Beruflich Dokumente

Kultur Dokumente

UK Mortar Brief Introduction of Screeding

Hochgeladen von

iask5275Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

UK Mortar Brief Introduction of Screeding

Hochgeladen von

iask5275Copyright:

Verfügbare Formate

General

Information

The type of screeding mortar used will

depend on the required strength and

end use. Levelling screeds are designed

for a number of applications and to

receive a final flooring, the thickness of

the screed is governed by the method

of construction being used. To achieve

the optimum performance from a

levelling screed a high standard of

workmanship is essential.

Screeds

BS 8204 a multi part standard. which has the

overall title Screeds, bases and in situ

floorings. This standard has seven parts but

only four of these are applicable to screeds

where cement based materials are/(may be)

the binder:

Part 1 Concrete bases and cementitious

levelling screeds to receive floorings;

Part 2 Concrete wearing surfaces;

Part 3 Polymer modified cementitious

levelling screeds and wearing screeds;

Part 7 Pumpable self-levelling screeds.

BS 8204 provides guidance on design,

material selection, workmanship and testing.

Prior to the introduction of BS EN 13813 it

was the UK standard screeds were

manufactured to. Factory produced screeds

are required to conform to BS EN 13813,

however screeds produced on a building or

construction site are normally manufactured

in accordance with the recommendations in

BS 8204 which is far more comprehensive

than BS EN 13813.

Cementitious

levelling screeds

A levelling screed may be installed for a

variety of reasons including:

to provide a smooth flat surface at the

correct level to receive a flooring,

to provide a finishing zone in which

different types of flooring may be

accommodated on a common structural

base,

to provide falls,

to accommodate services, (traditionally

screeds have been used as a convenient

cover for cables and pipes. These are now

Definitions

BS EN 13318 defines a screed as: A layer or

layers of screed material laid in situ, directly

onto a base, bonded or unbonded, or onto

an intermediate layer or insulating layer, to

obtain one or more of the following

purposes:

to obtain a defined level;

to carry the final flooring;

to provide a wearing surface.

BS 8204-1 defines a levelling screed as a

screed suitably finished to obtain a defined

level and to receive the final flooring.

A wearing screed is defined as a screed that

serves as a flooring.

Curling is an upward deformation of the

edges of a screed.

In situ crushing resistance is defined as the

resistance of levelling screeds to the crushing

effect of imposed loads and traffic in service,

traditionally this was called soundness.

Standards

BS EN 13813 is entitled Screed material and

floor screeds- Screed material- Properties and

requirements, covers both levelling screeds

and wearing screeds. This is a performance

based standard which does not deal with the

specification of constituent materials; it states

that materials shall have established

suitability.

Definitions for different types of floor screeds,

constituent materials and construction

terminology related to screeds may be found

in BS EN 13318, which is entitled: Screed

material and floor screeds- Definitions.

mia mortar industry association Mineral Products Association

Yq4

Issue 1 May 2012

CI/SfB

Data sheet 22

placed in purpose designed ducts which

are incorporated into the full depth of the

screed.

to cover and protect thermal/sound

insulation,

to cover and protect a damp proof

membrane system,

to accommodate underfloor heating.

Levelling screeds are classified as

Bonded: A screed that is bonded to the

base,

Unbonded: A screed laid either onto a

separating layer or onto a base not

prepared to achieve bonding,

Floating: A screed laid on an acoustic

and/or thermal insulating layer and

completely separated from other building

elements, such as walls and pipes.

The majority of cement sand levelling screeds

consist of a cementitious material, fine

aggregate and an admixture. Fine concrete

screeds are produced with a maximum

aggregate size up to 10mm.

Types of levelling

screed

Bonded screeds

A bonded screed should have a minimum

thickness of 25mm and to accommodate

deviations in the base, a thickness of 40mm

should normally be specified. Fully bonded

screeds have the least risk of cracking, curling

and hollowness and is the preferred method

of construction where heavy duty usage or a

rigid flooring is required. The hardened base

concrete must be prepared by mechanical

methods to maximise bond.

Unbonded screeds

An unbonded screed is used where a bond

to the base is not possible, such as when the

base is contaminated or has an overlain

damp proof membrane. An unbonded

screed should be of a minimum thickness of

50mm, to allow for deviations in the base a

thickness of 70mm should be specified.

Curling and hollowness are likely to occur

with this form of construction at joints, cracks

and perimeters.

Floating screeds

A floating screed is used where thermal or

acoustic insulation is interposed between the

This table is applicable to all screed types and

the higher strength classes are not relevant

for cementitious levelling screeds.

