Beruflich Dokumente

Kultur Dokumente

Fabricators of Pressure Vessels

Hochgeladen von

laleye_olumideOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Fabricators of Pressure Vessels

Hochgeladen von

laleye_olumideCopyright:

Verfügbare Formate

GUIDE TO LOCAL FABRICATORS OF PRESSURE VESSELS

1 Introduction

Recently a fatal accident occurred in a factory in Singapore where a pressure

vessel that was undergoing a pneumatic test using nitrogen gas, exploded.

This Guide is specifically prepared to highlight the safety issues involved to the

manufacturers that fabricate and test pressure vessels.

2 What is a pressure vessel?

A pressure vessel is a container, a tank or a vessel, which is subjected to an

internal pressure higher than atmospheric pressure during use.

The vessel may, while it is subjected to the internal pressure, be holding or

containing any substance either in the form of a gas, a liquid or a powder.

3 Why is a pressure vessel potentially hazardous?

A pressure vessel is a potentially hazardous piece of equipment as it is under

pressure and it may fail without warning during tests or use.

Any design or fabrication fault or misuse of the vessel could lead to an

explosion. A number of such explosions have occurred around the world

(including Singapore) causing extensive damage to buildings, properties and

considerable loss of human life. Therefore, it is essential that the design,

fabrication and use of these pressure vessels be stringently controlled in order

to ensure that they are safe for use.

4 How to assure safe design, fabrication, tests and inspections of pressure

vessel?

The following considerations are necessary to assure the safe design,

fabrication, tests and inspections of a pressure vessel:

(a) Design

The pressure vessel should be designed to an approved code. The

code will specify the requirements for design, manufacture, tests and

inspection of the pressure vessel. The code therefore serves to ensure

that the pressure vessel to be fabricated has been adequately designed

to serve its purpose.

(b) Fabrication

The pressure vessel should be fabricated in accordance with the design

calculations and drawings, and the method of construction as stipulated

by the approved code.

Where welding is involved, the welding procedures and specifications

described in the code for the pressure vessel should be followed

strictly. It is also necessary to ensure that the welders tasked to carry

out the welding of pressure vessel are competent to carry out the type

of welding required by the design code.

OSD Guide 1.0/J uly 2002

2

A competent inspector should be engaged to survey the fabrication of

the pressure vessel to assure that it complies with the design

calculations and drawings, and the method of construction stipulated by

the approved code.

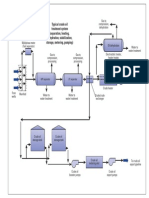

(c) Tests and Inspections

Tests and inspections form a very important part of the process of

making sure that the pressure vessel fabricated can withstand the

pressure and temperature to which it will be subjected.

Where required, non-destructive tests such as dye penetrant tests and

radiographic tests could be carried out on the welds to detect cracks

and other defects.

Pressure tests of the vessel should always be conducted using water

(hydrostatic test) or an incompressible liquid (hydraulic test). It is not

recommended that air or any other gas be used for pressure tests. This

is because air/gases are highly compressible and could result in an

explosion in the event of a rupture during the tests.

5 Conclusion

Pressure vessels are potentially hazardous equipment and should be

designed and fabricated to an approved code.

Pressure tests of a pressure vessel should be carried out using water or an

incompressible fluid.

The factory occupier and the employer have to draw up safe work procedures

for the fabrication and testing of pressure vessels. They have to ensure that

their workers are briefed on these procedures and trained to deal with the

hazards arising from the hazardous processes in the course.

Note: The above serves only as a general guide to safe design, fabrication, tests and inspections of

pressure vessel. It is recommended that reference be made to the relevant codes for specific

details.

