Non-E transmissions had

a smaller TCC electrical connector on the driver side ahead of the governor.

The 700-R4/4L60 uses a TV cable that attaches to the right rear of the case's passenger si

Enter The 4L60E

The next big change was in 1993 with the introduction of the 4L60E in pickup trucks, vans, and

SUVs. "E" derivatives are entirely controlled by the computer via electronic solenoids installed

on the valvebody.E-type transmissions require a computer to function-either the original

factory GM ECM or available aftermarket standalone solutions-but now shift quality can be

easily dialed in without having to go into the trans itself. Also, with the computer controlling

line pressure, E transmissions eliminate the TV cable and its associated bracket geometry and

adjustment issues.

Not all '93 vehicles got the 4L60E. Rear-wheel-drive cars continued to use the 700-R4, but in

keeping with GM's new nomenclature, the carryover trans was renamed the 4L60 (without the

E). Other than the name, the 4L60 is essentially the same trans as a similar-vintage 700-R4. All

GM transmissions use the new identification system: the first digit is the number of forward

gears (4), the letter indicates whether the trans is intended for front-wheel-drive (T for

transverse) or rear-wheel-drive (L for longitudinal) applications, and the last two numbers

provide a guide to the unit's relative torque capacity (60, in this case) compared with other GM

transmissions. If both nonelectronically controlled and electronically controlled versions of an

otherwise similar transmission design are offered, an E suffix (for electronic) is appended to

the designator.

Rear-wheel-drive cars received the 4L60E starting in 1994. Although many internal mechanical

components interchange, the cases, electronic controls, and valvebodies are so different that

it's not practical to upgrade a non-E to an E (or vice versa)

Many internal electronic changes occurred on 4L60E transmissions between 1993 and 1996.

These included the introduction of a pulse-width-modulated torque-converter lockup function

on some models starting around 1995. This smoothes out the converter lockup function by

pulsing the apply function using a PWM solenoid. There are several unique evolutions on this

system with matching solenoids and electrical switches. Although not really important for

performance use, it is of concern if you just need a replacement trans with full functionality for

a late-model and want to make sure everything works as intended.

Here are some common four-bolt TH700-R4 extension housings, from left: two-wheel-drive

truck, Camaro/Firebird with torque-arm mount, and Caprice-style (GM PN 24214689) with an

extra mount the same distance from the case front as a TH400/ TH200-4R mount. You can

usually swap four-bolt housings from one main case to another.

Here are some common four-bolt TH700-R4 extension housings, from left: two-wheel-drive tru

You can identify a 700-R4/ 4L60 by its square, 16-bolt pan. Stock pans vary in depth and filter

style; they don't all necessarily interchange. Universal aftermarket deep pans are available (like

this B&M cast unit, PN 70260).

You can identify a 700-R4/ 4L60 by its square, 16-bolt pan. Stock pans vary in depth and f

Three-Piece Case

In 1996, with the 4L60E in use for most rear-drive applications and with new engine designs on

the drawing board, GM began moving to a common main case with a bolt-on bellhousing.

Previously, there were just two separate case patterns: a metric case for 60-degree V-6

engines and the classic Chevy case that fit traditional big- and small-block V-8s, straight Chevy

L6s, and V6-90 engines. The move to a separate bellhousing let one common core fit a variety

of different engine families and also opened up the interesting possibility of aftermarket

adapter bellhousings to fit oddball or niche classic engines, such as Keisler Engineering has

done with its Mopar conversion kits.

Other changes coincided with the move to separate bellhousings. The input-shaft tip

configuration was revised, although the overall shaft diameter and spline-count still remained

at 30. When retrofitting, the new spline tip requires a corresponding torque converter to mate

with the revised shaft. GM also changed the tailhousing from a four-bolt to a six-bolt design.

The 4l65E

Stock 4L60Es are rated at 360 lb-ft of torque. By 2001, engine output had increased to the

point that further internal modifications were needed for Corvette, Hummer, and some other

applications. The uprated transmission-in stock form rated to withstand up to 380 lb-ft-is

known as the 4L65E (RPO M32). There were significant improvements, including five-pinion

planetaries, a higher-capacity input housing, and an induction-hardened input-shaft assembly.

