Beruflich Dokumente

Kultur Dokumente

b15 Concrete Repairs 806

Hochgeladen von

Upali Karunarathne0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

89 Ansichten5 SeitenThis Specification sets out the requirements for the preparation and reinstatement of damage to mass or reinforced concrete. The Contractor shall determine whether temporary shoring or propping is required for any concrete repairs, and submit proposals to the Superintendent for approval. Where damage results from carbonation of the cover concrete, the extent of repair shall be confirmed during preparation.

Originalbeschreibung:

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis Specification sets out the requirements for the preparation and reinstatement of damage to mass or reinforced concrete. The Contractor shall determine whether temporary shoring or propping is required for any concrete repairs, and submit proposals to the Superintendent for approval. Where damage results from carbonation of the cover concrete, the extent of repair shall be confirmed during preparation.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

89 Ansichten5 Seitenb15 Concrete Repairs 806

Hochgeladen von

Upali KarunarathneThis Specification sets out the requirements for the preparation and reinstatement of damage to mass or reinforced concrete. The Contractor shall determine whether temporary shoring or propping is required for any concrete repairs, and submit proposals to the Superintendent for approval. Where damage results from carbonation of the cover concrete, the extent of repair shall be confirmed during preparation.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 5

DEPARTMENT of INFRASTRUCTURE, ENERGY and RESOURCES, TASMANIA

BRIDGE MAINTENANCE SPECIFICATION

B15 - CONCRETE REPAIRS OCTOBER 2006

Previously MB10

Contents Page

B15.1 SCOPE 2

B15.2 EXTENT OF WORKS 2

B15.3 CONCRETE PREPARATION 2

B15.4 REINFORCEMENT PREPARATION 2

B15.5 FORMWORK 3

B15.6 MATERIALS 3

B15.7 REPAIR 3

B15.8 EXTENSIVE REPAIRS 3

B15.9 CURING 4

B15.10 FAIRING COATINGS 4

B15.11 PROTECTIVE COATINGS 4

B15.12 WORK RECORDS 4

B15.13 PAYMENT 4

Table B 15.1 Concrete Repair Materials 5

B15 - CONCRETE REPAIRS October 2006

B15.1 SCOPE

This Specification sets out the requirements for the preparation and reinstatement of damage to

mass or reinforced concrete.

B15.2 EXTENT OF WORKS

The area of repair shall be as detailed on the drawings, as specified elsewhere or as defined on site

by the Superintendent.

Where damage results from carbonation of the cover concrete, the extent of repair shall be confirmed

during preparation by the application of phenolphthalein solution to remove all carbonated concrete

over the defined area of repair.

Where damage results from the delamination of cover concrete, the extent of repairs shall be

confirmed after preparation of repair works to ensure that all delaminated cover concrete has been

removed.

The Contractor shall determine whether temporary shoring or propping is required for any concrete

repairs, and submit proposals to the Superintendent for approval.

B15.3 CONCRETE PREPARATION

Preparation for concrete repairs shall be undertaken using high-pressure water blasting, at a

pressure in excess of 140 MPa (20,000 psi) to avoid creating micro cracks.

Before high pressure blasting, the perimeter of the areas to be repaired shall be cut to a depth of 10

mm. Featheredges shall not be permitted.

All damaged, carbonated, delaminated or otherwise unsound concrete shall be removed within the

extent of works until sound concrete is reached. Where concrete has been damaged by impact, the

minimum depth of preparation shall be 40 mm.

Where reinforcement is exposed, or the remaining cover is negligible, breaking out shall continue to

expose the full circumference of the reinforcement and to a further depth not less than 20 mm.

Care shall be taken to ensure that the removal of concrete does not result in damage to

reinforcement or other embedments such as conduits or sockets.

The prepared surface shall be shaped so that there is no entrapment of air or moisture during

application of repair material.

The prepared concrete surface shall be sound and clean and free of loose particles, dust and debris.

B15.4 REINFORCEMENT PREPARATION

Where exposed reinforcement is sound or shows signs of corrosion it shall be mechanically cleaned

of rust and loose millscale.

