Beruflich Dokumente

Kultur Dokumente

Light Crude Oil Treatment Sulfur

Hochgeladen von

Chelsea SkinnerCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Light Crude Oil Treatment Sulfur

Hochgeladen von

Chelsea SkinnerCopyright:

Verfügbare Formate

Light crude oil treatment

T

he development of sour light crude oils or

condensates in certain areas of the world,

such as Kazakhstan and Qatar, has created

a problem in storage and transportation to crude

oil refning centres where these oils are fraction-

ated and converted to fuel products and

petrochemicals.

Crude oils contain all kinds of sulphur

compounds, both inorganic as in the case of H

2

S,

and organic as in the case of mercaptans and

thiophenes. Both H

2

S and mercaptans are highly

odorous and volatile sulphur compounds and, in

the case of H

2

S, its presence raises major safety

considerations since it is a poison to animal life

as well as humans. When crude oils are light

(above 40 API gravity) and contain volatile

sulphur in suffcient quantities, these oils require

either treatment to remove the noxious sulphur

in order to allow their storage and transporta-

tion, or the use of more costly and sophisticated

facilities along with special safety and environ-

mental handling procedures.

The typical crude oil production facility

employs a processing scheme that includes oil

and gas separation followed by desalting of the

oil, stabilisation, and fnally storage in atmos-

pheric tanks. In the case of light crude oils or

condensate from sour felds, the fnal stabilised

crude oil could contain several hundred ppm of

H2S and several thousand ppm of mercaptans,

forcing these facilities to further prepare the oil

for safe and non-odorous storage and transpor-

tation that mitigate any releases of poisonous

H

2

S and highly odorous mercaptans.

Many countries prohibit the storage or trans-

portation of these sour crude oils within their

territories unless certain specifcations for H

2

S

and mercaptans are met. Pipelines impose simi-

Felipe Suarez and Herbert Wizig Merichem Chemicals & Renery Services LLC

Liu Youchao China National Petroleum Corporation

Jack Zhang Jackson International Inc

lar specifcations as they not only transport these

oils, but also provide intermediate storage at

their terminals. Waterborne vessels also limit

the level of volatile sulphur that they will permit

while transporting crude oils.

Historically, oil producers have used various

schemes to mitigate the problem. These schemes

include processing facilities for stripping H

2

S

and mercaptan, pressurised storage facilities and

alternate higher-cost transportation options such

as rail in lieu of lower cost pipeline transport.

With ever-stricter safety and environmental

regulations, storage facilities have become

extremely costly. It was not until recently that

producers began searching for a chemical treat-

ing process, such as caustic treating, for a more

attractive option to solve their sour oil storage

and transportation dilemma.

Project objectives

In March 2002, CNPC-AMG, in Aktyubinsk,

Kazakhstan, approached Merichem with a need

to treat a six million tons/year crude oil stream

already in production. Up to that time, a portion

of the crude oil had been transported to a refn-

ery in Orsk, Russia, via pipeline at depressed

pricing and the rest by rail to Russia and other

Central Asian countries via rail tank cars at an

average cost of US$23.4/ton. The new require-

ment to treat the oil was an increase in

production coupled with the construction of a

new oil pipeline that would reduce oil transpor-

tation costs to US$8.5/ton and open new

markets for CNPC-AMG, provided that they

could reduce the volatile sulphur to meet the

following specifcations:

H

2

S (1ppm/wt)

C

1

and C

2

mercaptans (<10ppm/wt)

www.digitalrening.com/article/1000760 PTQ Q4 2004 1

A review of caustic treating technologies useful in the removal of volatile

sulphur from sour light crudes

C

1

, C

2

and C

3

mercaptans (<30ppm/wt).

Design basis

The characteristics of the raw crude oil produced

by CNPC are shown in Table 1. As the table

shows, the oil not only has the sulphur impuri-

ties already mentioned but also contains two

additional caustic extractable impurities, CO2

and naphthenic acids (the latter is measured as

feed acidity in mg KOH/g).