Beginning in 2002, many of the technologies from the 4L65 applications that added durability

were incorporated into the 4L60, including more robust bushings and bearings. Many of the

other durability-enhancing parts can also be swapped into earlier 4L60 transmissions.

The 4l70E

Classified as the 4L70E, the ultimate production evolution of the original 700-R4 trans family is

used in selected '07 trucks and includes further refinements over the 4L65E. The 4L70 is a

variation of the five-pinion 4L65, with additional strengthening in the output shaft and

reaction internal gear to handle increased engine torque. It is doubtful that GM will continue

to upgrade the trans any further, as it will be phased out once the new six-speed automatic

production lines are ramped up.

Beginning in 1996, GM transitioned to new cases with separate bellhousings. Changing the

bellhousings let the same basic cases fit many different applications. The new cases are also

machined for six-bolt extension housings rather than the four-bolt housings used previously.

Beginning in 1996, GM transitioned to new cases with separate bellhousings. Changing the b

A good valvebody-recalibration kit plus a supplementary professional-grade upgrade kit like

Sonnax's Sure Cure reconditioning kit fix many problems without costing a bundle. Compared

with the basic B&M Shift-Improver Kit, the Transpak is more aggressive and includes

valvebody, boost-valve, and pressure-regulator upgrades. For a complete high-perf rebuild,

use the B&M Transkit.

A good valvebody-recalibration kit plus a supplementary professional-grade upgrade kit lik

On the surrounding pages we've illustrated some of the most important improvements and

variations, many of which can be used to upgrade earlier transmissions. But there are so many

details that we can only scratch the surface here. If you really want to get into what makes this

trans tick and get the lowdown on all the changes, fixes, and improvements, the best sources

are Automatic Transmission Service Group (ATSG) Techtran and upgrade handbooks available

directly from ATSG's Web site as well as on eBay

1 Planetary Carriers

Planetaries are used both forward (the input planetary carrier) and at the rear (the reaction

planetary carrier). Early failure-prone planetary carriers should be upgraded to at least the

improved design with batwing washers (circa 1985). The improved four-pinion input carrier

carries GM PN 24226173 and bolts in to any trans. The best four-pinion reaction carrier was

introduced at about the same time for selected high-perf applications like Corvettes and

IROCs. Besides the batwing washers, this carrier also adds a pinion oiling system with internal

passages. Even better-although much more expensive-are the late five-pinion carriers

introduced on the 4L65E, available from both GM and aftermarket sources.

In 2001, GM introduced the 4L65E on selected high-perf, high-load applications. One of the

improvements was even stouter five-pinion planetary carriers: GM PN 24227481 is the input

planetary carrier (left); PN 24227591 is the reaction planetary carrier (right). Aftermarket

equivalents are available. The improved carriers retrofit, but are pricey.

In 2001, GM introduced the 4L65E on selected high-perf, high-load applications. One of the

Note the small lubrication holes in the PN 24228402 "Corvette" four-pinion carrier. An oil dam

was also added to the rear of the Corvette carrier (right); the extra clearance needed by the

dam requires upgrading to the later reaction internal gear.

Note the small lubrication holes in the PN 24228402 "Corvette" four-pinion carrier. An oil

2 Reaction Sun Shell And Input Shaft

The reaction sun gear shell helps apply both Second and Reverse gears and is a key part for

holding all the internals together. It has been a major failure item since the 700's inception.

Originally, the Low and Reverse clutch roller race rode against the shell, separated only by a

thin thrust washer. Aftermarket beast shells became available made from thicker material

around the neck. A Torrington bearing replaced the spindly thrust washer, and better roller

races became available as well. Finally, starting in 2001, GM completely redesigned the sun

shell. The thrust washer was eliminated, and a new fully rollerized thrust bearing was added to

the reaction carrier shaft and front carrier ring gear. The new-design sun gear shell (GM PN

24229604), reaction carrier shaft (PN 24222756), and sun shell thrust bearing (PN 24217328)

will back-fit as a complete assembly.

The original reaction shaft and input gear (left) were prone to wear in the shaft bushing area

and to spline breakage. Starting in 1987 on high-perf apps, GM went to tougher material and

revised the input gear to accommodate an improved five-disc 3-4 clutch pack (center). The '01-

and-up design gets the roller bearing and accommodates a six-disc clutch pack (right).

