Beruflich Dokumente

Kultur Dokumente

13

Hochgeladen von

Thao DophuongOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

13

Hochgeladen von

Thao DophuongCopyright:

Verfügbare Formate

Comparison of electrodialysis reversal (EDR) and electrodeionization reversal (EDIR)

for water softening

Hong-Joo Lee

a

, Jung-Hoon Song

b, 1

, Seung-Hyeon Moon

b,

a

Department of Bioenergy Science and Technology, Chonnam National University, 77 Yongbong-ro, Buk-gu, Gwangju 500-757, Republic of Korea

b

School of Environmental Science and Engineering, Gwangju Institute of Science and Technology (GIST), 123 Cheomdangwagi-ro, Buk-gu, Gwangju 500-712, Republic of Korea

H I G H L I G H T S

Periodical change of the polarity was

examined as a water softening process.

Appropriate current density was cho-

sen for the constant current operation.

Process performances of EDR and EDIR

were compared for water softening.

EDIR process showed a lower electric

resistance and power consumption.

G R A P H I C A L A B S T R A C T

The empirical limiting current density as functions of ow rate and hardness concentration was determined

for the operation current in the electrodeionization reversal (EDIR).

a b s t r a c t a r t i c l e i n f o

Article history:

Received 6 November 2012

Received in revised form 28 December 2012

Accepted 29 December 2012

Available online 30 January 2013

Keywords:

Electrodeionization reversal (EDIR)

Groundwater

Water softening

Ion exchange membrane process

Polarity change

In the present study, EDR (electrodialysis reversal) and EDIR (electrodeionization reversal), ion exchange

membrane processes using periodic change of the polarity, were examined as water softening process. The

LCD (limiting current density) was empirically determined as a function of linear ow velocity with different

hardness concentrations in synthetic solutions. In addition, the inuence of the LCD on the transport phe-

nomena and water splitting were investigated. Accordingly, an appropriate operating current was selected

for the constant current operation based on the LCD.

The process performances of EDR and EDIR were compared for removal of hardness materials from a ground-

water. Water softening performances of both EDR and EDIR processes were performed with various opera-

tion parameters including current density, ow velocity and hardness concentration. The EDIR process

showed notably lower electric resistance and power consumption than the EDR process. The study showed

that the EDIR process with an optimized constant current mode and periodic polarity change could be

used as an effective water softening process by decreasing resistance and power consumption.

2013 Elsevier B.V. All rights reserved.

1. Introduction

Hardness in water systems represents divalent or trivalent cation

species such as calcium, magnesium and, to a less extent, aluminum

and iron. They usually react with soap anions or precipitate in the

Desalination 314 (2013) 4349

Corresponding author. Tel.: +82 62 970 2435; fax: +82 62 970 2434.

E-mail address: shmoon@gist.ac.kr (S.-H. Moon).

1

Current address of J.H. Song: Secondary Battery Research Team, Research Institute of

Industrial Science and Technology (RIST), 32 Hyoja-dong, Nam-gu, Pohang, Gyeongbuk

790-330, Republic of Korea.

0011-9164/$ see front matter 2013 Elsevier B.V. All rights reserved.

http://dx.doi.org/10.1016/j.desal.2012.12.028

Contents lists available at SciVerse ScienceDirect

Desalination

j our nal homepage: www. el sevi er . com/ l ocat e/ desal

formof sulfates or carbonates in many streams [1,2]. Various water soft-

ening processes such as ion exchange, nanoltration, and precipitation

have been applied to remove hardness materials from water [35].

Among the processes, ion exchange is broadly used for water softening

due to the easiness of its operation and high hardness removal efcien-

cy. However, it has shortcomings such as the release of exchanged ions

and the periodic chemical regeneration of ion exchange resins.

As an alternative process of ion exchange, electrodialysis (ED), an

electrochemical process using ion exchange membranes in an electric

eld, has been considered for the removal of ionic species including

hardness and organics from electrolytes [6,7]. However, its perfor-

mance decreases due to the deposition of foulants (colloidal particles

and organic materials) in many cases. Change of the electric polarity

is considered as one of the methods to minimize membrane fouling

and increase process performance in the ED system. Until now, the

electrodialysis reversal (EDR) process, an ED process that employs

the periodic change of polarity, has shown good feasibility in many

industrial application areas including water softening and the pro-

duction of potable water [8,9].

Electrodeionization (EDI), an ion exchange membrane process

combined with ED and ion change, has been used to produce

ultrapure water [10,11]. In EDI, ion exchange resins packed between

cation and anion exchange membranes in a diluate compartment re-

move ions with high removal efciency [12,13]. The process perfor-

mance of EDI, however, decreases due to the scale formation on the

surface of resins and membranes as a form of hydroxides when the

solution pH becomes basic during the operation. With the reversal

of the polarity of electrodes, scale formation can be prevented in the

operation, so called electrodeionization reversal (EDIR) [14,15]. Inter-

ests in the periodic change of polarity in EDR and EDIR have increased

due to their environmentally friendly aspect since it can remove

hardness materials without severe scale formation compared with

corresponding conventional ion exchange membrane processes (ED

and EDI).

