Beruflich Dokumente

Kultur Dokumente

Project On Entrepreneurship Development

Hochgeladen von

Hemen Sarma0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

169 Ansichten19 SeitenIt is a formulated project on setting up of a Rice mill. Entrepreneurial Venture Setup.

Originaltitel

Project on Entrepreneurship Development

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenIt is a formulated project on setting up of a Rice mill. Entrepreneurial Venture Setup.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

169 Ansichten19 SeitenProject On Entrepreneurship Development

Hochgeladen von

Hemen SarmaIt is a formulated project on setting up of a Rice mill. Entrepreneurial Venture Setup.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 19

NORTH EASTERN REGI ONAL I NSTI TUTE OF MANAGEMENT

PROJECT REPORT ON A ENTREPRENEURSHIP

DEVELOPMENT

TOPIC:

GOGOI MINI MODERN RICE MILL

SUBMITTED TO: SUBMITTED BY

Mr. M. I. Singh Mr Naba Gogoi

Faculty of Business Adm. Dept. MBA 2

nd

sem(B)

NERIM Roll No-111

NERIM

CONTENT

1. ACKNOWLEDGEMENT

2. HIGHLIGHTS OF THE PROJECT

3. I NTRODUCTI ON

4. MARKETABI LI TY

5. TECHNI CAL FEASI BI LI TY

6. PRODUCTI ON TARGET

7. PLANT CAPACI TY

8. BASI S AND PRESUMPTI ON

9. FI NANCI AL ASPECTS

10. CONCLUSI ON

ACKNOWLEDGEMENT

No project can be completed by individual effort only. It

always takes lots of peoples contribution too. The contributions

of some are direct and evident and of others are indirect and

obscured. I expressed my sincere gratitude towards all those who

have directly or indirectly helped me throughout this project.

At first, I would like to express my sincere thanks and

gratefulness to our faculty Mr.Samannay Baruah from business

administration department, NERIM for giving me the

opportunity to evince my dream.

I would like to offer my gratitude to the Libarian of the Indian

I nstitute of Entrepreneurship, Guwahati; who provides me a valuable

guidance.

I am pleased to offer my sincere thanks to my seniors, which also

stand as a pillar of inspiration to me as well.

Naba Gogoi

MBA 2

nd

Sem

PREFACE

Project is the indispensable part of any kind of formal education; they help us in

practical learning for MBA. We are basically trained and equipped with strong

theoretical knowledge of how business operates and what is the time tested

methods of running a successful business.

The entrepreneur project has given us the opportunity to practical applicability of

management concepts and theory and developing better ability to analyze the

problems and decision that contribute significantly for better use of resources

available to the management.

This project offers the glimpse of the various stages of the project work in order to

serve the purpose of the study in a systematic manner, hope that the project will go

way in establishing and running my own business.

1.1 HIGHLIGHTS OF THE PROJECT

Name of the unit : Gogoi Rice Mill

.Constitution : Proprietorship

Name of entrepreneur : Naba Gogoi

Proposed Location : Dhenukhana ,P.O-Ghilamara

Dist-Lakhimpur(Assam)

Telephone No :

(O) +91-9706243452

(R) +91-9577055793

Name/address of the promoter:

Name: Naba Gogoi

Address: AT & P.O. - Dhenukhana

Dist- North Lakhimpur

State: Assam, 787053

Qualification of the entrepreneur:

Academic Qualification : B.COM , MBA (Finance &

Marketing)

Name and address of promoters Bank: STATE BANK OF INDIA

North Lakhimpur Branch

Total Capital Cost :

S.NO PARTICULARS AMOUNT(Rs)

1. Land & building 3,00,000.00

2. Plant & Machinery 4,00,000.00

3. Tools & Equipment 28,000.00

4. Furniture& Fixer 12,000.00

5. Preliminary & Pro-Operative Exp. 15,000.00

6. Working Capital 5,49,500.00

1.2 Means of Finance :

I. Promoters Contribution @ 20% =2,60,900

II. Loan from Bank @ 80% =10,43,600

1.3 Loan Repayment period : 5 (Five) Years

1.4 Important Financial Findings :

Rate of return : 26.44%

BEP : 15.19%

1.5 Introduction of the Product

Rice is one of major crops of our country and constitutes the staple diet of a large

population. India is the second largest producer of rice with annual production of

more than 90 million tonnes. Good quality and varieties of rice are grown in

different parts of our countrys demand for rice but has earned a special place for

itself in international markets.

