Beruflich Dokumente

Kultur Dokumente

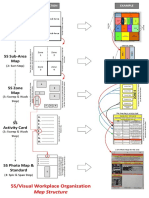

5S Implementation Plan at Work Place

Hochgeladen von

manishlmehtaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

5S Implementation Plan at Work Place

Hochgeladen von

manishlmehtaCopyright:

Verfügbare Formate

What ? Where?

Team Leader Team Members P-D-C-A Jul-07 Aug-07 Sep-07 Oct-07 Nov-07 Dec-07

Actual

Who ?

S5 = Shitsuke

[Self - discipline

at workplace]

S1 = Seiri

[Sort out what is

needed and

what is not]

S2 = Seiton

[Do systematic

arrangement for

all needed items]

S3 = Seiso

[Ensure spic &

span cleanliness

with inspection]

S4 = Seiketsu

[Create a highly

standardised

workplace]

Gemba-2:

Gemba-1:

S0 = Enablers

[Motivate people

for 5-S

implementation]

Actual

S3

S0

When?

'5-S' Road map - Department

Plan S0

S0

S1 S2 S2

To do

Plan S0 S2

S0

S0

S1 S2 S3

Jan-08 Feb-08 Mar-08

1 ] Through continuous education,

training, display of results & PDCA

improvement cycles

Zero setup PQCDEFSHE

1 ] CLIA: Deploy Clean-Inspect-Lubricate-

Adjust 2 ] CPCP

Zero

accidents

PQCD

1 ] SOPs Developed & Displayed 2

] Establish SDCA

Zero

breakdown

PQCD

1 ] Demonstrate PQI by doing Kaizens

2 ] Remove 3 D's at Gemba

Zero defect SHE

1 ] Develop criteria for need/want to

release 50% place

Zero

inventory/

More

space

EFSHE

1 ] PEEP: Place for everything &

everything in its place

Zero

waiting

PQCD

Remarks

Why ?

S4 S4 S5

MOP

When?

'5-S' Road map - Department

S4 S4 S5

Requisites Who Freq Status Remark

Official information HOD Once

5-S Billboards / Camera TL X

Participation of all TL N/A Gemba identified & teams formed

Effective training TL / TM Weekly X

PQCDEFSHE objectives TL / TM Qtr 5S awareness sessions

1-30-300 principle TL / TM Qtr 5S awareness sessions

Roadmap TL Once Prepared & displayed

5-S as a part of Kaizen roadmap

Progress review TL / Auditor Qtr

Publishing & widely communicating about the progress TM Monthly

Active involvement of the teams TL

Regular meetings TM Fortnight

Developing suggestion schemes TM Weekly

ACTION PLAN FOR "S0" Enablers

Motivating people for 5S implementation (J ul - Aug 07)

Requisites Area Who Status Remark

TM

TM

TM

TM

TM X

TM X

TM X

TM X

X

X

X

X

TM X

TM X

TM X

TM X

TM X

TM X

TM X

TM X

Listing Wants in an Area after

eliminating waste

Audit / Visual Inspection of wants /

wastes

Scrap Disposal

TL

ACTION PLAN FOR "S1" Seiri

Work Area

Sorting out what is required & dipose unwanted (Aug - Sep 07)

Classification in work areas

Gemba

Work Area

TM

Freq. Rare Never Good Worst Yes No Yes No Yes No

Process / Equipment / Item in area

Condition Repairable

Better

Substitute

avl

Usage

outside area

(S1) Waste Identification Checklist

Waste

Usage

(S1) Waste Identification Checklist

Remark

Requisites Area Who Status Remark

TM X

TM X

TM X

TM X

TM X

TM X

TM X

TM X

TM X

TM X

TM X

TM X

Organising in compliance with PEEP &

Identifying missing / abnormal item or

structure

ACTION PLAN FOR "S2" Seiton

Organising wants in an area in terms of

usage / value / importance to process / life

cycle

Systematic Arrangement of wanted (Oct - Nov 07)

Identifying amenities / infrastructure / tools

required for correct organisation (P tags)

Gemba

Work Area

TM

Process / Equipment / Item in area Usage Value Qty (Nos)