In general, a high current density affects water dissociation and

scale formation in ion exchange membrane systems. Especially, water

dissociation occurs in a bipolar interface between cation exchange

membrane and anion exchange resins. The water dissociation in the

membrane leads to pH change in the compartment. In addition, scale

formation is a critical consideration in the operation of ion exchange

membrane processes when operated at a higher current density than

the limiting current density (LCD), causing to generate an alkaline envi-

ronment [16,17]. Therefore, the operating current density should be

lower than the LCD value, even though a higher current is preferred

for a high ux.

In a previous study, the EDIR process was applied to remove hard-

ness from tap water with low hardness concentration [16]. It was con-

cluded that EDIR could be used as a promising water softening

process without scale formation. However, the study did not show the

process performance in detail from a practical point of view. Further-

more, Lee et al. studied the inuences of the operation parameters

(ow rate, hardness concentration, and polarity reversal period) on

the process performance and long term experiments using synthetic

solutions [17]. However, the inuence of the current density on the

membrane transport phenomena and the process performances was

not examined in the EDIR system since the study was performed at a

constant voltage.

In the present study, the LCD equation was empirically determined

as a function of ow velocity with different hardness concentration. At

the determined constant current operation, the inuence of the operat-

ing parameters (current density, ow velocity, hardness concentration

and the polarity change) on the hardness removal efciency was inves-

tigated for a wide range of hardness concentrations (between 20

and 300 mg/L as CaCO

3

) in synthetic solutions. Also, EDR and EDIR

were operated to remove hardness from a groundwater in a constant

current operation and to compare their performance.

2. Experimental

2.1. Experimental setup

Both EDR and EDIR systems, which consist of 6 cell pairs in three

hydraulic stages, were operated to remove hardness from synthetic

solution and a groundwater. A schematic illustration of the EDIR system

is found elsewhere [16]. The effective area of Pt coated Ti electrodes for

both anode and cathode was 100 cm

2

with the height of 12.5 cm and

the width of 8.0 cm. The thickness of the compartments was 0.4 cm

each after being packed with resins. The EDIR stack was prepared by

lling a mixture of cation and anion ion exchange resins (mixing ratio

of 2:3) in the rst and third hydraulic stages. Cation exchange resin,

Amberlite IR 120 (Na

+

form) (Rhom and Hass Co., France), and anion

exchange resin, Amberlite IRA 402 (Cl

form), were used for the

setup of the EDIR system. Fig. 1 shows the experimental setup and the

schematic explanation for the polarity change of the EDIR system with

three hydraulic stages.

Ion exchange membranes, NEOSEPTA CMX and AMX (ASTOM

Co., Japan) with an effective area of 100 cm

2

, were used in the exper-

imental setup for the EDR and EDIR operation. Table 1 shows the

properties of ion exchange membranes, which were characterized

with appropriate methods found elsewhere [17].

Feed solutions with different hardness concentrations were pre-

pared for synthetic solutions by dissolving CaCl

2

2H

2

O, MgCl

2

6H

2

O,

and Na

2

SO

4

with the same molar ratio in distilled water. Table 2

shows the composition of prepared synthetic solutions. The concentra-

tionof cations was analyzedinanionchromatography, DX120 (Dionex,

USA).

2.2. Determination of the empirical limiting current density

Currentvoltage relations were obtained by measuring a potential

response for a step-wise increase in current with a digital multimeter,

HP 34401 (Agilent, USA). LCD values were calculated from the inter-

section of two slopes between the ohmic and plateau regions in the

plot of the currentvoltage. The LCD values were determined for differ-

ent hardness concentrations (between 20 and 300 mg/L as CaCO

3

) and

different feed ow rates (between 30 and 120 mL/min) in synthetic

solutions. The ow rates of concentrate and electrode rinse solution

were maintained at 20 mL/min during experiments. A feed solution

containing hardness materials was pumped through three compart-

ments (diluate, concentrate and electrode rinsing compartments).

2.3. Operation of EDR and EDIR systems in the synthetic solutions

The EDR and EDIR systems were operated with different feed ow

rate and hardness concentrations at a constant current after the LCD

values were determined. The operation current density was set at

70% of the determined LCD value through experiments. The feed solu-

tion, containing the hardness concentration from 20 to 110 mg/L as

CaCO

3

, was pumped through three compartments. The ow rates in

the diluate compartment were varied from 30 to 120 mL/min during

the operation. In addition, the inuence of the polarity reversal time

on the process performances was investigated by increasing time

from 15 to 30 min.