If the structural capacity of the reinforcing is compromised by the extent of corrosion or pitting then

the diameter of the reinforcement shall be measured after preparation and, as directed by the

Superintendent, the reinforcement cut out and replaced, or additional bars added. Where bars are

replaced, full strength butt welds, using backing plates are required.

Reinforcement damaged during preparation shall be repaired or replaced, as directed by the

Superintendent. Reinforcement used in repairs shall comply with the requirements of AS 4671.

Exposed reinforcement shall be coated with Zinga prior to flash rust occurring. The Zinga shall be

applied by brush to ensure that all surfaces of the reinforcement, including hidden surfaces, are

coated. Any rust that cannot be removed shall be stabilised with Resene 167 pre-prime and then

coated with Zinga prior to rebuilding of the concrete section.

DIER SPEC B15 2 of 5

B15 - CONCRETE REPAIRS October 2006

B15.5 FORMWORK

Where required, formwork shall be provided in accordance with AS 3610.

Formwork shall be securely fixed to withstand the hydraulic pressures of the repair material.

Fixing of the formwork shall not compromise the durability of the structure.

Facing of the formwork shall be selected so that the finish of the repaired area matches that of the

surrounding concrete.

An appropriate release agent shall be applied to the formwork.

Where repair material is introduced into the repair by hydrostatic pressure or pumping, the entry point

for the feed point shall be at the lowest point of the formwork. Where necessary, provision shall be

made for controllable inspection ports to prevent air entrapment and to enable the extent of flow of

the repair material to be assessed.

B15.6 MATERIALS

Concrete repair materials and associated primers shall be supplied by the one manufacturer, and

shall be shrinkage compensated polymer modified cementitious materials.

The materials listed in Table B 15.1 are acceptable; the use of other products is subject to approval

by the Superintendent, with the chosen materials listed in the Contract Management Plan.

B15.7 REPAIR

Repairs shall not be undertaken when the ambient temperature is below 5

o

C, 5

o

C on a falling

thermometer, or above 35

o

C.

Preparation, application of bonding agent, recoating, and machine mixing shall be in accordance with

the manufacturer's instructions.

Water shall be measured with graduated measuring equipment. The repair material shall be pre-

bagged and added to the quantity of mixing water prescribed by the material manufacturer. Full bag

mixes only shall be permitted.

Retempering, remixing and the addition of water to restore the workability of the repair material shall

not be permitted, and any unsuitable material shall be rejected.

Repair material shall be applied taking particular care to pack behind and between reinforcement.

The required depth and profile of repair shall be achieved by building successive wet on wet layers.

If sagging occurs, the material must be completely removed and the void filled by two or more

successive layers, or by providing formwork.

B15.8 EXTENSIVE REPAIRS

Conventional pre-mixed concrete shall be used for any extensive repairs as detailed in this

Specification or on the drawings.

Preparation shall be in accordance with this Specification, except that impact methods may be used

for bulk concrete removal.

Concrete shall be Grade 32S for inland locations and Grade 50S within 1 km of the coast, tidal

estuaries or other bodies of salt water, in accordance with Specification B10, Supply of Concrete,

unless otherwise specified.

Reinforcement shall be placed at the locations detailed in the Specification or as shown on the

drawings. Splicing to the existing structure shall be by full penetration butt-welding or by laps in

accordance with AS 5100 Bridge Design Code. Supply and placement of reinforcement and

concrete shall comply with Specification B11, Reinforced, Prestressed or Mass Concrete.

DIER SPEC B15 3 of 5

B15 - CONCRETE REPAIRS October 2006

B15.9 CURING

Repaired areas shall be fully cured, by moist curing, for not less than seven days. Surfaces are to be

continuously wet when moist curing is used. The Superintendent may approve the use of a curing

agent when continuous moist curing is not feasible.

B15.10 FAIRING COATINGS

A fairing coating shall be applied when required by this Specification for architectural reasons, or to

provide protection against further carbonation or chloride ingress.

The extent of application shall be as specified or as directed by the Superintendent.

All surfaces shall be free of oil, grease, loose particles, decayed matter, moss or algal growth, curing

compounds, laitance and surface contamination. Cleaning shall be in accordance with specification

R54, Road and Bridge Cleaning.