The original reaction shaft and input gear (left) were prone to wear in the shaft bushing

Sun shells, from left: original stock with thin thrust washer and stock roller race; thick,

aftermarket sun shell with Torrington bearing and heavy-duty race; and '01-and-later GM new-

design setup with thrust bearing on the reaction shaft.

Sun shells, from left: original stock with thin thrust washer and stock roller race; thick

3 Input Clutch Housing (below left and center)

Over the years, both GM and the aftermarket have upgraded the input housing. The material

thickness was increased, the input shaft hardened, and the housing depth slightly increased to

accommodate additional 3-4 clutch packs.

TH700s first used a weak 27-spline input shaft (left). Starting in 1984, V-8/V6-90 versions got a

larger, 30-spline input (center). Separate-bellhousing 4L60Es use a 30-spline input with a

revised tip (right). Torque-converter selection must match the input-shaft design. Upgrading a

27-spline input to 30-spline configuration also requires changing the forward clutch assembly

and front pump.

TH700s first used a weak 27-spline input shaft (left). Starting in 1984, V-8/V6-90 version

On stock input housings, cracks often form near the female splines, which could lead to

complete trans failure. A special 30-spline input housing available from aftermarket suppliers is

reinforced with a steel collar. It also has a shot-peened input shaft that's been cryogenically

treated for strength. The entire housing is X-rayed for cracks then spin-balanced at 9,000 rpm.

On stock input housings, cracks often form near the female splines, which could lead to co

In 1987, GM changed from a steel apply piston with a check ball in the housing (left) to an

aluminum piston with relief holes in the piston (right, arrows). The early design had a wavy

spring clutch plate. The late style has a conical spring clutch plate. This change eliminates the

clunk going from Neutral/Park into Reverse. You can upgrade to these parts as a set.

In 1987, GM changed from a steel apply piston with a check ball in the housing (left) to a

4 Reverse Input Housing (above right)

The reverse input housing engages Reverse, but it also supports the 2-4 band. Check the drum

surface carefully for signs of wear. Because of the nonadjustability of the band that contacts

the drum, there is no way to resurface the drum without having adjustment problems or

having the drum crack if returned to service. Drums manufactured starting midway through

the '86 model year are slightly thicker in the 2-4 band apply area, which improves 2-4 band

performance.

5 Front Pump

Overall pump design has been continually upgraded to improve hydraulic pressure. There are

three major factory pump designs: one for the early small input shaft and torque converter,

one for the '84-'96 large input shaft and torque converter, and one for '97-and-up

transmissions. The early style had only a 7-vane pump; the second design (usually cast 732 on

the cover) had a 10-vane rotor set, and the beefy, late third-design has 13 vanes. There are

subvariants that may affect interchange, but in general, the '84-'95 10-vane pump can replace

a 7-vane pump by plugging its auxiliary valvebody port and changing the reverse drum and

torque converter. Installing the 13-vane pump in place of an early 7- or 10-vane pump requires

considerable machining to back-fit as a complete assembly.

Oil-pump performance may be further improved by modifying control orifice size, altering

spool valve land shapes, and adjusting spool valve diameters to meet specific operational

requirements. For example, boost-valve pressure-regulator components installed in the pump

cover regulate boost-line pressure throughout the trans. Up to a point, higher pressure is

better.

It is possible to install upgraded rotor sets into existing pump housings. The 13-vane rotor

components (right) can replace the 10-vane (center) or 7-vane (left). However, the vane-sets

are select-fit components requiring precise assembly techniques.

It is possible to install upgraded rotor sets into existing pump housings. The 13-vane rot

The pump slide spring fits into the pump body. The early single-piece slide spring is no good

and should be replaced by an '86-and-later dual spring (shown). Sonnax offers a high-output

pump slide spring, PN 77722-01K.

The pump slide spring fits into the pump body. The early single-piece slide spring is no g

The TH700/4L60 (left group) uses different pressure regulators than a 4L60E (right group). In

1987, GM upped boost valve outside diameter from 0.496 inch to 0.500 inch. For even more

pressure in a full-race app, install a B&M blue spring and 0.570 extreme valve. Up the 4L60E's

aluminum sleeve-and-valve combo from 0.496 to 0.500 and go to a stiffer spring.

