Beruflich Dokumente

Kultur Dokumente

Fiber Reinforced Concrete in Pavements

Hochgeladen von

Kagna Srun0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

60 Ansichten4 Seiten1) Fiber reinforced concrete is a composite material consisting of concrete reinforced with discrete randomly distributed short length fibers that can improve properties like strength, toughness, and ductility.

2) Studies on two sites using polymer fiber reinforced concrete with vacuum dewatering showed that it is better to place it over a lean mix base concrete rather than an unbound base like gravel.

3) It was also observed that the concrete should be laid in panels around 3-4 feet square and include grooves to control cracking, with the grooves cut after concrete sets but before it reaches full strength.

Originalbeschreibung:

Technology of Concrete in Pavement

Copyright

© © All Rights Reserved

Verfügbare Formate

DOC, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument melden1) Fiber reinforced concrete is a composite material consisting of concrete reinforced with discrete randomly distributed short length fibers that can improve properties like strength, toughness, and ductility.

2) Studies on two sites using polymer fiber reinforced concrete with vacuum dewatering showed that it is better to place it over a lean mix base concrete rather than an unbound base like gravel.

3) It was also observed that the concrete should be laid in panels around 3-4 feet square and include grooves to control cracking, with the grooves cut after concrete sets but before it reaches full strength.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

60 Ansichten4 SeitenFiber Reinforced Concrete in Pavements

Hochgeladen von

Kagna Srun1) Fiber reinforced concrete is a composite material consisting of concrete reinforced with discrete randomly distributed short length fibers that can improve properties like strength, toughness, and ductility.

2) Studies on two sites using polymer fiber reinforced concrete with vacuum dewatering showed that it is better to place it over a lean mix base concrete rather than an unbound base like gravel.

3) It was also observed that the concrete should be laid in panels around 3-4 feet square and include grooves to control cracking, with the grooves cut after concrete sets but before it reaches full strength.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 4

Fiber Reinforced Concrete in Pavements

Dr. K.M.Soni, Superintending Engineer, Central P.W.D., New Delhi

Fiber reinforced concrete (FRC) i defined a a co!poite !aterial coniting of concrete

reinforced with dicrete rando!l" but unifor!l" dipered hort length fiber. #he fiber can be

!ade of teel, pol"!er or natural !aterial. Wo$en fabric, long wire, bar, and continuou wire

!eh are not conidered dicrete fiber.

FRC i conidered a a !aterial of i!pro$ed propertie and not a reinforced ce!ent concrete

wherea reinforce!ent i pro$ided for local trengthening of concrete in tenion region. Since in

FRC, fiber are ditributed unifor!l" in concrete, it ha better propertie to reit internal tree

due to hrin%age. & fiber i!pro$e pecific !aterial propertie of the concrete, i!pact

reitance, fle'ural trength, toughne, fatigue reitance, ductilit" alo i!pro$e.

Fiber generall" ued in ce!ent concrete pa$e!ent are teel fiber and organic pol"!er fiber

uch a pol"prop"lene and pol"eter.

Steel Fiber Reinforced Concrete

Steel fiber ha$e been ued for a long ti!e in contruction of road and alo in flooring,

particularl" where hea$" wear and tear i e'pected. Specification and no!enclature are

i!portant for a !aterial to be ued a the tender are in$ited baed on pecification and

no!enclature of the ite!. Such no!enclature i not a$ailable in Delhi Schedule of Rate. (n a

wor% where teel fiber reinforced concrete wa ued for o$erla" )ut li%e flooring, the following

no!enclature can be adopted for concreting of !all thic%ne.

Pro$iding and la"ing *+ !! teel fiber reinforced ce!ent concrete in pa$e!ent (in panel ha$ing

area not !ore than ,.- .!) coniting of teel fiber / *+%g per cubic !eter of concrete and

ce!ent concrete !i' of ,0,.1-0,.1- (, ce!ent0 ,.1- coare and of finene !odulu 2.*20 ,.1-

tone aggregate ,+ !! and down gauge of finene !odulu -.11) o$er e'iting urface i3c

ce!ent lurr", conolidating, tapping, and finihing but e'cluding the cot of teel fiber which

hall be paid eparatel", co!plete a per direction of Engineer in Charge (Ce!ent to be ued

hall be 4PC *5 grade and and and aggregate ha$e to be wahed).