Critical to

process

Total Pref. No

0

0

0

0

0

0

0

0

0

0

0

0

(S2) Systematic arrangement checklist

List down amenities / tools / structure for correct arrangement. When identified

can be purchased or can be picked up from scrap

Scores can be 1/ 3/ 5 for low / Med / High categories repectively & Pref. no will

be in descending order of total score

Item with pref. no "1" should always be the easiest accesible and further on

In case of consumables qty. to be re-ordered when inventory level for High /

Med or Low value items reaches 25 % / 50 % levels

Arrangement to comply PEEP concept so that any missing / misplaced item

can be identified by visual inspection

Requisites Area Who Status Remark

TL / TM X

TL / TM X

TL / TM X

TL / TM X

TM X

TM X

TM X

TM X

TM X

TM X

TM X

TM X

All Items / Process / Equipments easly

identifiable / accesible / safe

ACTION PLAN FOR "S3" Seiso

External / Internal man power

arrangement for through cleaning

Systematic Arrangement of wanted (Nov - Dec 07)

Through cleaning done & scrap disposed

safely

Requisites Area Who Status Remark

TM X

TM X

TM X

TM X

TM X

TM X

TM X

TM X

ACTION PLAN FOR "S4" Seiketsu

Daily Inspection / Reporting

abnormalities

Systematic Arrangement of wanted (J an - Feb 08)

Action for deviation / 5S awareness

session or training

Requisites Area Who Status Remark

TL / Auditor X

TL / Auditor X

TL / Auditor X

TL / Auditor X

TL / TM X

TL / TM X

TL / TM X

TL / TM X

TL / TM X

TL / TM X

TL / TM X

TL / TM X

TL X

TL X

TL X

TL X

Gains in terms of value, life cycle,

availability to be published

ACTION PLAN FOR "S5" Shitsuke

Monthly / Qtrly. "5S" audit by Internal /

External accesor

Systematic Arrangement of wanted (Mar 08)

5S awareness session / training for

continual improvement / Visits

Action for deviation / findings /

document learnings

0 1 2 3 4

Materials / parts Does the inventory or in-process inventory include unneeded mtrl / parts

Machines / Equipment Are there any unused machines or other equipment

Papers / Plastic Mtrl Is there any paper / plastic scrap around

Visual Control Is the waste identified

Sub Total 0 0 0 0 0

0 1 2 3 4

Location Indicators Are shelves and other storage areas marked with addresses

Item Indicators Do the shelves have signboards showing which items go where

Qty. Indicators Are Max / Min Inventory levels indicated

Walkway Demarcation Storage areas / Process Area / Units marked

Sub Total 0 0 0 0 0

0 1 2 3 4

Floor / Work station Are floors / work station shiny to spot any waste

M/c & Equipments Are they Dust free, running healthy with allowed noise / vibration

Cleaning Stewards Is there a dedicated staff / do they do it voluntarily

Sub Total 0 0 0 0 0

0 1 2 3 4

Improvement Idea Is any action plan in place for its deployment

Standard procedure Is the 5S implementation plan documented / published / communicated

Future scope Any continual improvement idea / process / recognition

First 3S Is Seiri / Seiton / Seiso maintained

Sub Total 0 0 0 0 0

0

Check Item Description

Score

0

1S Check Item Description

2S

3S Check Item Description

Score

S

E

I

R

I

Score

S

E

I

T

O

N

S

E

I

S

O

0

4S Check Item Description

Score

0 = Very Bad 1 = Bad 2 = Avg 3 = Good 4 = Very Good

S

E

I

K

T

S

U

0

0 = Very Bad 1 = Bad 2 = Avg 3 = Good 4 = Very Good

0 1 2 3 4

Equipments / Process Are they easily gettable / managable

Stock levels Is the inventory control adhered to

Training Is Training / 5S awareness in progress

Support Is top management active support available

5-S Billboards Are they updated

Sub Total 0 0 0 0 0

Grand Total

S

H

I

T

S

U

K

E

0

0

5S Check Item Description

Score

SEIRI 0

SEITON 0

SEISO 0

SEIKTSU 0

SHITSUKE 0

0

0.5

1

SEIRI

SEITON

SEISO SEIKTSU

SHITSUKE

Audit Result

Das könnte Ihnen auch gefallen

- 5S Implementation Plan at Work PlaceDokument18 Seiten5S Implementation Plan at Work Placebrock100% (24)

- Manufacturing Process Audit ChecklistDokument4 SeitenManufacturing Process Audit Checklistgksp100% (4)