The TH700/4L60 (left group) uses different pressure regulators than a 4L60E (right group).

6 Valvebody

There are several major valvebody configurations. The early '82-'87 configuration had no

auxiliary valvebody; the torque converter clutch (TCC) lockup function was actuated

hydraulically at a set pressure without computer input. Although this makes retrofit easy into

early vehicles, the first-generation valvebodies often have leaky, low-capacity 1-2 and 3-4 shift

valves that produce inconsistent shift quality.

The late '87-'93 second-design valvebody solved the problems. It added an additional auxiliary

valvebody to fix a Park/Drive bang/clunk problem. A new abuse valve smoothed out rock-

shifting, helping cars get out of snow and mud easier. A new one-piece 1-2 shift valve

improved consistency, reduced leakage, and permitted downshifting from Second to First gear

at fairly high rpm. The 3-4 shift valve was redesigned to permit WOT 3-4 upshifts. B&M offers

the improved WOT 3-4 upshift kit under PN 70249.

Most second-generation valvebodies have a plugged TCC hydraulic lockup port, as GM

transferred TCC lockup control directly to the engine computer. The early valve can be

installed in place of the port plug to permit locking up the TCC via hydraulic pressure through

the '88 models. From '89-'93, the former TCC hydraulic lockup port is completely blocked off,

and no valve can be retrofitted. Instead, a computer or electric toggle switch is needed to

actuate TCC lockup. Various coordinated aftermarket shift-improver kits are also available to

recalibrate the shift feel on pre-4L60E valvebodies.

The 4L60E phased in a valvebody controlled by the computer acting through electric solenoids

in lieu of shift valves. There is no interchange between E and non-E valvebodies.

A typical 700-R4 valvebody, showing the TCC hydraulic lockup, 3-4 shift valve, 2-3 shift valve no

changes needed), and 1-2 shift valve. Early designs used a hydraulically-actuated valve for TCC

lockup. '87-'88 bodies still have the port, but it's plugged; the A1 parts can be swapped in to

achieve pressure-based TCC lockup. You can replace leaky early 3-4 parts with the '88-'93 parts

for improved performance. Stock early and late 1-2 parts don't interchange, but higher-

capacity aftermarket replacements for early 1-2 parts are available.

A typical 700-R4 valvebody, showing the TCC hydraulic lockup, 3-4 shift valve, 2-3 shift v

An improved throttle-valve sleeve was used on some high-perf apps. It allowed the trans to

stay in Fourth at WOT. If the existing throttle-plunger valve is stamped 94, the assembly can be

upgraded. Caution: For durability, prolonged WOT Fourth gear operation requires upgrading

other internal parts and performing oiling mods. B&M sells the sleeve under PN 70237.

An improved throttle-valve sleeve was used on some high-perf apps. It allowed the trans to

Rather than messing with the valvebody or governor weights to change shift quality, on a

4L60E and derivatives, you reflash the computer. Aftermarket standalone computers are

available for retrofit applications. TCI PN 377010 fits the 4L60E as well as the TH400's

electronic overdrive descendent, the 4L80E.

Rather than messing with the valvebody or governor weights to change shift quality, on a 4

Servo Assembly

The 2-4 servo assembly applies the 2-4 band. Upgraded servo assemblies have more surface

area and volume to increase the holding force and yield firmer shifts. The best GM servo was

used on C4/C5 Corvettes, as well as '93-and-later Camaros and Firebirds equipped with LT1

and LS1 engines. TCI sells the Corvette servo assembly under PN 376003. Aftermarket Super

Hold servos are available with even more holding power. Changing the servo should be

coordinated with valvebody recalibration, all matched to the intended application. Production

inner (second apply) and outer (fourth apply) servo pistons can even be mixed and matched to

fine-tune the feel.

Governor

Valvebody mods contained in typical aftermarket shift-improver kits can alter individual shift

points, but playing with the governor weights allows the end user to change all shift points

equally. The 4L60E no longer has a governor.