2.4. Operation of EDR and EDIR systems in a groundwater

In the present study, the EDR and EDIR systems were operated for

hardness removal from a groundwater. The compositions and the

water quality of the groundwater are shown in Table 3. As shown in

the table, the groundwater consists of 12 mg/L of Ca

2+

and 2.5 mg/L

of Mg

2+

, the total hardness being estimated as 40.5 mg/L as CaCO

3

.

The feed solution was continuously supplied to three compartments

at a ow rate of 60 mL/min. For the hardness removal from the

44 H.-J. Lee et al. / Desalination 314 (2013) 4349

groundwater, the polarity was changed every 20 min during the opera-

tion. The process performances of EDIR for the removal of hardness in

the groundwater were compared with those of EDR under the same ex-

perimental conditions.

3. Results and discussion

3.1. Determination of the empirical limiting current density

Through the LCD determination experiments, the current in the

stack was increased step-wisely and the corresponding voltage drop

was measured using a multimeter. Fig. 2(a) shows the currentvoltage

curves obtained for the ED stack consisting of three stages. The LCD

value of three hydraulic stages was determined in a similar plot of the

currentvoltage curve for the stack. The LCD value was determined as

1.15 A/m

2

in the gure at a hardness concentration of 20 mg/L as

CaCO

3

and a ow rate of 90 mL/min. After the current exceeded the

limiting current, the sudden change of slope occurred due to drastic

increase in the boundary layer resistance. The results reect a complete

depletion of salt at the membrane surface facing the dilute solution [18].

At higher current densities than LCD, the sudden increase in resistance

of the membrane cell occurred, which was shown in the cell resistance

plot versus the reciprocal current in Fig. 2(b).

Fig. 3 shows the LCD measurement results as a function of feed

velocity with different hardness concentrations. The gure shows that

the value of LCD increased with the increasing ow rate and hardness

concentration. In this study, the empirical LCD, i

lim,emp

, was estimated

as a function of feed velocity for various feed concentrations using

Eq. (1), i.e.,

i

lim;emp

aCu

b

1

where C represents the concentration of the feedsolution and u the feed

velocity. In addition, a and b in the equation are characteristic constants

depending on the spacer geometry and the feed conditions in a given

stack conguration.

The constants a and b were obtained from a double logarithmic

graph of i

lim,emp

/C over u as explained in the previous study [18]. Fig. 4

shows the values of constants a and b, which was determined as a func-

tion of owrate for different hardness concentration. The characteristic

value of the constant a decreased signicantly with increasing hardness

concentration. Meanwhile, the constant b showed similar values within

a range between 0.6 and 0.8 even with the increasing hardness concen-

tration. Estimation of the empirical LCDshowed that the constant a was

affected by the concentration of an electrolyte condition, while the

constant b was affected by hydrodynamic conditions, as reported in

the previous studies [18,19].

3.2. Inuence of current density on water splitting and transport

phenomena

When an ion exchange membrane process is operated at a higher

current density than LCD, water dissociation occurs on the membrane

surface thus increasing the pH value [20]. From the estimated LCD

value, the EDR experiments were carried out at three current densities,

(a) Before the polarity change

(b) After the polarity change

Fig. 1. Schematic illustration on the EDIR congurations consisting of three hydraulic

stages.

Table 1

Characteristic properties of ion exchange membranes.

CMX AMX Solution condition for

characterization

Electric resistance (cm

2

) 3.07 2.75 0.5 M NaCl

Thickness (mm) 0.17 0.18

Exchange capacity (meq/g dry membrane) 1.8 1.5 0.1 M HCl

Transport number 0.98 0.98 0.5 M KCl/0.1 M KCl

Water content 0.25 0.28 Distilled water

Table 2

Different hardness concentration of synthetic solutions.

Hardness

(mg/L as CaCO

3

)

CaCl

2

2H

2

O

(mol/L)

MgCl

2

6H

2

O

(mol/L)

Na

2

SO

4

(mol/L)

20 0.10 0.10 0.10

50 0.25 0.25 0.25

80 0.40 0.40 0.40

110 0.55 0.55 0.55

160 0.80 0.80 0.80

300 1.50 1.50 1.50

Table 3

Compositions and water quality in the ground water.

Characteristic value

Conductivity (S/cm) 145

pH 7.13

Concentration (mg/L) Na

+

10.9

Ca

2+

12.1

Mg

2+

2.5

SO

4

2

42.3

Cl

6.9

Total hardness (mg/L as CaCO

3

) 40.5

45 H.-J. Lee et al. / Desalination 314 (2013) 4349

i.e., under LCD (70% of LCD), LCD, and above LCD (130% of LCD). Fig. 5

shows the diluate pH at representative current densities for various

hardness concentrations. The pH in the diluate compartment increased

rapidly when the current density was higher than LCD due to water

dissociation on the surface of an anion exchange membrane for all

examined hardness concentrations [20]. With the increasing hardness

concentration, the water dissociation increased further at lower

hardness concentrations due to the concentration depletion in the

boundary layer on the membrane surface. The diluate pH increased up

to 7.6 at the hardness concentration of 20 mg/L as CaCO

3

, while the

diluate pH values were measured as 6.4 at the higher concentrations

(80 and 110 mg/L as CaCO

3

). As the applied current density increased,

the resulting pH value increased more as shown in the gure. The pH

values for examined hardness concentrations were notably increased

at a higher than LCD.

