Beruflich Dokumente

Kultur Dokumente

Report of IR Music Transmitter Receiver

Hochgeladen von

Suraj DuhanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Report of IR Music Transmitter Receiver

Hochgeladen von

Suraj DuhanCopyright:

Verfügbare Formate

1

CONTENTS

S.no CHAPTER PAGENO

1. CHAPTER: 1 Introduction 3

1.1 Description of IR Music Transmitter & Receiver 4

1.2 Specifications 4-5

2. CHAPTER: 2 Fundamentals 6

2.1 How IR Music Transmitter & Receiver Works 7

2.2 List of Figures 8

2.2.1 Circuit Diagram of IR Music Transmitter & Receiver 8

2.2.2 PCB Layout of IR Music Transmitter & Receiver 9

2.2.3 Block Diagram of IR Music Transmitter & Receiver 10-11

2.2.4 Description of the Project 12-13

2.3 List of Components 14

2.4 Datasheet 15

2.4.1 npn general purpose amplifier 15-16

2.4.2 pnp General purpose transistor 17

2.4.3 IC 741 Operational amplifier 17-18

2.4.4 IC LM386 19-21

2.5 PCB Manufacturing process 22

2.6 PCB Designing 23-27

3. CHAPTER :3 28

3.1 Result 29

3.2 Conclusion 30

3.3 Future Enhancement 31

3.4 Applications 32

3.5 Advantages & Disadvantages 33

3.6 References 34

2

LIST OF FIGURES :

FIGURES Page No

Circuit Diagram

Transmitter 8

Receiver 8

PCB layout

Transmitter 9

Receiver 9

Block Diagram

Transmitter 10

Receiver 10

3

CHAPTER 1

INTRODUCTION

4

INTRODUCTION

1.1 DESCRIPTION OF IR MUSIC TRANSMITTER & RECEIVER

The main idea behind the project is to generate musical notes by infrared

radiations. The infrared radiations are transmitted and received by IR

LED and Phototransistor respectively.

This project emphasizes the way by which music is generated and driven

by IR rays. This circuit uses a popular melody generator IC UM66 that

can continuously generate musical notes. The melody produced is heard

through the receivers loudspeaker.

For maximum sound transmission the IR LEDs should be oriented

towards IR phototransistor.

It can be used in wireless music systems, mobile gadgets and cc cameras.

1.2 Specifications :

1.2(a) Infrared (IR) LED - As normal PN junction diode provide current

as the output when subjected to forward bias, in the same way an IR led

gives IR radiation at its output in forward bias. Infrared light is

electromagnetic radiation with a wavelength longer than that of visible

light, measured from the nominal edge of visible red light at 0.7

micrometers, and extending conventionally to 300 micrometers. These

wavelengths correspond to a frequency range of approximately 430Hz to

1THz, and include most of the thermal radiation emitted by objects near

room temperature. Microscopically, IR light is typically emitted or

absorbed by molecules when they change their rotational or irrational

movements.

5

1.2(b) Photo Diode A photodiode is a type of photo detector, capable

of converting light into either current or voltage, depending upon the

mode of operation. Photodiode works on the principle of

photoconductivity. When light is absorbed by a semiconductor material,

the number of free electrons and electrons holes changes and raises its

electrical conductivity, this phenomenon is called photoconductivity. To

cause excitation, the light that strikes the semiconductor must have

enough energy to raise electrons across the band gap Photoconductivity

may also be defined as an electrical property of Light Emitting Diode

(LED) which is the fact that a LED produces a voltage difference across

its leads when it is subjected to light, as if it was in photo-cell, but with

much lower output current. In other words, the voltage generated by the

LED cannot be, in any way, used to generate electrical power from the

output voltage, it can barely be detected. This is why we used an Op-Amp

(operational Amplifier) to accurately detect very small voltage changes.

Photoconductivity is a phenomenon in which a material becomes more

electrically conductive due to the absorption of electromagnetic radiation

such as visible light, ultraviolet light, infrared light, or gamma radiation.

Photodiodes are similar to regular semiconductor diodes except that they

may be either exposed to (detect UV or X-rays) or an optical fiber

connection to allow light to reach the sensitive part of the device.