- Kaizen Structure Rev0Dokument86 SeitenKaizen Structure Rev0hiattolaNoch keine Bewertungen

- 5S Audits Check Sheet and Comments Sheet - Issue2Dokument2 Seiten5S Audits Check Sheet and Comments Sheet - Issue2vipindixit78100% (1)

- 5S Audit TemplateDokument1 Seite5S Audit Templateashblack160Noch keine Bewertungen

- The Fat CatsDokument7 SeitenThe Fat CatsMarilo Jimenez AlgabaNoch keine Bewertungen

- QE (5S) Responsibilities and RolesDokument3 SeitenQE (5S) Responsibilities and RolesAdie Caberte0% (1)

- Quality Circle (Hindi) 14 - 05 - 2011 (Read-Only)Dokument40 SeitenQuality Circle (Hindi) 14 - 05 - 2011 (Read-Only)Atul Sharma100% (1)

- Manufacturing Process Audit Checklist: Reference DocumentsDokument4 SeitenManufacturing Process Audit Checklist: Reference DocumentsAri Rosyadi100% (1)

- Quality Kaizen Supervisor + Manager DatabaseDokument17 SeitenQuality Kaizen Supervisor + Manager DatabaseMohamed AbdelAzizNoch keine Bewertungen

- 7 QC ToolsDokument127 Seiten7 QC Toolssathyabalaraman100% (2)

- 5S Audit SheetDokument4 Seiten5S Audit SheetJohn Robert StoneNoch keine Bewertungen

- SMED PPT EditedDokument28 SeitenSMED PPT EditedPrashant Gaurav100% (1)

- 5S Audit SheetDokument3 Seiten5S Audit Sheetleansensei67% (3)

- Internal Audit Check List MRDokument3 SeitenInternal Audit Check List MRGanesh Iyer100% (1)

- 5S Presentation For NTCDokument121 Seiten5S Presentation For NTCLyne LerinNoch keine Bewertungen

- ABC Sdn. BHD.: First (1S) Audit ChecklistDokument2 SeitenABC Sdn. BHD.: First (1S) Audit ChecklistRamesh KumarNoch keine Bewertungen

- Submitted By,: Jarzid Alam Alomgir Badsha Saif MahabubDokument26 SeitenSubmitted By,: Jarzid Alam Alomgir Badsha Saif MahabubSaif KhanNoch keine Bewertungen

- 5S Map Structure Handout 20160108Dokument2 Seiten5S Map Structure Handout 20160108Ramesh Babu100% (1)

- GLC - 5 S Presentation PDFDokument118 SeitenGLC - 5 S Presentation PDFVenkatesanNoch keine Bewertungen

- 5s Audit Check SheetDokument2 Seiten5s Audit Check SheetElizabethMayMendiolaSabando100% (2)

- 7 QC Tools - MasterDokument115 Seiten7 QC Tools - MasterAmit YadavNoch keine Bewertungen

- 5S Implementation Plan UploadDokument21 Seiten5S Implementation Plan UploadRahul KumarNoch keine Bewertungen

- 1S, 2S & 6S Audit ChecklistDokument46 Seiten1S, 2S & 6S Audit ChecklistSudhagarNoch keine Bewertungen

- 5S Implementation ProcedureDokument18 Seiten5S Implementation Procedurehim123verNoch keine Bewertungen

- 5S Audit ProcessDokument5 Seiten5S Audit ProcessChatnoir NoirNoch keine Bewertungen

- 5S Audit Report - V3Dokument1 Seite5S Audit Report - V3Rachmat Boerhan100% (1)

- Pocket Book AGDokument67 SeitenPocket Book AGsudiraharjaNoch keine Bewertungen

- 5S Checklist OkDokument2 Seiten5S Checklist Okmichelle ann100% (1)

- 5S Audit SheetsDokument5 Seiten5S Audit Sheetsgandee2017Noch keine Bewertungen

- 5S Audit Checklist - Workplace EvaluationDokument5 Seiten5S Audit Checklist - Workplace EvaluationDaniel2116Noch keine Bewertungen

- Kaizen ProcedureDokument3 SeitenKaizen ProcedureVinayNoch keine Bewertungen

- OEE Explained PDFDokument3 SeitenOEE Explained PDFcarrot123456Noch keine Bewertungen