Fig. 6 illustrates water dissociation and transport phenomena

occurring on the interface between an ion exchange membrane and

ion exchange resins with different current densities. In general, water

dissociation becomes dominant especially at a higher current density

than the LCDas explained in the gure. The pHchange at a high current

density increases possibility of the scale formation during the operation

[17]. It is suggested that ion exchange membrane processes should be

operated at a lower current density than LCD to minimize the scale

formation.

3.3. Inuence of operation parameters on the water softening

Table 4 shows the removal efciencies of cations (Na

+

, Ca

2+

and

Mg

2+

) in the EDR system at different current densities. The removal

efciency of ions increased with increasing current density even at a

higher current density than LCD [20,21]. Also the table shows that the

removal efciencies of divalent ions such as Mg

2+

and Ca

2+

ions

were higher than that of monovalent ion (Na

+

) for all examined

current densities. The higher removal efciencies of divalent ions can

(a) Relationship between applied current and voltage

Reciprocal current (1/A)

0 100 200 300 400 500

R

e

s

i

s

t

a

n

c

e

(

V

/

A

)

0

200

400

600

800

1000

Stack

First stage

Second stage

Third stage

(b) Relationship between the reciprocal current

and resistance

Voltage (V)

0 5 10 15 20

C

u

r

r

e

n

t

d

e

n

s

i

t

y

(

A

/

m

2

)

0.0

0.5

1.0

1.5

2.0

2.5

Stack

First stage

Second stage

Third stage

Limiting current density

Fig. 2. Determination of the limiting current density (hardness of 20 mg/L as CaCO

3

and ow rate of 90 mL/min).

Flow rate (ml/min)

20 40 60 80 100 120 140

L

i

m

i

t

i

n

g

c

u

r

r

e

n

t

d

e

n

s

i

t

y

(

A

/

m

2

)

0

2

4

6

8

10

300 mg/L as CaCO

3

160 mg/L as CaCO

3

110 mg/L as CaCO

3

80 mg/L as CaCO

3

50 mg/L as CaCO

3

20 mg/L as CaCO

3

Fig. 3. Measurement of the empirical limiting current density as functions of ow rate

and hardness concentration.

Hardness (mg/L as CaCO

3

)

0 50 100 150 200 250 300 350

a

x

1

0

3

(

A

s

b

m

1

-

b

/

g

)

0

1

2

3

4

5

b

0.55

0.60

0.65

0.70

0.75

0.80

Fig. 4. Determination of constants for the empirical limiting current density.

Operation current density

p

H

5.6

6.0

6.4

6.8

7.2

7.6

8.0

20 mg/L as CaCO

3

50 mg/L as CaCO

3

80 mg/L as CaCO

3

110 mg/L as CaCO

3

70 % LCD 130 % LCD LCD

Fig. 5. pH change in diluate as functions of current density and hardness concentration.

46 H.-J. Lee et al. / Desalination 314 (2013) 4349

be explained by the higher mobility of divalent ions than sodium ion

[22]. The removal efciency of Ca

2+

was higher than that of Mg

2+

in

Table 4, which is attributed by the fact that Ca

2+

has a higher adsorp-

tion capacity than Mg

2+

on the cation exchange resins [17,23].

The EDR was performed for hardness removal from synthetic solu-

tions containing different hardness concentrations at a constant current

density. Fig. 7 shows the removal efciencies of divalent and monova-

lent ions at a feed velocity of 60 mL/min. The removal efciencies of

divalent ions showed higher values than that of sodium ions due to

the higher ionic mobility, while those of sodium ions were between

40 and 50%. Also the removal efciencies of divalent cations were

(a) At a lower than the limiting current density

(b) At a higher than the limiting current density

+

Cation exchange resin

Anion exchange resin

Diluate

AMX

AMX

Concentrate

CMX

H

+

OH

-

H

+

OH

-

H

+

OH

-

H

+

OH

-

Diluate

+

AMX

AMX

Concentrate

Cation exchange resin

Anion exchange resin

CMX

Ca

2+

Ca

2+

Ca

2+

SO

4

2-

SO

4

2-

SO

4

2-

SO

4

2-

SO

4

2-

SO

4

2-

Fig. 6. Illustrated explanation on water dissociation and transport phenomena with different current densities.

Table 4

Removal efciencies of cations with different limiting current densities (hardness:

20 mg/L as CaCO

3

, ow rate: 60 mL/min).