6

CHAPTER 2

FUNDAMENTALS

7

2.1 HOW IR MUSIC TRANSMITTER & RECEIVER WORKS

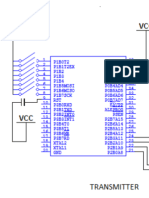

TRANSMITTER

The IR music transmitter works off a 9V battery. Figure (1) shows the

circuit of the IR music Transmitter. It uses popular melody generator IC

U M-66 (IC1) that can continuously generate musical tones. The output

of IC1 is fed to the IR driver stage (Built across the transistors T1 and T2)

to get the maximum range. Here the red LED (LED1) flickers according

to t he musical tones generated by UM66 IC, indicating modulation. IR

LED2 and LED3 are infrared transmitting LEDs. For maximum sound

transmission these should be oriented towards IR phototransistor L14F1

(T3).

RECEIVER

The IR music receiver uses popular op-amp IC A741 and audio-

frequency amplifier IC LM386 along with phototransistor L14F1 and

some discrete components(Fig. 2).The melody generated by IC UM66 is

transmitted through IR LEDs, received by phototransistor T3 and fed to

pin 2 of IC A741 (IC2). Its gain can be varied using pot meter VR1. The

output of IC A741 is fed to IC LM386 (IC3) via capacitor C5 and pot

meter V- R 2 .The melody produced is heard through the receivers

loudspeaker. Pot meter VR2 is used to control the volume of Loudspeaker

LS1 (8-ohm, 1W).

8

2.2 LIST OF FIGURES :

2.2.1. Circuit Diagram:

[a] Transmitter:

Fig: 1

[b] Receiver:

Fig: 2

9

2.2.2. PCB Layout:

[a] Transmitter:

Fig: 3

[b] Receiver:

Fig: 4

10

2.2.3. Block Diagram:

[a] Transmitter:

Fig: 5

+9v

3.3 v

regulator

Melody

Generator

Transistor

Driver

Stage - 1

Transistor

Driver

Stage - 2

IR LED

LED Music

Flicker

Indicator

11

[b] Receiver:

Fig: 6

+9V

Photo

Transistor

Audio

Amplifier

stage-1

Audio

Amplifier

stage-2

Loud

Speaker

Gain

Control

Gain

Control

12

2.2.4 Description of the Prjoect

Using this circuit, audio musical notes can be generated and can be heard up

to a distance of 10 meters. The receiver can be placed at a maximum

distance of 1 meter from the transmitter with our any considerable noise

interference. The circuits of transmitter and receiver are quite simple and

can be placed and carried any where easily. The small apparatus provided

with the infrared communication function is in many cases operated by a

battery incorporated inside so that it is convenient when a user carries it

during movement, and it is preferable that power consumption be minimized

also to lengthen the continuous operation possible time of IR emission is

optimized. Here there is no use of any modulation technique when working

with the IT rays. Hence there is no use of necessity of carrier generation.

This makes the transmitter and receiver designs much simpler. However the

communication distance can be improved by using Far IR LEDs. The range

of communication can be increased to about 250 meters by using far IR

LEDs. In the apparatus provided with a conventional communication

function, however, the infrared light with a constant intensity is constantly

radiated regardless of the communication distance. This project emphasizes

the way by which music is generated and driven by IR rays and gives an

explanation to the one of the methods of receiving IR rays without

considerable noise interference.

The circuit can be divided into two parts: IR music transmitter and receiver.

The IR music transmitter works off a 9V battery, while the IR music

receiver works off regulated 9V to 12V. Fig. 1.1 shows the circuit of the IR

music transmitter. It uses popular melody generator IC UM66 (IC1) that can

continuously generate musical tones. The output of IC1 is fed to the IR

driver stage (built across the transistors T1 and T2) to get the maximum

range. Here the red LED (LED1) flickers according to the musical tones

generated by UM66 IC, indicating modulation. IR LED2 and LED3 are

infrared transmitting LEDs. For maximum sound transmission these should

be oriented towards IR phototransistor L14F1 (T3). The IR music receiver

uses popular op-amp IC A741 and audio-frequency amplifier IC LM386

along with phototransistor L14F1 and some discrete components. The

melody generated by IC UM66 is transmitted through IR LEDs, received by

phototransistor T3 and fed to pin2 of IC A741 (IC2). Its gain can be varied

using potential meter VR1. The output of IC A741 is fed to IC LM386

13

(IC3) via capacitor C5 and potential meter VR2.The melody produced is

heard through the receivers loudspeaker. Potential meter VR2 is used to

control the volume of loudspeaker LS1 (8-ohm, 1W). Switching off the

power supply stops melody generation.