Second ite! of fiber wa pro$ided eparatel" a 6Pro$iding and !i'ing teel fiber of dia +.*-

!! in ce!ent concrete dul" cut into piece not !ore than 2- !! in length.7

#hough the ite! of teel fiber reinforced concrete

ha been pro$ided with a deign !i' of concrete, which i al!ot of ,0202 grading, it can now be

ued of !i' li%e 85+ or 85-. Since in the e'ecuted ite!, the thic%ne wa to be retricted, the

tone aggregate ued were of ,+ !! i9e and below howe$er, in cae of the concrete of !ore

than :- !! thic%ne, tone aggregate of 2+ !! grading can be ued.

#he contruction wa carried out !ore than a decade bac%. (t iober$ed that the perfor!ance of

the concrete i atifactor" e$en after !an" "ear of contruction (Figure ,). E$en, no corroion

ha been ober$ed in the teel fiber. (n fact the concreting ha been done )ut li%e flooring ite!

in thi cae o$er alread" e'iting hard urface. (n uch a cae a bonding coat hould alo be

pro$ided li%e a coat of ce!ent lurr". #he fiber reinforced concrete ha been pro$ided in !all

panel conidering the wor%abilit". #hough $acuu! dewatered concrete ha not been done with

teel fiber reinforced concrete but the a!e i alo poible. ;acuu! dewatered concrete, though

cannot be done in !all thic%ne li%e *+ or -+ !! but can be ued if thic%ne i ,++ !! or

!ore.

Polymer Fiber Reinforced Concrete

Pol"!eric fiber are being ued now becaue of their no ri% of corroion and alo being cot

effecti$e (Si%dar et al, 2++-). Pol"!eric fiber nor!all" ued are either of pol"eter or

pol"prop"lene. Pol"!er fiber reinforced concrete (PFRC) wa ued on two ite with read" !i'

concrete and ;acuu! dewatering proce.

#he no!enclature can be ued in the wor% a gi$en here.

<Pro$iding and la"ing read" !i' fiber reinforced ce!ent concrete of 85- grade (#he concrete

hall alo ha$e !ini!u! wor% tet bea! fle'ural trength of *+ %g per .! at 2= da") in

re.uired lope and ca!ber in panel i3c haping at drainage point a re.uired uing

ce!entitiou !aterial not le than *5- %g per cu! of finihed concrete fro!

&CC3>?#3&@>C4N3 AN(#EC@ or e.ui$alent batching plant for all lead and lift with Fiberco!B

CF3Fiber!eh3Recron or e.ui$alent (,++ C $irgin "nthetic fiber i9e ,2 !! long) to be !i'ed /

1++ gra! per cu! of concrete i3c finihing with creed $ibration, $acuu! dewatering proce,

floating, trowelling, broo!ing and nor!al curing etc. co!plete a per tandard !anufacturerD

pecification and a per direction of EngineerD in charge (&ll related e.uip!ent hall be

arranged b" the contractor. Cot of centering, huttering, groo$ing etc. hall be paid eparatel".

Deign 8i' hall be got appro$ed fro! the Engineer in Charge).

(n both the ite, $acuu! dewatered concrete wa ued. Eoth the ite are to be ued for

par%ing. (n a ite, fiber reinforced concrete wa ued o$er a bae ce!ent concrete of lean !i' of

,0*0= (Figure 2) while in other ite it wa laid o$er water bound !acada! (WE8) (Figure 5).

When dewatered concrete it ha no proble! of water being co!ing out on urface during

co!paction proce but when it i done o$er WE8, a lot of concrete water i oa%ed b" WE8

and thu the concrete loe the water to WE8 and the water which co!e out during

dewatering3co!paction proce i not in a!e .uantit" ain cae of lean concrete. (t appear that

it i better to pro$ide bae concrete than WE8 a the bae. #he groo$e wa !ade in one cae

before etting of concrete and alo panel were cat with e'panion )oint in one direction. No

crac% were ober$ed in the direction in which e'panion )oint were pro$ided au!ing thi i

longitudinal direction. (n lateral direction, no )oint were pro$ided and the width of uch panel wa

about ,2 !. (t wa later ober$ed that crac% ha$e de$eloped in thi direction (Figure *).

