Beruflich Dokumente

Kultur Dokumente

Secciones Clasificacion

Hochgeladen von

Anonymous ya6gBBwHJFOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Secciones Clasificacion

Hochgeladen von

Anonymous ya6gBBwHJFCopyright:

Verfügbare Formate

P1: GIG

GRBT055-B AISC-Sample (LRFD) June 17, 2005 16:3 Char Count= 0

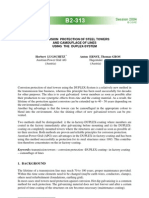

16 [Sect. B4. CLASSIFICATION OF SECTIONS FOR LOCAL BUCKLING

TABLE B4.1

Limiting Width-Thickness Ratios for

Compression Elements

C

a

s

e

Width

Thick-

ness

Ratio

Limiting Width-

Thickness Ratios

p

r

Description of

Element (compact) (noncompact) Example

1 Flexure in anges of

rolled I-shaped

sections and

channels

b/t

0.38

E/F

y

1.0

E/F

y

t

b

2 Flexure in anges of

doubly and singly

symmetric I-shaped

built-up sections

b/t

0.38

E/F

y 0.95

k

c

E/F

L

[a],[b]

b

t

U

n

j

u

s

t

i

e

d

E

l

e

m

e

n

t

s

3 Uniform

compression in

anges of rolled

I-shaped sections,

plates projecting

from rolled I-shaped

sections;

outstanding legs of

pairs of angles in

continuous contact

and anges of

channels

b/t NA

0.56

E/F

y

t

b

4 Uniform

compression in

anges of built-up

I-shaped sections

and plates or angle

legs projecting from

built-up I-shaped

sections

b/t NA

0.64

k

c

E/F

y

[a]

t

b

b

t

5 Uniform

compression in legs

of single angles,

legs of double

angles with

separators, and all

other unstiffened

elements

b/t NA

0.45

E/F

y

t

b

6 Flexure in legs of

single angles

b/t

0.54

E/F

y

0.91

E/F

y

t

b

Specication for Structural Steel Buildings, March 9, 2005

AMERICAN INSTITUTE OF STEEL CONSTRUCTION, INC.

U

n

s

t

i

f

f

e

n

e

d

E

l

e

m

e

n

t

s

P1: GIG

GRBT055-B AISC-Sample (LRFD) June 17, 2005 16:3 Char Count= 0

CLASSIFICATION OF SECTIONS FOR LOCAL BUCKLING Sect. B4.] 17

TABLE B4.1 (cont.)

Limiting Width-Thickness Ratios for

Compression Elements

C

a

s

e

Width

Thick-

ness

Ratio

Limiting Width-

Thickness Ratios

p

r

Description of

Element (compact) (noncompact) Example

7 Flexure in anges of

tees

b/t

0.38

E/F

y

1.0

E/F

y

b

t

8 Uniform

compression in

stems of tees

d/t NA

0.75

E/F

y

t

d

9 Flexure in webs of

doubly symmetric

I-shaped sections

and channels

h/t

w

3.76

E/F

y

5.70

E/F

y

t

w

h

10 Uniform

compression in

webs of doubly

symmetric I-shaped

sections

h/t

w

NA 1.49

E/F

y

t

w

h

11 Flexure in webs of

singly-symmetric

I-shaped sections

h

c

/t

w

h

c

h

p

E

F

y

0.54

M

p

M

y

0.09

2

r

5.70

E/F

y h

pna

p

2

2

c

h

cg

w

t

S

t

i

f

f

e

n

e

d

E

l

e

m

e

n

t

s

12 Uniform

compression in

anges of

rectangular box and

hollow structural

sections of uniform

thickness subject to

bending or

compression; ange

cover plates and

diaphragm plates

between lines of

fasteners or welds

b/t

1.12

E/F

y

1.40

E/F

y

t

b

13 Flexure in webs of

rectangular HSS

h/t 2.42

E/F

y

5.70

E/F

y

t

h

Specication for Structural Steel Buildings, March 9, 2005

AMERICAN INSTITUTE OF STEEL CONSTRUCTION, INC.

P1: GIG

GRBT055-B AISC-Sample (LRFD) June 17, 2005 16:3 Char Count= 0

18 [Sect. B5. FABRICATION, ERECTION AND QUALITY CONTROL

TABLE B4.1 (cont.)

Limiting Width-Thickness Ratios for

Compression Elements

C

a

s

e

Width

Thick-

ness

Ratio

Limiting Width-

Thickness Ratios

p

r

Description of

Element (compact) (noncompact) Example

14 Uniform

compression in all

other stiffened

elements

b/t NA 1.49

E/F

y

t

b

15 Circular hollow

sections

t

D

In uniform

compression

D/t NA 0.11E/F

y

In exure D/t 0.07E/F

y

0.31E/F

y

[a]

k

c

=

4

h/t

w

, but shall not be taken less than 0.35 nor greater than 0.76 for calculation purposes. (See

Cases 2 and 4)

[b]

F

L

= 0.7F

y

for minor-axis bending, major axis bending of slender-web built-up I-shaped members, and

major axis bending of compact and noncompact web built-up I-shaped members with S

xt

/S

xc

0.7; F

L

=

F

y

S

xt

/S

xc

0.5F

y

for major-axis bending of compact and noncompact web built-up I-shaped members with

S

xt

/S

xc

< 0.7. (See Case 2)

B5. FABRICATION, ERECTION AND QUALITY CONTROL

Shop drawings, fabrication, shop painting, erection, and quality control shall

meet the requirements stipulated in Chapter M, Fabrication, Erection, and Quality

Control.

B6. EVALUATION OF EXISTING STRUCTURES

Provisions for the evaluation of existing structures are presented in Appendix 5,

Evaluation of Existing Structures.

Specication for Structural Steel Buildings, March 9, 2005

AMERICAN INSTITUTE OF STEEL CONSTRUCTION, INC.

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Cigre B2-313Dokument6 SeitenCigre B2-313salvandyNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Arcing DevicesDokument10 SeitenArcing DevicessalvandyNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Cable 400kV CleusonDokument4 SeitenCable 400kV CleusonsalvandyNoch keine Bewertungen

- HERRAJES Transmission LineDokument20 SeitenHERRAJES Transmission LinesalvandyNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Pole Line Hardware JoslynDokument140 SeitenPole Line Hardware Joslynsalvandy100% (1)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)