Beruflich Dokumente

Kultur Dokumente

TPFF

Hochgeladen von

leehai1980Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

TPFF

Hochgeladen von

leehai1980Copyright:

Verfügbare Formate

1

DECEMBER 2013 COMMON TEST

School of Life Sciences & Chemical Technology

(Diploma in Chemical and Biomolecular Engineering)

Level 2 Time Allowed: 1.5 Hours

TRANSFER PROCESSES - FLUID FLOW

INSTRUCTIONS TO CANDIDATES:

1. Answer all questions.

2. The following tables and charts are appended as Appendices 1 to 4.

Chart A - Friction Factor Chart (Appendix 1)

Table A - Constants and Coefficients (Appendix 2)

Table B - Formulae & Equations (Appendix 3)

Table C - Properties of water (Appendix 4)

3. This paper consists of 7 pages including this cover page. Check carefully to

make sure your set is complete.

QUESTION 1 (20 marks)

1.1 A pipeline of 100 mm diameter conveying water at a velocity of 2.5 m/s

branches into two pipes of 50 mm and 75 mm as shown in Figure 1.1. If the

velocity in the 75 mm pipe is 1.8 m/s, determine the velocity of flow in the 50

mm pipe and the total flow rate in 100 mm pipe.

Figure 1.1

(10 marks)

1.2 Water at 25C flows at the rate of 0.25 m

3

/s through a 200 mm diameter pipe.

The pipe enlarges suddenly to 450 mm diameter. Further downstream the

pipe diameter contract suddenly to 250 mm diameter as shown Figure 1.2.

Calculate

(a) the head loss due to the sudden expansion

(b) the head loss due to the sudden contraction

(c) the head losses at the entrance from and the exit to the water tanks.

2

Figure 1.2

(10 marks)

QUESTION 2 (20 marks)

2.1 If 30 litres of a liquid has a mass of 15 kg, determine its mass density, weight

density and specific gravity.

(6 marks)

2.2 Water at 20C flows out of a tank through a siphon formed by a bent pipe, 25

mm in diameter as shown in Figure 2.1. The pipe discharges into the

atmosphere at C. The absolute atmospheric pressure is 101.325 kN/m

2

. The

energy loss in the whole length of the pipe is equivalent to a total of

[60(v

2

/2g)] m head of water. Calculate

(a) the volumetric flow rate through the pipe

(b) the absolute pressure at B.

B

9 m

A

2 m

0.4 m 5 m

C

Figure 2.1

(14 marks)

QUESTION 3 (20 marks)

3.1 A pipe of 25 mm diameter carries water at 35C flowing with a velocity of 1.6

m/s. Calculate the Reynolds number and determine the type of flow.

(6 marks)

3

3.2 Water at 30C flows in a 250 mm diameter wrought iron pipeline over a

distance of 2.5 km with a velocity of 1.4 m/s. The pipeline contains fittings as

follows: two fully open gate valves, two swing check valves, seven 90

standard elbows, and three long radius 90 elbows. Calculate:

(a) the head loss due to friction in the pipeline

(b) the head loss due to all the fittings using equivalent length method

(14 marks)

QUESTION 4 (20 marks)

4.1 Define steady non-uniform flow and unsteady uniform flow.

(6 marks)

4.2 A pipeline is designed to convey water flowing at 25C from Upper Peirce

Reservoir to Lower Peirce Reservoir as shown in Figure 4.1. The difference in

water level between the two reservoirs is 15 m and the length of the pipeline

is 13 km. The total localised fittings losses amount to [10(V

2

/2g)]. The

entrance from and exit to the reservoirs are sharp. Determine the volumetric

flow rate if the diameter of the coated cast iron pipeline is 500 mm.

Figure 4.1

(14 marks)

4

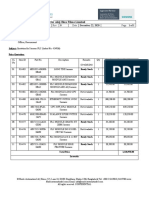

Appendix 1

Chart A: Friction Factor Chart (Source: Mott, R. L., Applied Fluid Mechanics, 6

th

edition, 2006)

5

Appendix 2

Table A: Constants and Coefficients

Universal Constants

Acceleration due to gravity 9.81 m/s

2

Specific gravity of mercury 13.6

Standard atmospheric pressure 101.325 kN/m

2

absolute value

Universal gas constant 8.314 kJ/kmol-K

Recommended Roughness Values of e (in mm)