Treatment, including wetting, priming, mixing, application and curing, shall be in accordance with the

manufacturer's instructions.

B15.11 PROTECTIVE COATINGS

When required, a protective coating shall be applied in accordance with specification B23 Penetrating

Sealers and Coatings to protect concrete against carbonation and chloride ingress.

Any blowholes or substantial pitting shall be repaired with a fairing coat in accordance with this

Specification.

B15.12 WORK RECORDS

Further to Specification G1 daily records shall be kept of the following:

Stability of Structure

Reinforcement Surface Finish

Materials - Generic Types, Brand Names and Batch Numbers

Temperature Records

Curing regime

B15.13 PAYMENT

Payment for concrete repairs shall be at the items as listed in the Schedule of Rates.

Payment shall include the provision of all plant, labour and materials required for traffic control,

access, scaffolding, shoring and propping, formwork, preparation, repairs, curing and the disposal of

any debris

DIER SPEC B15 4 of 5

B15 - CONCRETE REPAIRS October 2006

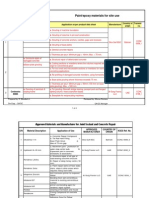

Table B 15.1 Concrete Repair Materials

EPIREZ FOSROC Degussa SIKA

Concrete Primer EPIPATCH PRIMER NITOBOND AR/HAR BARRA EMULSION AC MONOTOP 610

Steel Primer Resene 167 pre-prime over

coated with Zinga cold

galvanising

Resene 167 pre-prime

over coated with Zinga

cold galvanising

Resene 167 pre-prime over

coated with Zinga cold

galvanising

Resene 167 pre-

prime over coated

with Zinga cold

galvanising

Concrete Repairs

Shallow EPIPATCH RENDEROC S Barra Mortar HS MONOTOP 610

High build, overhead EPIPATCH HB RENDEROC HB Barra Mortar HL MONOTOP 615 HB

Large scale, congested,

reinforcement

RENDEROC LA EMACO S66

Rendering, fairing RENDEROC FC BARRA 80 MONOTOP 620

Curing CONCURE CR MASTERKURE 410 TILTSEAL

Protective Coating ENVIROBLOCK NITOCOTE DEKGUARD BARRACRYL D

DIER SPEC B15 5 of 5

Das könnte Ihnen auch gefallen

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringVon EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringBewertung: 4 von 5 Sternen4/5 (5)

- General Specification For The Construction OF Elevated Water TankDokument30 SeitenGeneral Specification For The Construction OF Elevated Water TankHani Ibrahim AbdoulayeNoch keine Bewertungen

- Waterproofing (Cementitious+HDPE)Dokument12 SeitenWaterproofing (Cementitious+HDPE)masahinNoch keine Bewertungen

- Paint and EpoxyDokument3 SeitenPaint and EpoxyRahul KalathingalNoch keine Bewertungen

- T Proc Notices Notices 040 K Notice Doc 35506 101032600Dokument20 SeitenT Proc Notices Notices 040 K Notice Doc 35506 101032600diranhurnananNoch keine Bewertungen

- Branz Appraisal Dampfix 2 & 3 581 2015Dokument5 SeitenBranz Appraisal Dampfix 2 & 3 581 2015DanielCarletonNoch keine Bewertungen

- 1.09 Item Wise Detailed DescriptionDokument37 Seiten1.09 Item Wise Detailed DescriptionRajesh ChowhanNoch keine Bewertungen

- 3550-8310-SP-0006 Rev D2.pdf MARKED-c.vanDokument8 Seiten3550-8310-SP-0006 Rev D2.pdf MARKED-c.vanPhuong ThaoNoch keine Bewertungen

- Method Statement - Structural ConcreteDokument7 SeitenMethod Statement - Structural Concretearif_rubinNoch keine Bewertungen

- Floor, Wall, Ceiling and Roof Finishings - SPECSDokument16 SeitenFloor, Wall, Ceiling and Roof Finishings - SPECSAhmed NasefNoch keine Bewertungen