Das könnte Ihnen auch gefallen

- Vessel Description: Pressure Vessel Engineering, LTDDokument40 SeitenVessel Description: Pressure Vessel Engineering, LTDSivateja NallamothuNoch keine Bewertungen

- Fabricators of Pressure VesselsDokument2 SeitenFabricators of Pressure Vesselslaleye_olumideNoch keine Bewertungen

- Chapter 2Dokument40 SeitenChapter 2laleye_olumideNoch keine Bewertungen

- Job Search Strategies - Schedule - July 11Dokument1 SeiteJob Search Strategies - Schedule - July 11laleye_olumideNoch keine Bewertungen

- Pressure Vessel PresentationDokument18 SeitenPressure Vessel Presentationlaleye_olumide0% (1)

- Vessel Description: Pressure Vessel Engineering, LTDDokument40 SeitenVessel Description: Pressure Vessel Engineering, LTDSivateja NallamothuNoch keine Bewertungen

- Position Description: (Financial, Operational, Etc)Dokument4 SeitenPosition Description: (Financial, Operational, Etc)laleye_olumideNoch keine Bewertungen

- PV Elite 2008Dokument3 SeitenPV Elite 2008laleye_olumideNoch keine Bewertungen

- Offshore & Structural Plate SizeDokument4 SeitenOffshore & Structural Plate Sizelaleye_olumideNoch keine Bewertungen

- Introductiontoprojectprogramportfoliomanagement 130115215129 Phpapp02Dokument16 SeitenIntroductiontoprojectprogramportfoliomanagement 130115215129 Phpapp02laleye_olumideNoch keine Bewertungen

- Separator Fundamentals - Process DesignDokument30 SeitenSeparator Fundamentals - Process Designlaleye_olumide100% (3)

- MOAHUC - International - Program OutlineDokument2 SeitenMOAHUC - International - Program Outlinelaleye_olumideNoch keine Bewertungen

- PrefacesDokument7 SeitenPrefaceslaleye_olumideNoch keine Bewertungen

- AD2000 (31barg) CalculationDokument10 SeitenAD2000 (31barg) CalculationMagdaline Matabang100% (1)

- ASME 9 Base Metal PDokument2 SeitenASME 9 Base Metal PRanjith GamageNoch keine Bewertungen

- Jobs and Role Descriptions Sept 2013Dokument8 SeitenJobs and Role Descriptions Sept 2013Teguh SetionoNoch keine Bewertungen

- Saipem Nigeria Carbon Steel Fittings RFQDokument21 SeitenSaipem Nigeria Carbon Steel Fittings RFQlaleye_olumideNoch keine Bewertungen

- Epf Crude Oil TreatmentDokument1 SeiteEpf Crude Oil Treatmentafroznishat100% (2)

- ThessaloniansDokument89 SeitenThessalonianslaleye_olumideNoch keine Bewertungen

- Mechanical TestDokument10 SeitenMechanical Testlaleye_olumideNoch keine Bewertungen

- PV Elite 2008Dokument3 SeitenPV Elite 2008laleye_olumideNoch keine Bewertungen

- Grad-Faculty of Graduate StudiesDokument1 SeiteGrad-Faculty of Graduate Studieslaleye_olumideNoch keine Bewertungen

- Trading 101 BasicsDokument3 SeitenTrading 101 BasicsNaveen KumarNoch keine Bewertungen

- SSETP 02 00 Agenda 5th EdDokument1 SeiteSSETP 02 00 Agenda 5th Edlaleye_olumideNoch keine Bewertungen

- PEH v5 BKDokument2 SeitenPEH v5 BKlaleye_olumideNoch keine Bewertungen

- Refining Crude Oil: Step 1 - SeparationDokument24 SeitenRefining Crude Oil: Step 1 - Separationho-faNoch keine Bewertungen

- Ssuk - Rov Event - Sep 2013 (Web)Dokument19 SeitenSsuk - Rov Event - Sep 2013 (Web)laleye_olumideNoch keine Bewertungen

- Eni in NigeriaDokument4 SeitenEni in Nigerialaleye_olumideNoch keine Bewertungen

- Remotely Operated Vehicles Market ReportDokument23 SeitenRemotely Operated Vehicles Market Reportlaleye_olumideNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- ST326 - Irdap2021Dokument5 SeitenST326 - Irdap2021NgaNovaNoch keine Bewertungen

- Mil B 49430BDokument36 SeitenMil B 49430Bparam.vennelaNoch keine Bewertungen

- U1L2 - Definitions of 21st Century LiteraciesDokument19 SeitenU1L2 - Definitions of 21st Century LiteraciesJerry Glenn Latorre CastilloNoch keine Bewertungen

