Beruflich Dokumente

Kultur Dokumente

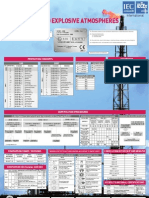

Atex Marking and Meaning For Hazardous

Hochgeladen von

act_rahul53Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Atex Marking and Meaning For Hazardous

Hochgeladen von

act_rahul53Copyright:

Verfügbare Formate

PROTECTING YOUR PROCESS

INSTALLATION AND SELECTION OF APPARATUS

SELECTION OF ELECTRICAL APPARATUS, PROTECTION FROM DANGEROUS SPARKING,

WIRING SYSTEMS AND FURTHER REQUIREMENTS ACCORDING TO IEC/EN 60079-14 (GAS)

AND IEC/EN 61241-14 (DUST)

E Ex ib IIC T4

Application area

Equipment that is certied according to

the ATEX 95 directive is provided with an

additional marking that describes the

usage site (or, in the case of corresponding

electric equipment, explains to where the

signal lines may lead). First the device

groups appear, then the category and

nally the information concerning the

atmosphere (gas and/or dust).

The following category division applies to

device group II:

Certied

according to

the European

CENELEC

standard

EN 50.../

EN 60079-...

Explosion

proof

Temperature

classes

Electrical equipment of

group II is divided into

temperature classes

according to its maximum

surface temperature.

In the same manner, the

gases are classied on

the basis of the different

ignition temperatures.

Highest surface

temperature at the

apparatus:

Device groups

Group I comprises equipment which

is approved for operation in redamp

endangered mines.

Group II applies to the areas

above-ground, such as chemical/

petrochemical plants, reneries and

mills (dust). For the ignition protection

classes Intrinsic safety and

Flameproof enclosure, a further

classication is made into the groups

IIA to IIC due to the different ignition

energies of the different gases.

Design

tested

according to

Directive 94/9/EC

ADDITIONAL MARKING ACCORDING

TO DIRECTIVE 94/9/EC (ATEX 95)

MARKING ACCORDING TO EN 50014

INSPECTION AND MAINTENANCE

DIRECTIVE 1999/92/EC (MINIMUM REQUIREMENTS FOR IMPROVING THE SAFETY AND HEALTH PROTECTION OF WORKERS POTENTIALLY AT RISK FROM EXPLOSIVE ATMOSPHERES), ANNEX II:

All necessary measures must be taken to ensure that the workplace, work equipment and any associated connecting device []

are maintained and operated in such a way as to minimize the risks of an explosion [].

The IEC/EN 60079-17 and IEC/EN 61241-17 respectively assists on complying with this legal requirement by describing various items such as the basics

of inspection and maintenance with regard to documentation, qualication of personnel, extent and manner of inspections and schedules.

Important: the valid national and regional standards and regulations must be observed.

www.pepperl-fuchs.com

PEPPERL+FUCHS AND THE PROCESS AUTOMATION MARKET

Pepperl+Fuchs delivers electronic instrumentation for the automation market. With over 3,400 employees in more than 30 countries to design, produce and

distribute products, we are located where our customers need us. The Process Automation Division is the market leader for intrinsic safety interfaces and

hazardous location equipment. Our FieldConnex

Fieldbus Installation System provides highest exibility to modern process automation applications while the

BEBCO EPS Purge & Pressurization System offers protection for any type of instrumentation. This comprehensive range of explosion protection systems is

complemented by further leading-edge technologies such as EXTEC Visualization+Operation Systems, Separator Alarm Systems, Level and Corrosion Monitoring

devices and, of course, our world-wide support services. Pepperl+Fuchs is the recognized expert in our technologies and we have earned this reputation by

supplying the worlds largest process industry companies with the broadest line of proven components for a diverse range of applications.

ZONE 0 if present continuously or for long

periods or frequently.

ZONE 1 if likely to occur in normal

operation occasionally.

ZONE 2 if not likely to occur in normal

operation but, if it does occur, will

persist for a short period only.

ZONE 20 if present continuously, or for

long periods or frequently for

short periods.

ZONE 21 if likely to occur occasionally in

normal operation.

ZONE 22 if not likely to occur in normal

operation but, if it does occur, will

persist for a short period only.