- Precast Concrete CurbsDokument3 SeitenPrecast Concrete Curbsgskodikara2000Noch keine Bewertungen

- 32 13 13 - Concrete PavingDokument6 Seiten32 13 13 - Concrete PavingKushagra AgarwalNoch keine Bewertungen

- Specifications FOR Single Storey Residential Building: Prepared byDokument9 SeitenSpecifications FOR Single Storey Residential Building: Prepared byruel buntog100% (1)

- Diaphragm Wall SpecificationDokument12 SeitenDiaphragm Wall SpecificationLee Cw100% (3)

- Guidelines On Water ProofingDokument88 SeitenGuidelines On Water ProofingViệt Đặng XuânNoch keine Bewertungen

- Concrete BundsDokument12 SeitenConcrete BundsPaul JamesonNoch keine Bewertungen

- Generic SpecsDokument8 SeitenGeneric SpecsHarold Valen MagpayoNoch keine Bewertungen

- Concrete Repair and Structure StrengtheningDokument5 SeitenConcrete Repair and Structure StrengtheningAidaJalaluddinNoch keine Bewertungen

- Specifications For Waterproofing WorksDokument16 SeitenSpecifications For Waterproofing WorkssplashierprinceNoch keine Bewertungen

- CCCC Et Ha Spec ST 650 00 Reply BDokument5 SeitenCCCC Et Ha Spec ST 650 00 Reply B黄赛赛Noch keine Bewertungen

- Standard SpecificationsDokument7 SeitenStandard SpecificationsMarshall BravestarNoch keine Bewertungen

- Sample Construction SpecificationsDokument14 SeitenSample Construction SpecificationsFrncesca MacalindongNoch keine Bewertungen

- Company Profile Sub-ContractorDokument54 SeitenCompany Profile Sub-ContractorAmyrah SyahyerahNoch keine Bewertungen

- Road Construction MethodDokument335 SeitenRoad Construction MethodABernardo Vinas100% (1)

- Appendix G - Specification For FlooringDokument19 SeitenAppendix G - Specification For FlooringAnil WadileNoch keine Bewertungen

- General NotesDokument11 SeitenGeneral NotesJADEL ALCANTARANoch keine Bewertungen

- Architectural Specifiactions CVCDokument18 SeitenArchitectural Specifiactions CVCJen AgabinNoch keine Bewertungen

- Division 01 General Requirements: Kaypian, San Jose Del Monte BulacanDokument7 SeitenDivision 01 General Requirements: Kaypian, San Jose Del Monte BulacanKristine MalabayNoch keine Bewertungen

- MS For Reinforcement Cement ConcretingDokument6 SeitenMS For Reinforcement Cement ConcretingShan THALANoch keine Bewertungen

- Specification For Bored Pile PDFDokument6 SeitenSpecification For Bored Pile PDFXuan DT75% (4)

- S9-CnS Waterproofing ConcreteDokument2 SeitenS9-CnS Waterproofing ConcreteLukeNoch keine Bewertungen

- Excavation and HardfillingDokument7 SeitenExcavation and Hardfillingagilan005Noch keine Bewertungen

- Concrete WeepingDokument2 SeitenConcrete WeepingM.Sreeram SanjayNoch keine Bewertungen

- CXC General SpecificationsDokument7 SeitenCXC General SpecificationsWilliam Harvey EvangelistaNoch keine Bewertungen

- Technical Specifications Construction of Fire StationDokument11 SeitenTechnical Specifications Construction of Fire Stationp.viloriaNoch keine Bewertungen

- Job Procedure For Concrete 28-4-21Dokument15 SeitenJob Procedure For Concrete 28-4-21Salmaan WasimNoch keine Bewertungen

- S.Q - FF - Rehabilitation & Strengthening of UG Pump Room and Water TankDokument8 SeitenS.Q - FF - Rehabilitation & Strengthening of UG Pump Room and Water TankBrijesh MishraNoch keine Bewertungen

- Marriot Grand Ballroom Concrete Works: Project Title: Contract Package No. Document TitleDokument10 SeitenMarriot Grand Ballroom Concrete Works: Project Title: Contract Package No. Document TitleImho TepNoch keine Bewertungen