Rice mill is used for obtaining rice from rice bran. Presently, different mills of

varying capacities are set up in many parts of one country the parts where rice is

principally grown. On once hand rice bran can be bought by such mills and can be

marketed after obtaining rice farm it, on the other hand the producers of rice be

marketed after obtaining rice farm it, on the other hand the producers of rice

themselves can hire service, of these rice mills. Along with the big rice mills, small

rice mills have also been proved lucrative especially when production and job

work, both are taken up, this unit can not only prove to be successful but quiet a

profitable means of self employment.

Milling of Rice are two types:

Step one-Removal of hard protective husk.The rice husk is the protective layer

surrounding the grain one removed,the rice grains is pachaged as brown rice .

Brown rice is healthy because it still contains the rice germ and outer bran layer

Important for healthy body functions.

Step two-Removal of the germ and brown layers.gentle milling removes the germ

and brown layers.Gentle milling removes the germ and bran layers from the grain

to expose a white starch centre .The polished white starch centre is what we know

as white rice.

1.6 Marketability: A small description of the market which I will us is mentioned

below.

Monthly my production will be 400 quintals of rice bran per month and market out

of which 300 quintals of good quality rice would be obtained. I have planned to

supply the good quality of rice bran in rural area .Not only rural area but also it

supply in whole sale price . I have already talked to the retailer of those rural area

and urban area and got a positive response from them. They told me that they

would collect the rice bran from my factory. The price will be determined as per

market condition and quality of the rice.

This is the primary market which I will use for business. In future when I will

expand my business market structure will be totally different.

Hereby I have mentioned the total marketability and market structure of the

business.

1.7 Technical Feasibility:

Manufacturing Process: The process of obtaining rice from rice bran is quite easy

and self obtaining. Rice mill is used for obtaining rice from rice bran. The major

portion of the paddy is milled through hullers. In the hullers,both shelling and

polishing operations are carried out simultaneously. Hence there is no contol on

the polishing of rice, bran, admixed with husk is obtained with higher breakage of

rice gain. To overcome these, a mini rice mill is available to meet the needs of the

villages and a substitute for a huller mill, to get polished rice, rice bran and paddy

husk. The rice bran bought from the markets or brought by the producers is put

into the machine and after being processed in sheller and polisher come out the

machine, which can either be sent for market or directly given to the customers.

Byproducts from the growing and processing of rice create many valuable new

products. Rice husks, rice stubble, rice bran, broken rice and ricestraw are used as

common in gredients inhorticultural ,livestock industrial, household, building and

food products

Rice husks

The rice husk is the hard, protective shell on the grain.The removal of therice

huskis the first stage of rice milling. Rice husks are the main by product of rice

production. For every one million tones of paddy rice harvested, about 200

000 tonnes of rice husk is produced.

1.8PRODUCTION TARGETS:

Work can be done in two ways under this unit both the production work and

taking working contracts from producers. Unit would 400 quintals of rice bran per

month from the market out of which 300 quintals of good quality rice would be

obtained.

1.9PLANT CAPACITY:

In assessing the proposed plant capacity, due consideration has given to technology

and financial factors, marketing consideration, availability of raw materials

utilization, infrastructure facilities, and economic viability.

The detailed requirement of the plant and machineries to achieve the plant capacity

is assessed by the unit technicians. While arriving at the requirement

of various type of equipment and machinery required for the unit, due

consideration had been given to the following points.