Na

+

(%) Mg

2+

(%) Ca

2+

(%)

Under LCD (70% of LCD) 38 58 60

LCD 51 65 71

Over LCD (130% of LCD) 68 85 90

Hardness (mg/L as CaCO

3

)

0 20 40 60 80 100 120

R

e

m

o

v

a

l

e

f

f

i

c

i

e

n

c

y

(

%

)

0

10

20

30

40

50

60

70

80

90

100

Na

+

Ca

2+

Mg

2+

Fig. 7. Removal efciency as a function of hardness concentration in synthetic solutions

(ow rate: 60 mL/min).

47 H.-J. Lee et al. / Desalination 314 (2013) 4349

observed in the range of 60 to 70% even with the increasing hardness

concentrations.

The inuence of ow rate on the removal efciencies of cationic

species was investigated and the results are presented in Fig. 8. As

the ow rate increased, the removal efciencies decreased linearly.

The removal efciency of the divalent cations decreased to about

40% at 120 mL/min. It is suggested that the decreased removal ef-

ciency is due to a shorter contact time between cations and mem-

brane surface or ion exchange resins during the operation.

It is reported that a change of the electric polarity in ion exchange

membrane processes prevents or minimizes membrane fouling and

scale due to the pulsation effects on the membrane surface [24]. Since

increasing the period of the polarity change or the lowfrequency causes

a low pulsation effects on the membrane surface, it is of importance to

determine the appropriate interval of the polarity change for a stable

and reliable operation of the ion exchange membrane systems [17,24].

The inuence of the polarity reversal interval on the conductivity

removal efciency was investigated with different hardness concentra-

tions. The removal efciency decreased linearly as the polarity interval

increased as shown in Fig. 9.

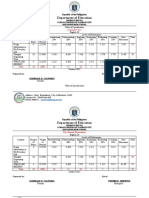

3.4. Water softening in a groundwater using the EDR and EDIR processes

The EDR and EDIR systems were performed for removal of hardness

from the groundwater at a constant current. Scale did not form on the

membrane surfaces during the hardness removal. The performances

of water softening for both systems were compared in terms of current

efciency and the cation removal efciency and the results are shownin

Table 5. The current efciency of the EDIR systemwas estimated as 82%,

higher value than that of the EDR system. The removal efciencies of

divalent cations showed higher than 60%, slightly higher values than

those of the EDR system.

Electric resistances of the stack and three hydraulic stages as a func-

tion of the owrate were estimated in the EDR and EDIR processes, and

the results are shown in Fig. 10. The stack resistance of EDIR process

decreased about 3050% compared with that of the EDR process.

Also, the signicant decrease in the resistance of each hydraulic stage

was observed in the EDIR process. The resistance of the rst stage,

which is the major portion of the total resistance, decreased about

6070% compared with the EDR process.

Considering the total power consumption of EDR and EDIR processes,

the estimated value to treat 1 L water of the EDIR process was 24.2 Wh,

Flow rate (ml/min)

R

e

m

o

v

a

l

e

f

f

i

c

i

e

n

c

y

(

%

)

0

20

40

60

80

100

Mg

Ca

Na

0 20 40 60 80 100 120 140

Fig. 8. Removal efciency as a function of ow rate in synthetic solutions (hardness

concentration: 50 mg/L as CaCO

3

).

Polarity reversal (min)

10 15 20 25 30 35

R

e

m

o

v

a

l

e

f

f

i

c

i

e

n

c

y

(

%

)

45

50

55

60

65

20 mg/L as CaCO

3

50 mg/L as CaCO

3

80 mg/L as CaCO

3

110 mg/L as CaCO

3

Fig. 9. Removal efciency according to the polarity reversal interval in synthetic solutions

(ow rate: 60 mL/min).

Table 5

Comparison of the process performance for water softening of the groundwater.

EDR EDIR

Current efciency (%) 74.5(0.7) 82.4(1.0)

Removal efciency of cations (%)

Mg

2+

59.1(1.3) 63.7(1.0)

Ca

2+

55.6(1.6) 61.6(1.3)

Na

+

35.1(0.1) 39.1(1.6)

Flow rate [ml/min]

0 30 60 90 120 150

Flow rate [ml/min]

0 30 60 90 120 150

R

e

s

i

s

t

a

n

c

e

[

]

0

50

100

150

200

250

300

Stack

First stage

Second stage

Third stage

(a) EDR process

0

50

100

150

200

250

300

Stack

First stage

Second stage

Third stage

(b) EDIR process

R

e

s

i

s

t

a

n

c

e

[

]

Fig. 10. Electric resistances for the water softening from the groundwater.

48 H.-J. Lee et al. / Desalination 314 (2013) 4349

much lower value than that of the EDR process (38.7 Wh/L). This study

shows that the EDIR process could be operated in an economically com-

petitive way when a proper current density is employed using the deter-

mined LCD values.