- Central Business District of The New Administrative Capital: Crystalline Waterproofing 071616 - Page ofDokument5 SeitenCentral Business District of The New Administrative Capital: Crystalline Waterproofing 071616 - Page oflf chNoch keine Bewertungen

- 60ac025038d3b8eda22a81c8 - 07 56 00.01 - Fluid-Applied Roofing (Asphalt)Dokument4 Seiten60ac025038d3b8eda22a81c8 - 07 56 00.01 - Fluid-Applied Roofing (Asphalt)Eng Victor FidelisNoch keine Bewertungen

- CTPM Unit 1Dokument25 SeitenCTPM Unit 1Vikaskumar Reddy100% (1)

- Specifications Section 1 GeneralDokument4 SeitenSpecifications Section 1 GeneralAgia Dela VegaNoch keine Bewertungen

- Bidding Document-Rio-21-01-008Dokument58 SeitenBidding Document-Rio-21-01-008Sen LinNoch keine Bewertungen

- BIADP - Technical Specifications - Volume 2Dokument83 SeitenBIADP - Technical Specifications - Volume 2ralpheaNoch keine Bewertungen

- Specification Jila Seva Sadan - 3Dokument176 SeitenSpecification Jila Seva Sadan - 3Jignesh P KoratNoch keine Bewertungen

- Underpin NotesDokument2 SeitenUnderpin Notesanele_amisNoch keine Bewertungen

- SECTION 03251 Expansion and Construction Joints: Part 1 GeneralDokument4 SeitenSECTION 03251 Expansion and Construction Joints: Part 1 GeneralJojolasNoch keine Bewertungen

- LAPRIL-C103 enDokument5 SeitenLAPRIL-C103 enalpha NEPALNoch keine Bewertungen

- General SpecificationDokument3 SeitenGeneral SpecificationKakoliNoch keine Bewertungen

- General Building Spec.Dokument20 SeitenGeneral Building Spec.Barry Daniel Saunders0% (1)

- Salt Barn SpecificationsDokument24 SeitenSalt Barn SpecificationsRomoex R RockNoch keine Bewertungen

- Technical Specifications (Building)Dokument51 SeitenTechnical Specifications (Building)Richard WestonyNoch keine Bewertungen

- Structured Method Statement For Concrete Repair - 1Dokument15 SeitenStructured Method Statement For Concrete Repair - 1m.umar100% (1)

- S120Dokument14 SeitenS120praveena61Noch keine Bewertungen

- SpecificationsDokument36 SeitenSpecificationsStephen Mark Garcellano DalisayNoch keine Bewertungen

- S120 2004 Minimum Specification For Concrete Walled SilosDokument14 SeitenS120 2004 Minimum Specification For Concrete Walled SilosDoug WeirNoch keine Bewertungen

- Cement BlocksDokument8 SeitenCement BlocksYannick PrattNoch keine Bewertungen

- C 14 PDFDokument4 SeitenC 14 PDFAnwar MohiuddinNoch keine Bewertungen

- 1183 Vol - IIBDokument152 Seiten1183 Vol - IIBVishal PatelNoch keine Bewertungen

- Technical ProposalDokument6 SeitenTechnical ProposalMark Sinclair100% (1)

- Progress of Design and Surveying 2010.11.2Dokument4 SeitenProgress of Design and Surveying 2010.11.2Upali KarunarathneNoch keine Bewertungen

- Material RequirementDokument2 SeitenMaterial RequirementPja ShanthaNoch keine Bewertungen

- Attendent Sheet of MeetingDokument4 SeitenAttendent Sheet of MeetingUpali KarunarathneNoch keine Bewertungen

- Progress Meeting No M-02!05!10-2010Dokument4 SeitenProgress Meeting No M-02!05!10-2010Upali KarunarathneNoch keine Bewertungen

- Attendent Sheet of MeetingDokument4 SeitenAttendent Sheet of MeetingUpali KarunarathneNoch keine Bewertungen

- Daily Work Record: Dockyard General Engineering Services (PVT) LTD.Dokument1 SeiteDaily Work Record: Dockyard General Engineering Services (PVT) LTD.Upali KarunarathneNoch keine Bewertungen