& it i %nown that the width of ,2 ! i too long for e'panion3

contraction. (t ha been ober$ed that al!ot at about oneFthird of the panel width, uch crac%

de$eloped i.e. i9e of panel fro! one ide i about * ! and fro! other ide it i about =!. Fro!

the ite ober$ation, it i therefore inferred that the panel hould ha$e the i9e of about *! ' *!

in the te!perature condition of Delhi howe$er !all $ariation can alo be !ade a per ite

condition. (n other cae, the contractor dela"ed the cutting of groo$e and thereafter the area

wa occupied due to o!e urgent re.uire!ent, the crac% in both the direction de$eloped. #he

crac% were al!ot in line. >ater on the groo$e were !ade through cutter. (t ha been

ober$ed that the ditance of crac% in one ide wa al!ot near to * ! and on other ide at

about : to 1 ! (Figure -). #hu fro! thi cae tud" alo, inference can be !ade that groo$e if

!ade in panel of *! ' *!, it would be appropriate.

(n both the cae, no lateral groo$e were !ade, a wor%ing wa not a proble! due to ue of

$acuu! dewatering proce. (n both the cae, hori9ontal line crac% ha$e been ober$ed

indicating that the groo$e in other direction are alo eential. Fro! thi, it i i!perati$e that

pol"!er fiber reinforced concrete hould be laid in panel or groo$e hould be pro$ided o that

concrete act li%e in panel. Cutting groo$e i ea" a it can be !ade after cating of the

concrete. Eut it hould not be dela"ed for long and hould be !ade before concrete achie$e it

deired trength. #he i9e of panel !a" be %ept around *! ' *!.

Conclusions

Fiber reinforced concrete ha ad$antage o$er nor!al concrete particularl" in cae of ce!ent

concrete pa$e!ent. Pol"!eric fiber uch a pol"eter or pol"prop"lene are being ued due to

their cot effecti$e a well a corroion reitance though teel fiber alo wor% .uite atifactoril"

for a long ti!e. (t appear that fiber reinforced concrete hould be laid on bae concrete of lean

!i' uch a ,0*0= ce!ent concrete rather than o$er WE8 and pro$ided with groo$e in panel of

about *! ' *! to a$oid e'panion3 contraction crac%. Groo$e can be !ade after cating of

concrete through cutter.

References

Si%dar, P.H., Gupta, Saro), Hu!ar Satander (2++-). &pplication of Fiber a Secondar"

Reinforce!ent in Concrete. Ci$il Engineering and Contruction Re$iew, Dece!ber iue, pp 52B

5-.,

Das könnte Ihnen auch gefallen

- Scientific American Supplement, No. 470, January 3, 1885Von EverandScientific American Supplement, No. 470, January 3, 1885Noch keine Bewertungen

- Viaduct 2 Final Method StatmentDokument6 SeitenViaduct 2 Final Method StatmentaminjolesNoch keine Bewertungen

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionVon EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNoch keine Bewertungen

- Specification of Items Important Notes Check ListDokument16 SeitenSpecification of Items Important Notes Check ListAshley BlackNoch keine Bewertungen

- Method Statement Structural Excavation BackfillingDokument16 SeitenMethod Statement Structural Excavation Backfillingthelast_aienNoch keine Bewertungen

- Components of A Basic Concrete Mix: What Is Concrete: Concrete & Cement DefinedDokument17 SeitenComponents of A Basic Concrete Mix: What Is Concrete: Concrete & Cement DefinedjunreymoralesNoch keine Bewertungen

- The MonopileDokument4 SeitenThe MonopilejiokoijikoNoch keine Bewertungen

- Sabs 1200 LC-1981Dokument7 SeitenSabs 1200 LC-1981Mustufa F KanjetaNoch keine Bewertungen

- Pile Integrity Test2 PDFDokument3 SeitenPile Integrity Test2 PDFSima Datta Deb100% (1)

- 005-Sample Method Statement CivilDokument2 Seiten005-Sample Method Statement CivilS.C.Satish Chander100% (1)

- Reply To QueriesDokument4 SeitenReply To QueriesMRITYUNJAY PANDEYNoch keine Bewertungen

- HP Specification 4-28-10Dokument17 SeitenHP Specification 4-28-10Reza KhajeNoch keine Bewertungen

- ML VII Enhanced PerformanceDokument6 SeitenML VII Enhanced PerformanceabdounouNoch keine Bewertungen