Carbon dioxide in itself does not present a

major diffculty in treating the crude oil but its

presence does affect chemical usage as this acid

gas is also caustic extractable. Fortunately, for

CNPC-AMG the CO

2

levels of 40ppm/wt are

minimal and do not result in large caustic usage.

However, the reaction of carbon dioxide with

caustic and the presence of magnesium and

calcium chlorides along with H

2

S in the crude

must be carefully considered in the design to

avoid precipitation of salts, which could affect

process performance and equipment reliability.

The naphthenic acid content of the crude,

while relatively low, must also be carefully

considered in the design because of several

factors. First, naphthenic acids react with caustic

to form soaps, which in conventional mixer

settler treating systems will tend to form emul-

sions and cause foaming, making the process

2 PTQ Q4 2004 www.digitalrening.com/article/1000760

inoperable at times. Second, naphthenic acids

also react with magnesium and calcium to form

metal carboxylate salts, which can precipitate

and/or plug the treating equipment.

Finally, naphthenic acids will interfere with

the oxidation of mercaptans as they consume

alkalinity needed for the mercaptan sweetening

process. In order to remove this frst set of

impurities, which can be categorised as strong

acids, Merichem licensed and supplied CNPC-

AMG its proprietary Napfning process.

The removal of H

2

S, CO

2

and naphthenic acids

would only take the producer of the crude oil

part of the way to preparing the crude oil for

storage and transportation because mercaptans

would still be present. Mercaptans are highly

volatile organic sulphur compounds, which are

only slightly acidic and very diffcult to remove

with caustic unless the caustic solution is main-

tained in a fresh condition (low spending and

high alkalinity).

Mercaptans are also extremely odorous and

removal to low levels is mandatory in most fuel

products produced for industrial and consumer

use. For example, in most industrialised coun-

tries the historical motor gasoline specifcations

for mercaptan is the qualitative Doctor test

which almost always requires below 10ppm

mercaptan and sometimes as low as 2ppm for

passing as Doctor negative.

The Zhanazol crude oil contains approximately

659ppm/wt of C

1

C

2

mercaptan measured as

sulphur. There are other heavier mercaptans in

the crude oil but fortunately the lighter (lower

molecular weight) C

1

C

3

mercaptan species,

which represent 469ppm of the total, are the

most odorous and thus the ones targeted for

removal. In order to successfully remove these

light mercaptans without creating very large

chemical (caustic) usage and operating costs, the

economics dictate that the process employed be

regenerative, allowing the caustic solution to

remain fairly fresh, as earlier stated. For mercap-

tan removal, Merichem designed and licensed to

CNPC-AMG its proprietary Mericat technology.

Once treating is accomplished, the producer

must then deal with the effuents produced in

the treating unit, which in this case only consists

of the spent caustic effuent leaving the

Napfning and Mericat treating stages. This

stream must be handled or disposed of in an

environmentally acceptable manner. For treat-

Design basis

Chargestock Light crude oil

Flow rate, bpsd

Maximum 67800

Design 56500

Normal 56500

Minimum 28250

Molecular wt 110

Specic gravity @ 15C 0.81

IBP-EP C CH4-398

Water content wt% 0.5

Inlet impurities

Acid number, MgKOH/g 0.05

H

2

S, ppm (wt) 30

CO

2

, ppm (wt) 40

Total mercaptans as S, ppm (wt) 659

C

1

-C

3

Mercaptans as S, ppm (wt) 469

Methyl mercaptan as S 49

Ethyl mercaptan as S 249

Propyl mercaptan as S 171

C

4

-C

5

Mercaptans as S, ppm (wt) 190

Table 1

2 PTQ Q4 2004 www.digitalrening.com/article/1000760

ment of this stream, Merichem

designed and licensed its

proprietary Mericon process.

Process solution

In the summer of 2002, CNPC-

AMG issued a letter of intent to

Merichem to license its tech-

nologies and to purchase the

proprietary equipment in order

to have the facility in operation

by the end of 2002, a project

duration of less than six

months. The fast track delivery

and startup of the facility was

necessary because it had to

coincide with the completion of

the new crude oil pipeline to

Kenkiak, where the Zhanazol

crude oil would ultimately be

transported via another pipe-

line to the Caspian Sea for

ultimate shipping to the Black

Sea and Mediterranean

markets.

