Beruflich Dokumente

Kultur Dokumente

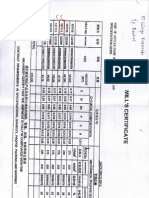

Inspection Checklist

Hochgeladen von

Sendi Dwi Oktaviandi67%(6)67% fanden dieses Dokument nützlich (6 Abstimmungen)

4K Ansichten2 SeitenQuality plans or inspection check lists for: (To be completed by the person(s) directly responsible for the work) WPS Have been approved and are available to welders and inspectors. All welder qualification certificates are valid. Joint fit-ups are to good workmanship standard and to code / WPS.

Originalbeschreibung:

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Dieses Dokument in anderen Sprachen lesen

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenQuality plans or inspection check lists for: (To be completed by the person(s) directly responsible for the work) WPS Have been approved and are available to welders and inspectors. All welder qualification certificates are valid. Joint fit-ups are to good workmanship standard and to code / WPS.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

67%(6)67% fanden dieses Dokument nützlich (6 Abstimmungen)

4K Ansichten2 SeitenInspection Checklist

Hochgeladen von

Sendi Dwi OktaviandiQuality plans or inspection check lists for: (To be completed by the person(s) directly responsible for the work) WPS Have been approved and are available to welders and inspectors. All welder qualification certificates are valid. Joint fit-ups are to good workmanship standard and to code / WPS.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

Quality plans or inspection check lists for:

(To be completed by the person(s) directly responsible for the work)

Contract Number:

Contract/Project Name:

Contractor:

Subcontractor:

Work area: Checklist Number:

Work Check Action Initialled/OK Comments

Before

Welding

Material

In accordance with drawing/WPS

Identified and can be traced to a test certificate

In suitable condition (free from damage and

contamination)

WPS

Have been approved and are available to welders

and inspectors

Welding equipment In suitable condition and calibrated as appropriate

Welding preparation In accordance with WPS and (or) drawing

Welder qualifications

Identification of welders qualified for each WPS to

be used. All welder qualification certificates are

valid

Welding

consumables

Those to be used are as specified by the WPS are

being stored /controlled as specified by the qc

procedure

Joint fit-ups

In accordance with WPS/drawings tack welds are

to good workmanship standard and to code/WPS

Weld Faces Are free from defect, contamination and damage

Preheat (if required) Minimum temperature is in accordance with WPS

I have carried out allnecessary inspections and verify that the above items/activities conform

to the contract specification/documents

Name:

Signature:

Date:

Work Check Action Initialled/OK Comments

During

welding

Site/field welding

Ensure weather conditions are suitable/comply

with code (Conditions will not affect welding)

Welding Process In accordance with WPS

Preheat (if required)

Minimum tempearature is being maintained in

accordance in WPS

Interpass

temperature

Maximum temperature is in accordance in WPS

Welding

consumables

Those to be used are as specified by the WPS are

being stored /controlled as specified by the qc

procedure

Welding parameters

Current, volts, travel speed are in accordance with

WPS

Root run Visually acceptable to code (before filling the joint)

Gouging/grinding

By an approved method and to good workmanship

standard

Interrun cleaning

welder

To good workmanship standard on the approval

register/qualified for the WPS being used

I have carried out allnecessary inspections and verify that the above items/activities conform

to the contract specification/documents

Name:

Signature:

Date:

Work Check Action Initialled/OK Comments

After Welding

Weld identification

Each weld is marked with the welders

identification and is identified in accordance with

drawing/weld map

Weld apperance

Ensure welds are suitable for all NDT (cleanness,

profile, etc) Visually inspect welds and sentence in

accordance with Code

Dimensional survey

Check dimensions are in accordance with

drawing/Code

Drawings

Ensure any modifications are included on as-built

drawings

After Welding

NDT

Ensure all NDT is complete and reports are

available for records

Repairs Monitor in accordance with the Procedure

PWHT (if required)

Monitor for compliance with Procedure (check

chart record)

Pressure/load test (if

required)

Ensure test equipment is calibrated Monitor test to

ensure compliance with Procedure/Code. Ensure

reports/records are available

Painting

Surface preparation, drying time, protective

measure, are in accordance with procedure and

(or) specification

Documentation

records

Ensure all reports/records are completed and

collated as required

I have carried out allnecessary inspections and verify that the above items/activities conform

to the contract specification/documents

Name:

Signature:

Date:

I have carried out allnecessary inspections and verify that the above work for this work area

has been completed and conforms to the contract specification/documents

Name:

Signature:

Date:

Das könnte Ihnen auch gefallen

- Before, During and After Welding.Dokument2 SeitenBefore, During and After Welding.ashwinNoch keine Bewertungen