1. Minimum Wastage.

2. High Productivity.

3. Maximum Flexibility

4. Adequate stock by provision wherever necessary.

1.10 INFORMATION ABOUT THE PROMOTER:

The promoter of the project is Mr Naba Gogoi. Mr Naba Gogoi is aged 22 years

old an MBA candidate. The promoter is a local resident of Dhenukhana ( Assam).

Mr Gogoi is highly encouraged by the market potential of such unit at North

Lakhimpur. With a view to provide quality service in a reasonable price the

promoter has proposed to set up the unit. The promoter has already obtained

requisite no objection certificate from the authorities.

2.1 PROPOSD LOCATION:

The proposed site for the unit is at Dhenukhana PO:-Dhenukhana P/S:- Ghilamara

Dist:-Lakhimpur( Assam). The location may be considered as feasible location due

to good infrastructural facilities available as govt provided all facilities:

. The location is suitable for availability of skilled labour.

. The location is adjacent to motor road which is an

advantageous

facility for the unit

The site is accessible to telephone &other communication

facilities.

. Technological factors.

. Socio - economic consideration.

2.2 BASIS & PRESUMPTION:

The unit remain open for 8 hours a day for 300 working days in a calendar year.

The price of raw materials and equipments is as per present market price.

Non-refundable deposits. feasibility study fees, trial production. establishment

expenses are considered under pre-operative expenses.

Rate of Interest is calculated at 12% per annum.

Written Down Value Method has calculated depreciation at the rate of 10% of the

fixed capital annually.

2.3About my rice mill:

Understanding the benefit, importance of Rice Mill in Assam and realizing my

capacity and potentiality I have decided to open a Rice Mill. I would open a Rice

Mill of 5 bigha. For this my father will give me a land area of 5 bigha. After

completing MBA I would start my work of opening the Rice Mill. But now only I

will final the planned.

2.4 FINANCIAL ASPECT OF THE PROJECT

FIXED CAPITAL:

a) Land & Building:- For the proposed unit, around 800 sq. ft. of working place

would be required. The promoters has own land. The cost of construction for

the building is around Rs.3,00000.00.

b) MACHINERIES:

SL No. Description Quan-

tity

Rate Amount (Rs)

1. Paddy Separator 1 1,00,000.00 1,00,000.00

2. Electronic Motor 30 Hp 1 70,000.00 70,000.00

3. D.Hasker with complete pulley 1 40,000.00 40,000.00

4. Cyclone fan 1 30,000.00 30,000.00

5. Motor Starter 1 20,000.00 20,000.00

6.

Paddy clear fan 1 20,000.00 20,000.00

7. Rice polisher 1 30,000.00 30,000.00

8. Elebeter 6 10,000.00 60,000.00

9. Block Searing & Delta &

Accessories Etc.

L.S 20,000.00

10. IPC Line Shaft two inces x

20 fit

L.S 5,000.00

11. Main Swits 63A L.S 5,000.00

Total 4,00,000.00

c)Furniture &Fixture:

SL No Description Nos Rate Amount(Rs)

1.

Almirah

1 8,000.00 8,000.00

2.

Table & Chairs

- 4,000.00

Total

12,000.00

d)Tools &Equipments

SL No. Description

Nos

Rate Amount(Rs)

1. Conveying System Like

Elevator

2 5,500.00 11,000.00

2.

Moisture Analysis Facility

1 5,000.00 5,000.00

3. Weight balance more 200 Kg

Capacity

1 12,000.00 12,000.00

Total 22,500.00 28,000.00

e ) Preliminary & Pre operative Expenses :

SL No. Description Amount

(Rs)

1.

Project Report Preparation

1500.00

2.

Travelling & Conveyance

6,000.00

3.

Legal Expenses

4,000.00

4.

General Insurance

2,000.00

5.