The best stock governor is the Corvette-style with pointed weights (Sonnax PN 730. The Vette

weights are lighter than typical standard V-8 governors with square weights. The B&M

governor recalibration kit (PN 20248, bottom) allows the end user to adjust the mile-per-hour

shift points of the trans. It also fits the GM TH200, TH350, and TH400. Also note the TCC lockup

plug used on TH700/4L60 (non-E) versions.

The best stock governor is the Corvette-style with pointed weights (Sonnax PN 730. The Vet

Typical servo assemblies, from left: GM standard, light-heavy-duty, and Corvette, with (arrow)

improved '85-and-up 2-4 servo cover that retrofits with the correct cover seal. Aftermarket

servos require their own covers, like the Sonnax and Superior Super Hold servos shown on the

right that yield 40-50 percent more holding power in Overdrive.

Typical servo assemblies, from left: GM standard, light-heavy-duty, and Corvette, with (ar

Complete transmissions upgraded with good heavy-duty parts are available from reputable

aftermarket performance trans specialists like B&M and TCI.

Das könnte Ihnen auch gefallen

- GM 4L80E Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyVon EverandGM 4L80E Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyBewertung: 5 von 5 Sternen5/5 (1)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideVon EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideBewertung: 4.5 von 5 Sternen4.5/5 (8)

- 4L60E SwapguideDokument3 Seiten4L60E Swapguideericproffitt100% (3)

- How to Rebuild & Modify Rochester Quadrajet CarburetorsVon EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsBewertung: 5 von 5 Sternen5/5 (2)

- How to Swap GM LS-Engines into Camaros & Firebirds 1967-1981Von EverandHow to Swap GM LS-Engines into Camaros & Firebirds 1967-1981Bewertung: 5 von 5 Sternen5/5 (1)

- How to Build Max-Performance Chevy LT1/LT4 EnginesVon EverandHow to Build Max-Performance Chevy LT1/LT4 EnginesBewertung: 3 von 5 Sternen3/5 (1)

- How to Build New Hemi Performance on the Dyno: Optimal Parts Combos for Max HorsepowerVon EverandHow to Build New Hemi Performance on the Dyno: Optimal Parts Combos for Max HorsepowerBewertung: 5 von 5 Sternen5/5 (1)

- Chevy Big-Block Engine Parts Interchange: The Ultimate Guide to Sourcing and Selecting Compatible Factory PartsVon EverandChevy Big-Block Engine Parts Interchange: The Ultimate Guide to Sourcing and Selecting Compatible Factory PartsBewertung: 4 von 5 Sternen4/5 (7)

- LS Gen IV Engines 2005 - Present: How to Build Max PerformanceVon EverandLS Gen IV Engines 2005 - Present: How to Build Max PerformanceBewertung: 5 von 5 Sternen5/5 (2)

- Jeep, Dana & Chrysler Differentials: How to Rebuild the 8-1/4, 8-3/4, Dana 44 & 60 & AMC 20Von EverandJeep, Dana & Chrysler Differentials: How to Rebuild the 8-1/4, 8-3/4, Dana 44 & 60 & AMC 20Noch keine Bewertungen

- LS Swaps: How to Swap GM LS Engines into Almost AnythingVon EverandLS Swaps: How to Swap GM LS Engines into Almost AnythingBewertung: 3.5 von 5 Sternen3.5/5 (2)

- Mopar Small-Blocks: How to Build Max PerformanceVon EverandMopar Small-Blocks: How to Build Max PerformanceBewertung: 5 von 5 Sternen5/5 (4)

- Swap LS Engines into Chevelles & GM A-Bodies: 1964-1972Von EverandSwap LS Engines into Chevelles & GM A-Bodies: 1964-1972Bewertung: 4.5 von 5 Sternen4.5/5 (3)

- Technical Documentation GM THM 4L60-EDokument108 SeitenTechnical Documentation GM THM 4L60-Ecyber_nautica100% (1)

- B&M Transpak Kit TH700Dokument14 SeitenB&M Transpak Kit TH700Ghostrider1100% (1)

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsVon EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsBewertung: 5 von 5 Sternen5/5 (5)

- Transmission Identification & DecodingDokument347 SeitenTransmission Identification & Decodingridler16100% (4)

- Muncie 4-Speed Transmissions: How to Rebuild & ModifyVon EverandMuncie 4-Speed Transmissions: How to Rebuild & ModifyBewertung: 5 von 5 Sternen5/5 (7)