- TM500 Design Overview (Complete ArchitectureDokument3 SeitenTM500 Design Overview (Complete ArchitectureppghoshinNoch keine Bewertungen

- PrEN 12271-10 - Factory Production ControlDokument17 SeitenPrEN 12271-10 - Factory Production ControlPedjaNoch keine Bewertungen

- Maytag MDG78PN SpecificationsDokument2 SeitenMaytag MDG78PN Specificationsmairimsp2003Noch keine Bewertungen

- Lux MeterDokument4 SeitenLux MeterNmg KumarNoch keine Bewertungen

- Saes H 201Dokument9 SeitenSaes H 201heartbreakkid132Noch keine Bewertungen

- G String v5 User ManualDokument53 SeitenG String v5 User ManualFarid MawardiNoch keine Bewertungen

- The Critical Need For Software Engineering EducationDokument5 SeitenThe Critical Need For Software Engineering EducationGaurang TandonNoch keine Bewertungen

- CH 11 & CH 12 John R. Schermerhorn - Management-Wiley (2020)Dokument16 SeitenCH 11 & CH 12 John R. Schermerhorn - Management-Wiley (2020)Muhammad Fariz IbrahimNoch keine Bewertungen

- GCSE H3 02g4 02 3D TrigonometryDokument2 SeitenGCSE H3 02g4 02 3D TrigonometryAndrei StanescuNoch keine Bewertungen

- Abiding LonelinessDokument9 SeitenAbiding Lonelinessgrupodelectura04Noch keine Bewertungen

- Face To Face Pre-Intermediate B1Dokument162 SeitenFace To Face Pre-Intermediate B1Andra OlariNoch keine Bewertungen

- Detect Plant Diseases Using Image ProcessingDokument11 SeitenDetect Plant Diseases Using Image Processingvinayak100% (1)

- Dewatering Well PointsDokument4 SeitenDewatering Well Pointssalloum3Noch keine Bewertungen

- Rúbrica de composición escritaDokument2 SeitenRúbrica de composición escritafrancisco alonsoNoch keine Bewertungen

- Small Healthcare Organization: National Accreditation Board For Hospitals & Healthcare Providers (Nabh)Dokument20 SeitenSmall Healthcare Organization: National Accreditation Board For Hospitals & Healthcare Providers (Nabh)Dipti PatilNoch keine Bewertungen

- Fort St. John - Tender Awards - RCMP Building ConstructionDokument35 SeitenFort St. John - Tender Awards - RCMP Building ConstructionAlaskaHighwayNewsNoch keine Bewertungen

- 713 Catalog PagesDokument2 Seiten713 Catalog PagesJosé AcostaNoch keine Bewertungen

- Sinavy Pem Fuel CellDokument12 SeitenSinavy Pem Fuel CellArielDanieli100% (1)

- DLP Din8Dokument2 SeitenDLP Din8KOUDJIL MohamedNoch keine Bewertungen

- IPA Assignment Analyzes New Public AdministrationDokument8 SeitenIPA Assignment Analyzes New Public AdministrationKumaran ViswanathanNoch keine Bewertungen

- 199-Article Text-434-1-10-20200626Dokument11 Seiten199-Article Text-434-1-10-20200626ryan renaldiNoch keine Bewertungen

- CorentineDokument559 SeitenCorentinejames b willardNoch keine Bewertungen

- Proejcr ManduaDokument552 SeitenProejcr ManduaDanny NguyenNoch keine Bewertungen

- Kuliah 1 - Konservasi GeologiDokument5 SeitenKuliah 1 - Konservasi GeologiFerdianNoch keine Bewertungen

- The Field: Health Services InformationDokument34 SeitenThe Field: Health Services InformationRyan Michael Oducado100% (4)

- The Influence of Teleworking On Performance and Employees Counterproductive BehaviourDokument20 SeitenThe Influence of Teleworking On Performance and Employees Counterproductive BehaviourCHIZELUNoch keine Bewertungen

- Radiograph Evaluation ChecklistDokument2 SeitenRadiograph Evaluation ChecklistZulfadli Haron100% (1)