Spun iron 0.03

Wrought iron 0.05

Uncoated steel 0.03

Coated steel 0.06

Galvanised iron 0.15

Coated cast iron 0.12

Cast iron 0.25

Concrete (class 4) 0.15

Concrete (class 3) 0.60

Concrete (class 2) 1.50

Concrete (class 1) 3.00

Loss Coefficients for Pipe Fittings

Fittings Values of

D

L

e

Coefficients, k

Screwed ends Flanged ends

Globe Valve Fully Open

Conventional

Y-Pattern

400 10 5

160 4 2

Gate Valve

Fully Open

75% Open

50% Open

25% Open

13 0.2 0.1

35 1 0.5

260 5.6 2.8

900 24 12

Tee line flow 20 0.9 0.2

Tee Branch branch flow 60 2 1

Standard 90 elbow 30 0.9 0.3

Standard 45 elbow 16 0.4 0.2

Long radius 90 elbow 20 0.6 0.2

Return Bend 50 2.2 0.4

Standard 45bend 15 0.2

Swing Check Valve 135 2.5

Plug Valve 18 0.324

Ball Valve Fully Open 3 0.05

Angle valve Fully Open 145 5

Foot valve 75 15

Butterfly valves 40 0.4

6

Appendix 3

Table B: Formulae & Equations

Energy Equation

Darcy`s Head Loss

Reynolds No

Venturi meter

)

[(

]

Orifice meter

)

[ (

]

Pitot-static tube:

Local Head Loss

Sudden contraction head loss

()

Sudden expansion head loss

()

Single stage isothermal compressor:

)

Single stage compressor:

Multi-stage Compressors (Inter-stage

cooling) Optimum compression ratio

(

Multi-stage Compressors

Multi-stage Compressors (Inter-stage cooling)(Adiabatic/Isentropic)

) [(

) [(

]

Pump Affinity Laws

Pump Impeller Size

()

Pump Specific Speed

()

Hydraulic

Power

Pump Efficiency

(

)

7

Appendix 4

Table C Properties of water

Properties of water at various temperatures

Temperature (C) Density (kg/m

3

) Dynamic Viscosity (Ns/m

2

)

0 1000 1.79 X 10

-3

5 1000 1.52 X 10

-3

10 1000 1.31 X 10

-3

15 999 1.14 X 10

-3

20 998 1.00 X 10

-3

25 997 0.89 X 10

-3

30 996 0.80 X 10

-3

35 994 0.72 X 10

-3

40 992 0.65 X 10

-3

45 990 0.60 X 10

-3

50 988 0.55 X 10

-3

55 986 0.51 X 10

-3

60 983 0.469 X 10

-3

65 980 0.437 X 10

-3

70 978 0.406 X 10

-3

75 975 0.380 X 10

-3

80 972 0.356 X 10

-3

85 969 0.335 X 10

-3

90 965 0.316 X 10

-3

95 962 0.299 X 10

-3

100 958 0.284 X 10

-3

END OF PAPER

1

JUNE 2013 COMMON TEST

School of Life Sciences & Chemical Technology

(Diploma in Environmental & Water Technology)

Level 2 Time Allowed: 1.5 Hours

TRANSFER PROCESSES - FLUID FLOW

INSTRUCTIONS TO CANDIDATES:

1. Answer all questions.

2. The following tables and charts are appended as Appendices 1 to 3.

Chart A - Friction Factor Chart (Appendix 1)

Table A - Constants and Coefficients (Appendix 2)

Table B - Useful Formulae (Appendix 3)

3. This paper consists of 6 pages including this cover page. Check carefully to

make sure your set is complete.

QUESTION 1 (30 marks)

(a) Calculate the density and the specific gravity of 24 litres of a liquid having a

mass of 18 kg.

(b) Oil flows at the rate of 3 L/s through a 50 mm diameter pipe which expand

suddenly to 75 mm diameter pipe. Further downstream the pipe contract

suddenly to a 35 mm diameter pipe. Calculate:

(i) head loss due to the sudden expansion

(ii) head loss due to the sudden contraction

(c) A pipeline of 250 mm diameter carrying water at an average velocity of 3.5

m/s branches into two pipes of 150 mm and 200 mm diameters. If the average

velocity in the 150 mm pipe is 2 m/s, determine the average velocity of flow in

the 200 mm pipe and the total flow rate in the 250 mm diameter pipe.

2

QUESTION 2 (20 marks)

(a) Water flows in a 250 mm diameter pipeline between pumps with a velocity of

1.7 m/s and a frictional factor of 0.02. The pipe contains fittings as follows:

three fully open gate valves, two check valve, six 90

0

standard elbows and

one long radius 90

0

elbows. Calculate the head loss due to all the fittings

using equivalent length method.