CLASSIFICATION OF EXPLOSION HAZARDOUS ENVIRONMENTS

IEC/EN 60079-10

A place in which an explosive atmosphere consisting of a mixture with air of ammable substances in the form of gas, vapor or mist is

IEC/EN 61241-10

A place in which an explosive atmosphere, in the form of a cloud of combustible dust in air, is

MARKING AND MEANING OF ATEX REGULATIONS

CENELEC

marking

I

II A

II B

II C

Typical

gas

Methane

Propane

Ethylene

Hydrogen

Ignition

engergy

J

280

> 180

60...180

< 60

T 1 450 C

T 2 300 C

T 3 200 C

T 4 135 C

T 5 100 C

T 6 85 C

Are you interested in more detailled information on explosion protection?

Please dont hesitate to contact your local Pepperl+Fuchs representative and

ask for the comprehensive Explosion Protection Manual and Video-DVD.

The manual is also available as free download on www.pepperl-fuchs.com.

Category 1

Very high

safety measure

Sufcient safety

by means of

2 protective

measures /

2 faults

For use in Zone

Atmosphere

Category 2

High

safety measure

Sufcient safety

in the case of

frequently

occuring equip-

ment faults /

1 fault

For use in Zone

Atmosphere

Category 3

Normal

safety measure

Sufcient safety

during normal

operation

For use in Zone

Atmosphere

0 20

G D

1 21

G D

2 22

G D

G=Gas, D=Dust

For details on dust explosion protection please refer to the

Pepperl+Fuchs Explosion Protection Manual.

The employer or person responsible for safety shall classify places where explosive atmospheres may occur into zones in accordance with Annex I [...] and

[...] shall ensure that the minimum requirements laid down in Annex II are applied [...] to these zones.

Source: directive 1999/92/EC, article 7

2 G II

Types of Protection

General

requirements

EN 50014

IEC 60079-0

All

applications

EEx e

Increased

safety

Prevention

of sparks

and

tempera-

tures

1 or 2

EN 50019

IEC 60079-7

Branching and

connecting

boxes,

housings,

engines,

luminaires,

terminals

Marking code

Type of

Protection

Protection

principle

Application

in zone

CENELEC*

standard

IEC/EN

standard

Use

EEx d

Flameproof

enclosure

Transmission

of an explosion

to the outside

is excluded

1 or 2

EN 50018

IEC 60079-1

Control units,

controllers,

engines,

command &

monitoring

units, power

electronics

EEx p

Pressurized

apparatus

Ex atmosphere

is isolated from

the source

of ignition

1 or 2

EN 50016

IEC 60079-2***

Control

cabinets,

engines,

measurement

and analytical

equipment,

computers

EEx m

Encapsulation

Ex atmosphere

is isolated from

the source of

ignition

1 or 2

EN 50028

IEC 60079-18

Relay and

engine coils,

electronics,

solenoid

valves,

connecting

systems

EEx q

Powder

lling

Transmission

of an explosion

to the outside

is excluded

1 or 2

EN 50017

IEC 60079-5

Transformers,

relays,

condensors

EEx o

Oil

immersion

Ex atmosphere

is isolated from

the source of

ignition

1 or 2

EN 50015

IEC 60079-6

Transformers,

relays,

start-up

controls,

switching

devices

* Cenelec Standards in process of being transferred to IEC/EN Norms.

** Equipment, *** Systems, **** ia used in Zone 0,1 and 2, **** ib used in Zone 1 and 2, **** ic used in Zone 2

For non-electric explosion protection please refer to the Pepperl+Fuchs Explosion Protection Manual.

EEx i

Intrinsic

safety

Energy

restriction

of sparks

and

temperatures

0,1 or 2****

EN 50020

IEC 60079-11**

Measurement,

control and

regulation

technology,

instrumentation

EEx n

Type of

protection n

Different

protection

principles

for Zone 2

2

EN 50021

IEC 60079-15

All applications

for zone 2

nA Non-sparking

equipment

(rotating machines,

fuses, luminaries,

measuring instru-

ments and low

power equipment)

nC Sparking equip-

ment with hot

surfaces (closed

switchgear and

non-igitable

components,

hermetically sealed

equipment, tightly

sealed equipment)

nR Equipment

protected by a

restricted breathing

enclosure

nL Energy-limited

equipment and

electric circuits (to

be integrated into

EEx ic-Standard)

MARKING ACCORDING TO IEC/EN 60079

Device Group

I = Mining

Equipment

II = Surface

Industries

Meaning of optional brackets

[E Ex ib]

Corresponding electrical equipment is

located in the safe area.