The contract involved supply-

ing CNPC-AMG with the basic

engineering design and propri-

etary equipment consisting of

the Fiber-Film Contactors,

process strainers and other

special equipment, the operat-

ing and maintenance manuals and the startup

services. In addition, Merichem also supplied

the process vessels fabricated by its sub-contrac-

tors in Ekaterinburg, Russia.

CNPC-AMG, using the East China Design

Institute as its engineering contractor, was

responsible for the detailed design of the plant,

procurement of all other materials and equip-

ment, installation, erection and interconnection

of the facility. The facility applied a combination

of US, Russian and Kazakhstan standards for

design of equipment, materials of construction

and methods of construction as well as safety

and environmental standards.

Process description

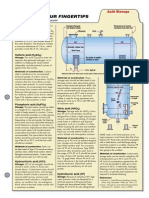

The Napfning system as illustrated in Figure 1

(following page) is designed to remove strong

acids with a weak caustic solution (3-5wt%

NaOH) in accordance to the following reactions:

www.digitalrening.com/article/1000760 PTQ Q4 2004 3

H

2

S + 2NaOH Na

2

S + 2H

2

O

Hydrogen sulphide

CO

2

+ 2NaOH Na

2

CO

3

+ 2H

2

O

Carbon dioxide

RCOOH + NaOH RCOONa + H

2

O

Naphthenic acids

The fashed and desalted crude oil supplied via

pumps P-1 and 2 from the existing production

facilities frst passes through a pair of hydrocar-

bon strainers (BS-1 and 2) to remove any scale,

rust or other solid matter that could interfere

with the proper functions of the system.

The crude oil then enters the Napfning stage

Fiber-Film Contactor (FFC-1) where it comes

into contact with a mixed fresh and recycled

caustic solution. The total caustic rate is approx-

imately equal to 10% by volume of the crude oil

rate. The actual make up caustic rate includes

LC

PC

PC

AC

PC

PC

AC

PC

PC

V-2 V-1

LC

P-3&4

P-5&6

P-1&2

Water

Oxidation air

Treated

light

crude

Naphthenic/sulp h idic

caustic to

spent caustic tank

Plant air

Untreated

light

crude oil

Fresh

caustic

(continuous)

BS-3&4

BS-1&2

Naphthenic acid extraction Mercaptan oxidation

BS-5&6

Catalyst

Figure 1 Napning/Mericat schematic ow diagram

fresh caustic being injected from the facilitys

fresh caustic supply system and cascaded from

the downstream Mericat mercaptan sweetening

system.

The total fresh caustic makeup rate is set after

a laboratory analysis of the circulating caustic

solution to determine its spending level (or

free alkalinity). Actual usage is directly propor-

tional to the total sum of H

2

S, CO

2

and

naphthenic acids contaminants contained in the

feed crude oil. The design caustic spending level

of the Napfning stage is 60%. The spent caustic

is removed from the bottom of the separator

vessel (V-1) on level control to the spent caustic

tank.

The previously mentioned Fiber-Film

Contactor (Figure 2) is a proprietary mass trans-

fer device licensed by Merichem consisting of a

cylinder packed with metallic fbres that provide

the surface area required for mass transfer to

take place. The fbres, being hydrophilic, attract

the aqueous (caustic) phase and provide the

surface on which the hydrocarbon (crude oil)

and aqueous (caustic) phases are in continuous

contact as both phases fow co-currently down-

ward though the contactor.

The caustic extractable impurities pass from

the hydrocarbon to the caustic phase where they

are removed from the system with the spent

caustic. The mass transfer mechanism is

non-dispersive, which is distinctly different from

the conventional mixing/settling approach,

where caustic droplets are formed for mass

transfer purposes. This results in a nearly perfect

separation of phases and avoids the formation of

emulsions, caustic carry-over with the crude oil

and hydrocarbon carry-under with the caustic as

would be experienced in mixer/settler processes.

The need for costly water washes to clean up

the treated product for caustic entrainment is

eliminated as well as losses of caustic with the

hydrocarbon product or losses of hydrocarbon

with the spent caustic leaving the system.