- Performance of Joints in Reinforced Concrete (Filigree) Slabs For Two-Way Spanning Action (Stehle 2011)Dokument13 SeitenPerformance of Joints in Reinforced Concrete (Filigree) Slabs For Two-Way Spanning Action (Stehle 2011)Eli WallachNoch keine Bewertungen

- Method Statement For Casting, Prestressing & Grounting of PSC GirdersDokument15 SeitenMethod Statement For Casting, Prestressing & Grounting of PSC Girdersrohit singhNoch keine Bewertungen

- Design and Construction Problems of A "Big Inch" Outfall: Carlo Avanzini and Pierantonio QuiriciDokument8 SeitenDesign and Construction Problems of A "Big Inch" Outfall: Carlo Avanzini and Pierantonio Quiricijean miguel oscorima celisNoch keine Bewertungen

- Composite BeamsDokument47 SeitenComposite BeamsdudynaynNoch keine Bewertungen

- Architecture QuestionDokument6 SeitenArchitecture QuestionPrince Q Chan100% (2)

- Tech. Specs. For 11 KV DP StructureDokument7 SeitenTech. Specs. For 11 KV DP StructureSaraswatapalitNoch keine Bewertungen

- Work-Bridge Design and Sequence of ConstructionDokument22 SeitenWork-Bridge Design and Sequence of ConstructionTom LeverNoch keine Bewertungen

- Specification GirleyDokument5 SeitenSpecification Girleykinkoi1020Noch keine Bewertungen

- Historical Perspective: Fiber-Reinforced Concrete (FRC) IsDokument3 SeitenHistorical Perspective: Fiber-Reinforced Concrete (FRC) IsDikshant HasbeNoch keine Bewertungen

- Causes of DampCauses of Dampness - DocnessDokument3 SeitenCauses of DampCauses of Dampness - DocnessAbu ZaforNoch keine Bewertungen

- Materials Selection Assignment. LiveDokument10 SeitenMaterials Selection Assignment. Liverichward5Noch keine Bewertungen

- Effect of Aggregate Size Distribution On Concrete Compressive StrengthDokument5 SeitenEffect of Aggregate Size Distribution On Concrete Compressive StrengthPrakash Kumar KumarNoch keine Bewertungen

- Advances in Structural Concrete: Association of Engineers, Gaza Governorates, PalestineDokument33 SeitenAdvances in Structural Concrete: Association of Engineers, Gaza Governorates, Palestinehanan-3000-1999Noch keine Bewertungen

- Applied Sciences: Ffect of Crack Orientation On Fatigue Life ofDokument16 SeitenApplied Sciences: Ffect of Crack Orientation On Fatigue Life ofTrầmLãngNoch keine Bewertungen

- C & S Design Brief (Putrajaya)Dokument35 SeitenC & S Design Brief (Putrajaya)jparsb100% (1)

- 4 Retrofitting of BridgesDokument19 Seiten4 Retrofitting of BridgeskhelanparmarNoch keine Bewertungen

- Multistoreyed BLDGDokument89 SeitenMultistoreyed BLDGsohanpmeharwadeNoch keine Bewertungen

- Bridge Method by JSJ 2019Dokument74 SeitenBridge Method by JSJ 2019John vincent SalazarNoch keine Bewertungen

- Review of Method Statement For Underground (Carbon Steel) Piping Construction and InstallationDokument22 SeitenReview of Method Statement For Underground (Carbon Steel) Piping Construction and InstallationBenjamin HoltNoch keine Bewertungen

- Proiect - PracticaDokument29 SeitenProiect - PracticaIoana ComanescuNoch keine Bewertungen

- Electrical Specification Division 16, Section 16116Dokument4 SeitenElectrical Specification Division 16, Section 16116eng_asayedNoch keine Bewertungen

- The Earthquake Proof Bridge: Gradinaru Andrei, Group 3412 I.C.E, "Gh. Asachi" University, Iasi, 700050, RomaniaDokument7 SeitenThe Earthquake Proof Bridge: Gradinaru Andrei, Group 3412 I.C.E, "Gh. Asachi" University, Iasi, 700050, RomaniaAlex PantiruNoch keine Bewertungen

- Ground Anchor Tendons in Carbon Fibre Reinforced Polymers A D Barley John Hartley For Presentation Atice London 2007Dokument10 SeitenGround Anchor Tendons in Carbon Fibre Reinforced Polymers A D Barley John Hartley For Presentation Atice London 2007Kenny CasillaNoch keine Bewertungen