Signal lines lead to the explosion

hazardous area.

S

u

b

je

c

t to

re

a

s

o

n

a

b

le

m

o

d

ific

a

tio

n

s

d

u

e

to

te

c

h

n

ic

a

l a

d

v

a

n

c

e

s

C

o

p

y

rig

h

t P

E

P

P

E

R

L

+

F

U

C

H

S

P

rin

te

d

in

G

e

rm

a

n

y

P

a

rt. N

o

. 2

0

4

8

0

6

0

9

/

0

7

0

0

Das könnte Ihnen auch gefallen

- Hazardous AREA ClassificationDokument10 SeitenHazardous AREA Classificationfarzam100% (1)

- A Guide To European (Eec) Certification For Hzardus AreasDokument5 SeitenA Guide To European (Eec) Certification For Hzardus AreasDeepak DinkarNoch keine Bewertungen

- Hazardous Area SH CourseDokument22 SeitenHazardous Area SH CourseafnakshNoch keine Bewertungen

- ATEX Explosion Protection and CE MarkingsDokument6 SeitenATEX Explosion Protection and CE MarkingsVASANHF1Noch keine Bewertungen

- Hazardous Areas Are Defined by Three Main CriteriaDokument10 SeitenHazardous Areas Are Defined by Three Main CriteriaviddyadrianNoch keine Bewertungen

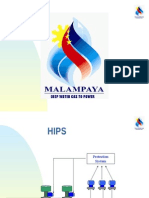

- HippsDokument31 SeitenHippsAjaykumar TiwariNoch keine Bewertungen

- Redapt Hazardous Area GuideDokument11 SeitenRedapt Hazardous Area Guidescribd8421Noch keine Bewertungen

- Hazardous Area ClassificationDokument0 SeitenHazardous Area ClassificationRoadieNoch keine Bewertungen

- CMP IECEx ATEX 01Dokument10 SeitenCMP IECEx ATEX 01rocket-vtNoch keine Bewertungen

- Safety Analysis Function Evaluation Chart: TBBM Tanjung Uban ProjectDokument3 SeitenSafety Analysis Function Evaluation Chart: TBBM Tanjung Uban ProjectAriz Joelee ArthaNoch keine Bewertungen

- Magnetic Flow Meter 1 - 6f9aDokument16 SeitenMagnetic Flow Meter 1 - 6f9aSilvaACANoch keine Bewertungen

- Fire ProtectionDokument14 SeitenFire ProtectionTeguh SetionoNoch keine Bewertungen

- OFFSHORE FUNCTIONAL SPECDokument35 SeitenOFFSHORE FUNCTIONAL SPECjtaylor2k1Noch keine Bewertungen

- Sil Assessment Study Basis and MethodologyDokument16 SeitenSil Assessment Study Basis and MethodologyShakeel AhmedNoch keine Bewertungen

- Hazardous Area Equipment Marking GuideDokument1 SeiteHazardous Area Equipment Marking GuideAgus RianNoch keine Bewertungen

- Hazardous Area To ATEX IECExDokument2 SeitenHazardous Area To ATEX IECExHakim YahiaouiNoch keine Bewertungen

- 143 344 Hipps-Ct224-E February 10 X StampaDokument8 Seiten143 344 Hipps-Ct224-E February 10 X StampaPramod AthiyarathuNoch keine Bewertungen

- International Reference Guide To Hazardous AreasDokument13 SeitenInternational Reference Guide To Hazardous Areasmalileo100% (1)

- Bluebook InsideDokument211 SeitenBluebook InsideNedumaran PalanisamyNoch keine Bewertungen

- Lcie Bureau Veritas Atex Poster PDFDokument1 SeiteLcie Bureau Veritas Atex Poster PDFAncaOniscuNoch keine Bewertungen

- Hipps - Azade To CeoDokument48 SeitenHipps - Azade To Ceoazade_qasemi100% (2)

- Gas Detection For Offshore ApplicationDokument11 SeitenGas Detection For Offshore ApplicationBryant Bruce Picon YangNoch keine Bewertungen

- 40-40I Flame DetectorDokument2 Seiten40-40I Flame DetectorSumeet Sisir SarkarNoch keine Bewertungen

- Integrated Control SystemsDokument8 SeitenIntegrated Control SystemsAnonymous FFMmIJyNoch keine Bewertungen

