Beruflich Dokumente

Kultur Dokumente

Sur - Erection-BOQ - PI - Mech Equip Rev B

Hochgeladen von

shaikhsajid242Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sur - Erection-BOQ - PI - Mech Equip Rev B

Hochgeladen von

shaikhsajid242Copyright:

Verfügbare Formate

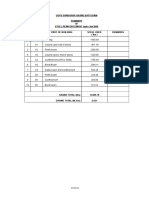

1500 MW

Rev

B 12/15/2010

Chapt. DESIGNATION Number

Total Weight

Tonnes

POWER ISLAND EQUIPMENT - BILL OF QUANTITIES

1 ERECTION BILL OF QUANTITIES B

Mechan. Open Cycle

2 SKIDS & FABRICATED EQUIPMENT W01 EB 030 11.748

3 ROTATING MACHINES W01 EB 040 10.2

21.9

Mechan. Combined Cycle

POWER ISLAND EQUIPMENT - DOCUMENT and DRAWINGS

4 SKIDS & FABRICATED EQUIPMENT W01 EB 030 B 213.2

5 ROTATING MACHINES W01 EB 040 B 175.4

6 CONDENSATION PLANT W01 EB 050 B 833.4

7 MAIN COOLING WATER EQUIPMENT W01 EB 131 B 13.3

B 1235.3

HANDLING EQUIPMENT W01 EB 031 A 158.1

7 PLANT INSTRUMENTATION (PI & ROP) W01 EB 110 A 13.4

B 1428.8

Remarks:

The Erection Standard Specification /EG.../EJ.../GS... will be provide later

2 x KA26-2 MS DC

ABCD ERECTION TECHNICAL DOCUMENT

Power Turbo Systems

SUR

TOTAL WEIGHT POWER ISLAND MECH. EQUIPMENT /

OPEN CYCLE (Tonnes) :

SUMMARY

MECHANICAL EQUIPMENT & PLANT INSTRUMENTATION

TOTAL WEIGHT POWER ISLAND MECH. EQUIPMENT,

Handl Equip and Instrum (Tonnes) :

Oman

POWER ISLAND

PARTICULAR TECHNICAL SPECIFICATIONS - DRAWINGS & BILLS OF QUANTITY

Nr. of Instruments : 628

TOTAL WEIGHT POWER ISLAND MECH. EQUIPMENT /

Comb. Cycle (Tonnes) :

232992393.xls.ms_office 6/8/2014

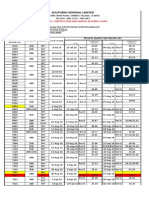

BOQ for Erection Valid for KA26-1 SS CT

SUR / Open cycle

Mech. Equipment WSC

31 32 33 35 36 36 Bis 37 38 39 40 41 44 45 49 50 56 57 58

Sorter Scope

Item Description

Nb of

block

Qty per

Bl.

Degree of

Pre-assembly

Equip

ment

Dimen

sions

Unit Net

Weight for all

plant

Total weight for

all plant

Transport Remarks

EB ES Number of Blocks : 1 Length Width Height Diam. (empty)

Particular

Installation

Specification

Equipment Drawing Incoterms Place of Dispatch

(Country, State)

No. I No. II [y / n] [m] [m] [m] [m] [Kg] [Kg]

EB30 y 11,748 EB030

EB30 B26 y

5,748

EB30 B26 y FWT / Deaerator 1 1 Pre-assembled 5.1 2.0 4.2 1.8 5,748 5,748

FWST 18-12-1

DCD/P 10.0

EXW Indonesia

EB30 B55 y 6,000

EB30 B55 y Sampling System For Water Steam Cycle 1 1 Container 5.0 2.4 2.8 6000 6,000 EXW England

EB40 y 10,200 EB040

EB40 B30 y

10,200

EB40 B30 y Feed water pump 1 3 Skid 3.1 1.4 0.8 3,400.0 10,200

SC FWP HGM 3_10

KSB

EXW India

y 21,948 TOTAL WEIGHT MECH. EQUIPMENT (Kg) :

232992393.xls.ms_office 1 / 8 Mechanical Open Cycle

BOQ for Erection, Valid for 1xKA26-1 SS DC

SUR / Comb Cycle

Mech Equipm Power Island

28 31 32 33 34 35 36 36 Bis 37 38 39 40 41 44 45 48 49 50 58

Rev Sorter Scope Item

No.

Item Description Nb of

block

Qty per

Bl.

Degree of

Pre-assembly

Equip

ment

Dimen

Unit Net

Weight for all

plant

Total weight for

all plant

Site Assembly Remarks

Rev EB ES

Number of Blocks : 2

Length Width Height Diam. (empty) General Installation

Specification

Particular Installation

Specification

Equipment Drawing

No. I No. II [y / n] [m] [m] [m] [m] [Kg] [Kg]

A EB30

y

SKIDS AND FABRICATED EQUIPMENT 213,200 EB030

A EB30 B15 y

CONDENSER VACCUUM EQUIPMENT 19,000

A EB30 B15 y Start-up Ejector 2 1 Skid 4.2 1.5 2.0 2,000 4,000 118.5949.1_118.5979.1

A EB30 B15 y silencer 2 1 Pre-assembled 1.0 3.5 1.0 2,500 5,000 118.5949.1_118.5979.1

A EB30 B15 y Service Ejector 2 1 Skid 4.3 1.5 2.0 5,000 10,000 Evac. GA-2stage-

118.5948.1

A

EB30 B26 y

DEAERATOR AND TANK

87,600 FWST Sines Outline

A EB30 B26 y FWT / Deaerator compl. 2 1 Pre-assembled 16.0 4.0 7.8 3.6 43,800 87,600 FWST 38-215-2 DCD/