Mercaptans, being a weak acid, are not

removed to any signifcant level in the Napfning

system. Any mercaptans extracted when the

caustic solution is at its highest level of free

alkalinity are displaced back into the crude as

the more acidic impurities are extracted into the

caustic solution and the caustic spending

increases. The product leaving the system will

then require further treating in the second

Mericat stage previously shown in Figure 1.

The partially treated crude oil enters the

Mericat system where mercaptans are extracted

and oxidised in accordance to the following

reactions:

RSH + NaOH RSNa + H

2

Extraction

2RSNa+1 O

2

+H

2

O catalyst RSSR+2NaOH

2 --------- Oxidation

2RSH + 1 O

2

+ H

2

O catalyst RSSR + H

2

O

2 --------- Combined

It should be noted that the combined reaction

illustrates a 100% regeneration of the caustic,

which fulflls the prior mentioned requirement

that the caustic solution must not be signif-

cantly spent in order to extract the mercaptans

with caustic. The RSSR (disulphide oil) by-prod-

uct will re-enter the treated crude oil product

and leave with the fnal product.

The crude oil entering the Mericat stage is frst

contacted with air in a specially designed air

sparger (SP-1) to dissolve the oxygen needed for

the oxidation reaction to take place. The crude

oil containing the dissolved oxygen enters the

Fiber-Film Contactor (FFC-2) where it comes

into contact with a combined fresh caustic and

re-cycled caustic solution containing a dissolved

4 PTQ Q4 2004 www.digitalrening.com/article/1000760

Clear

hydrocarbon

phase in

Hydrocarbon

phase in

Aqueous

phase in

Clear

aqueous

phase out

FIBER-FILM

Contactor

Figure 2 Fiber-Film Contactor

oxidation catalyst. The latter promotes the

mercaptan oxidation reaction mentioned earlier.

Catalyst additions are made on a batch or

continuous basis depending on requirements

and plant preference.

As the crude oil and caustic/catalyst solution

fow co-currently downward through the contac-

tor mercaptans are converted to disulphdes,

which re-enter the crude oil phase. The treated

crude oil, free of H

2

S, naphthenic acids and C

1

C

3

mercaptans, passes on to product tankage on

pressure control. Since H

2

S is no longer present

and mercaptans have been converted to much

less volatile/odorous compounds, the treated

crude oil can then be stored in conventional

facilities and transported via truck, railcar and,

more importantly, the lower cost pipeline to its

fnal end user.

Operating performance

On 17 February 2003 the Napfning/ Mericat

system was started up by CNPC-AMG. Despite

the extremely accelerated project schedule,

which consisted of a total of eight months from

contract execution to mechanical completion,

the crude oil treating system successfully started

up and has been running on-specifcation and

onstream continuously ever since.

Some of the key results obtained since the

startup are listed as follows:

The system has processed an average of 11500

tonnes/day of crude oil. Additional throughput

will be processed once oil feld production is

expanded

The crude oil product has been successfully

transferred via the new Kenkiak pipeline to its

market destination, fulflling one of the most

important economic objectives of the project

The system has operated with a 100%

onstream service factor since startup

Fresh caustic consumption as 100% NaOH has

averaged 4.28 tonnes/day versus a design rate

(adjusted to crude oil throughput) of 4.13

tonnes/day. This represents 104% of the design

expectations

Spent caustic production has averaged 7.9m

3

/

hr versus an adjusted design rate of 5.26m

3

/hr.

This indicates that in addition to the H

2

S, CO

2

and naphthenic acids, the caustic is also picking

up free water contained in the desalted crude

entering the caustic treating unit

The raw crude oil H

2

S content has ranged from

20~90ppm/wt, 300~2000 ppm/wt for C

1

and C

2

mercaptans respectively; and 400~2500ppm/wt

C

1

, C

2

and C

3

mercaptans, fgures which are

waved far away from the design basis

Product H

2

S content has averaged 0ppm/wt,

0ppm/wt for C

1

and C

2

mercaptans respectively,

and 10ppm/wt C

1

, C

2

and C

3

mercaptans, fgures

which are well below design requirements of

1ppm/wt, 10ppm/wt and 30ppm/wt,

respectively.