4. Conclusions

In this study, ion exchange membrane processes using the peri-

odic change of the polarity, EDR (electrodialysis reversal) and EDIR

(electrodeionization reversal), were operated for the removal of

hardness materials from synthetic solutions and a groundwater as a

water softening process. The LCD (limiting current density) was empir-

ically determined as a function of the owvelocity with different hard-

ness concentrations. In addition, the inuence of current density on the

transport phenomena occurring on the membrane surface was investi-

gated in a constant current mode.

When the process was operated at a higher current density than

LCD, the hardness removal efciency increased and the pH notably

changed due to water dissociation on the membrane surface. The EDR

and EDIR processes were operated at a constant current density of

70% of the determined LCD to remove hardness materials and showed

high removal efciency without scale formation using the change of

the polarity. EDIR process showed signicantly lower total resistance

and power consumption than EDR process. The study shows that the

EDIR process could be an economical water softening process when a

proper current density is employed.

References

[1] D. Nanda, K.L. Tung, Y.L. Li, N.J. Lin, C.J. Chuang, Effect of pHon membrane morphol-

ogy, fouling potential, and ltration performance of nanoltration membrane for

water softening, J. Membr. Sci. 349 (2010) 411420.

[2] E. Yildiz, A. Nuhoglu, B. Keskinler, G. Akay, B. Farizoglu, Water softening in a

crossow membrane reactor, Desalination 159 (2003) 139152.

[3] B. van der Bruggen, C. Vandecateele, Removal of pollutants from surface water

and groundwater by nanoltration: overview of possible applications in the

drinking water industry, Environ. Pollut. 122 (2003) 435445.

[4] J.H. Kweon, D.F. Lawler, Fouling mechanisms inthe integratedsystemwithsoftening

and ultraltration, Water Res. 38 (2004) 41644172.

[5] S.J. Seo, H. Jeon, J.K. Lee, G.Y. Kim, D. Park, H. Nojima, J. Lee, S.H. Moon, Investigation

on removal of hardness ions by capacitive deionization (CDI) for water softening

applications, Water Res. 44 (2010) 22672275.

[6] T. Xu, Ion exchange membranes: state of their development and perspective,

J. Membr. Sci. 263 (2005) 129.

[7] H.J. Lee, M.K. Hong, S.D. Han, J. Shim, S.H. Moon, Analysis of fouling potential

in the electrodialysis process in the presence of an anionic surfactant foulant,

J. Membr. Sci. 325 (2008) (2008) 719726.

[8] B.V. Pilat, Industrial application of electrodialysis reversal systems, Desalination

158 (2003) 8789.

[9] M. Turek, P. Dydo, Electrodialysis reversal of calcium sulphate and calcium

carbonate supersaturated solution, Desalination 158 (2003) 9194.

[10] J.H. Song, K.H. Yeon, S.H. Moon, A study on water dissociation phenomena and

removal performances in a continuous electrodeionization (CEDI) with current

densities, J. Membr. Sci. 291 (2007) 165171.

[11] J.W. Lee, K.H. Yeon, J.H. Song, S.H. Moon, Characterization of electrochemical

regeneration in a continuous electrodeionization (CEDI) system using electrical

impedance spectroscopy, Desalination 207 (2007) 276285.

[12] J. Wood, J. Gifford, J. Arba, M. Shaw, Production of ultrapure water by continuous

electrodeionization, Desalination 250 (2010) 973976.

[13] L. Fu, J. Wang, Y. Su, Removal of low concentrations of hardness ions from aqueous

solutions using electrodeionization process, Sep. Purif. Technol. 68 (2009) 390396.

[14] Y. Oren, Y. Egozy, Studies on polarity reversal with continuous deionization,

Desalination 86 (1992) 155171.

[15] K. Dermentzis, Continuous electrodeionization through electrostatic shielding,

Electrochim. Acta 53 (2008) 29532962.

[16] J.S. Park, J.H. Song, K.H. Yeon, S.H. Moon, Removal of hardness ions from tap water

using electromembrane processes, Desalination 202 (2007) 18.

[17] H.J. Lee, M.K. Hong, S.H. Moon, A feasibility study on water softening by electro-

deionization with the periodic polarity change, Desalination 284 (2012) 221227.

[18] H.J. Lee, H. Strathmann, S.H. Moon, Determination of the limiting current density in

electrodialysis desalination as an empirical function of linear velocity, Desalination

190 (2006) 4350.

[19] H.J. Lee, F. Sarfert, H. Strathmann, S.H. Moon, Designing of an electrodialysis desali-

nation plant, Desalination 142 (2002) 267286.

[20] J.J. Krol, M. Wessling, H. Strathmann, Concentrationpolarization with monopolar ion

exchange membranes: currentvoltage curves and water dissociation, J. Membr. Sci.

162 (1999) 145154.