H18.0-0.5

A EB30 B45 y

DRAIN/FLASH TANK 10,000

A EB30 B45 y ADV(Atmospheric drain

vessel)

2 1 Pre-assembled 3.5 3.5 7.0 2.3 5,000 10,000 ADV 230-3 GA dwg

_1AHA062525

A EB30 K50 y

NOISE ATTENUATION EQUIPMENT 15,600

A EB30 K50 y ADV Silencer 2 1 Pre-assembled 3.8 1.0 700 1,400

A EB30 K50 y HP Blow out Silencer 2 1 Pre-assembled 1.5 2.6 1,300 2,600

A EB30 K50 y LP Blow out Silencer 2 1 Pre-assembled 1.5 1.5 1,000 2,000

A EB30 K50 y

Acoustic Enclosure HP-FW-

Pump

2 3

Loose parts 5.8 2.5 2.9

1,600 9,600

A EB30 G65 y

EMISSION CONTROL EQUIPMENT 5,000

A EB30 G65 y

HRSG exhaust gas analysis

system

2 1 Container 3.0 2.5 2.8

2,500 5,000

1AHA029933

A EB30 C20 y

CLOSED CIRCUIT COOLING WATER EXCHANGER 38,000

A EB30 C20 y

Closed cooling water coolers

(water / water)

2 2 Pre-assembled 4.0 1.4 3.2

9,500 38,000

1AHA034286

A EB30 K10 y

MISCELLANEOUS TANKS 4,000

A EB30 K10 y

Head tank for CCW

2

1 Pre-assembled 2.0 1.8

2,000 4,000

1AHA029935

A EB30 B50 y

FEEDWATER AND CLOSED CIRCUIT DOSING PLANT 6,000 1AHA029938

A EB30 B50 y

HRSG dosing unit incl.

storage tank

2 1 Container 2.8 1.2 2.1

1,500 3,000

A EB30 B50 y

W/S cycle dosing unit incl.

storage tank

2 1 Container 2.3 1.7 2.5

1,500 3,000

A EB30 B55 y

STEAM AND WATER SAMPLING PLANT 28,000

A EB30 B55 y Sampling System for WSC 2 1 Container 13.5 2.4 2.8 14,000 28,000 MDG/19M/QUL---

B55/GA001

232992393.xls.ms_office 1 / 11 Print Date 6/8/2014

BOQ for Erection, Valid for 1xKA26-1 SS DC

SUR / Comb Cycle

Mech Equipm Power Island

28 31 32 33 34 35 36 36 Bis 37 38 39 40 41 44 45 48 49 50 58

Rev Sorter Scope Item

No.

Item Description Nb of

block

Qty per

Bl.

Degree of

Pre-assembly

Equip

ment

Dimen

Unit Net

Weight for all

plant

Total weight for

all plant

Site Assembly Remarks

Rev EB ES

Number of Blocks : 2

Length Width Height Diam. (empty) General Installation

Specification

Particular Installation

Specification

Equipment Drawing

No. I No. II [y / n] [m] [m] [m] [m] [Kg] [Kg]

A EB40 y ROTATING MACHINES 175,400 EB040

A EB40 B20

y

CONDENSATE EXTRACTION PUMPS 24,000

A EB40 B20 y Condensate Pumps, Compl.

with motor

2 3 Skid 1.8 7.0 1.8 4,000 24,000 CEP GA drw

Pembroke

A EB40 B30

y

HP FEEDWATER PUMPS 139,200

A EB40 B30 y HP / IP FW-Pumps w. Voith

coupling

2 3 Skid 8.5 2.2 3.1 21,000 126,000 FWP GA dwg_MD

159-360_1d+10

Sulzer

A EB40 B30 y FW PreheaterPumps 2 3 Skid 3.4 1.4 1.4 2200.0 13,200 FWP recirc pump

GA dwg_ZF 150-

630 Sulzer

A EB40

J15 y

MISCELLANEOUS CENTRIFUGAL PUMPS

5,000

A EB40 J15 y ADV Drain Pump 2 2 Skid 1.4 0.7 1.0 250 1,000 ADV pump GA-

Apollo

A EB40 J15 y Blowdown Pump 2 2 Skid 0.5 0.5 0.8 1,000 4,000

A EB40

J01 y

CLOSED CIRCUIT COOLING WATER PUMPS

7,200

A EB40 J01 y

Closed cooling water pumps

incl. E.Motors

2 2 Pre-assembled 2.0 0.8 1.4

1,800 7,200

1AHA 029936

A EB50

y

CONDENSING PLANT 833,400 EB050

EB50

B01 y

WATER COOLED CONDENSING PLANT 833,400

CM/S 60+85-2-97.0-

4x5874 / 24.1 / 0.4

A EB50 B01 y Upper tubed module 2 1 Pre-assembled 18.0 16.2 12.0 139,000 278,000

A EB50 B01 y Lower tubed module 2 1 Pre-assembled 18.0 16.2 12.0 139,000 278,000

A EB50 B01 y hotwell 2 1 Pre-fabricated 12.5 4.8 1.8 24,000 48,000

A EB50 B01 y neck (half) 2 2 Pre-fabricated 7.0 9.0 10.1 56,650 226,600 In two parts

A EB50 B01 y Flash box 2 1 Pre-fabricated 4.0 1.0 1,300 2,600

A EB50 B01 y Level Pipe 2 1 Loose parts 1.5 0.5 0.5 100 200

232992393.xls.ms_office 2 / 11 Print Date 6/8/2014

BOQ for Erection, Valid for 1xKA26-1 SS DC

SUR / Comb Cycle

Mech Equipm Power Island

28 31 32 33 34 35 36 36 Bis 37 38 39 40 41 44 45 48 49 50 58

Rev Sorter Scope Item

No.