- Only The Strong Survive: Building A 10-Second-Capable Century Automotive 4L60EDokument6 SeitenOnly The Strong Survive: Building A 10-Second-Capable Century Automotive 4L60Ecaliangel175% (4)

- 700r4 Rebuild Tips, Tricks & Tools - Corvette ForumDokument33 Seiten700r4 Rebuild Tips, Tricks & Tools - Corvette Forumstringstrange100% (2)

- Sonnax HP 4L60E Catalog v1Dokument12 SeitenSonnax HP 4L60E Catalog v1Brad Franc100% (2)

- 4l60e Pump RevisionsDokument22 Seiten4l60e Pump RevisionsJerry Burns100% (2)

- GM THM 4L60-E ServosDokument7 SeitenGM THM 4L60-E Servoscyber_nauticaNoch keine Bewertungen

- THM 700-R4 (4L60)Dokument121 SeitenTHM 700-R4 (4L60)Luis Antonio Castillo Arispe100% (12)

- Chrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildVon EverandChrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildBewertung: 5 von 5 Sternen5/5 (1)

- 700r4 Checkball LocationsDokument2 Seiten700r4 Checkball LocationsMatt Trout50% (2)

- 700r4 Cable Adjustment InstructionsDokument3 Seiten700r4 Cable Adjustment InstructionsTito Tales100% (1)

- 700r4 DiagramDokument1 Seite700r4 Diagramgman4dx266100% (1)

- THM 700 R4 4L60 1982 1986 - ATSG Automatic Transmission Service Group PDFDokument96 SeitenTHM 700 R4 4L60 1982 1986 - ATSG Automatic Transmission Service Group PDFAntonio Perez100% (4)

- 700 R4 - 4l60e - 4l65eDokument17 Seiten700 R4 - 4l60e - 4l65eabcfghjkl100% (6)

- 4 L60 DiagnosisDokument4 Seiten4 L60 DiagnosisGypsyR75% (4)

- TH700-R4 / 4L60E / 4L65E / 4L70E: RWD 4 SpeedDokument14 SeitenTH700-R4 / 4L60E / 4L65E / 4L70E: RWD 4 SpeedByung C Kim100% (1)

- Auto Transmission TroubleshootDokument26 SeitenAuto Transmission Troubleshootwei foo100% (3)

- 4l60e PDFDokument112 Seiten4l60e PDFverenais6sarabia88% (8)

- 4l60e No Lock UpDokument2 Seiten4l60e No Lock Uptambache69100% (1)

- THM 700 r4 4l60 1987 1993 Atsg Automatic Transmission Service GroupDokument119 SeitenTHM 700 r4 4l60 1987 1993 Atsg Automatic Transmission Service GroupOtniel de la Vega80% (5)

- CHEVROLET - Th700r4 Automatic Transmission Repair ManualDokument125 SeitenCHEVROLET - Th700r4 Automatic Transmission Repair ManualPier Angelo Palumbo0% (3)

- 4l60 1 PDFDokument55 Seiten4l60 1 PDFwantierNoch keine Bewertungen

- General Motors - Hydra-matic 4L60E (2003 г.RUS)Dokument150 SeitenGeneral Motors - Hydra-matic 4L60E (2003 г.RUS)030186100% (1)

- Oil Circuit Diagrams - 700R4 - MD8Dokument11 SeitenOil Circuit Diagrams - 700R4 - MD8Luchito E. Cueva100% (1)

- 2001 ATRA Seminar Manual Contents PDFDokument218 Seiten2001 ATRA Seminar Manual Contents PDFchoco84Noch keine Bewertungen

- 2001-2003 4L60-E Transmission OverhaulDokument104 Seiten2001-2003 4L60-E Transmission Overhaulbullfly60% (5)

- 30 Common 4L60E Transmission ProblemsDokument4 Seiten30 Common 4L60E Transmission ProblemsJorge Pires100% (5)

- TH350 GDDokument1 SeiteTH350 GDJose CencičNoch keine Bewertungen

- 4L80E Modifications Guide v2Dokument36 Seiten4L80E Modifications Guide v2sonyaNoch keine Bewertungen

- 4R70WDokument3 Seiten4R70WFSR14070% (1)