- 501 - PilingDokument12 Seiten501 - Pilingrelu1986Noch keine Bewertungen

- Burj Al Arab Technical Report EportfolioDokument7 SeitenBurj Al Arab Technical Report EportfolioYasser BaroudyNoch keine Bewertungen

- Method Statement For Bored PilingDokument5 SeitenMethod Statement For Bored Pilingjhc112386% (7)

- 20210331Dokument2 Seiten20210331aniketNoch keine Bewertungen

- Rail-Weld Failures Prevention, Monitoring & DetectionDokument8 SeitenRail-Weld Failures Prevention, Monitoring & DetectionShipra MishraNoch keine Bewertungen

- Silt CurtainDokument3 SeitenSilt CurtainarvindkaushikNoch keine Bewertungen

- Bearing Capacity Shear WaveDokument17 SeitenBearing Capacity Shear WaveMohan ManickamNoch keine Bewertungen

- Concrete Encased Duct Bank PDFDokument8 SeitenConcrete Encased Duct Bank PDF101079Noch keine Bewertungen

- SpecificationsDokument6 SeitenSpecificationsRachelle QuilalaNoch keine Bewertungen

- Tolerances For Precast Concrete Structures PDFDokument14 SeitenTolerances For Precast Concrete Structures PDFHari HaranNoch keine Bewertungen

- Applied Sciences: Behaviour Analysis of Reinforced Soil Retaining Wall According To Laboratory Scale TestDokument17 SeitenApplied Sciences: Behaviour Analysis of Reinforced Soil Retaining Wall According To Laboratory Scale TestraghuramammavajjalaNoch keine Bewertungen

- Example Bridge: Design Step 2 - Example Bridge Prestressed Concrete Bridge Design ExampleDokument11 SeitenExample Bridge: Design Step 2 - Example Bridge Prestressed Concrete Bridge Design ExampleshivamomshantiNoch keine Bewertungen

- Soil Drainage/Sewerage: Measurement of Construction Works V BQS601Dokument36 SeitenSoil Drainage/Sewerage: Measurement of Construction Works V BQS601Syamimi AmirahNoch keine Bewertungen

- Advantages of Steel Sleeves Over Composite Materials For Pipeline RepairDokument4 SeitenAdvantages of Steel Sleeves Over Composite Materials For Pipeline RepairAlzaki AbdullahNoch keine Bewertungen

- Technical Specification - PSC PoleDokument8 SeitenTechnical Specification - PSC PoleJogendra Nath NeogNoch keine Bewertungen

- ConstructionDokument3 SeitenConstructionAldever BretanaNoch keine Bewertungen

- Design Jacking Pipa Australia STDDokument10 SeitenDesign Jacking Pipa Australia STDDaniel SalehNoch keine Bewertungen

- QuestinoriesDokument5 SeitenQuestinoriesMohanraj ThangarajNoch keine Bewertungen

- Gabion, Geo Textile & RenomatressDokument4 SeitenGabion, Geo Textile & RenomatressSandun NimanthaNoch keine Bewertungen

- B Paper IESLDokument21 SeitenB Paper IESLJanaka DineshNoch keine Bewertungen

- Evaluating Structural Damage Caused by The Oklahoma City BombingDokument15 SeitenEvaluating Structural Damage Caused by The Oklahoma City BombingConstantino Guevara BNoch keine Bewertungen

- API 570 Bench Mark Quiz (1-55)Dokument56 SeitenAPI 570 Bench Mark Quiz (1-55)Christopher Randolph100% (5)

- Applications of Sustainable Post-Tensioned Concrete SlabsDokument12 SeitenApplications of Sustainable Post-Tensioned Concrete Slabsmohamed.s.elsayedNoch keine Bewertungen

- 1 s2.0 S0038080621001475 MainDokument15 Seiten1 s2.0 S0038080621001475 Mainioa sisNoch keine Bewertungen

- សង្គមវិជ្ជា sangkumvicheaDokument114 Seitenសង្គមវិជ្ជា sangkumvicheaCheng Por EngNoch keine Bewertungen

- Kfamux: Nibn ExmrDokument3 SeitenKfamux: Nibn ExmrKagna SrunNoch keine Bewertungen

- Conversion TablesDokument2 SeitenConversion TablesKagna SrunNoch keine Bewertungen