Item Description Nb of

block

Qty per

Bl.

Degree of

Pre-assembly

Equip

ment

Dimen

Unit Net

Weight for all

plant

Total weight for

all plant

Site Assembly Remarks

Rev EB ES

Number of Blocks : 2

Length Width Height Diam. (empty) General Installation

Specification

Particular Installation

Specification

Equipment Drawing

No. I No. II [y / n] [m] [m] [m] [m] [Kg] [Kg]

A EB131

y

MAIN COOLING WATER PIPING EQUIPMENT 13,300 EB131

A

EB131 C40 y 1,600 GGG / 00 / M /

MCPL61 / EB / 131

A EB131 C40 y

Strainer (for CCW-Cooler) 2 2 Loose parts 2.8 1.0 1.0

300 1,200

1AHA 032475

A EB131 C40 y

Control cubicle 2 1 Cabinet 0.3 0.2 0.4

200 400

A EB131 C40 y 1,500

1AHA 034287

y

Debris Filter 2 1 Pre-assembled 1.0 1.0 1.0

500 1,000

y

Control Panel 1 1 Cabinet 1.0 1.0 1.0

500 500

B

EB131 B10 y

CONTINUOUS TUBE CLEANING EQUIPMENT

10,200 GGG / 00 / M /

MCPL61 / EB / 131

1AHA 029941

B EB131 B10 y

Strainer section 2 2 Loose parts 2.5 1.7 2.3

2,000 8,000

B EB131 B10 y

Recirculating unit incl.

control panel

2 1 Skid 2.5 1.5 2.2

1,100 2,200

A

y

TOTAL WEIGHT PI MECH. EQUIPMENT (Kg) : 1,235,300

DEBRIS FILTER IN COOL. WAT. SUPPLY LINES

(For Condensor)

DEBRIS FILTER IN COOL. WAT. SUPPLY LINES

(For CCW-Cooler)

232992393.xls.ms_office 3 / 11 Print Date 6/8/2014

BOQ for Erection, Handling Equipment

Sur 2 x KA26-2

MS

28 31 32 33 34 35 36 36 Bis 37 38 39 40 41 44 45 48 49 50 57 58 59

Rev Sorter Sco

pe

Item

No.

ItemDescription Nb of

block

Qty per

block

Degree of

Pre-assembly

Equip

ment

Dimen

Unit Net

Volume

Total

Volume

Unit Net

Weight

Total weight

for all plant

Site Assembly Remarks Power Island /

Non Power Island

Rev EB ES Length Width Height Diam. Volume Volume (empty) General

Installation

Specification

Particular

Installation

Specification

Equipment Drawing Place of Dispatch

(Country, State)

No. I No. II y [m] [m] [m] [m] [m

3

] [m

3

] [Kg] [Kg]

EB31 y HANDLING EQUIPMENT 1,217 158,090 EB031

EB31 G01 y double girder crane span=17.0 m / capacity 125/20 t 2 1 Pre-assembled 24.0 6.5 3.0 468 936 48000 96,000 ok main machine crane

Power Island

EB31 G02 y Single Girder crane span = 5.90 m / capacity 3.2 t 2 1 Pre-assembled 8.0 2.2 1.8 32 63 4500 9,000 ok above ST oil room

Power Island

EB31 G02 y Single Girder crane span = 12.00 m / capacity 5t 1 1 Pre-assembled 8.0 2.2 1.8 32 32 4500 4,500 ok Workshop & Warehouse

BoP Area

EB31 G03 y monorail hoist capacity 10 t 2 3 Pre-assembled 1.4 1.2 1.2 2 12 550 3,300 ok FWpump area

Power Island

EB31 G04 y monorail hoist capacity 5 t 2 3 Pre-assembled 1.4 1.2 1.2 2 12 450 2,700 ok Recirculation pump area

Power Island

EB31 G05 y monorail hoist capacity 1.5 t 0 0 Pre-assembled 0.7 0.8 1.0 1 - 250 - above feedwater preheating pumps

Power Island

EB31 G06 y monorail hoist capacity 3.20 t 2 2 Pre-assembled 1.8 0.9 0.9 1 6 320 1,280 ok Monorail above HRSG Platform

Power Island

EB31 G07 y Wall mounted jib crane capacity 0.5 t 2 2 Pre-assembled 2.5 1.2 1.2 4 14 220 880 ok GT Air intake

Power Island

EB31 G08 y monorail hoist capacity 3 t 2 1 Pre-assembled 0.7 0.8 1.0 1 1 300 600 ok above feedwater tank

Power Island

EB31 G09 y monorail hoist capacity 0.5 t 2 1 Pre-assembled 0.7 0.8 1.0 1 1 80 160 ok above LBS valve

Power Island

EB31 G10 y monorail hoist capacity 5t 2 1 Pre-assembled 0.7 0.8 1.0 1 1 400 800 ok above condensate pump area

Power Island

EB31 G11 y monorail hoist capacity 5t 0 0 Pre-assembled 0.7 0.8 1.0 1 - 400 - above condensate pump

Power Island

EB31 G12 y monorail hoist capacity 1 t 2 1 Pre-assembled 0.7 0.8 1.0 1 1 180 360 ok above atmospheric drain pump

Power Island

EB31 G13 y monorail hoist capacity 1 t 0 0 Pre-assembled 0.7 0.8 1.0 1 - 180 - above CCWpumps

Power Island

EB31 G14 y manual chain hoist 1 t 0 0 Pre-assembled 0.7 0.8 1.0 1 - 110 - above CCWpumps

Power Island

EB31 G15 y monorail hoist capacity 5 t 0 0 Pre-assembled 0.7 0.8 1.0 1 - 320 - above ball strainer