Market survey

1,500.00

Total

15,000.00

2.5 WORKING CAPITAL ESTIMATES:

a) Raw Materials

SL

No.

Description Quantity Rate Amount (Rs)

P.M A.M

1. Rice Bran 500.00 1000.00 5,00,000.00 60,00,000.00

b) Manpower

SL

No.

Personnel Nos. Rate Amount (Rs)

P.M A.M

1.

Manager

1 10,000.00 10,000.00 1,20,000.00

2.

Skilled Worker

4 5,000.00 20,000.00 2,40,000.00

3.

Chowkidar

1 2,000.00 2,000.00 24,000.00

Total

32,000.00 3,84,,000.00

c) Administrative Expenses:

SL No. Description Amount (Rs)

P.M A.M

1.

Electricity

5,000.00 60,000.00

2.

Transportation

7,000.00 84,000.00

3.

Insurance

1,000.00 12,000.00

4.

Maintenance &Repair

2,000.00 24,000.00

5.

Telephone & Postage

1,500.00 18000.00

6.

Stationary

1,000.00 12,000.00

Total

17,500 2,10,000.00

WORKING CAPITAL REQUIRED:

SL No. Description Stock

Period

Amount (Rs)

P.M A.M

1. Raw Material 1month 5,00,000.00 60,00,000.00

2. Manpower 1month 32,000.00 3,84,000.00

3. Administrative Expenses 15 days 17,500.00 2,10,000.00

Total 5,49,500.00 65,94,000.00

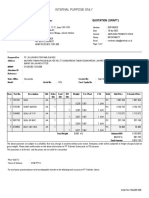

TOTAL PROJECT COST

SL No. Particular Amount (Rs)

1. Land & Building 3,00,000.00

2.

Plant & Machinery

4,00,000.00

3. Furniture & Fixture 12,000.00

4. Tools & Equipment 28,000.00

4. Preliminary & Pro-Operative Exp 15,000.00

5. Working Capital 5,49,500.00

Total 13,04,500.00

Means Of Finance:

i) Promoters contribution @ 20% =2,60,900.00

ii) Loan from Bank @ 80% =10,43,600.00

Total = 13,04,500.00

2.6SALES REALIZATION: The total income from the unit would be as

shown below:

SL

No.

Description Quantity Rate Amount (Rs)

P.M A.M

1. Rice 300 1700 5,10,000.00 61,20,000.00

2. Public Milling 200 100 20,000.00 2,40,000.00

T0tal 6,30,000.00 63,60,000.00

There for total profit per month----------

(Total rice & public milling sell price Total expense per month other expense

per month)

(6,30,000.00-5,49,500.00)=80,500.00

There for total profit per year---------

(80,500.00 x 12) =9,66,000.00

Depreciation schedule:

Total Cost on Land & Building =3,00,000

5% Depreciation on Land &Building =3,00,000 x 5/100

=15,000

Total Cost on Machinery & Equipment =4,28,000

10% Depreciation on Machinery &Equipment =4,28,000 x10/100

=42,800

Total Cost on Furniture &Fixture =12,000

10% Depreciation on Furniture &Fixture =12,000x10/100

=1,200

BREAK-EVEN POINT :

Fixed cost in 1

st

year

1) Interest (13.25%) on total capital investment = Rs.10,43,600X

13.25/100

= Rs.1,38,277

2) Depreciation on building @ 5% on13,04,500 = Rs.65,225

Depreciation on equipments @ 10% on 4,28,000 = Rs. 42,800

3) 20% of salaries (in year) = Rs. 76,800

4) 20% of electricity = Rs.12,000

5) Insurance = Rs12,000

TOTAL = Rs. 3,47,102

Fixed cost x 100

BEP = -----------------------------------------

Fixed cost + Profit per year

34710200

=-------------------------------------------

347102+ 966000

34710200

=-------------------------------------------

1313102

= 26.44%

RETURN ON INVESTMENT:-

Net Profit x 100

A) Return of Investment -------------------------

Total investment

966000 x 100

----------------------------

6360000

= 15.19%

Net profit x 100

B) Return on Sales = ------------------------------------

Total Sales

966000 x 100

= ------------------------------------

6360000

= 15.19%

-: CONCLUSION:-

I have a dream to be a independent man. So I want to be a good

entrepreneur. To become a successful entrepreneur and to become a self

independent I select a Rice Mill. I found lots of opportunity has in this line and