- Stresses in A Soil Mass: (Numbers Only An Example, Actual Calculated Stresses Will Be Different)Dokument20 SeitenStresses in A Soil Mass: (Numbers Only An Example, Actual Calculated Stresses Will Be Different)Kagna SrunNoch keine Bewertungen

- Define SectionDokument7 SeitenDefine SectionKagna SrunNoch keine Bewertungen

- JListDokument39 SeitenJListsidhanshuNoch keine Bewertungen

- Formula SuspensiDokument7 SeitenFormula SuspensiAlvian RamadyaNoch keine Bewertungen

- AFFF 3% F-25 PD4344: Foam ConcentrateDokument2 SeitenAFFF 3% F-25 PD4344: Foam ConcentrateArturNoch keine Bewertungen

- Blending Model ExamplesDokument4 SeitenBlending Model Examplespriyachoudhary1Noch keine Bewertungen

- Cataloguing of Museum Objects - by Bhujang Bobade.Dokument10 SeitenCataloguing of Museum Objects - by Bhujang Bobade.Aaron DudleyNoch keine Bewertungen

- Examination of Petroleum Products.Dokument27 SeitenExamination of Petroleum Products.SHIVANI PATELNoch keine Bewertungen

- HTG Katalog 2022 Mail PDFDokument132 SeitenHTG Katalog 2022 Mail PDFemre akhanNoch keine Bewertungen

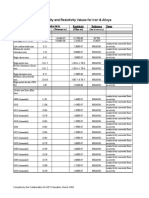

- Conductivity and Resistivity Values For Iron & AlloysDokument6 SeitenConductivity and Resistivity Values For Iron & AlloysrexNoch keine Bewertungen

- Ahmed Faisal Zeinaddin: Petroleum EngineerDokument1 SeiteAhmed Faisal Zeinaddin: Petroleum EngineerAryan AreNoch keine Bewertungen

- Indian Oil Corporation Limited: Bhubaneswar Divisional OfficeDokument3 SeitenIndian Oil Corporation Limited: Bhubaneswar Divisional OfficeBinay SahooNoch keine Bewertungen

- Conductivity NickelDokument2 SeitenConductivity Nickelkishormujumdar998Noch keine Bewertungen

- Solutions - Short Notes - Lakshya NEET 2.0 2024Dokument3 SeitenSolutions - Short Notes - Lakshya NEET 2.0 2024umamahfarooq75Noch keine Bewertungen

- Material With Electrode SelectionDokument3 SeitenMaterial With Electrode SelectionpmkarNoch keine Bewertungen

- Jurnal Sipil - NurkhalifahDokument11 SeitenJurnal Sipil - NurkhalifahNurkhalifah Umar daniNoch keine Bewertungen

- Sodium Nano Uid For Efficient Oil Recovery in Heavy Oil and Oil Sand ReservoirsDokument12 SeitenSodium Nano Uid For Efficient Oil Recovery in Heavy Oil and Oil Sand ReservoirsAhmedNoch keine Bewertungen

- 15 Taber.1997 EOR - Screening.criteria - Revisited Part.1Dokument10 Seiten15 Taber.1997 EOR - Screening.criteria - Revisited Part.1Mishell Ariana GuerraNoch keine Bewertungen

- HD PulyDokument37 SeitenHD PulyTOKO CAHAYA PERMATANoch keine Bewertungen

- Miscellaneous ColaMid AlkanolamidesDokument1 SeiteMiscellaneous ColaMid AlkanolamidesmndmattNoch keine Bewertungen

- EncyclopediaofemulsiontechnologyDokument2 SeitenEncyclopediaofemulsiontechnologyمحمد المعموريNoch keine Bewertungen

- UNS No. British Specs Alloy Name Trade Name: Nickel and High Temperature AlloysDokument24 SeitenUNS No. British Specs Alloy Name Trade Name: Nickel and High Temperature AlloysJoaquin AlvarezNoch keine Bewertungen

- Science: First Quarter - Module 4A Unsaturated SolutionDokument23 SeitenScience: First Quarter - Module 4A Unsaturated SolutionMher Buenaflor100% (1)

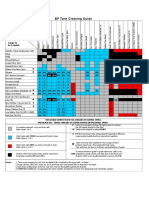

- BP Tank Cleaning Guide05Dokument1 SeiteBP Tank Cleaning Guide05CELESTIALNoch keine Bewertungen