Power Island

EB31 G16 y monorail hoist capacity 1 t 0 0 Pre-assembled 0.7 0.8 1.0 1 - 220 - above OTC valves

Power Island

EB31 G17 y monorail hoist capacity 1 t 0 0 Pre-assembled 0.7 0.8 1.0 1 - 220 - APWDummy valve

Power Island

EB31 G18 y monorail hoist capacity 1 t 2 2 Pre-assembled 0.7 0.8 1.0 1 2 180 720 ok Bypass Control valve

Power Island

EB31 G19 y monorail hoist capacity 1.5 t 0 0 Pre-assembled 0.7 0.8 1.0 1 - 220 - IP Bypass valve

Power Island

EB31 G20 y monorail hoist capacity 1.5 t 0 0 Pre-assembled 0.7 0.8 1.0 1 - 220 - LP Bypass valve

Power Island

EB31 G40 y monorail hoist capacity 2.5 t 2 2 Pre-assembled 0.7 0.8 1.0 1 2 300 1,200 ok Generator bearing (GT-side)

Power Island

EB31 G40 y monorail hoist capacity 2.5 t 2 2 Pre-assembled 0.7 0.8 1.0 1 2 300 1,200 ok Generator bearing (Exit-side)

Power Island

EB31 G21 y monorail hoist capacity 1 t 2 2 Pre-assembled 0.7 0.8 1.0 1 2 220 880 ok above OTC valves

Power Island

EB31 G22 y push travel trolley 1 t 0 0 Pre-assembled 0.7 0.8 1.0 1 - 180 - above HP CS valves

Power Island

EB31 G23 y monorail hoist capacity 1.5 t 2 2 Pre-assembled 0.7 0.8 1.0 1 2 220 880 ok above HP Main Stream Line valves

Power Island

EB31 G24 y manual chain hoist 1.5 t 2 2 Pre-assembled 0.7 0.8 1.0 1 2 110 440 ok above HP Main Stream Line valves

Power Island

EB31 G25 y push travel trolley 1.5 t 0 0 Pre-assembled 0.7 0.8 1.0 1 - 190 - above LP Main Stream Line valves

Power Island

EB31 G26 y monorail hoist capacity 1.5 t 2 2 Pre-assembled 0.7 0.8 1.0 1 2 220 880 ok above HP Drum safety valves

Power Island

EB31 G27 y monorail hoist capacity 1.5 t 2 2 Pre-assembled 0.7 0.8 1.0 1 2 220 880 ok above IP Drum safety valves

Power Island

EB31 G28 y monorail hoist capacity 1.5 t 0 0 Pre-assembled 0.7 0.8 1.0 1 - 220 - above HP Drum safety valves

Power Island

EB31 G29 y monorail hoist capacity 1.5 t 0 0 Pre-assembled 0.7 0.8 1.0 1 - 220 - above IP Drum safety valves

Power Island

EB31 G30 y monorail hoist capacity 1.5 t 2 2 Pre-assembled 0.7 0.8 1.0 1 2 220 880 above IP Drum safety valves

Power Island

EB31 G31 y monorail hoist capacity 1.5 t 2 2 Pre-assembled 0.7 0.8 1.0 1 2 220 880 ok above LP Drum safety valves

Power Island

EB31 G32 y monorail hoist capacity 1.5 t 0 0 Pre-assembled 0.7 0.8 1.0 1 - 220 - above LP Drum safety valves

Power Island

EB31 G33 y monorail hoist capacity 1.5 t 2 2 Pre-assembled 0.7 0.8 1.0 1 2 220 880 ok above HP Feed Control Station Valve

Power Island

EB31 G34 y monorail hoist capacity 1.5 t 2 2 Pre-assembled 0.7 0.8 1.0 1 2 220 880 ok above IP Feed Control Station Valve

Power Island

EB31 G35 y monorail hoist capacity 1.5 t 2 2 Pre-assembled 0.7 0.8 1.0 1 2 220 880 ok above LP Feed Control Station Valve

Power Island

EB31 G36 y monorail hoist capacity 0.75 t 2 3 Pre-assembled 0.6 0.7 0.9 0 2 210 1,260 ok above Geno circuit braker

Power Island

232992393.xls.ms_office 1 / 8 Print Date 6/8/2014

BOQ for Erection, Handling Equipment

28 31 32 33 34 35 36 36 Bis 37 38 39 40 41 44 45 48 49 50 57 58 59

Rev Sorter Sco

pe

Item

No.

ItemDescription Nb of

block

Qty per

block

Degree of

Pre-assembly

Equip

ment

Dimen

Unit Net

Volume

Total

Volume

Unit Net

Weight

Total weight

for all plant

Site Assembly Remarks Power Island /

Non Power Island

Rev EB ES Length Width Height Diam. Volume Volume (empty) General

Installation

Specification

Particular

Installation

Specification

Equipment Drawing Place of Dispatch

(Country, State)

No. I No. II y [m] [m] [m] [m] [m

3

] [m

3

] [Kg] [Kg]

EB31 G37 y manual chain hoist 1 t 2 1 Pre-assembled 0.7 0.8 1.0 1 1 80 160 ok above HRSG blow down pumps

Power Island

EB31 G38 y push travel trolley 1 t 2 1 Pre-assembled 0.7 0.8 1.0 1 1 160 320 ok above HRSG blow down pumps

Power Island

EB31 G39 y Monorail hoist 0.5 t 2 1 Pre-assembled 0.7 0.8 1.0 1 1 50 100 ok above cold reheat NRV

Power Island

EB31 G40 y monorail hoist capacity 3 t 1 1 Pre-assembled 0.7 0.8 1.0 1 1 300 300 ok Water Treatment building