(b) Water flows at a rate of 15 L/s in a horizontal galvanised iron pipe of 200 mm

diameter. If the pipe is of uniform diameter, determine head loss due to

frictional resistance in 400 m length of pipe? What is the pressure drop in this

length of pipe?

QUESTION 3 (20 marks)

(a) A pipe of diameter 75 mm carries water at a flow rate of 8 L/s for a distance of

20 m. The pressure in the pipe at the upstream end is 25 kPa and at the

downstream end the pipe has decreased in elevation by 1.5 m. Assuming the

head loss is 0.5(v

2

/2g) per meter length of pipe, Calculate the pressure at the

downstream end.

(b) Oil with specific gravity 0.8 is pump through a uniform 30 mm diameter pipe at

a flow rate of 0.03 m

3

/s. Calculate the pump head required given that the total

head loss in the system is 15 m. Neglect all other head losses in the system.

oil

oil

P= 45 kPa

Pressurized

pump

8

m

3

m

S.G = 0.8

4 m ID

5 m ID

S.G = 0.8

3

QUESTION 4 (10 marks)

A pump is used to pump oil of specific gravity 0.85 and dynamic viscosity 0.006

Pa.s as shown in Figure b e l o w. Oi l is pumped from tank and discharged to

the atmosphere through a 100 mm diameter pipeline, 150 m long commercial steel

pipe. The oil level in tank is 8 m below the discharge point to the atmosphere. The

oil in the tank i s open t o t he atmospheric pressure. The entrance f r om t he

t ank to the pipe is sharp-edged and all fitting head loss in the piping system is 7

times the velocity head (7V

2

/2g). If the head developed by the pump is 30 m,

calculate discharge from the pipe in m

3

/s.

8 m

4

Appendix 1

Chart A: Friction Factor Chart (Source: Mott, R. L., Applied Fluid Mechanics, 6

th

edition, 2006)

5

Appendix 2

Table A: Constants and Coefficients

Constants

Acceleration due to gravity 9.81 m/s

2

Specific gravity of mercury 13.6

Water density 1000 kg/m

3

Water viscosity 0.001 Ns/m

2

Standard atmospheric pressure 101.325 KN/m

2

absolute value

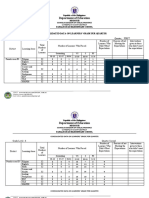

Loss Coefficients for Pipe Fittings

Values of

D

L

e

Loss Coefficients, k

Fittings

D

L

e

Screwed ends Flanged ends

Globe Valve

Conventional

Y-Pattern

400 10 5

160

Gate Valve

Fully Open

75% Open

50% Open

25% Open

10 0.2 0.1

35

150

900

Standard Tee Run 10 0.9 0.2

Standard Tee Branch 60 2 1

90Standard Elbow 30 0.9 0.3

45Standard Elbow 16 0.4 0.2

90

o

Long Radius Elbow 20 0.6 0.2

Return Bend 50 2.2 0.4

Check Valve 50 2.5

Plug Valve 18 0.324

Ball Valve (Fully

Open)

3

0.05

Angle valve 55 5

Foot valve 75 1.5

Loss coefficients for sudden contraction K

c

0 0.2 0.4 0.6 0.8 1.0

K

c

0.5 0.4 0.3 0.2 0.1 0

6

Appendix 3

Table B: Formulae

Energy Equation

Darcy`s Head Loss

Reynolds No

Orifice meter

)

[(

]

Venturi meter

Pitot-static tube:

Sudden contraction (entrance loss)

Sudden expansion (exit loss)

Sudden contraction head loss (within

pipe channel)

Sudden expansion head loss (within

pipe channel)

Single stage isothermal compressor:

)

Single stage compressor:

Multi-stage Compressors

Optimum compression ratio

(

Multi-stage Compressors

Multi-stage Compressors (Adiabatic Process)

) [(

) [(

]

Pump Affinity Laws

Pump Impeller Size

()

Pump Specific Speed

()

Pump Power

Pump Efficiency

(

)

END OF PAPER

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- ME-6501Computer Aided Design (CAD) WITH QB - BY Civildatas - Com 1Dokument85 SeitenME-6501Computer Aided Design (CAD) WITH QB - BY Civildatas - Com 1Nathar ShaNoch keine Bewertungen

- Management PriniciplesDokument87 SeitenManagement Priniciplesbusyboy_spNoch keine Bewertungen