BS 8204-1 contains the statement in Clause

5.6. that ready mixed screeds should conform

to the performance requirements of BS EN

13813.

Prior to the introduction of BS EN 13813

screeds were specified in the United

Kingdom by prescription. BS 8204-1

recommends nominal proportions by weight

of cement to fine aggregate of 1:4 with a

lower limit of 1:3 and an upper limit of 1:4.5.

The standard states that a screed produced

with these material proportions would meet

the expected criteria for in situ crushing

resistance. It is also stated that a screed with

a compressive strength class of C20 or C25

would also meet the in situ crushing

requirements.

Where fine concrete levelling screeds are to

be laid, the standard recommends that the

constituent material proportions should be in

the range 1:4 and 1:5 guidance is given on

the permissible proportions of fine to coarse

aggregates.

base and screed. The minimum thickness

should be 75mm although 65mm is normally

considered satisfactory for domestic housing.

Screed specification

BS EN 13813 is as previously stated a

performance based standard it does not

cover traditional screed materials supplied in

accordance with a traditional prescription or

recipe. Cementitious levelling screeds are

required to be classified on the basis of both

compressive and flexural strength; the

standard contains a table listing strength

classes as shown in Table 1.

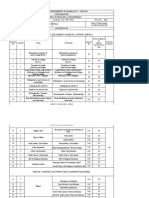

Compressive

strength N/mm

2

5 7 12 16 20 25 30 35 40 50 60 70 80

Flexural

strength N/mm

2

1 2 3 4 5 6 7 10 15 20 30 40 50

Class

Table 1: Compressive and flexural strength for screeds

There is a real danger of contact dermatitis or

serious burns if skin comes into contact with

wet mortar. Wear suitable protective clothing

and eye protection. Where skin contact occurs

either directly or through saturated clothing

wash immediately with soap and water. For eye

contact immediately wash out eyes thoroughly

with clean water. If swallowed wash out mouth

and drink plenty of water.

The relevant codes of practice, standards and

statutory regulations must always be observed.

The information in this data sheet may be freely

copied with acknowledgement to the Mortar

Industry Association. Current issue numbers of

all MIA publications are available from the MIA

website.

The Mortar Industry Association is part of the

Mineral Products Association, the trade

association for the aggregates, asphalt,

cement, concrete, lime, mortar and silica sand

industries

Mineral Products Association Ltd

Gillingham House

38 - 44 Gillingham Street

London SW1V 1HU

Tel +44 (0)20 7963 8000

Fax +44 (0)20 7963 8001

brian.james@mineralproducts.org

www.mortar.org.uk

Mineral Products Association 2012

Curing

Screeds should be protected from damage

after laying. To achieve the full performance

of ready to use levelling screeds adequate

curing is essential and the screed should be

covered with plastic sheeting or other

suitable material to retain moisture for at

least five days.

Testing

The in situ crushing resistance of a screed

may be assessed by use of the BRE Screed

Tester. This involves dropping a weight of 4kg

vertically 1m down a guide onto a hardened

steel anvil in contact with the screed surface.

The depth of indentation after four blows is

measured. The acceptable level of

indentation depends on the intended floor

usage and the type of floor covering to be

applied over the levelling screed. BS 8204-1

gives guidance on indentation depths, it

should be noted that a modification to the

test weight is required for some floating

screeds.

BS 8000-9 Workmanship on building sites. Cementitious levelling and wearing screeds. Code of practice.

BS 8204-1 Screeds, bases and in situ floorings. Part 1 Concrete bases and cement sand levelling screeds to receive floorings: Code

of practice.

BS EN 13318 Screed materials and floor screeds - Definitions.

BS EN 13813 Screed materials and floor screeds: Screed material - Properties and requirements.

References

For a full list of British and European Standards see the MIA data sheet of technical references.

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Section 26 24 13-LV Power Distribution Boards PDFDokument15 SeitenSection 26 24 13-LV Power Distribution Boards PDFmasoodaeNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- SCHWING Concrete Pump Working Range DrawingsDokument57 SeitenSCHWING Concrete Pump Working Range Drawingsiask527583% (6)

- C Rollway PDFDokument16 SeitenC Rollway PDFoxonoerNoch keine Bewertungen

- ABACUS High Mast Data SheetDokument74 SeitenABACUS High Mast Data Sheetiask5275Noch keine Bewertungen

- pd10196 Tetra Alsafe PDFDokument2 Seitenpd10196 Tetra Alsafe PDFEusebio NavarroNoch keine Bewertungen