The summary of the operating cost variables

based on design light crude fow rate and impu-

rity levels are contained in Table 2.

Some of the problems faced during the opera-

tion can be summarised as follows:

The hydraulic throughput of the facilities has

been restricted by some bottle-necks in the pipe-

lines feeding the Napfning/Mericat system.

CNPC-AMG is in the process of debottlenecking

these pipelines in order to achieve the full

processing potential of the facilities as the oil

production in the feld continues to increase

The spent caustic currently being produced

has been plugging existing disposal facilities due

to its high salt content. The proprietary Mericon

system, which will be used for treatment of this

effuent, is expected to eliminate this problem.

Future plans

CNPC-AMG is planning to increase crude oil

production in the near future and will be consid-

ering additional processing facilities that will

allow them to transport and market the Zhanazol

crude oil to far away places like mainland China.

A new 1300km pipeline is planned for comple-

tion by 2006.

In order to improve its environmental abate-

ment programmes and eliminate the problems

www.digitalrening.com/article/1000760 PTQ Q4 2004 5 4 PTQ Q4 2004 www.digitalrening.com/article/1000760

Operating cost variables

Crude oil Crude oil

Napning Mericat

Fresh NaOH, kg 2.2 million*

Spent caustic, m

3

65821*

Oxidation air, m

3

/h 562

Oxidation catalyst, kg 1134

Electricity, kWh 231779 296162

Operating labour, MH 300 300

Maintenance labour, MH 150 150

*Combined caustic use for Napning and Mericat

Table 2

associated with spent caustic disposal, CNPC-

AMG is planning the implementation of the

previously mentioned Mericon spent caustic

neutralisation process in the near future (Figure

3). The basic engineering and licensing of this

technology has already been completed.

The processing scheme consists of a low pH

neutralisation of the spent caustic followed by

H2S stripping and then a re-neutralisation of the

neutralised aqueous material to a neutral pH.

The goal is to achieve near

total removal of reactive

sulphur compounds;

sodium sulphide (Na2S),

sodium hydrosulphide

(NaHS) and sodium

mercaptide (RSNa). This

will allow the safe and

non-odorous handling of

the material in the plant

effuent treating systems.

In addition, the spent

caustic neutralisation

system will also provide for

removal of organic acids,

primarily naphthenic acids

that are extracted by the

caustic solution. The

systems spent caustic feed

and treated spent caustic

specifcations are shown in

Table 3.

Investment justication

The investment made by CNPC-AMG for caustic

treating the Zhanazol crude oil has been a very

successful and proftable project. The caustic

treatment of light crude oil for removal of light

volatile sulphur compounds is not only techni-

cally feasible with the appropriate technology,

but also extremely attractive from an economic

standpoint and environmentally sound when a

well-designed effuent caustic treating

unit is made part of the project.

Oil producers should avoid the use of

conventional mixing/settling caustic

treating processes that will create emul-

sions as crude oils have a strong

propensity to emulsify when contacted

with a caustic solution.

Napning, Mericat, Mericon, Fiber-Film Contactor

and Mericon are trademarked technologies owned by

Merichem Chemicals and Renery Services LLC.

Felipe Suarez is vice president of Merichem Chemicals

& Renery Services LLC, responsible for the process

technology and caustic management services

business units. He holds a BS in chemical engineering

from Louisiana State University and is a registered

professional engineer in Louisiana.