BoP Area

EB31 G40 y monorail hoist capacity 3 t 1 1 Pre-assembled 0.7 0.8 1.0 1 1 300 300 ok Electrochlorination Plant

BoP Area

EB31 G41 y monorail hoist capacity 5 t 1 5 Pre-assembled 0.7 0.8 1.0 1 3 300 1,500 ok Fuel Oil pumpstation

BoP Area

EB31 G42 y geared travel trolley 3 t 0 0 Pre-assembled 0.7 0.8 1.0 1 - 180 - FF Pump House

BoP Area

EB31 G43 y Goliath crane 35t 1 1 Pre-assembled 31.0 3.0 1.0 93 93 20000 20,000 ok obove Cooling water pumps

BoP Area

EB31 G44 y monorail hoist capacity 3 t 1 2 Pre-assembled 0.7 0.8 1.0 1 1 300 600 ok different location

BoP Area

EB31 G45 y monorail hoist capacity 1 t 1 2 Pre-assembled 0.7 0.8 1.0 1 1 180 360 ok different location

BoP Area

EB31 G45 y monorail hoist capacity 0.5 t 1 2 Pre-assembled 0.7 0.8 1.0 1 1 50 100 ok different location

BoP Area

EB31 G46 y Chain hoist block capacity 3 t 1 2 Pre-assembled 0.5 0.5 0.8 0 0 300 600 ok different location

BoP Area

EB31 G46 y Chain hoist block capacity 1 t 1 2 Pre-assembled 0.5 0.5 0.8 0 0 140 280 ok different location

BoP Area

EB31 G47 y Chain hoist block capacity 0.5 t 1 2 Pre-assembled 0.5 0.5 0.7 0 0 135 270 ok different location

BoP Area

EB31 G48 y Hoist suspension eye capacity 3 t 1 2 Pre-assembled 0.5 0.5 0.6 0 0 220 440 ok different location

BoP Area

EB31 G48 y Hoist suspension eye capacity 1 t 1 2 Pre-assembled 0.5 0.5 0.6 0 0 120 240 ok different location

BoP Area

EB31 G49 y Hoist suspension eye capacity 0.5 t 1 2 Pre-assembled 0.5 0.5 0.6 0 0 100 200 ok different location

BoP Area

TOTAL WEIGHT f. complete plant (kg) : 158,090

232992393.xls.ms_office 2 / 8 Print Date 6/8/2014

ABCD

Power Turbo Systems Date :

Rev A

Project : Author: L, delValle

Analogical For one unit For 2unit

DESIGNATION DWG N COMMENTS DIMENSION Unit Total Total Total

ES if any Qty. Weight(T) Weight(T) Qty Weight(T)

8 PLANT INSTRUMENTATION 314 6.7 628 13.4

Reference Document

GGG / 00 / M / MCP- - - / EB/110 Combined Cycle Power Plant Technical Specification, Bill of Quantity Instrumentation

90 Note: The erection works shall include the supply and erection of necessary materials specified in document 1AHA040219, chapter 3.2

This list does not include the instrument already erected with equipment skid or supply with equipment.

90

N01/1 INSTRUMENT / Power Island 203 2.4 406 4.8

FC 4000 Flow (Water) 1AHA024981 11 0.02 0.22 22 0.44

LL 2009 Level Indicator 1AHA024970 3 0.02 0.06 6 0.12

LC 200F Level Switch 1AHA024968 9 0.01 0.09 18 0.18

LC 2100 Level Measurement (Transmitter) 1AHA024959 19 0.02 0.38 38 0.76

DC 3000 Diff. Pressure Measurement (not Level) 1AHA024993 5 0.02 0.1 10 0.2

PL 5000 Pressure Gauge 1AHA024946 21 0.01 0.21 42 0.42

PC 5000 Pressure Measurement (Transmitter) 1AHA024934 41 0.01 0.41 82 0.82

TL 6003 Temperature Indicator 1AHA024912 11 0.01 0.11 22 0.22

TC 6002 Temperature Element & Transmitter 1AHA024910 55 0.01 0.55 110 1.1

TP 6000 T or TP (Thermowell only) 1AHA024908 28 0.01 0.28 56 0.56

N01/2 INSTRUMENT RACK / Power Island 85 3.6 170 7.2

Instrument Rack without roof 1AHA020708 65 0.04 2.6 130 5.2

Instrument Rack with roof 1AHA020711 20 0.05 1 40 2

N01/1 INSTRUMENT / Rest of Plant 16 0.2 32 0.4

FC 4000 Flow (Water) 1AHA024912 1 0.02 0.02 2 0.04

LC 2100 Level Measurement (Transmitter) 1AHA024959 3 0.02 0.06 6 0.12

PL 5000 Pressure Gauge 1AHA024946 3 0.01 0.03 6 0.06

PC 5000 Pressure Measurement (Transmitter) 1AHA024934 3 0.01 0.03 6 0.06

TC 6002 Temperature Element & Transmitter 1AHA024910 6 0.01 0.06 12 0.12

N01/2 INSTRUMENT RACK / Rest of Plant 10 0.5 20 1.0

Instrument Rack with roof 1AHA020711 10 0.05 0.5 20 1

LABELLING Supplied by ALSTOM POWER

Consisting of : Supporting plate in stainless steel, Slide-in plate in plastic, Brackets & rivets in stainless steel 3000 6000

Collar in stainless steel or galvanized steel

15-Dec-10

PLANT INSTRUMENTATION (PI & ROP)

LIST OF EQUIPMENT TO BE ERECTED

8 : PLANT INSTRUMENTATION

SUR 2 x KA26-2 MS DC / Oman

232992393.xls.ms_office Quantity and weight are theoritical empty value mentionned on drawing 3/8