a good profitable business. As well as I have own resources at home so that I

can able to utilize these resources in profitable manner.

Initially I implement this project for a little product for a small area, if I able to

run my business with my expectation than I will add as many as product in the

product line. I have a confidence to be a successful entrepreneur in this line.

---------------------------x------------------------

Das könnte Ihnen auch gefallen

- Consumer Behaviour Broadbband AirtelDokument23 SeitenConsumer Behaviour Broadbband AirtelGaurav Kumar TiwariNoch keine Bewertungen

- Study On Start Up FailuresDokument19 SeitenStudy On Start Up FailuresRITHINNoch keine Bewertungen

- MBA ProjectDokument5 SeitenMBA ProjectNaushad KhanNoch keine Bewertungen

- Project ReportDokument60 SeitenProject ReportSumit KohliNoch keine Bewertungen

- Glbimr Sip 2019-21Dokument60 SeitenGlbimr Sip 2019-21amanNoch keine Bewertungen

- Vishal MegamartDokument66 SeitenVishal MegamartJatin SaxenaNoch keine Bewertungen

- Internship Report of MBADokument41 SeitenInternship Report of MBAJackson faleiroNoch keine Bewertungen

- Marketing Strategies of AdidasDokument61 SeitenMarketing Strategies of AdidasAnkit YadavNoch keine Bewertungen

- A PROJECT REPORT ON MBA ON ItDokument62 SeitenA PROJECT REPORT ON MBA ON ItlalsinghNoch keine Bewertungen

- Amity ProDokument72 SeitenAmity ProSidhotam Kumar SinghNoch keine Bewertungen

- SnehalDokument70 SeitenSnehalKinjal KhorasiaNoch keine Bewertungen

- UI17EC16 Project ReportDokument52 SeitenUI17EC16 Project ReportPratyush GuptaNoch keine Bewertungen

- Summer ProjectDokument58 SeitenSummer Projectjainamshah872222Noch keine Bewertungen

- Usha MartinDokument101 SeitenUsha MartinAtul Tigga100% (1)

- Niit ReportDokument122 SeitenNiit ReportMohammad ShoebNoch keine Bewertungen

- Amity School of BusinessDokument18 SeitenAmity School of BusinessYash MittalNoch keine Bewertungen

- Recrutiment Selection Strategy ICICI BankDokument70 SeitenRecrutiment Selection Strategy ICICI BankShubhamNoch keine Bewertungen

- MBA Marketing Research Project On Customer PreferenceDokument79 SeitenMBA Marketing Research Project On Customer PreferenceanoopNoch keine Bewertungen

- Consumer Behaviour and Perception Towards Big Bazaar in ChennaiDokument64 SeitenConsumer Behaviour and Perception Towards Big Bazaar in ChennaiRahul PandeyNoch keine Bewertungen

- MBA Project Yogesh PDokument42 SeitenMBA Project Yogesh Pankush jubliantNoch keine Bewertungen

- Disserrtation FINALDokument41 SeitenDisserrtation FINALDevangshi SarafNoch keine Bewertungen

- Mishra Shaishav U.: "A Dissertation Project Report On Social Media Marketing in India"Dokument53 SeitenMishra Shaishav U.: "A Dissertation Project Report On Social Media Marketing in India"Shaishav MishraNoch keine Bewertungen