- Duties & Responsibilities of Welding InspectorDokument3 SeitenDuties & Responsibilities of Welding InspectorAshwani Dogra60% (5)

- Duties Before WeldingDokument1 SeiteDuties Before WeldingMuhammed ThanzeelNoch keine Bewertungen

- AWS D1.1 - Acceptance Criteria For RTDokument11 SeitenAWS D1.1 - Acceptance Criteria For RTHoras Canman67% (3)

- Weld Repair ReportDokument1 SeiteWeld Repair Reportkerons100% (1)

- Visual Weld InspectionDokument7 SeitenVisual Weld InspectioninsiderrNoch keine Bewertungen

- Saic-W-2xxx-15 Pre Welding & Joint Fit-Up InspectionDokument4 SeitenSaic-W-2xxx-15 Pre Welding & Joint Fit-Up InspectionAnsuman Kalidas100% (1)

- Welding Consumable Control ProcedureDokument15 SeitenWelding Consumable Control ProcedureJoni Carino Suni89% (9)

- QC Inspection ChecklistDokument2 SeitenQC Inspection ChecklistIslam Sahafayat100% (1)

- PQR & WPQ Standard Testing Parameter WorksheetDokument4 SeitenPQR & WPQ Standard Testing Parameter WorksheetcosmicbunnyNoch keine Bewertungen

- Inspection Release NoteDokument1 SeiteInspection Release NoteKarthik S67% (3)

- Weld Repair Procedure Rev0Dokument2 SeitenWeld Repair Procedure Rev0aszliza100% (1)

- Welding Consumable and Storage ProcedureDokument10 SeitenWelding Consumable and Storage Procedurehasan_676489616100% (1)

- Welder Qualification Procedure PDFDokument13 SeitenWelder Qualification Procedure PDFEngineersEDGE Coimbatore0% (1)

- Welder Continuity LogDokument3 SeitenWelder Continuity Log942519100% (1)

- AL Wps PDFDokument4 SeitenAL Wps PDFprem nautiyalNoch keine Bewertungen

- 0.hydro Test Package Index - 1Dokument13 Seiten0.hydro Test Package Index - 1VISHNUPRASAD ARAKKAL MOHANDASNoch keine Bewertungen

- Guideline For Weld Reject Rate Reduction: Table of ContentsDokument14 SeitenGuideline For Weld Reject Rate Reduction: Table of ContentsMohammad Irfandi100% (1)

- AWS D1.1 (2020) - Essential Variable For WPS & WeldersDokument7 SeitenAWS D1.1 (2020) - Essential Variable For WPS & WeldersFouad OudinaNoch keine Bewertungen

- Wps For Aluminium WeldingDokument8 SeitenWps For Aluminium WeldingPutry NHy Saya0% (1)

- Welding Consumable Receiving LogDokument11 SeitenWelding Consumable Receiving LogKandula Raju100% (1)

- Procedure For Visual InspectionDokument4 SeitenProcedure For Visual InspectionAkhilesh Kumar100% (4)

- Approval - Procedure For Control of Welding ConsumablesDokument16 SeitenApproval - Procedure For Control of Welding Consumablesimran100% (1)

- Weld Fit-Up Inspection Employee TrainingDokument10 SeitenWeld Fit-Up Inspection Employee Trainingcosmicbunny100% (22)

- Procedure For Calibration of Machines WeldingDokument3 SeitenProcedure For Calibration of Machines Weldinglewgne08100% (6)

- AWS D1 1 Acceptance StandardsDokument2 SeitenAWS D1 1 Acceptance Standardsrohim100% (1)

- SAIC-W-2081 Receiving Inspection of Welding Consumables (EE)Dokument2 SeitenSAIC-W-2081 Receiving Inspection of Welding Consumables (EE)karioke mohaNoch keine Bewertungen

- Repair and Buttering ProcedureDokument14 SeitenRepair and Buttering Proceduremohd as shahiddin jafri100% (3)

- RT Acceptance CriteriaDokument9 SeitenRT Acceptance CriteriaNguyễn Giang Nam100% (1)

- Welding Consumable Handling Storage & Issue Control ProcedureDokument19 SeitenWelding Consumable Handling Storage & Issue Control ProcedureFerdie OSNoch keine Bewertungen

- WpsDokument39 SeitenWpsAkhilesh Kumar100% (1)

- Steel ChecklistDokument2 SeitenSteel ChecklistBruce Weathers100% (8)

- QC WELDING WORKS CHECKLIST Rev.0Dokument2 SeitenQC WELDING WORKS CHECKLIST Rev.0Rajesh Kumar Ravi100% (2)

- Welding Qualification As Per AWS D1.1Dokument19 SeitenWelding Qualification As Per AWS D1.1Ouni AchrefNoch keine Bewertungen