Das könnte Ihnen auch gefallen

- Boq Take OffDokument8 SeitenBoq Take OffMerry YonasNoch keine Bewertungen

- الدليل الانشائي لحساب الاحمال الزلزاليةDokument42 Seitenالدليل الانشائي لحساب الاحمال الزلزاليةTarek AbulailNoch keine Bewertungen

- Steel Joists - MST PDFDokument7 SeitenSteel Joists - MST PDFwafikmh4Noch keine Bewertungen

- 2010 CDOT Construction Cost Data BookDokument528 Seiten2010 CDOT Construction Cost Data Bookb2058793Noch keine Bewertungen

- Break DownDokument67 SeitenBreak DownSenthilnathan NagarajanNoch keine Bewertungen

- Sub Surface DrainageDokument5 SeitenSub Surface DrainageawaisjalaliNoch keine Bewertungen

- 2013 Actual Man HourDokument907 Seiten2013 Actual Man HourwessamalexNoch keine Bewertungen

- Cost Comparison 5-5-18Dokument76 SeitenCost Comparison 5-5-18Charlote EspinosaNoch keine Bewertungen

- Labor Productivity and AnalysisDokument27 SeitenLabor Productivity and AnalysisBasit AnwarNoch keine Bewertungen

- Form WorkDokument38 SeitenForm WorkromahiNoch keine Bewertungen

- Staad Load Combinations With Notional LoadsREV3Dokument6 SeitenStaad Load Combinations With Notional LoadsREV3ramonortiz55Noch keine Bewertungen

- RMGF (Repair & Maintenance of Government Facility) ProjectsDokument65 SeitenRMGF (Repair & Maintenance of Government Facility) ProjectsJong DrilonNoch keine Bewertungen

- Topographical Survey Drawing ModelDokument1 SeiteTopographical Survey Drawing ModelArunashish MazumdarNoch keine Bewertungen

- HO Manhour SheetDokument6 SeitenHO Manhour SheetPrasad GowriNoch keine Bewertungen

- Project Schedule: ABC Construction, IncDokument1 SeiteProject Schedule: ABC Construction, IncGolamMostafaNoch keine Bewertungen

- Welding Design For Rebar To Cast in PlateDokument1 SeiteWelding Design For Rebar To Cast in PlateMyat Thu Zar KhineNoch keine Bewertungen

- Imp Design GuideDokument32 SeitenImp Design GuideRahulNoch keine Bewertungen

- Roof Drainage PDFDokument68 SeitenRoof Drainage PDFFrancisco BonillaNoch keine Bewertungen

- D.M.Plant OperatorsDokument5 SeitenD.M.Plant OperatorsTiu TonNoch keine Bewertungen

- Mining Equipment Sealing SolutionsDokument5 SeitenMining Equipment Sealing SolutionsSenthilKumar100% (1)

- WL130 PE4710 FM Approved Pipe: IPS & DIPS Pipe Sizes - Class 150, 200 & 267Dokument3 SeitenWL130 PE4710 FM Approved Pipe: IPS & DIPS Pipe Sizes - Class 150, 200 & 267Tanwir AhmadNoch keine Bewertungen

- Ggps Sandasar Qasim, Battgram OF STEEL REINFORCEMENT (Upto 2nd Bill) S.No Sheet # Part of Building Remarks Steel Used (LBS)Dokument7 SeitenGgps Sandasar Qasim, Battgram OF STEEL REINFORCEMENT (Upto 2nd Bill) S.No Sheet # Part of Building Remarks Steel Used (LBS)syukNoch keine Bewertungen

- Rig Weight NormsDokument1 SeiteRig Weight NormsDPSprojectsNoch keine Bewertungen

- 010 Estimate DetailDokument1 Seite010 Estimate DetailSatria PinanditaNoch keine Bewertungen

- Steelwork GlossaryDokument24 SeitenSteelwork Glossaryshailesh9jan100% (3)

- CSR-2014-Sindh NHA PDFDokument262 SeitenCSR-2014-Sindh NHA PDFSohail Ahmed Khilji100% (1)

- 8062Dokument27 Seiten8062Aashish Moyal100% (1)

- Item Rate Boq: Validate Print HelpDokument5 SeitenItem Rate Boq: Validate Print HelpSOMNATH JANANoch keine Bewertungen

- Foundation Plan and Anchor Locations: Section CDokument1 SeiteFoundation Plan and Anchor Locations: Section CJavier Guerra TriviñoNoch keine Bewertungen

- Strain Pole Ver 1.1 97-2003Dokument32 SeitenStrain Pole Ver 1.1 97-2003Rajas AlshiNoch keine Bewertungen

- CPWD NormsDokument13 SeitenCPWD NormsBIJAY KRISHNA DASNoch keine Bewertungen

- EstimationDokument48 SeitenEstimationcdawan dawanNoch keine Bewertungen

- 2012 Final PG&E Generator Interconnection Unit Cost Guide 60/70 KV 115 KV 138 KV 230 KV 500 KVDokument9 Seiten2012 Final PG&E Generator Interconnection Unit Cost Guide 60/70 KV 115 KV 138 KV 230 KV 500 KVdineshsoni29685Noch keine Bewertungen

- Scaffold CalculationDokument6 SeitenScaffold Calculationrajkamal_eNoch keine Bewertungen

- Material Specification: A Concrete and Masonry WorksDokument3 SeitenMaterial Specification: A Concrete and Masonry WorksRoselle AlviarNoch keine Bewertungen

- Carpentry Works Man HourDokument2 SeitenCarpentry Works Man HourTrending JuanNoch keine Bewertungen

- Design Example of Pipe Rack StructureDokument16 SeitenDesign Example of Pipe Rack StructureJimit PayNoch keine Bewertungen