- UjjijuDokument80 SeitenUjjijuMannu BhardwajNoch keine Bewertungen

- Report On HR Policies For Induction ProgrammeDokument82 SeitenReport On HR Policies For Induction ProgrammeSatyendra YadavNoch keine Bewertungen

- Research Project ReportDokument77 SeitenResearch Project ReportsumitNoch keine Bewertungen

- Recruitment and SelectionDokument60 SeitenRecruitment and SelectionudayNoch keine Bewertungen

- Ratio Analysis Mohit Pandit - 2Dokument107 SeitenRatio Analysis Mohit Pandit - 2silent readersNoch keine Bewertungen

- CRM Big Bazaar3Dokument88 SeitenCRM Big Bazaar3Kumar Abhishek100% (3)

- 17SKCMD069 - Kavya M - ReportDokument62 Seiten17SKCMD069 - Kavya M - ReportKAVYANoch keine Bewertungen

- Suraj Project ReportDokument10 SeitenSuraj Project ReportSuraj Singh RajvanshiNoch keine Bewertungen

- Summer Training Report Human Resource (HR) Employee Welfare and Employee Satisfaction by Ankit Thapliyal Uttaranchal UniversityDokument61 SeitenSummer Training Report Human Resource (HR) Employee Welfare and Employee Satisfaction by Ankit Thapliyal Uttaranchal Universityankit thapliyal0% (1)

- Moil Project Mba IVDokument57 SeitenMoil Project Mba IVSingh ArjunNoch keine Bewertungen

- T Financial PerformanceDokument74 SeitenT Financial PerformanceKarthikeyan ThangarajNoch keine Bewertungen

- MBA 2nd Sem Syllabus FinanceDokument17 SeitenMBA 2nd Sem Syllabus FinanceKuldeep RawatNoch keine Bewertungen

- Inventory Management ProjectDokument87 SeitenInventory Management ProjectPriyadarshan NairNoch keine Bewertungen

- Measuring Consumer Perception of Social MediaDokument14 SeitenMeasuring Consumer Perception of Social Mediabandi_2340Noch keine Bewertungen

- Labour Welfare ManagementDokument73 SeitenLabour Welfare ManagementAbhay JainNoch keine Bewertungen

- Internship Report Data AnalysisDokument37 SeitenInternship Report Data AnalysisKase Hija IndiaNoch keine Bewertungen

- Project Report On Ratio Analysis at Axis BankDokument53 SeitenProject Report On Ratio Analysis at Axis Bankgaurav kashyapNoch keine Bewertungen

- Final Project Ril Onboardding ProcessDokument63 SeitenFinal Project Ril Onboardding Processkajal.priyadarshiniNoch keine Bewertungen

- Chapter-I: 1.1 Introduction About The StudyDokument108 SeitenChapter-I: 1.1 Introduction About The StudyMathi ShankarNoch keine Bewertungen

- PROJECT REPORT FinalDokument33 SeitenPROJECT REPORT FinalJobanpreet SinghNoch keine Bewertungen

- A Research Report ON: A Comparative Study of Recruitment & Selection Process inDokument71 SeitenA Research Report ON: A Comparative Study of Recruitment & Selection Process inJitendra YadavNoch keine Bewertungen

- PROJECT Final 9 (SIP)Dokument70 SeitenPROJECT Final 9 (SIP)Shefali ShuklaNoch keine Bewertungen

- Operation Management HandoutDokument93 SeitenOperation Management HandoutNahom gelayeNoch keine Bewertungen

- A STUDY ON EFFECTIVENESS OF DIGITAL MARKETING SERVICES AT DOMAIN2HOST (With Table of Contents) (5 SPSS) 120 SamplesDokument109 SeitenA STUDY ON EFFECTIVENESS OF DIGITAL MARKETING SERVICES AT DOMAIN2HOST (With Table of Contents) (5 SPSS) 120 SamplesNaga LakshmiNoch keine Bewertungen

- A Study On Employee SatisfactionDokument97 SeitenA Study On Employee SatisfactionAvinash Joseph0% (1)