- ATRA GM 4L60-4L60E (700R4) Rebuild ProceduresDokument0 SeitenATRA GM 4L60-4L60E (700R4) Rebuild ProceduresJuan Manuel Aguero Diaz83% (12)

- 4L60E TechGuide PDFDokument150 Seiten4L60E TechGuide PDFGhostrider1100% (6)

- Ford Inline Six: How to Rebuild & Modify: How to Rebuild & ModifyVon EverandFord Inline Six: How to Rebuild & Modify: How to Rebuild & ModifyNoch keine Bewertungen

- Ford AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WVon EverandFord AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Chevrolet Small-Block Parts Interchange Manual - Revised EditionVon EverandChevrolet Small-Block Parts Interchange Manual - Revised EditionBewertung: 5 von 5 Sternen5/5 (31)

- Cuerpos de Válvulas Catálogo PDFDokument68 SeitenCuerpos de Válvulas Catálogo PDFTransmisiones Automáticas Chepe83% (6)

- Torque Converter Catalogue For Web PDFDokument345 SeitenTorque Converter Catalogue For Web PDFTransmisiones Automáticas Chepe100% (7)

- Código P0171Dokument4 SeitenCódigo P0171Transmisiones Automáticas ChepeNoch keine Bewertungen

- 4L60E Common ProblemsDokument4 Seiten4L60E Common ProblemsTransmisiones Automáticas Chepe100% (2)

- AX4N Vs AX4S OPERACIÓN DE SOLENOIDESDokument7 SeitenAX4N Vs AX4S OPERACIÓN DE SOLENOIDESTransmisiones Automáticas Chepe100% (2)

- Revista de TransmisionesDokument68 SeitenRevista de TransmisionesTransmisiones Automáticas Chepe100% (4)

- 4f27e 2006 Workshop ManualDokument23 Seiten4f27e 2006 Workshop ManualTransmisiones Automáticas Chepe100% (5)

- 4L60 eDokument112 Seiten4L60 eFelipe Jaramillo RoblesNoch keine Bewertungen

- Previous MenuDokument88 SeitenPrevious MenuTransmisiones Automáticas Chepe100% (2)

- Mercedes 722.0 To 722.6 5 Speed Chassis Ending 177-123 - 4 Bolt Pan Chassis Ending 123-126 - 6 Bolt Pan 3-4 SPEEDDokument6 SeitenMercedes 722.0 To 722.6 5 Speed Chassis Ending 177-123 - 4 Bolt Pan Chassis Ending 123-126 - 6 Bolt Pan 3-4 SPEEDTransmisiones Automáticas Chepe0% (1)

- A4ld HBDokument110 SeitenA4ld HBTransmisiones Automáticas ChepeNoch keine Bewertungen

- Previous MenuDokument95 SeitenPrevious MenuTransmisiones Automáticas Chepe100% (2)

- TD 201102Dokument68 SeitenTD 201102Transmisiones Automáticas Chepe50% (2)

- No 3-4 Ax4n Forward Control ValveDokument2 SeitenNo 3-4 Ax4n Forward Control ValveTransmisiones Automáticas ChepeNoch keine Bewertungen

- Previous MenuDokument88 SeitenPrevious MenuTransmisiones Automáticas ChepeNoch keine Bewertungen

- AX4N, Problemas 3-4, Neutralización Por Válvula de Control Del Embrague de AvanceDokument6 SeitenAX4N, Problemas 3-4, Neutralización Por Válvula de Control Del Embrague de AvanceTransmisiones Automáticas ChepeNoch keine Bewertungen

- 4t65e Epc Sol FallaDokument3 Seiten4t65e Epc Sol FallaTransmisiones Automáticas Chepe100% (1)

- Project On Teaining DevelopmentDokument88 SeitenProject On Teaining Developmentsurya annamdevulaNoch keine Bewertungen

- 460 Mr. Abhijit GadekarDokument4 Seiten460 Mr. Abhijit GadekarAbhishekSengaokarNoch keine Bewertungen

- Tds Turbine Oil 560 EngDokument2 SeitenTds Turbine Oil 560 EngJerome Cardenas TablacNoch keine Bewertungen