- 130 - S-HZL Storage tankBOQ - 20.12.19Dokument4 Seiten130 - S-HZL Storage tankBOQ - 20.12.19ananthu.uNoch keine Bewertungen

- HSFG BoltsDokument4 SeitenHSFG BoltspajipitarNoch keine Bewertungen

- Spreadsheets To BS 8110Dokument11 SeitenSpreadsheets To BS 8110NitinShepurNoch keine Bewertungen

- Sample BOQ For Structural SteelDokument2 SeitenSample BOQ For Structural SteelWakanda PoreberNoch keine Bewertungen

- Mining Equipment Testing: Application GuideDokument8 SeitenMining Equipment Testing: Application Guiderk6482100% (1)

- Structural Steel PTD ModuleDokument91 SeitenStructural Steel PTD ModulefaridNoch keine Bewertungen

- Model Bills of Quantities: Federation of Piling SpecialistsDokument9 SeitenModel Bills of Quantities: Federation of Piling SpecialistsAllahjurioNoch keine Bewertungen

- A6561 Bollard DetailDokument1 SeiteA6561 Bollard DetailMarvinPatricioNarcaNoch keine Bewertungen

- Southern General Limited: Civil Works, Construction and General Building WorksDokument4 SeitenSouthern General Limited: Civil Works, Construction and General Building WorksJohn DoeNoch keine Bewertungen

- Report Writing Style Guide For Engineering StudentsDokument64 SeitenReport Writing Style Guide For Engineering StudentsBobi PitropNoch keine Bewertungen

- Unfactored Load ItemDokument43 SeitenUnfactored Load ItemVivek Manohar PatilNoch keine Bewertungen

- Buckling CheckingDokument1 SeiteBuckling CheckingSabbir SiddiqueNoch keine Bewertungen

- Detail Cost Estimation of Roads (Complete)Dokument664 SeitenDetail Cost Estimation of Roads (Complete)Sandeep BhandariNoch keine Bewertungen

- Project Output ESTIMATEDokument21 SeitenProject Output ESTIMATEedgezy07Noch keine Bewertungen

- Contractora Estimate Cost - Propelat RapDokument192 SeitenContractora Estimate Cost - Propelat RapMr. RudyNoch keine Bewertungen

- Weekly ReportDokument170 SeitenWeekly Reportafrozamjad003Noch keine Bewertungen

- Weather Conditions: Daily Progress ReportDokument2 SeitenWeather Conditions: Daily Progress Reportbishu70Noch keine Bewertungen

- Sub-Project Title: Construction of Evacuation Center: WagesDokument4 SeitenSub-Project Title: Construction of Evacuation Center: WagesMark Arboleda GumamelaNoch keine Bewertungen

- Sur - Erection BOQ - Electr Equipm - RevADokument11 SeitenSur - Erection BOQ - Electr Equipm - RevAshaikhsajid242100% (1)

- SUR - Erection BOQ - ST & Geno - Rev ADokument5 SeitenSUR - Erection BOQ - ST & Geno - Rev Ashaikhsajid242Noch keine Bewertungen

- Wind World W2700Dokument60 SeitenWind World W2700paolosementa100% (1)

- Motor Data Sheet LT MOTORDokument12 SeitenMotor Data Sheet LT MOTORHarshit GautamNoch keine Bewertungen

- Cb-7770 DR Modelcble Sept09Dokument14 SeitenCb-7770 DR Modelcble Sept09kosmc123Noch keine Bewertungen

- LV BOQ For Warehouse, Office BLDG & Workers Block PricingDokument6 SeitenLV BOQ For Warehouse, Office BLDG & Workers Block Pricingshaikhsajid242Noch keine Bewertungen

- Detuned ReactorsDokument4 SeitenDetuned Reactorsshaikhsajid242Noch keine Bewertungen

- AADC Transformer RoomDokument3 SeitenAADC Transformer Roomshaikhsajid242Noch keine Bewertungen

- Annexure E - Division of ResponisbilityDokument4 SeitenAnnexure E - Division of Responisbilityshaikhsajid242Noch keine Bewertungen

- SVC in Steel Manufacturing: An Indian Case: Single-Line Diagram of The SVC and EAFDokument2 SeitenSVC in Steel Manufacturing: An Indian Case: Single-Line Diagram of The SVC and EAFshaikhsajid242Noch keine Bewertungen

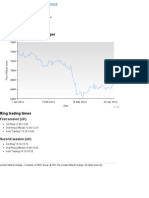

- London Metal Exchange - Copper 2012Dokument2 SeitenLondon Metal Exchange - Copper 2012shaikhsajid242Noch keine Bewertungen

- London Metal Exchange - Copper 2013Dokument2 SeitenLondon Metal Exchange - Copper 2013shaikhsajid242Noch keine Bewertungen

- Sur - Erection Boq - I&c - Rev ADokument14 SeitenSur - Erection Boq - I&c - Rev Ashaikhsajid242Noch keine Bewertungen

- London Metal Exchange - CopperDokument1 SeiteLondon Metal Exchange - Coppershaikhsajid242Noch keine Bewertungen

- London Metal Exchange - Copper 2007Dokument2 SeitenLondon Metal Exchange - Copper 2007shaikhsajid242Noch keine Bewertungen

- Sur - Erection Boq - HRSG Harps - Rev BDokument15 SeitenSur - Erection Boq - HRSG Harps - Rev Bshaikhsajid242100% (1)

- SUR - Erection BOQ - ST & Geno - Rev ADokument5 SeitenSUR - Erection BOQ - ST & Geno - Rev Ashaikhsajid242Noch keine Bewertungen

- SUR - Erection - BOQ - PI - Piping - Rev ADokument8 SeitenSUR - Erection - BOQ - PI - Piping - Rev Ashaikhsajid242Noch keine Bewertungen