- Abhishek MBA Project ReportDokument68 SeitenAbhishek MBA Project ReportjagrutiNoch keine Bewertungen

- Corporate Salary Account Report For HDFC BankDokument42 SeitenCorporate Salary Account Report For HDFC BankShubhranshu SumanNoch keine Bewertungen

- A Study On Migration of Existing HDFC Customers To Digital PlatformDokument36 SeitenA Study On Migration of Existing HDFC Customers To Digital PlatformMoreshwarNoch keine Bewertungen

- Dissertation Report-Rahul UppalDokument45 SeitenDissertation Report-Rahul UppalshubhamNoch keine Bewertungen

- Market Potential of Precision Tubes in Jamshedpur: A Project Report ONDokument4 SeitenMarket Potential of Precision Tubes in Jamshedpur: A Project Report ONgosaiajayNoch keine Bewertungen

- Comparision of Tata and Reliance Broadband at BareillyDokument68 SeitenComparision of Tata and Reliance Broadband at BareillyAnup Singh100% (1)

- A Project Report On Cash Flow Statement Front PageDokument4 SeitenA Project Report On Cash Flow Statement Front PageZain RahmanNoch keine Bewertungen

- Antima TyagiDokument89 SeitenAntima TyagiShivankar TyagiNoch keine Bewertungen

- Untitled DocumentDokument16 SeitenUntitled DocumentBharath MahendrakarNoch keine Bewertungen

- Untitled DocumentDokument16 SeitenUntitled DocumentBharath MahendrakarNoch keine Bewertungen

- Mahajan Mini Flour Mill, UdhampurDokument24 SeitenMahajan Mini Flour Mill, UdhampurMj PayalNoch keine Bewertungen

- Ekta Singh (Roll No - 31) - Mini ProjectDokument57 SeitenEkta Singh (Roll No - 31) - Mini ProjectEkta singhNoch keine Bewertungen

- Amar Bajaj Steel Summer ProjectDokument91 SeitenAmar Bajaj Steel Summer Projectrautyogesh100% (1)

- Job DesignDokument10 SeitenJob DesignHemen SarmaNoch keine Bewertungen

- IS 257 Database Management Final Project Report: John Fritch, Diane Ghorbani, Leticia Valdez December 5, 2002Dokument25 SeitenIS 257 Database Management Final Project Report: John Fritch, Diane Ghorbani, Leticia Valdez December 5, 2002Hemen SarmaNoch keine Bewertungen

- Imporatance of Agriculture in Indian EconomyDokument6 SeitenImporatance of Agriculture in Indian EconomyHemen Sarma100% (1)

- Harmonization of DifferencesDokument8 SeitenHarmonization of DifferencesHemen SarmaNoch keine Bewertungen

- Design Overview IIT GuwahatiDokument32 SeitenDesign Overview IIT GuwahatiHemen SarmaNoch keine Bewertungen

- I&s FinalDokument22 SeitenI&s FinalHemen SarmaNoch keine Bewertungen

- ICICI Prudential ProjectDokument52 SeitenICICI Prudential Projectapi-3830923100% (13)

- Intro To Income TaxDokument4 SeitenIntro To Income TaxJennifer Arcadio100% (1)

- JAIIB Legal Sample Questions by MuruganDokument63 SeitenJAIIB Legal Sample Questions by MuruganRizz Ahammad80% (5)

- Assignment Subject Code BM 0001 (4 Credits) 60 Marks Set I Subject: Financial Accounting - An IntroductionDokument6 SeitenAssignment Subject Code BM 0001 (4 Credits) 60 Marks Set I Subject: Financial Accounting - An IntroductionAbdul Lateef KhanNoch keine Bewertungen

- Schedule of New Fees - RetooledDokument2 SeitenSchedule of New Fees - RetooledRaymund Fernandez CamachoNoch keine Bewertungen