- Welding Repair ProcedureDokument4 SeitenWelding Repair Proceduregstketut100% (2)

- Welding Consumable Control Procedure 1Dokument9 SeitenWelding Consumable Control Procedure 1eklavyak076757100% (4)

- Weld Repair ProcedureDokument2 SeitenWeld Repair ProcedurePer DC100% (3)

- Welding Inspection ProcedureDokument7 SeitenWelding Inspection ProcedureVaradaraj CkNoch keine Bewertungen

- BPV IX-16-3 QW-283 - ButteringDokument1 SeiteBPV IX-16-3 QW-283 - ButteringyutweldingNoch keine Bewertungen

- Welding InspectionDokument16 SeitenWelding Inspectionraguraman4u100% (3)

- Wps For Aluminium WeldingDokument8 SeitenWps For Aluminium Weldingvishal bailur50% (2)

- Checklist For Welding Visual InspectionDokument1 SeiteChecklist For Welding Visual InspectiontreyNoch keine Bewertungen

- Duties of Tank InspectorDokument1 SeiteDuties of Tank InspectorJawed AlamNoch keine Bewertungen

- Procedure For WQTDokument13 SeitenProcedure For WQTdevikar8umNoch keine Bewertungen

- WPS 6G CS Pipe CorrectDokument4 SeitenWPS 6G CS Pipe CorrectAla ReguiiNoch keine Bewertungen

- ITP - Fabrication of Structural SteelDokument2 SeitenITP - Fabrication of Structural Steelsahad100% (6)

- NDT Weld Visual Inspection ProcedureDokument4 SeitenNDT Weld Visual Inspection Procedureg_sancheti100% (2)

- Welding Machine Calibration ProcedureDokument12 SeitenWelding Machine Calibration ProcedureNDTInstructor88% (8)

- QIR-104-Welding Parameters Record SheetDokument1 SeiteQIR-104-Welding Parameters Record SheetSamer Bayati100% (1)

- Duties of QCDokument2 SeitenDuties of QCAnonymous 4e7GNjzGWNoch keine Bewertungen

- #2 Duties of Welding InspectorsDokument13 Seiten#2 Duties of Welding InspectorsherawanadifNoch keine Bewertungen

- Preparation: Inspection Before WeldingDokument3 SeitenPreparation: Inspection Before WeldingDaison PaulNoch keine Bewertungen

- ARAMCO Interview 2015 PDFDokument15 SeitenARAMCO Interview 2015 PDFm.srinivasanNoch keine Bewertungen

- Welding Inspection CourseDokument23 SeitenWelding Inspection CoursepouyaNoch keine Bewertungen

- Welding InspectorDokument2 SeitenWelding Inspectorrahul063Noch keine Bewertungen

- Faizur Rahman CVDokument6 SeitenFaizur Rahman CVmuneeshwaraperumalNoch keine Bewertungen

- Duties of Welding InspectorDokument3 SeitenDuties of Welding InspectorSalman SyedNoch keine Bewertungen

- Piping Work Method For Fuel Oil Pipe Fabrication Installation and TestingDokument7 SeitenPiping Work Method For Fuel Oil Pipe Fabrication Installation and Testingsamsul maarif100% (1)

- Section 2 DutiesDokument3 SeitenSection 2 DutiesUmaibalanNoch keine Bewertungen

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AVon EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANoch keine Bewertungen

- Structural Bolts, Steel, Heat Treated, 120/105 Ksi Minimum Tensile StrengthDokument8 SeitenStructural Bolts, Steel, Heat Treated, 120/105 Ksi Minimum Tensile StrengthSendi Dwi OktaviandiNoch keine Bewertungen

- Sertifikat SQ Bar (Mill Certificate)Dokument1 SeiteSertifikat SQ Bar (Mill Certificate)Sendi Dwi OktaviandiNoch keine Bewertungen

- Mju IDokument37 SeitenMju ICobra DanielNoch keine Bewertungen

- Incoming Material ChecklistDokument4 SeitenIncoming Material ChecklistSendi Dwi OktaviandiNoch keine Bewertungen

- Idbm RL VPZZZ J02804 PDFDokument5 SeitenIdbm RL VPZZZ J02804 PDFSendi Dwi OktaviandiNoch keine Bewertungen

- UT Procedure PDFDokument23 SeitenUT Procedure PDFcentaury2013Noch keine Bewertungen

- Dimensional Before Welding Spindo Unit 1,2,3Dokument3 SeitenDimensional Before Welding Spindo Unit 1,2,3Sendi Dwi OktaviandiNoch keine Bewertungen

- Form Hasil PenelitianDokument3 SeitenForm Hasil PenelitianSendi Dwi OktaviandiNoch keine Bewertungen