- R1234yf 2018Dokument22 SeitenR1234yf 2018bogdan100% (1)

- 19 - Wartsila - Turbocharging 2 Stroke Engine - Existing & Future DemandsDokument18 Seiten19 - Wartsila - Turbocharging 2 Stroke Engine - Existing & Future DemandsCháu Bác HồNoch keine Bewertungen

- CITEL SPD Surge Protection Device Catalog 2013Dokument136 SeitenCITEL SPD Surge Protection Device Catalog 2013iask527567% (3)

- Italy Mont Blanc Tunnel Fire 1999 Case StudyDokument3 SeitenItaly Mont Blanc Tunnel Fire 1999 Case Studyiask5275Noch keine Bewertungen

- RUSKIN Fire and Smoke Damper Application GuideDokument16 SeitenRUSKIN Fire and Smoke Damper Application Guideiask5275100% (2)

- Chap 4 PDFDokument35 SeitenChap 4 PDFKamarul Nizam100% (1)

- TROX Air Flow Control Design ManualDokument36 SeitenTROX Air Flow Control Design Manualiask5275Noch keine Bewertungen

- KSB Know-How, Volume 0 - Selecting-Centrifugal-Pumps-data PDFDokument92 SeitenKSB Know-How, Volume 0 - Selecting-Centrifugal-Pumps-data PDFRodrigo Astudillo AedoNoch keine Bewertungen

- Kiln Preheater Fan CoatingDokument6 SeitenKiln Preheater Fan CoatingVijay Bhan100% (1)

- Ascot Roller Shutter General BrochureDokument16 SeitenAscot Roller Shutter General Brochureiask5275Noch keine Bewertungen

- Cable Trunking Test Report BS 4678 IEC61084 G275Dokument5 SeitenCable Trunking Test Report BS 4678 IEC61084 G275iask5275Noch keine Bewertungen

- BCA Accessibility Code 2013Dokument0 SeitenBCA Accessibility Code 2013hoshientung3119Noch keine Bewertungen

- Secure Access Module SAM Card OverviewDokument23 SeitenSecure Access Module SAM Card Overviewiask5275Noch keine Bewertungen

- Atlas Aluminium Datasheet 5052 Rev Oct 2013Dokument3 SeitenAtlas Aluminium Datasheet 5052 Rev Oct 2013Jason-chungNoch keine Bewertungen

- Ascot Fire Roller Shutters BrochureDokument8 SeitenAscot Fire Roller Shutters Brochureiask5275Noch keine Bewertungen

- Alcoa Aluminum 5052 6061 Data SheetDokument2 SeitenAlcoa Aluminum 5052 6061 Data Sheetiask5275Noch keine Bewertungen

- En 124 Access Cover Frame Loading (Gully)Dokument1 SeiteEn 124 Access Cover Frame Loading (Gully)iask5275Noch keine Bewertungen

- Sympholux Infrastructure Solution GuideDokument19 SeitenSympholux Infrastructure Solution Guideiask5275Noch keine Bewertungen

- Macau GDSE Energy Saving GuidelineDokument21 SeitenMacau GDSE Energy Saving Guidelineiask5275Noch keine Bewertungen

- ADT Intrusion Alarm CatalogueDokument144 SeitenADT Intrusion Alarm Catalogueiask5275Noch keine Bewertungen

- 3M Zinc Spray 16-501 Data SheetDokument2 Seiten3M Zinc Spray 16-501 Data Sheetiask5275Noch keine Bewertungen

- TANDA HongKong Fire Door BrochureDokument18 SeitenTANDA HongKong Fire Door Brochureiask5275Noch keine Bewertungen

- ATDEC Spacedec Workstation Desk Adjustable SD-POS-HA Data SheetDokument4 SeitenATDEC Spacedec Workstation Desk Adjustable SD-POS-HA Data Sheetiask5275Noch keine Bewertungen

- ADS Corrugated Heavy Duty Pipe Data SheetDokument4 SeitenADS Corrugated Heavy Duty Pipe Data Sheetiask5275Noch keine Bewertungen

- Vent-Axia Flexible Round Duct Data SheetDokument5 SeitenVent-Axia Flexible Round Duct Data Sheetiask5275Noch keine Bewertungen

- Philips UV Light Data SheetDokument17 SeitenPhilips UV Light Data Sheetiask5275Noch keine Bewertungen

- ABB Circuit Breaker Bus Communication Manual Vol-9 (MOE+AUX-E)Dokument2 SeitenABB Circuit Breaker Bus Communication Manual Vol-9 (MOE+AUX-E)iask5275Noch keine Bewertungen