- Raiders of SuluDokument1 SeiteRaiders of SuluBlexx LagrimasNoch keine Bewertungen

- ChatGPT & EducationDokument47 SeitenChatGPT & EducationAn Lê Trường88% (8)

- Accessoryd-2020-07-31-185359.ips 2Dokument20 SeitenAccessoryd-2020-07-31-185359.ips 2Richard GarciaNoch keine Bewertungen

- Community Profile and Baseline DataDokument7 SeitenCommunity Profile and Baseline DataEJ RaveloNoch keine Bewertungen

- End-Of-Chapter Answers Chapter 7 PDFDokument12 SeitenEnd-Of-Chapter Answers Chapter 7 PDFSiphoNoch keine Bewertungen

- Man Bni PNT XXX 105 Z015 I17 Dok 886160 03 000Dokument36 SeitenMan Bni PNT XXX 105 Z015 I17 Dok 886160 03 000Eozz JaorNoch keine Bewertungen

- Control ValvesDokument95 SeitenControl ValvesHardik Acharya100% (1)

- 2014 - Intelligence As A Predictor of Outcome in Short-And Long-Term PsychotherapyDokument9 Seiten2014 - Intelligence As A Predictor of Outcome in Short-And Long-Term PsychotherapyZayne CarrickNoch keine Bewertungen

- Philo Q2 Lesson 5Dokument4 SeitenPhilo Q2 Lesson 5Julliana Patrice Angeles STEM 11 RUBYNoch keine Bewertungen

- Polysep... Sized For Every Application: Psg-7 Psg-15 Psg-30 Psg-60 Psg-90Dokument1 SeitePolysep... Sized For Every Application: Psg-7 Psg-15 Psg-30 Psg-60 Psg-90Carlos JiménezNoch keine Bewertungen

- Unit 1 PrinciplesDokument17 SeitenUnit 1 PrinciplesRohit YadavNoch keine Bewertungen

- Load Chart Crane LiftingDokument25 SeitenLoad Chart Crane LiftingLauren'sclub EnglishBimbel Sd-sma100% (1)

- LC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Dokument2 SeitenLC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Mahadi Hassan ShemulNoch keine Bewertungen

- Construction Project - Life Cycle PhasesDokument4 SeitenConstruction Project - Life Cycle Phasesaymanmomani2111Noch keine Bewertungen

- How Transformers WorkDokument15 SeitenHow Transformers Worktim schroderNoch keine Bewertungen

- Spanish Greeting Card Lesson PlanDokument5 SeitenSpanish Greeting Card Lesson Planrobert_gentil4528Noch keine Bewertungen

- Third Party Risk Management Solution - WebDokument16 SeitenThird Party Risk Management Solution - Webpreenk8Noch keine Bewertungen

- Pitch DeckDokument21 SeitenPitch DeckIANoch keine Bewertungen

- (Gray Meyer) Analysis and Design of Analog Integrated Circuits 5th CroppedDokument60 Seiten(Gray Meyer) Analysis and Design of Analog Integrated Circuits 5th CroppedvishalwinsNoch keine Bewertungen

- Radio Ac DecayDokument34 SeitenRadio Ac DecayQassem MohaidatNoch keine Bewertungen

- RSW - F - 01 " ": Building UtilitiesDokument4 SeitenRSW - F - 01 " ": Building Utilities62296bucoNoch keine Bewertungen

- Darkle Slideshow by SlidesgoDokument53 SeitenDarkle Slideshow by SlidesgoADITI GUPTANoch keine Bewertungen

- Logistic RegressionDokument7 SeitenLogistic RegressionShashank JainNoch keine Bewertungen

- Basic Terms/Concepts IN Analytical ChemistryDokument53 SeitenBasic Terms/Concepts IN Analytical ChemistrySheralyn PelayoNoch keine Bewertungen

- Gas Compressor SizingDokument1 SeiteGas Compressor SizingNohemigdeliaLucenaNoch keine Bewertungen

- Department of Education: Consolidated Data On Learners' Grade Per QuarterDokument4 SeitenDepartment of Education: Consolidated Data On Learners' Grade Per QuarterUsagi HamadaNoch keine Bewertungen

- DTR Testastretta Valve Adjustment ProcedureDokument10 SeitenDTR Testastretta Valve Adjustment ProcedureTony LamprechtNoch keine Bewertungen

- Poster-Shading PaperDokument1 SeitePoster-Shading PaperOsama AljenabiNoch keine Bewertungen