- Degrees of Protection Provided by Enclosures ThisDokument2 SeitenDegrees of Protection Provided by Enclosures ThisPemaWangchukNoch keine Bewertungen

- New Atex Directive: Lars EkströmDokument23 SeitenNew Atex Directive: Lars EkströmvalimironescuNoch keine Bewertungen

- Compex Manual Rev3 For Printing-1Dokument262 SeitenCompex Manual Rev3 For Printing-1aryo ganda pakpahanNoch keine Bewertungen

- Safety Analysis Function Evaluation (S.A.F.E.) Chart: Project Document No. RevisionDokument19 SeitenSafety Analysis Function Evaluation (S.A.F.E.) Chart: Project Document No. RevisionCandraNoch keine Bewertungen

- Treon Introduction - Industrial NodeDokument11 SeitenTreon Introduction - Industrial NodeAibek AltynbekNoch keine Bewertungen

- SS SamplingValveBrochureDokument12 SeitenSS SamplingValveBrochureJOBRAN SofienNoch keine Bewertungen

- Hazardous Areas Are Defined by Three Main CriteriaDokument5 SeitenHazardous Areas Are Defined by Three Main Criteriaswarm62Noch keine Bewertungen

- PVC - Explosion Caused by Flashing Liquid in A Process VesselDokument8 SeitenPVC - Explosion Caused by Flashing Liquid in A Process Vesselwiboonwi100% (1)

- IP-19 Fire Precautions at Petroleum Refineries and Buk Storage InstallationsDokument166 SeitenIP-19 Fire Precautions at Petroleum Refineries and Buk Storage InstallationsPetrNoch keine Bewertungen

- Hazardous Area Classification GuideDokument9 SeitenHazardous Area Classification GuideVraja KisoriNoch keine Bewertungen

- Draeger Flame 2500 3IR DatasheetDokument10 SeitenDraeger Flame 2500 3IR DatasheetCobra_007Noch keine Bewertungen

- Section 1 Explosive Atmospheres 07-2017 Rev 3Dokument17 SeitenSection 1 Explosive Atmospheres 07-2017 Rev 3kingmltNoch keine Bewertungen

- Iec60079 18 2009Dokument35 SeitenIec60079 18 2009Victor Castellanos AlegriaNoch keine Bewertungen

- Offshore Containers: Standard For Certification No. 2.7-1Dokument30 SeitenOffshore Containers: Standard For Certification No. 2.7-1Teknik MarinaNoch keine Bewertungen

- Buckling Pin Pressure Relief Technology PDFDokument12 SeitenBuckling Pin Pressure Relief Technology PDFfkboulosNoch keine Bewertungen

- Hazardous Area Classification PONSL RevisedDokument106 SeitenHazardous Area Classification PONSL RevisedRestoration2010100% (1)

- Dr. Asit Patra-Dmi - CraDokument53 SeitenDr. Asit Patra-Dmi - CraWRGWSRNoch keine Bewertungen

- Iec Hazardous Locations Certification DocumentsDokument2 SeitenIec Hazardous Locations Certification DocumentsbubuluqNoch keine Bewertungen

- HIPPSDokument21 SeitenHIPPSAhmed Mohamed Khalil100% (2)

- Understanding Hazardous Locations: An Ebook By: Pepperl+Fuchs, The Intrinsic Safety ExpertsDokument19 SeitenUnderstanding Hazardous Locations: An Ebook By: Pepperl+Fuchs, The Intrinsic Safety Experts04422236558Noch keine Bewertungen

- Safety Interlocks in Crude Heaters Using PLC: Cochin University of Science and Technology KOCHI - 682 022Dokument75 SeitenSafety Interlocks in Crude Heaters Using PLC: Cochin University of Science and Technology KOCHI - 682 022Niju ShamilNoch keine Bewertungen

- BAHREGAN CRUDE OIL STORAGEDokument9 SeitenBAHREGAN CRUDE OIL STORAGEFatholla SalehiNoch keine Bewertungen

- Fisher 2500 249 Pneumatic Controllers Transmitters en 127050Dokument16 SeitenFisher 2500 249 Pneumatic Controllers Transmitters en 127050GOKUL PRASADNoch keine Bewertungen

- Safety Instrumented Systems: Angela E. Summers, PH.D., P.E. SIS-TECH Solutions, LLCDokument19 SeitenSafety Instrumented Systems: Angela E. Summers, PH.D., P.E. SIS-TECH Solutions, LLCsayedNoch keine Bewertungen