[21] P. Sistat, G. Pourcelly, Chronopotentiometric response of an ion-exchange mem-

brane in the underlimiting current-range. Transport phenomena within the diffu-

sion layers, J. Membr. Sci. 123 (1997) 121131.

[22] L. Marder, E.M.O. Navarro, V. Prez-Herranz, A.M. Bernardes, J.Z. Ferreira, Evaluation

of transition metals transport properties through a cation-exchange membrane by

chronopotentiometry, J. Membr. Sci. 284 (2006) 267275.

[23] T. Sata, T. Sata, W. Yang, Studies on cation-exchange membranes having

permselectivity between cations in electrodialysis, J. Membr. Sci. 206 (2002) 3160.

[24] H.J. Lee, S.H. Moon, S.P. Tsai, Effects of pulsed electric elds on membrane fouling

in electrodialysis of NaCl solution containing humate, Sep. Purif. Technol. 27

(2002) 8995.

49 H.-J. Lee et al. / Desalination 314 (2013) 4349

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- công nghệ khử cặnDokument29 Seitencông nghệ khử cặnThao DophuongNoch keine Bewertungen

- 2Dokument7 Seiten2Thao DophuongNoch keine Bewertungen

- Visa Application Form 2012Dokument2 SeitenVisa Application Form 2012Honey OliverosNoch keine Bewertungen

- Non Chemical DescalingDokument32 SeitenNon Chemical DescalingKiran DuggarajuNoch keine Bewertungen

- 16Dokument9 Seiten16Thao DophuongNoch keine Bewertungen

- 6Dokument7 Seiten6Thao DophuongNoch keine Bewertungen

- Electrochemical Water Softening: Principle and ApplicationDokument14 SeitenElectrochemical Water Softening: Principle and ApplicationThao DophuongNoch keine Bewertungen

- 12Dokument6 Seiten12Thao Dophuong0% (1)

- 11Dokument5 Seiten11Thao DophuongNoch keine Bewertungen

- Desalination: Kristen S. Brastad, Zhen HeDokument6 SeitenDesalination: Kristen S. Brastad, Zhen HeThao DophuongNoch keine Bewertungen

- New Composite Membrane For Water SofteningDokument7 SeitenNew Composite Membrane For Water SofteningThao DophuongNoch keine Bewertungen

- 15Dokument9 Seiten15Thao DophuongNoch keine Bewertungen

- Softening of Hamma Drinking Water by Nanofiltration and by Lime in The Presence of Heavy MetalsDokument6 SeitenSoftening of Hamma Drinking Water by Nanofiltration and by Lime in The Presence of Heavy MetalsThao DophuongNoch keine Bewertungen

- 7Dokument13 Seiten7Thao DophuongNoch keine Bewertungen

- Water Softening Using A Generic Low Cost Nano-Filtration MembraneDokument6 SeitenWater Softening Using A Generic Low Cost Nano-Filtration MembraneThao DophuongNoch keine Bewertungen

- Use of Nanofiltration For Partial Softening of Very Hard WaterDokument8 SeitenUse of Nanofiltration For Partial Softening of Very Hard WaterThao DophuongNoch keine Bewertungen

- Electrochemical Water Softening: Principle and ApplicationDokument14 SeitenElectrochemical Water Softening: Principle and ApplicationThao DophuongNoch keine Bewertungen

- International Journal of Heat and Mass TransferDokument12 SeitenInternational Journal of Heat and Mass TransferThao DophuongNoch keine Bewertungen

- 11Dokument5 Seiten11Thao DophuongNoch keine Bewertungen

- Softening of Hamma Drinking Water by Nanofiltration and by Lime in The Presence of Heavy MetalsDokument6 SeitenSoftening of Hamma Drinking Water by Nanofiltration and by Lime in The Presence of Heavy MetalsThao DophuongNoch keine Bewertungen

- Economic Feasibility Study of Polyelectrolyte-Enhanced Ultrafiltration (PEUF) For Water SofteningDokument15 SeitenEconomic Feasibility Study of Polyelectrolyte-Enhanced Ultrafiltration (PEUF) For Water SofteningThao DophuongNoch keine Bewertungen

- 12Dokument6 Seiten12Thao Dophuong0% (1)

- New Composite Membrane For Water SofteningDokument7 SeitenNew Composite Membrane For Water SofteningThao DophuongNoch keine Bewertungen

- 7Dokument13 Seiten7Thao DophuongNoch keine Bewertungen

- 6Dokument7 Seiten6Thao DophuongNoch keine Bewertungen

- Desalination: Kristen S. Brastad, Zhen HeDokument6 SeitenDesalination: Kristen S. Brastad, Zhen HeThao DophuongNoch keine Bewertungen

- Water Softening Using A Generic Low Cost Nano-Filtration MembraneDokument6 SeitenWater Softening Using A Generic Low Cost Nano-Filtration MembraneThao DophuongNoch keine Bewertungen