- Schedule Oil Institut 2014 (Rev 01)Dokument12 SeitenSchedule Oil Institut 2014 (Rev 01)Sendi Dwi OktaviandiNoch keine Bewertungen

- Submission Form 'JAKARTA... 'Dokument1 SeiteSubmission Form 'JAKARTA... 'Sendi Dwi OktaviandiNoch keine Bewertungen

- SBO Achievement Week 5 January-1Dokument1 SeiteSBO Achievement Week 5 January-1sultan bintangNoch keine Bewertungen

- Testing of Distance Protection RelaysDokument8 SeitenTesting of Distance Protection RelaysAhmed HamzehNoch keine Bewertungen

- The Worldest Tallest BuildingsDokument22 SeitenThe Worldest Tallest BuildingsJacob BuntingNoch keine Bewertungen

- Cbse4103 920713135047 Final Exam AnswerDokument9 SeitenCbse4103 920713135047 Final Exam Answerhafizuddin hussinNoch keine Bewertungen

- Necessity For Ethics in Social EngineeringDokument14 SeitenNecessity For Ethics in Social EngineeringMatt BaileyNoch keine Bewertungen

- Contoh Motivation LetterDokument1 SeiteContoh Motivation LetterWismoyo Indra ZoelmanNoch keine Bewertungen

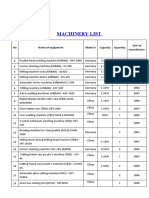

- Machinery List-1Dokument2 SeitenMachinery List-1Hồng HạnhNoch keine Bewertungen

- Proteck Corporate BrochureDokument16 SeitenProteck Corporate Brochurebaskars39Noch keine Bewertungen

- UG-37 F FactorDokument7 SeitenUG-37 F FactorjamesNoch keine Bewertungen

- ArcelorMittal Cofrastra 40 Brochure enDokument12 SeitenArcelorMittal Cofrastra 40 Brochure endinoNoch keine Bewertungen

- Week 5 General Properties of MaterialsDokument3 SeitenWeek 5 General Properties of MaterialsSamantha NamzugNoch keine Bewertungen

- Ud 6 Naturales 2º - Tools and MachinesDokument27 SeitenUd 6 Naturales 2º - Tools and MachinesLola FrancoNoch keine Bewertungen

- Apqp 2017Dokument124 SeitenApqp 2017ubraghuNoch keine Bewertungen

- Chapter 2 NewDokument50 SeitenChapter 2 NewKishore BhatNoch keine Bewertungen

- Report On Industrial Visit ScribdDokument11 SeitenReport On Industrial Visit ScribdJakeer CJNoch keine Bewertungen

- Asst EngrDokument10 SeitenAsst EngrIbrahim MeharoofNoch keine Bewertungen

- The Data Analytics Handbook V.4Dokument30 SeitenThe Data Analytics Handbook V.4timcantangoNoch keine Bewertungen

- USACE Contractor Database As of 23 MAY 22 For PostingDokument45 SeitenUSACE Contractor Database As of 23 MAY 22 For Postingdora tavarezNoch keine Bewertungen

- EPLAN Pro Panel PDFDokument8 SeitenEPLAN Pro Panel PDFHussain AbouelkhairNoch keine Bewertungen

- Resume PremDokument4 SeitenResume PrempremNoch keine Bewertungen

- Euro CokeDokument13 SeitenEuro Cokedhawal gargNoch keine Bewertungen

- Comparative Study of Tolerance Analysis MethodsDokument6 SeitenComparative Study of Tolerance Analysis MethodsZvonko TNoch keine Bewertungen

- AnnualReport2004 05Dokument315 SeitenAnnualReport2004 05archana_patroNoch keine Bewertungen

- LIEP Program - School of Continuing StudiesDokument2 SeitenLIEP Program - School of Continuing StudiesshaikhbwcNoch keine Bewertungen

- Petri Jacob ResumeDokument1 SeitePetri Jacob Resumeapi-545756504Noch keine Bewertungen

- Methodology Dandeli UGDDokument2 SeitenMethodology Dandeli UGDPrathyaksh ShettyNoch keine Bewertungen

- Microsoft Word - SIGMA 2018 - 6!6!2017Dokument2 SeitenMicrosoft Word - SIGMA 2018 - 6!6!2017er_aman11Noch keine Bewertungen

- NST2602 SGDokument148 SeitenNST2602 SGTshepi Carol DavidsNoch keine Bewertungen

- ABS Under 90m - Part 4Dokument356 SeitenABS Under 90m - Part 4blindstrom42Noch keine Bewertungen

- Mastip Technology IntroductionDokument12 SeitenMastip Technology IntroductionQuang PhamNoch keine Bewertungen