- Site Expences Account August-2012Dokument45 SeitenSite Expences Account August-2012Upali KarunarathneNoch keine Bewertungen

- Hydraulic Assesment of RoadDokument2 SeitenHydraulic Assesment of RoadUpali KarunarathneNoch keine Bewertungen

- Certified X Sextion (From 35+000 To 45+000) To CHECDokument2 SeitenCertified X Sextion (From 35+000 To 45+000) To CHECUpali KarunarathneNoch keine Bewertungen

- NIII BANK BOQ - XLSX Price LessDokument56 SeitenNIII BANK BOQ - XLSX Price LessUpali KarunarathneNoch keine Bewertungen

- DM Dsi SPEC04Dokument39 SeitenDM Dsi SPEC04nadhabindhuNoch keine Bewertungen

- Progress Report Month of Mat 2017fffffffDokument11 SeitenProgress Report Month of Mat 2017fffffffUpali KarunarathneNoch keine Bewertungen

- Section 2.5 Water SupplyDokument31 SeitenSection 2.5 Water SupplyDaryl BadajosNoch keine Bewertungen

- Site Expences Account Aug 2013Dokument42 SeitenSite Expences Account Aug 2013Upali KarunarathneNoch keine Bewertungen

- Ith 400epoxDokument5 SeitenIth 400epoxUpali KarunarathneNoch keine Bewertungen

- BS 812-103.2 PDFDokument13 SeitenBS 812-103.2 PDFUpali KarunarathneNoch keine Bewertungen

- Sub AdvanceDokument1 SeiteSub AdvanceUpali KarunarathneNoch keine Bewertungen

- Section 2.5 Water SupplyDokument31 SeitenSection 2.5 Water SupplyDaryl BadajosNoch keine Bewertungen

- 1479724099-2027 Part 4 Ver2Dokument22 Seiten1479724099-2027 Part 4 Ver2Upali KarunarathneNoch keine Bewertungen

- NIII BANK BOQ - XLSX Price Less PDFDokument56 SeitenNIII BANK BOQ - XLSX Price Less PDFUpali KarunarathneNoch keine Bewertungen

- 1479724099-2027 Part 4 Ver2Dokument22 Seiten1479724099-2027 Part 4 Ver2Upali KarunarathneNoch keine Bewertungen

- The Control of Air Pressure Within Tall Building Drainage-SoPHE - PPT (Compatibility Mode)Dokument24 SeitenThe Control of Air Pressure Within Tall Building Drainage-SoPHE - PPT (Compatibility Mode)mohdnazirNoch keine Bewertungen

- DM Dsi SPEC04Dokument39 SeitenDM Dsi SPEC04nadhabindhuNoch keine Bewertungen

- 2 5 PDFDokument31 Seiten2 5 PDFUpali KarunarathneNoch keine Bewertungen

- NIII BANK BOQ - XLSX Price LessDokument56 SeitenNIII BANK BOQ - XLSX Price LessUpali KarunarathneNoch keine Bewertungen

- Actual ProgramDokument1 SeiteActual ProgramUpali KarunarathneNoch keine Bewertungen

- 3rd Floor Plan UCSCDokument1 Seite3rd Floor Plan UCSCUpali KarunarathneNoch keine Bewertungen

- Architectural LayoutDokument1 SeiteArchitectural LayoutUpali KarunarathneNoch keine Bewertungen

- New Extra Work UCSCDokument33 SeitenNew Extra Work UCSCUpali KarunarathneNoch keine Bewertungen

- PDM Appendix3 Ex Letters NoticesDokument54 SeitenPDM Appendix3 Ex Letters NoticesUpali KarunarathneNoch keine Bewertungen

- Research Article: Dynamic Modelling of A Solar Water Pumping System With Energy StorageDokument13 SeitenResearch Article: Dynamic Modelling of A Solar Water Pumping System With Energy Storagehabtamu melsewNoch keine Bewertungen

- MSC 200Dokument18 SeitenMSC 200Amit KumarNoch keine Bewertungen

- The Accreditation Committee Cityland Development CorporationDokument5 SeitenThe Accreditation Committee Cityland Development Corporationthe apprenticeNoch keine Bewertungen