- BA 421-Feasibility StudyDokument14 SeitenBA 421-Feasibility StudyMary Ann Jacolbe BaguioNoch keine Bewertungen

- Final Defense ScriptDokument4 SeitenFinal Defense Scriptandeng100% (1)

- NHB Vishal GoyalDokument24 SeitenNHB Vishal GoyalSky walkingNoch keine Bewertungen

- Fac4863 104 - 2020 - 0 - BDokument93 SeitenFac4863 104 - 2020 - 0 - BNISSIBETINoch keine Bewertungen

- History of Insu-Wps OfficeDokument2 SeitenHistory of Insu-Wps OfficeSIDHARTH TiwariNoch keine Bewertungen

- Auditing Finance and Accounting FunctionsDokument14 SeitenAuditing Finance and Accounting FunctionsApril ManjaresNoch keine Bewertungen

- Investment Environment and Investment Management Process-1Dokument1 SeiteInvestment Environment and Investment Management Process-1CalvinsNoch keine Bewertungen

- Section 14 Unab Rid Dged Written VersionDokument17 SeitenSection 14 Unab Rid Dged Written VersionPrashant TrivediNoch keine Bewertungen

- Allux Indo 8301385679Dokument2 SeitenAllux Indo 8301385679Ardi dutaNoch keine Bewertungen

- Project Report LissstDokument6 SeitenProject Report LissstShivareddyNoch keine Bewertungen

- 3.2 Accounting For Corporation Reviewer With Sample ProblemDokument82 Seiten3.2 Accounting For Corporation Reviewer With Sample Problemlavender hazeNoch keine Bewertungen

- BPI v. IAC & ZshornackDokument1 SeiteBPI v. IAC & ZshornackRon DecinNoch keine Bewertungen

- Banking Theory, Law and PracticeDokument51 SeitenBanking Theory, Law and PracticePrem Kumar.DNoch keine Bewertungen

- Issues and Challenges of Insurance Industry in IndiaDokument3 SeitenIssues and Challenges of Insurance Industry in Indianishant b100% (1)

- A Guide To Business PHD ApplicationsDokument24 SeitenA Guide To Business PHD ApplicationsSampad AcharyaNoch keine Bewertungen

- NEW Clearance Worklife 03.03.22 1Dokument3 SeitenNEW Clearance Worklife 03.03.22 1Ibe AstorgaNoch keine Bewertungen

- 2316 Jan 2018 ENCS FinalDokument2 Seiten2316 Jan 2018 ENCS FinalKirsten Bairan100% (2)

- Financial Performance of Retail Sector Companies in India-An AnalysisDokument7 SeitenFinancial Performance of Retail Sector Companies in India-An Analysisaniket jadhavNoch keine Bewertungen

- Solved Exercises 2Dokument10 SeitenSolved Exercises 2ScribdTranslationsNoch keine Bewertungen

- UPRevised Banking ReviewerDokument76 SeitenUPRevised Banking ReviewerRomel TorresNoch keine Bewertungen

- Direst Selling Agent Policy-Retail & Consumer LendingDokument13 SeitenDirest Selling Agent Policy-Retail & Consumer LendingVijay DubeyNoch keine Bewertungen

- Day CareDokument21 SeitenDay CareSarfraz AliNoch keine Bewertungen

- Accounting PretestDokument4 SeitenAccounting PretestseymourwardNoch keine Bewertungen

- Quarterly Publication of Individuals, Who Have Chosen To Expatriate, As Required by Section 6039GDokument17 SeitenQuarterly Publication of Individuals, Who Have Chosen To Expatriate, As Required by Section 6039GKelly Phillips ErbNoch keine Bewertungen

- Ethical Issues in Finance PDFDokument2 SeitenEthical Issues in Finance PDFCheraghearzu0% (1)

- Mcq-Income TaxesDokument7 SeitenMcq-Income TaxesRandy Manzano100% (1)