- FL4000H Multi-Spectrum Infrared Flame DetectorDokument2 SeitenFL4000H Multi-Spectrum Infrared Flame DetectorRomdhoni Widyo BaskoroNoch keine Bewertungen

- SRSDokument28 SeitenSRSChristopher WeilNoch keine Bewertungen

- Denver Fire Alarm Test Prep: Initiating Devices and Notification AppliancesDokument39 SeitenDenver Fire Alarm Test Prep: Initiating Devices and Notification AppliancesawadalmekawyNoch keine Bewertungen

- Dust Explosion Protection Using Flameless Venting - FIKE EXEMPLOSDokument18 SeitenDust Explosion Protection Using Flameless Venting - FIKE EXEMPLOSPedro Ceriolli100% (1)

- Appendix A Environmental Identification (ENVID) SummaryDokument14 SeitenAppendix A Environmental Identification (ENVID) SummaryJag KhadseNoch keine Bewertungen

- CenpesDokument20 SeitenCenpesnskumarmNoch keine Bewertungen

- Major Accidents to the Environment: A Practical Guide to the Seveso II-Directive and COMAH RegulationsVon EverandMajor Accidents to the Environment: A Practical Guide to the Seveso II-Directive and COMAH RegulationsNoch keine Bewertungen

- UMS-IMC-F07-0011 - Terms of Reference (ToR) For SIL ClassificationDokument20 SeitenUMS-IMC-F07-0011 - Terms of Reference (ToR) For SIL ClassificationRichard Ikwubute100% (1)

- Cooper - Intrinsic Safety GuideDokument20 SeitenCooper - Intrinsic Safety Guidetkdrt2166100% (2)

- ATEX Poster ENG PDFDokument1 SeiteATEX Poster ENG PDFCvitaCvitićNoch keine Bewertungen

- ATEX PosterDokument1 SeiteATEX PosterJuan Ramon RodriguezNoch keine Bewertungen

- ATEX ExplainedDokument1 SeiteATEX ExplainedDonal O'SullivanNoch keine Bewertungen

- Multiline CTDokument3 SeitenMultiline CTact_rahul53Noch keine Bewertungen

- Resume Electrical EngineerDokument6 SeitenResume Electrical Engineeract_rahul5350% (2)

- Nec Cable Bending RadiusDokument3 SeitenNec Cable Bending Radiusact_rahul53Noch keine Bewertungen

- Sheet No. Component /detail DescriptionDokument11 SeitenSheet No. Component /detail Descriptionact_rahul53Noch keine Bewertungen

- Tech GuideDokument153 SeitenTech Guideact_rahul53Noch keine Bewertungen

- Load Flow NotesDokument20 SeitenLoad Flow NotesMike CerreroNoch keine Bewertungen

- ECE 261 Power Flow Analysis Step-by-Step GuideDokument6 SeitenECE 261 Power Flow Analysis Step-by-Step GuideAhmad Fateh Mohamad NorNoch keine Bewertungen

- 1-IEC List 2014Dokument120 Seiten1-IEC List 2014act_rahul53Noch keine Bewertungen

- Cable Technical DataDokument8 SeitenCable Technical Dataact_rahul53Noch keine Bewertungen

- Dependent PassDokument6 SeitenDependent Passact_rahul53Noch keine Bewertungen

- Mom WP Med RPTDokument1 SeiteMom WP Med RPTravi kumar v100% (1)

- DISDokument4 SeitenDISact_rahul53Noch keine Bewertungen

- Transformer Data SheetDokument5 SeitenTransformer Data Sheetact_rahul53Noch keine Bewertungen

- Front PageDokument1 SeiteFront Pageact_rahul53Noch keine Bewertungen

- Sample Calculation Forpower Cable Size (Y-D)Dokument2 SeitenSample Calculation Forpower Cable Size (Y-D)act_rahul53Noch keine Bewertungen

- Product Data Sheet: BLITZDUCTOR® XT - Protection Modules BXT ML4 BD 24 (920 344)Dokument1 SeiteProduct Data Sheet: BLITZDUCTOR® XT - Protection Modules BXT ML4 BD 24 (920 344)Alex RivasNoch keine Bewertungen

- Transmisores de Presion Series 266gsh y Ash AbbDokument28 SeitenTransmisores de Presion Series 266gsh y Ash AbbmelisaBNoch keine Bewertungen