- Automotive Engineering - November-DecemberDokument36 SeitenAutomotive Engineering - November-DecembervenkiNoch keine Bewertungen

- Agreements Signed During President Duterte's 2019 Japan TripDokument2 SeitenAgreements Signed During President Duterte's 2019 Japan TripRappler100% (2)

- Comparative Market Strategy of Bajaj & HeroDokument97 SeitenComparative Market Strategy of Bajaj & Heroravi singhNoch keine Bewertungen

- Seti Sample TestDokument6 SeitenSeti Sample TestKiran Kumar ReddyNoch keine Bewertungen

- Summer Training in Royal Enfield (Oxina Motors) Trichy: in Partial Fulfillment For The Award of The DegreeDokument38 SeitenSummer Training in Royal Enfield (Oxina Motors) Trichy: in Partial Fulfillment For The Award of The DegreeAman MittalNoch keine Bewertungen

- 05/12/11 Moneysaver - Lewis-Clark EditionDokument20 Seiten05/12/11 Moneysaver - Lewis-Clark EditionDavid ArndtNoch keine Bewertungen

- HistoryDokument53 SeitenHistoryMani KrishNoch keine Bewertungen

- Project Report On Maruti Showroom ManagementDokument92 SeitenProject Report On Maruti Showroom Managementneoratm100% (1)

- After Sales Service - ATHERDokument12 SeitenAfter Sales Service - ATHERPrasath NagendraNoch keine Bewertungen

- A Study On Consumer's Perception Towards Honda Activa in Muzaffarpur CityDokument34 SeitenA Study On Consumer's Perception Towards Honda Activa in Muzaffarpur CityabhaybittuNoch keine Bewertungen

- Oc-500 RFDokument20 SeitenOc-500 RFPhilippine Bus Enthusiasts Society0% (1)

- 2005 Atlas Copco XAH4 OEM Drilling Compressor For Sale ADokument9 Seiten2005 Atlas Copco XAH4 OEM Drilling Compressor For Sale AJohn NottyNoch keine Bewertungen

- Ewm Referenzen Coldarc-GbDokument4 SeitenEwm Referenzen Coldarc-Gbsepe00Noch keine Bewertungen

- MR394X8586D000Dokument48 SeitenMR394X8586D000Nick Buzatu100% (2)

- Classic Car Crochet AppliqueDokument6 SeitenClassic Car Crochet AppliqueGloria RendonNoch keine Bewertungen

- OTC D730 en Aust PrintDokument4 SeitenOTC D730 en Aust PrintJuan IdrovoNoch keine Bewertungen

- Palioindiaversion en 04 03.03-User ManualDokument156 SeitenPalioindiaversion en 04 03.03-User Manualelango19100% (1)

- Robotic and CNC Deburring Tools: NEW CatalogDokument12 SeitenRobotic and CNC Deburring Tools: NEW Catalogspace2kNoch keine Bewertungen

- CasesDokument25 SeitenCasesLindsey CookNoch keine Bewertungen

- Crown Lift Trucks LTD 4 Wheel Sit Down Counterbalanced Trucks 217097Dokument8 SeitenCrown Lift Trucks LTD 4 Wheel Sit Down Counterbalanced Trucks 217097Jesus Andrade MendozaNoch keine Bewertungen

- Pauselli 700 Solar Pile Driver BrochureDokument4 SeitenPauselli 700 Solar Pile Driver BrochureJaouad Id BoubkerNoch keine Bewertungen

- Brosur Lift KaleaDokument8 SeitenBrosur Lift Kalearoni KhairulNoch keine Bewertungen

- Japanese Tyre MarketDokument6 SeitenJapanese Tyre Marketshivi yoloNoch keine Bewertungen

- Appeal Sitapur 4 FullDokument9 SeitenAppeal Sitapur 4 FullAlokNoch keine Bewertungen

- Tamil Selvan RESUMEDokument2 SeitenTamil Selvan RESUMETamil SelvanNoch keine Bewertungen

- Project Report Ontata Motors Consumer BehaviourDokument63 SeitenProject Report Ontata Motors Consumer BehaviourVijay Vikas100% (1)

- Mitsubishi Vla CleaningDokument3 SeitenMitsubishi Vla Cleaningramsi17Noch keine Bewertungen