- Types of SolutionDokument2 SeitenTypes of SolutionPretty SwanNoch keine Bewertungen

- 1st Monthly ExamDokument8 Seiten1st Monthly ExamRaven AvoNoch keine Bewertungen

- Gasoline StationDokument39 SeitenGasoline StationrjunaoNoch keine Bewertungen

- Identification of Phases of Various Oil, Surfactant/ Co-Surfactants and Water System by Ternary Phase DiagramDokument9 SeitenIdentification of Phases of Various Oil, Surfactant/ Co-Surfactants and Water System by Ternary Phase DiagramBushra ShaukatNoch keine Bewertungen

- Major Mail IDsDokument369 SeitenMajor Mail IDsAnkit Gupta100% (3)

- The Oil and Gas Industry: NRGI ReaderDokument5 SeitenThe Oil and Gas Industry: NRGI ReaderFaisal ShafiqNoch keine Bewertungen

- Material Groups and StandardsDokument1 SeiteMaterial Groups and StandardsJohn Rymar LameraNoch keine Bewertungen

- What Is Mixture: Is Matter Around Us PureDokument19 SeitenWhat Is Mixture: Is Matter Around Us PureAditya Kumar SinghNoch keine Bewertungen

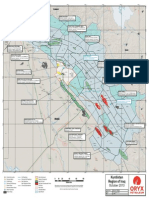

- Kurdistan Region of Iraq Investors MapDokument1 SeiteKurdistan Region of Iraq Investors Maphasan_676489616Noch keine Bewertungen

- Process Plant Equipment: Operation, Control, and ReliabilityVon EverandProcess Plant Equipment: Operation, Control, and ReliabilityBewertung: 5 von 5 Sternen5/5 (1)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactVon EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactBewertung: 5 von 5 Sternen5/5 (5)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeVon EverandChemistry for Breakfast: The Amazing Science of Everyday LifeBewertung: 4.5 von 5 Sternen4.5/5 (14)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincVon EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincBewertung: 3.5 von 5 Sternen3.5/5 (137)

- ICH Quality Guidelines: An Implementation GuideVon EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleNoch keine Bewertungen

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsVon EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsBewertung: 5 von 5 Sternen5/5 (3)

- Well Control for Completions and InterventionsVon EverandWell Control for Completions and InterventionsBewertung: 4 von 5 Sternen4/5 (10)

- AP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeVon EverandAP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeBewertung: 5 von 5 Sternen5/5 (1)

- It's Elemental: The Hidden Chemistry in EverythingVon EverandIt's Elemental: The Hidden Chemistry in EverythingBewertung: 4 von 5 Sternen4/5 (10)

- Piping Engineering Leadership for Process Plant ProjectsVon EverandPiping Engineering Leadership for Process Plant ProjectsBewertung: 5 von 5 Sternen5/5 (1)

- Taste: Surprising Stories and Science About Why Food Tastes GoodVon EverandTaste: Surprising Stories and Science About Why Food Tastes GoodBewertung: 3 von 5 Sternen3/5 (20)

- AP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeVon EverandAP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeNoch keine Bewertungen

- Handbook of Formulating Dermal Applications: A Definitive Practical GuideVon EverandHandbook of Formulating Dermal Applications: A Definitive Practical GuideNoch keine Bewertungen

- The Production of Volatile Oils and Perfumery Plants in the United StatesVon EverandThe Production of Volatile Oils and Perfumery Plants in the United StatesNoch keine Bewertungen

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeVon EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeBewertung: 4 von 5 Sternen4/5 (1)

- An Applied Guide to Water and Effluent Treatment Plant DesignVon EverandAn Applied Guide to Water and Effluent Treatment Plant DesignBewertung: 5 von 5 Sternen5/5 (4)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactVon EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactBewertung: 5 von 5 Sternen5/5 (1)

- Guidelines for Defining Process Safety Competency RequirementsVon EverandGuidelines for Defining Process Safety Competency RequirementsBewertung: 3 von 5 Sternen3/5 (1)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyVon EverandSodium Bicarbonate: Nature's Unique First Aid RemedyBewertung: 5 von 5 Sternen5/5 (21)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeVon EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeBewertung: 5 von 5 Sternen5/5 (4)

- Guidelines for Chemical Process Quantitative Risk AnalysisVon EverandGuidelines for Chemical Process Quantitative Risk AnalysisBewertung: 5 von 5 Sternen5/5 (1)