- ABB Circuit Breaker AUX-E MOE Trip Unit InstructionDokument23 SeitenABB Circuit Breaker AUX-E MOE Trip Unit Instructioniask5275Noch keine Bewertungen

- Air-Water Systems For Air Conditioning Design ManualDokument60 SeitenAir-Water Systems For Air Conditioning Design ManualSchreiber_Dieses100% (1)

- FTIR Spectrometer AnalysisDokument16 SeitenFTIR Spectrometer AnalysisßraiñlĕsšȜĭnšteĭñNoch keine Bewertungen

- QIS College Engineering & Tech Session Plan Metal CuttingDokument13 SeitenQIS College Engineering & Tech Session Plan Metal CuttingKalai ArasanNoch keine Bewertungen

- Lec 6Dokument5 SeitenLec 6Abderrahim HAMDAOUINoch keine Bewertungen

- Materials Question PackDokument20 SeitenMaterials Question PackSuper Dila12Noch keine Bewertungen

- Vulcan LIBS Analyser For QA QC - 2Dokument6 SeitenVulcan LIBS Analyser For QA QC - 2Trần Văn LộcNoch keine Bewertungen

- Properties of commercial copper alloy powdersDokument2 SeitenProperties of commercial copper alloy powdersLilian RoseNoch keine Bewertungen

- Progress Report I: Presented By: Yousaf Makkouk (3612016) Presented To: Dr. Sultan SalamahDokument12 SeitenProgress Report I: Presented By: Yousaf Makkouk (3612016) Presented To: Dr. Sultan SalamahMuhammad NisarNoch keine Bewertungen

- Wire Rope (Trawl Rope) - Galvanized, Bright, Stainless, IWRC, Fillerwire & RDokument6 SeitenWire Rope (Trawl Rope) - Galvanized, Bright, Stainless, IWRC, Fillerwire & RralishNoch keine Bewertungen

- Katherine Davis, Gary Eddy, Alex Johannigman, Nathan ValdezDokument1 SeiteKatherine Davis, Gary Eddy, Alex Johannigman, Nathan Valdezanon_760617705Noch keine Bewertungen

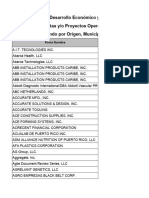

- Directorio de Empresas Operando Noviembre 2021 (Nov 30, 2021) PubDokument238 SeitenDirectorio de Empresas Operando Noviembre 2021 (Nov 30, 2021) PubnewprojectsNoch keine Bewertungen

- 13 MembranesDokument49 Seiten13 Membraneswatersoul.nNoch keine Bewertungen

- 7 Total SolidsDokument8 Seiten7 Total SolidsKashif Ali JalilNoch keine Bewertungen

- Rotary Vane PumpDokument7 SeitenRotary Vane PumpSanny HamdaniNoch keine Bewertungen

- Thermodynamics control volume analysisDokument6 SeitenThermodynamics control volume analysisLUISRONoch keine Bewertungen

- Basement ConstructionDokument12 SeitenBasement Constructionfgfghhffgh100% (2)

- Building Design 2 Drainage NotesDokument2 SeitenBuilding Design 2 Drainage NotesLemis Sean VerasNoch keine Bewertungen

- Aibel PDF 18 Advanced MethodsDokument34 SeitenAibel PDF 18 Advanced Methodsbaiju79Noch keine Bewertungen

- Retrofilling Aging Transformers With Natural Ester Based Dielectric Coolant For Safety and Life ExtensionDokument7 SeitenRetrofilling Aging Transformers With Natural Ester Based Dielectric Coolant For Safety and Life Extension王阳Noch keine Bewertungen

- Trouble With Paint Blistering of Paint Films On Metal Part 1 Osmotic BlisteringDokument10 SeitenTrouble With Paint Blistering of Paint Films On Metal Part 1 Osmotic Blisteringandreathome100% (1)

- Waterwell Catalog WebDokument96 SeitenWaterwell Catalog WebJuan Carlos Sequeira RoblesNoch keine Bewertungen

- Welding Metallurgy and Weldability of Stainless SteelsDokument6 SeitenWelding Metallurgy and Weldability of Stainless SteelsoifhiudsnfNoch keine Bewertungen

- Impact of Covid-19 On The Automotive Industry: By: Raman ATUL (19109029) RohitDokument14 SeitenImpact of Covid-19 On The Automotive Industry: By: Raman ATUL (19109029) RohitRaman BansalNoch keine Bewertungen