- Sur - Erection BOQ - Electr Equipm - RevADokument11 SeitenSur - Erection BOQ - Electr Equipm - RevAshaikhsajid242100% (1)

- Sur - Boq 4x Gt26 Ms - BDokument9 SeitenSur - Boq 4x Gt26 Ms - Bshaikhsajid242Noch keine Bewertungen

- Fujairah 2 Uae Ka26 CogenerationDokument2 SeitenFujairah 2 Uae Ka26 Cogenerationshaikhsajid242Noch keine Bewertungen

- SUR - Erection - BOQ-Painting Rev ADokument2 SeitenSUR - Erection - BOQ-Painting Rev Ashaikhsajid242Noch keine Bewertungen

- LatestDokument602 SeitenLatestshaikhsajid242Noch keine Bewertungen

- Sample Load ListDokument2 SeitenSample Load Listshaikhsajid242Noch keine Bewertungen

- Load Schedule Rev-04Dokument35 SeitenLoad Schedule Rev-04shaikhsajid242100% (1)

- Danieli LRF CommentsDokument2 SeitenDanieli LRF Commentsshaikhsajid242Noch keine Bewertungen

- ETAP Real Time - Steel PlantDokument20 SeitenETAP Real Time - Steel Plantshaikhsajid242Noch keine Bewertungen

- Thdi LVDokument2 SeitenThdi LVshaikhsajid242Noch keine Bewertungen

- 12-24kV SafeRing SafePlus enDokument76 Seiten12-24kV SafeRing SafePlus enyesfriend28Noch keine Bewertungen

- DS350 1318 OperatorsDokument61 SeitenDS350 1318 Operatorsluiscremaschi100% (1)

- LOLERDokument68 SeitenLOLERpraba8105100% (3)

- Navy Crane ManualDokument330 SeitenNavy Crane ManualGary J. Davis, P. E.100% (4)

- REMA C-21 Hand Chain Hoist: PropertiesDokument5 SeitenREMA C-21 Hand Chain Hoist: PropertiesRanaNoch keine Bewertungen

- KOLO Information For HandbookDokument1 SeiteKOLO Information For HandbookYoga SamNoch keine Bewertungen

- BS EN 280-2-2022Dokument26 SeitenBS EN 280-2-2022gokhanekinci92Noch keine Bewertungen

- Gis 38-201Dokument22 SeitenGis 38-201Arash SotoudehNoch keine Bewertungen

- Backup of Submitil CraneDokument17 SeitenBackup of Submitil CraneAhmed AhmedNoch keine Bewertungen

- Lebus BulletinDokument4 SeitenLebus BulletinNaval2014DNNoch keine Bewertungen

- Program - Winch Tear DownDokument11 SeitenProgram - Winch Tear DownAnonymous 1qAH6CKCNoch keine Bewertungen

- Manual 160928Dokument18 SeitenManual 160928JUANKMUGNONoch keine Bewertungen

- Serial-9 CHAPTER VII-Details of Escalator & LiftDokument20 SeitenSerial-9 CHAPTER VII-Details of Escalator & LiftshifatNoch keine Bewertungen

- Demag DMR (Brochure)Dokument20 SeitenDemag DMR (Brochure)MadhaneNoch keine Bewertungen

- Trolley Hoist & Maintenance PadeyesDokument16 SeitenTrolley Hoist & Maintenance PadeyesSivakumarNoch keine Bewertungen

- Crane Components PDFDokument24 SeitenCrane Components PDFMahmoud AllamNoch keine Bewertungen

- LIFTING RIGGING CATALOGUE FinalDokument24 SeitenLIFTING RIGGING CATALOGUE FinalJuna PasaribuNoch keine Bewertungen

- Estimatingcalculation MalaysiaDokument136 SeitenEstimatingcalculation MalaysiaAbdulBari100% (1)

- Vendor Document Cover Sheet: Record of RevisionDokument28 SeitenVendor Document Cover Sheet: Record of RevisionSagar SawantNoch keine Bewertungen

- BOP Handling Systems - Ingersoll RandDokument20 SeitenBOP Handling Systems - Ingersoll RandrahulNoch keine Bewertungen

- D51E-22 BRAZIL (Eng) CEBM019102Dokument1.174 SeitenD51E-22 BRAZIL (Eng) CEBM019102Tulio Cafezakis100% (4)

- Hitachi HoistDokument74 SeitenHitachi HoistlifttecNoch keine Bewertungen

- Rope HoistDokument12 SeitenRope HoistArvindNoch keine Bewertungen

- PV 351 Assembly PicsDokument67 SeitenPV 351 Assembly PicsJose M100% (1)

- Rigging and Lifting (Rev.1)Dokument33 SeitenRigging and Lifting (Rev.1)windell Patalinghug100% (2)

- Occupational Health and Safety ActDokument558 SeitenOccupational Health and Safety ActWaleed Barakat Maria0% (1)

- Container Crane 2DT2014 Część-3 STS Technical Specification PDFDokument143 SeitenContainer Crane 2DT2014 Część-3 STS Technical Specification PDFTfk BajaNoch keine Bewertungen

- Rope HoistDokument12 SeitenRope HoistKa Hau TeyNoch keine Bewertungen

- MP-5 800x400 Manual 2007 Rev BDokument162 SeitenMP-5 800x400 Manual 2007 Rev Bcpmailing10Noch keine Bewertungen

- Wciagniki Linowe As F 7 AngielskiDokument48 SeitenWciagniki Linowe As F 7 Angielskimoha19841Noch keine Bewertungen

- April 2012 Wire Rope ExchangeDokument84 SeitenApril 2012 Wire Rope ExchangeWire Rope ExchangeNoch keine Bewertungen