- PT205 CombustiblesDokument2 SeitenPT205 Combustiblescecilia aguilarNoch keine Bewertungen

- Ts 613Dokument43 SeitenTs 613pwkannonNoch keine Bewertungen

- Eletrostatica Big BagsDokument3 SeitenEletrostatica Big BagsNicolas150956Noch keine Bewertungen

- Waring Lab Blender - 120volt - Lab - CatalogDokument12 SeitenWaring Lab Blender - 120volt - Lab - CatalogCarlos PereaNoch keine Bewertungen

- Development of Combustible GasDokument10 SeitenDevelopment of Combustible Gasaugur886Noch keine Bewertungen

- 1756 Pa75 PDFDokument24 Seiten1756 Pa75 PDFDiogo FiaesNoch keine Bewertungen

- Levelflex M FMP40: Operating InstructionsDokument92 SeitenLevelflex M FMP40: Operating Instructionsabuzer1981Noch keine Bewertungen

- Technor TNCN JunctionboxDokument8 SeitenTechnor TNCN Junctionboxtakyaw9Noch keine Bewertungen

- TZIDC, TZIDC-110, TZIDC-120: Digital PositionerDokument72 SeitenTZIDC, TZIDC-110, TZIDC-120: Digital PositionerMaria Regina Reyes100% (1)

- NI cRIO-9072/9073/9074: User Manual and SpecificationsDokument26 SeitenNI cRIO-9072/9073/9074: User Manual and SpecificationselpelotudoNoch keine Bewertungen

- AITE FittingsDokument31 SeitenAITE FittingsZubeer AhamedNoch keine Bewertungen

- ABB Certificate of Conformity Abb Group of Conformity Awarded To Bureau VeritasDokument15 SeitenABB Certificate of Conformity Abb Group of Conformity Awarded To Bureau VeritasposmarichardNoch keine Bewertungen

- Datasheet Equipment PDFDokument66 SeitenDatasheet Equipment PDFBach Nguyen VanNoch keine Bewertungen

- Novocranes Electric Chain HoistDokument20 SeitenNovocranes Electric Chain HoistFiroj Alam0% (1)

- Standart Instrument Proses PDFDokument9 SeitenStandart Instrument Proses PDFCak NhassNoch keine Bewertungen

- Catalogo de Motores ToshibaDokument228 SeitenCatalogo de Motores ToshibaemersonNoch keine Bewertungen

- Catalogo AntiexplosivoDokument166 SeitenCatalogo AntiexplosivoNahuel GonzalezNoch keine Bewertungen

- JDN Air Hoists ProfiDokument8 SeitenJDN Air Hoists ProfiRichard EVNoch keine Bewertungen

- D - Type: Lift Control SystemDokument87 SeitenD - Type: Lift Control Systemمحمدحماد100% (3)

- Offer 1055R2 Detroit 8v92ta Engine Kit Zone 2Dokument4 SeitenOffer 1055R2 Detroit 8v92ta Engine Kit Zone 2Ilham Yoga SaputraNoch keine Bewertungen

- Gs01c22b01-00e (32) Eja110Dokument9 SeitenGs01c22b01-00e (32) Eja110Nguyen ThuongNoch keine Bewertungen

- Specifications of OHBF51D PDFDokument7 SeitenSpecifications of OHBF51D PDFJawad AziziNoch keine Bewertungen

- Moisture Analyzer TroubleshootingDokument36 SeitenMoisture Analyzer TroubleshootingKim BaoNoch keine Bewertungen

- Installation Manual VITO IP Upgrade Kit: August 2013 Part No. 4416656 Rev. 2Dokument16 SeitenInstallation Manual VITO IP Upgrade Kit: August 2013 Part No. 4416656 Rev. 2Thái NgọcNoch keine Bewertungen

- EC 350 User Manual: Release R100.1Dokument194 SeitenEC 350 User Manual: Release R100.1Kashif VohraNoch keine Bewertungen

- Ecm3 Electronic Fuel Injection Control: Installation ManualDokument104 SeitenEcm3 Electronic Fuel Injection Control: Installation ManualMohamed ElsayedNoch keine Bewertungen

- ISCO Fusion ManualDokument96 SeitenISCO Fusion ManualJoel CristobalNoch keine Bewertungen

- Coordinating with Algerian Regulatory AuthoritiesDokument80 SeitenCoordinating with Algerian Regulatory AuthoritiesHussein Adnan Fneish100% (3)