- Answer Key: Entry TestDokument4 SeitenAnswer Key: Entry TestMaciej BialyNoch keine Bewertungen

- Ga-z68p-Ds3 v2.x eDokument104 SeitenGa-z68p-Ds3 v2.x ejohnsonlimNoch keine Bewertungen

- Chapter-4 Conditional and Iterative Statements in PythonDokument30 SeitenChapter-4 Conditional and Iterative Statements in Pythonashishiet100% (1)

- Form IEPF 2 - 2012 2013FDokument2.350 SeitenForm IEPF 2 - 2012 2013FYam ServínNoch keine Bewertungen

- BDC Based Phase ControlDokument14 SeitenBDC Based Phase ControlTiewsoh LikyntiNoch keine Bewertungen

- DWDMDokument41 SeitenDWDMKarthik KompelliNoch keine Bewertungen

- Understand Fox Behaviour - Discover WildlifeDokument1 SeiteUnderstand Fox Behaviour - Discover WildlifeChris V.Noch keine Bewertungen

- E-Cat35xt014 Xtro PhantomsDokument32 SeitenE-Cat35xt014 Xtro PhantomsKari Wilfong100% (5)

- Applied Social Research A Tool For The Human Services 9th Edition Monette Test Bank 1Dokument36 SeitenApplied Social Research A Tool For The Human Services 9th Edition Monette Test Bank 1wesleyvasquezmeoapcjtrb100% (25)

- Phrasal Verbs en Inglés.Dokument2 SeitenPhrasal Verbs en Inglés.David Alexander Palomo QuirozNoch keine Bewertungen

- Statistics 2Dokument121 SeitenStatistics 2Ravi KNoch keine Bewertungen

- WP05 - ACT 01 - Development 1909Dokument53 SeitenWP05 - ACT 01 - Development 1909ramesh9966Noch keine Bewertungen

- CHAPTER I KyleDokument13 SeitenCHAPTER I KyleCresiel Pontijon100% (1)

- Flyweis Services Pvt. LTDDokument11 SeitenFlyweis Services Pvt. LTDFlyweis TechnologyNoch keine Bewertungen

- 1.2.2.5 Packet Tracer - Connecting Devices To Build IoTDokument4 Seiten1.2.2.5 Packet Tracer - Connecting Devices To Build IoTyayasan dharamabharataNoch keine Bewertungen

- Filtomat M300Dokument4 SeitenFiltomat M300Sasa Jadrovski100% (1)

- English Literature Coursework Aqa GcseDokument6 SeitenEnglish Literature Coursework Aqa Gcsef5d17e05100% (2)

- ROBONIK - Prietest EasylabDokument2 SeitenROBONIK - Prietest EasylabAlexis Armando Ramos C.Noch keine Bewertungen

- Read The Text and Answer The QuestionsDokument5 SeitenRead The Text and Answer The QuestionsDanny RuedaNoch keine Bewertungen

- S L Dixon Fluid Mechanics and Thermodynamics of TurbomachineryDokument4 SeitenS L Dixon Fluid Mechanics and Thermodynamics of Turbomachinerykuma alemayehuNoch keine Bewertungen

- Article On Role of Cyberspace in Geopolitics-PegasusDokument5 SeitenArticle On Role of Cyberspace in Geopolitics-PegasusIJRASETPublicationsNoch keine Bewertungen

- Personal ComputerDokument3 SeitenPersonal ComputerDan Mark IsidroNoch keine Bewertungen

- FoodhallDokument3 SeitenFoodhallswopnilrohatgiNoch keine Bewertungen

- Rated Operational Current: InstructionsDokument12 SeitenRated Operational Current: InstructionsJhon SanabriaNoch keine Bewertungen

- Catalyst 4500 SeriesDokument1.230 SeitenCatalyst 4500 SeriesnvleninkumarNoch keine Bewertungen

- Bajaj Allianz General Insurance CompanyDokument4 SeitenBajaj Allianz General Insurance Companysarath potnuriNoch keine Bewertungen