- MSE507 Lean Manufacturing: 5S and The Visual WorkplaceDokument85 SeitenMSE507 Lean Manufacturing: 5S and The Visual WorkplaceSAYFUDDINSG100% (1)

- 5s Audit Check ListDokument2 Seiten5s Audit Check Listravi.rimc3869100% (2)

- Training Need IdentificationDokument58 SeitenTraining Need Identificationrohitbagga100% (1)

- 5 S Presentation Basic TrainingDokument82 Seiten5 S Presentation Basic TrainingEmman Bosito100% (1)

- 5S Audit FormDokument2 Seiten5S Audit Formmounirs719883Noch keine Bewertungen

- 5S Audit FormDokument2 Seiten5S Audit FormWaqar DarNoch keine Bewertungen

- 5S TrainingDokument81 Seiten5S Trainingamresh kumar tiwari100% (1)

- Kaizen CriteriaDokument4 SeitenKaizen Criteriaj_buan67% (3)

- 5S Roles and ResponsibilitiesDokument5 Seiten5S Roles and Responsibilitiessenk197100% (1)

- Zero Defect PresentationDokument4 SeitenZero Defect PresentationRanjith Kumar100% (1)

- 5S - Excellence Assessment PDFDokument2 Seiten5S - Excellence Assessment PDFAshokNoch keine Bewertungen

- Homoeopathy and MigraineDokument4 SeitenHomoeopathy and MigraineEditor IJTSRDNoch keine Bewertungen

- 1s, 2s & 5S Audit SheetDokument5 Seiten1s, 2s & 5S Audit SheetKhushboo Gupta100% (5)

- 5S Audit Check Sheet: Department: - Completed By: - Supervisor: - DateDokument1 Seite5S Audit Check Sheet: Department: - Completed By: - Supervisor: - DateP K Senthil Kumar33% (3)

- A Strategy For Performance ExcellenceDokument31 SeitenA Strategy For Performance ExcellenceMahesh KumarNoch keine Bewertungen

- What Is 5'S S.No. Principal Picture General Description: Prepared by - Pankaj Agrahari Approved by - Mohit SNGHDokument1 SeiteWhat Is 5'S S.No. Principal Picture General Description: Prepared by - Pankaj Agrahari Approved by - Mohit SNGHMohit SinghNoch keine Bewertungen

- Food ProductionDokument106 SeitenFood ProductionAna Marie100% (1)

- Dojo Establishment in DNHADokument16 SeitenDojo Establishment in DNHAanamika tripathi100% (1)

- 6S - 5S - Evaluation and Implementation Tool - LeanDokument8 Seiten6S - 5S - Evaluation and Implementation Tool - LeanShekhar RaviNoch keine Bewertungen

- 5s Audit PlanDokument3 Seiten5s Audit PlansomuanindianNoch keine Bewertungen

- Sample Procedure - 5S Standard Colour CodeDokument2 SeitenSample Procedure - 5S Standard Colour Codesl1828100% (1)

- 5S Audit FormDokument1 Seite5S Audit FormViorel IosubNoch keine Bewertungen

- 5S Audit Checklist and Report 1663039107Dokument2 Seiten5S Audit Checklist and Report 1663039107Ashish R. SinghNoch keine Bewertungen

- Iso Ts 16949 Tamil Training ProgramDokument51 SeitenIso Ts 16949 Tamil Training ProgramGanesan Sankaranarayanan88% (8)

- MSA Bias & GRRDokument2 SeitenMSA Bias & GRRRamchandrarao DeshpandeNoch keine Bewertungen

- Manufacturing Facilities A Complete Guide - 2019 EditionVon EverandManufacturing Facilities A Complete Guide - 2019 EditionNoch keine Bewertungen

- Five SDokument60 SeitenFive SShrikant MojeNoch keine Bewertungen

- TPS Checklist UpdatedDokument28 SeitenTPS Checklist UpdatedMani Rathinam RajamaniNoch keine Bewertungen

- Welcome: Training ProgrammeDokument89 SeitenWelcome: Training ProgrammesafewayibmNoch keine Bewertungen

- Team Spirit.: 5S Gives You A Workplace Which Is Clean,, Safe, AndorganizedDokument6 SeitenTeam Spirit.: 5S Gives You A Workplace Which Is Clean,, Safe, AndorganizedPuja PrasadNoch keine Bewertungen