E-mail: fsuarez@merichem.com

6 PTQ Q4 2004 www.digitalrening.com/article/1000760

Fuel gas

Solvent

Sulp h uric

acid

Water

Spent

caustic

feed

PC

FC

FC

LC

FC

FC

FC

LC

LC

Offgas to

sulp h ur plant

Fresh

caustic

Neutralised

brine to

WWTP

Acid oils to

storage tank

NC

Cooler

Figure 3 Mericon schematic ow diagram

Spent caustic data

Caustic type Mixed naphthenic and sulphidic

Standard density or gravity @ 15C 1.01

Operating density or gravity @ 45C 1014kg/m

3

Flow rates @ 15C Design 20.0m

3

/h

Normal 18.0m

3

/h

Spent caustic specications Composition, wt%

Water 97.76

NaSH

Na

2

S 0.31

NaSR

Free NaOH 1.26

NaOR

NaOOCR 0.46

Na

2

CO

3

0.22

Hydrocarbon oil Trace

Treated brine specications, max: Product specications

pH 6.08.5

Na

2

S as sulphur <10ppm wt

Mericon spent caustic specications

Table 3

6 PTQ Q4 2004 www.digitalrening.com/article/1000760

Herbert Wizig is assistant director of marketing for the process

technology division of Merichem Chemicals & Renery Services

LLC. He holds a BS in chemical engineering from the University

of Texas and MS in chemical engineering from Georgia Institute of

Technology, Atlanta.

E-mail: hwizig@merichem.com

Liu Youchao is chief process engineer for CNPC-AMG in

Kazakhstan, in charge of project management and new process

application. He is a member of the China Petroleum Society with

more than 20 years experience in the petroleum industry.

Jack Zhang is vice president of Jackson International Inc, Beijing

ofce. Jackson International is the sole representative of

Merichem technology and service in China. He graduated from

the chemical engineering department of Dalian University of

Science and Technology in 1987.

Email: jack.zhang@jackson-international.com

www.digitalrening.com/article/1000760 PTQ Q4 2004 7

LINKS

More articles from: Merichem Company

More articles from the following categories:

Caustic Treating

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Mechanisms of Formation DamageDokument18 SeitenMechanisms of Formation DamagePrince Oma100% (1)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Naphthenic Acid Corrosion Risk Assessment and MitigationDokument24 SeitenNaphthenic Acid Corrosion Risk Assessment and MitigationSampat100% (3)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Refining High Acid CrudeDokument10 SeitenRefining High Acid CrudeHsein WangNoch keine Bewertungen

- Data For Oil Used in TransformerDokument31 SeitenData For Oil Used in TransformerPlanning EngineeringNoch keine Bewertungen

- Exhanger Leakages in VDU - ModifiedDokument14 SeitenExhanger Leakages in VDU - ModifiedJay LawsonNoch keine Bewertungen

- Naphthenic Acid CorrosionDokument6 SeitenNaphthenic Acid Corrosionbkmuduli100% (1)

- Naphthenic Acid Corrosion in Synthetic FuelsDokument15 SeitenNaphthenic Acid Corrosion in Synthetic FuelsNXVNNoch keine Bewertungen

- CDUDokument4 SeitenCDUmohamedyoussef1Noch keine Bewertungen

- Reasons for Enhanced Corrosion in Crude Oil Distillation UnitDokument9 SeitenReasons for Enhanced Corrosion in Crude Oil Distillation UnitnishilgeorgeNoch keine Bewertungen

- Implementing a comprehensive CUI programDokument4 SeitenImplementing a comprehensive CUI programChelsea Skinner100% (1)

- Caustic Treatment of Jet FuelsDokument6 SeitenCaustic Treatment of Jet FuelsNishat M PatilNoch keine Bewertungen

- Design Guidelines For Chemical Treatments in Distillation ColumnsDokument29 SeitenDesign Guidelines For Chemical Treatments in Distillation Columnsjuan_don_2100% (1)

- Chemistry - of - PETROCHEMICAL NEWDokument116 SeitenChemistry - of - PETROCHEMICAL NEWvivaline AchiengNoch keine Bewertungen

- Oil ConsumptionDokument25 SeitenOil Consumptionmuhammadsaeed78767% (3)

- LESSONS FROM CONFINED SPACESDokument5 SeitenLESSONS FROM CONFINED SPACESChelsea SkinnerNoch keine Bewertungen

- Naphthenic Acid Removal From Crude Oil Through CatalyticDokument7 SeitenNaphthenic Acid Removal From Crude Oil Through CatalyticHisyam Saufi TajudinNoch keine Bewertungen