- 2Dokument7 Seiten2Thao DophuongNoch keine Bewertungen

- Use of Nanofiltration For Partial Softening of Very Hard WaterDokument8 SeitenUse of Nanofiltration For Partial Softening of Very Hard WaterThao DophuongNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- DEMO 2 Critical Reading As ReasoningDokument3 SeitenDEMO 2 Critical Reading As ReasoningConnieRoseRamosNoch keine Bewertungen

- Philippine Electronics & Communication Institute of TechnologyDokument3 SeitenPhilippine Electronics & Communication Institute of TechnologyAngela MontonNoch keine Bewertungen

- Subject and Power - FoucaultDokument10 SeitenSubject and Power - FoucaultEduardo EspíndolaNoch keine Bewertungen

- Final Thesis Owura Kofi AmoabengDokument84 SeitenFinal Thesis Owura Kofi AmoabengKunal AgarwalNoch keine Bewertungen

- An Approach To The Aural Analysis of Emergent Musical FormsDokument25 SeitenAn Approach To The Aural Analysis of Emergent Musical Formsmykhos0% (1)

- Viola Jones AlgorithmDokument4 SeitenViola Jones AlgorithmBhumika GowdaNoch keine Bewertungen

- Countable and Uncountable Nouns Lesson PlanDokument7 SeitenCountable and Uncountable Nouns Lesson PlanAndrea Tamas100% (2)

- Rolfsen Knot Table Guide Crossings 1-10Dokument4 SeitenRolfsen Knot Table Guide Crossings 1-10Pangloss LeibnizNoch keine Bewertungen

- Dswd-As-Gf-018 - Rev 03 - Records Disposal RequestDokument1 SeiteDswd-As-Gf-018 - Rev 03 - Records Disposal RequestKim Mark C ParaneNoch keine Bewertungen

- Saline Water Intrusion in Coastal Aquifers: A Case Study From BangladeshDokument6 SeitenSaline Water Intrusion in Coastal Aquifers: A Case Study From BangladeshIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNoch keine Bewertungen

- Develop Your Kuji In Ability in Body and MindDokument7 SeitenDevelop Your Kuji In Ability in Body and MindLenjivac100% (3)

- 2-Eagan Model of CounsellingDokument23 Seiten2-Eagan Model of CounsellingVijesh V Kumar100% (4)

- EdiTasc EDokument89 SeitenEdiTasc EOglasnik MostarNoch keine Bewertungen

- What Is Science Cornell Notes ExampleDokument3 SeitenWhat Is Science Cornell Notes Exampleapi-240096234Noch keine Bewertungen

- Gpredict User Manual 1.2Dokument64 SeitenGpredict User Manual 1.2Will JacksonNoch keine Bewertungen

- Shailesh Sharma HoroscopeDokument46 SeitenShailesh Sharma Horoscopeapi-3818255Noch keine Bewertungen

- Advance Control Systems LabDokument2 SeitenAdvance Control Systems Labpadmajasiva100% (1)

- Investigation of Water Resources Projects - Preparation of DPRDokument148 SeitenInvestigation of Water Resources Projects - Preparation of DPRN.J. PatelNoch keine Bewertungen

- Table of Specification ENGLISHDokument2 SeitenTable of Specification ENGLISHDonn Abel Aguilar IsturisNoch keine Bewertungen

- Structural Testing Facilities at University of AlbertaDokument10 SeitenStructural Testing Facilities at University of AlbertaCarlos AcnNoch keine Bewertungen

- COS1512 202 - 2015 - 1 - BDokument33 SeitenCOS1512 202 - 2015 - 1 - BLina Slabbert-van Der Walt100% (1)

- Engineering Mathematics I - Class Test December 2015Dokument6 SeitenEngineering Mathematics I - Class Test December 2015Kunal RamnatsingNoch keine Bewertungen

- Topic 4 Petrophysics - Part 4Dokument32 SeitenTopic 4 Petrophysics - Part 4Aneesch PreethaNoch keine Bewertungen

- Bluehill BrochureDokument24 SeitenBluehill BrochureGeorge SingerNoch keine Bewertungen

- Roadmap For SSC CGLDokument11 SeitenRoadmap For SSC CGLibt seoNoch keine Bewertungen

- Circle Midpoint Algorithm - Modified As Cartesian CoordinatesDokument10 SeitenCircle Midpoint Algorithm - Modified As Cartesian Coordinateskamar100% (1)

- RAGHAV Sound DesignDokument16 SeitenRAGHAV Sound DesignRaghav ChaudhariNoch keine Bewertungen

- Co2 d30 Laser MarkerDokument8 SeitenCo2 d30 Laser MarkerIksan MustofaNoch keine Bewertungen

- Mind MapDokument1 SeiteMind Mapjebzkiah productionNoch keine Bewertungen

- Upstream Color PDFDokument16 SeitenUpstream Color PDFargentronicNoch keine Bewertungen