- O221771s - Mil Pipe Pro 450 RFC PDFDokument84 SeitenO221771s - Mil Pipe Pro 450 RFC PDFJavier Isaac Berrocal Torres100% (1)

- DRS Rev.0 GTP-TR1!01!002 Condensate RecyclingDokument4 SeitenDRS Rev.0 GTP-TR1!01!002 Condensate RecyclingBalasubramanianNoch keine Bewertungen

- An Infallible JusticeDokument7 SeitenAn Infallible JusticeMani Gopal DasNoch keine Bewertungen

- TamasDokument180 SeitenTamaslike 2Noch keine Bewertungen

- One - Touch Fittings: Series: WP2Dokument12 SeitenOne - Touch Fittings: Series: WP2PrashantNoch keine Bewertungen

- Naskah Soal PeroranganDokument16 SeitenNaskah Soal PeroranganRiza FatimahNoch keine Bewertungen

- Consent For Diagnostic And/or Therapeutic ParacentesisDokument2 SeitenConsent For Diagnostic And/or Therapeutic ParacentesisnaveenNoch keine Bewertungen

- Journal Homepage: - : IntroductionDokument9 SeitenJournal Homepage: - : IntroductionIJAR JOURNALNoch keine Bewertungen

- The Church of Kapnikarea in Athens - N. GkiolesDokument13 SeitenThe Church of Kapnikarea in Athens - N. GkiolesMaronasNoch keine Bewertungen

- Yamaha rx-v395 v395rds htr-5130 5130rdsDokument55 SeitenYamaha rx-v395 v395rds htr-5130 5130rdsdomino632776Noch keine Bewertungen

- Chemical Resistance TableDokument6 SeitenChemical Resistance TableEdgarDavidDiazCamposNoch keine Bewertungen

- HPLC Columns by SciencixDokument49 SeitenHPLC Columns by SciencixBrett HarrisNoch keine Bewertungen

- Quiz - Ionic EquilibriumDokument2 SeitenQuiz - Ionic EquilibriumSiddNoch keine Bewertungen

- Engineering Drawings and Plans: Engr. Rolly S. TambeDokument4 SeitenEngineering Drawings and Plans: Engr. Rolly S. TambeFred Joseph G. AlacayanNoch keine Bewertungen

- Model A SOLUTIONSDokument8 SeitenModel A SOLUTIONSasdfNoch keine Bewertungen

- Neoliberalism and Altered State Developmentalism in The Twenty First Century Extractive Regime of IndonesiaDokument26 SeitenNeoliberalism and Altered State Developmentalism in The Twenty First Century Extractive Regime of IndonesiaErwin SuryanaNoch keine Bewertungen

- Hot Process Liquid SoapmakingDokument11 SeitenHot Process Liquid SoapmakingPanacea PharmaNoch keine Bewertungen

- 765 p1+2+3 Guide Limta Mock 2022Dokument8 Seiten765 p1+2+3 Guide Limta Mock 2022Théophile MbameNoch keine Bewertungen

- Department of Mechanical EnginneringDokument11 SeitenDepartment of Mechanical EnginneringViraj SukaleNoch keine Bewertungen

- Maximum Influence at A Point Dueto A Series of Concentrated LoadsDokument12 SeitenMaximum Influence at A Point Dueto A Series of Concentrated LoadsAyad SlabyNoch keine Bewertungen

- Cad, CamDokument16 SeitenCad, CamRakhi Mol BVNoch keine Bewertungen

- Tools, Equipment, and ParaphernaliaDokument35 SeitenTools, Equipment, and Paraphernaliajahnis lopez100% (1)

- Jetline: Theoretical Working Point Performance ChartDokument1 SeiteJetline: Theoretical Working Point Performance ChartMohamed GamalNoch keine Bewertungen

- Idlers: TRF Limited TRF LimitedDokument10 SeitenIdlers: TRF Limited TRF LimitedAjit SarukNoch keine Bewertungen

- Block-1 BLIS-03 Unit-2 PDFDokument15 SeitenBlock-1 BLIS-03 Unit-2 PDFravinderreddynNoch keine Bewertungen

- Truong Quang Tuong ITITIU20130 Lab 2 CDokument6 SeitenTruong Quang Tuong ITITIU20130 Lab 2 CTrương Quang TườngNoch keine Bewertungen