- Acid StorageDokument1 SeiteAcid StorageChelsea SkinnerNoch keine Bewertungen

- Acid StorageDokument1 SeiteAcid StorageChelsea SkinnerNoch keine Bewertungen

- Piping System Leak Detection and MonitoringDokument7 SeitenPiping System Leak Detection and MonitoringChelsea SkinnerNoch keine Bewertungen

- Safety - Lessons Relearned - Inadequate IsolationsDokument5 SeitenSafety - Lessons Relearned - Inadequate IsolationsChelsea SkinnerNoch keine Bewertungen

- Acids HandlingDokument8 SeitenAcids HandlingChelsea SkinnerNoch keine Bewertungen

- Soda AshDokument1 SeiteSoda AshChelsea Skinner100% (1)

- Safety - Lessons Relearned - Inadequate IsolationsDokument5 SeitenSafety - Lessons Relearned - Inadequate IsolationsChelsea SkinnerNoch keine Bewertungen

- Methyl ChlorideDokument1 SeiteMethyl ChlorideChelsea SkinnerNoch keine Bewertungen

- Processing Industrial Byproducts To Yield As FertilizerDokument13 SeitenProcessing Industrial Byproducts To Yield As FertilizerChelsea SkinnerNoch keine Bewertungen

- Acids HandlingDokument8 SeitenAcids HandlingChelsea SkinnerNoch keine Bewertungen

- Updating the Chemical Engineering Plant Cost Index for the 21st CenturyDokument9 SeitenUpdating the Chemical Engineering Plant Cost Index for the 21st CenturyChelsea SkinnerNoch keine Bewertungen

- Naphthenic Acid Corrosion (NAC)Dokument1 SeiteNaphthenic Acid Corrosion (NAC)balajiupesNoch keine Bewertungen

- Production Chemicals For The Oil and Gas Industry (Book Review)Dokument8 SeitenProduction Chemicals For The Oil and Gas Industry (Book Review)Najem A. SakorNoch keine Bewertungen

- Naphthenic Acids - Registration Dossier - ECHADokument6 SeitenNaphthenic Acids - Registration Dossier - ECHANiculescu MariusNoch keine Bewertungen

- Baker Hughes DesalterDokument5 SeitenBaker Hughes DesalteralexHuy88Noch keine Bewertungen

- Fluid Flow Assurance Issues Literature ReviewDokument12 SeitenFluid Flow Assurance Issues Literature ReviewMatahari SenjaNoch keine Bewertungen

- Corrosion in Distillation ColuDokument5 SeitenCorrosion in Distillation ColuOmar EzzatNoch keine Bewertungen

- Nalco Hac ReportDokument81 SeitenNalco Hac Report00083583rfNoch keine Bewertungen

- Factors Controlling Naphthenic Acid Corrosion: A. Turnbull, E. Slavcheva, and B. ShoneDokument9 SeitenFactors Controlling Naphthenic Acid Corrosion: A. Turnbull, E. Slavcheva, and B. ShoneSteve OoiNoch keine Bewertungen

- Calcium Naphthenate Solid Deposit Identification and Control in Offshore Nigerian FieldsDokument13 SeitenCalcium Naphthenate Solid Deposit Identification and Control in Offshore Nigerian FieldsengrkrisNoch keine Bewertungen

- Development of A Naphthenic Acid Corrosion ModelDokument6 SeitenDevelopment of A Naphthenic Acid Corrosion ModelHimanshu SharmaNoch keine Bewertungen

- Nap Acid Paper FinalDokument18 SeitenNap Acid Paper Finalpapaya123Noch keine Bewertungen

- LAB Brochure - May2016Dokument20 SeitenLAB Brochure - May2016Majed DawaNoch keine Bewertungen

- Página Da NafténicaDokument2 SeitenPágina Da NafténicaAldair FranciscoNoch keine Bewertungen

- Sulfidic Corrosion in Refineries - A Review: October 2011Dokument12 SeitenSulfidic Corrosion in Refineries - A Review: October 2011rajiv_quantumNoch keine Bewertungen

- Fuchs RenolitDokument14 SeitenFuchs RenolitFakhrudin HalimNoch keine Bewertungen

- Astm D564Dokument3 SeitenAstm D564NizarHamrouni100% (1)