The electrical signal from your music player is converted into an invisible

infrared light signal by the infrared light emitting diode (IR LED) in the

transmitter circuit. To transmit this over a longer distance, a brighter IR

LED is needed or an invisible light is to be focused using lens. The invisible

infrared light signal must hit the photo transistor in the receiver. The photo

transistor in the receiver converts this invisible infrared light signal into an

electrical signal. Then, the amplifier in the receiver circuit takes this

electrical signal and makes it larger using energy from the battery. Finally,

this larger electrical signal drives the speaker which turns electrical energy

into sound energy.

14

2.3 LIST OF COMPONENTS

S.No. Name Of The Component Quantity

1. IC UM-66(IC1) 1

2. IC LM741 (IC2) 1

3. IC LM386 (IC3) 1

4. RED LED(1) 1

5. IR LED(2 & 3) 2

6. Resistance R1 & R11 (1 K) 2

7. Resistance R2(4.7 K) 1

8. Resistance R3(22 K) 1

9. Resistance R4(82 ohm) 1

10. Resistance R5 & R12(10 ohm) 2

11. Resistance R6 & R7(10 K) 2

12. Resistance R8 & R13(15 K) 2

13. Resistance R9(100K) 1

14. Resistance R10(680 ohm) 1

15. Capacitor C1(1uF,16V) 1

16. Capacitor C2,C4,C8 & C10(220 uF, 25V) 4

17. Capacitor C3,C5,C7 & C9(0.1 uF) 4

18. Capacitor C6(10 uF,16V) 1

19. Transistor BC547(T1) & SK140/BD140(T2) 2

20. IR Phototransistor L14F1(T3) 1

21. Zener diode 3.3V 1/4W 2

22.

23.

24.

Speaker (8 ohm, 1W)

Preset VR1 (1M) & VR2 (10K)

9V battery

1

2

2

15

2.4 DATASHEET

2.4.1 NPN General Purpose Amplifier

Absolute Maximum Ratings TA=25C :-

Symbo

l

Par

ame

ter

Value Units

VCEO

Collector-Emitter Voltage 3

0

V

VCES

Collector-Base Voltage 3

0

V

V

EBO Emitter-Base Voltage 5

.

0

V

IC Collector Current - Continuous 5

0

0

m

A

TJ,

Tstg

Operating and Storage Junction

Temperature Range

-55 to

+150

C

NOTES:

1) These ratings are based on a maximum junction temperature of 150 degrees C.

2) These are steady state limits. The factory should be consulted on applications

involving pulsed or low duty cycle operations.

Thermal Characteristics TA=25C :-

Symbol Characteristic M

ax

Units

BC548 / A / B /

C

PD Total Device Dissipation

Derate above 25 C

6

2

5

5

.

0

m

W

mW

/ C

R JC

Thermal Resistance, Junction to

Case

8

3.

3

C/

W

R JA

Thermal Resistance, Junction to

Ambient

2

0

0

C/

W

Electrical Characteristics TA = 25C :-

16

OFF CHARACTERISTICS

V(BR)CE

O

Collector-Emitter Breakdown

Voltage

IC = 10 mA, IB = 0 30 V

V(BR)CB

O

Collector-Base Breakdown

Voltage

IC = 10 A, IE = 0 30 V

V(BR)CE

S

Collector-Base Breakdown

Voltage

IC = 10 A, IE = 0 30 V

V(BR)EB

O

Emitter-Base Breakdown

Voltage

IE = 10 A, IC = 0 5.0 V

ICBO Collector Cutoff Current VCB = 30 V, IE = 0

VCB = 30 V, IE = 0, TA

= +150 C

15

5.0

nA

A

ON CHARACTERISTICS

hFE DC Current Gain VCE = 5.0 V, IC = 2.0

mA 548

548A

548B

548C

110

110

200

420

800

220

450

800

VCE(sat) Collector-Emitter Saturation

Voltage

IC = 10 mA, IB = 0.5

mA IC = 100 mA, IB =

5.0 mA

0.25

0.60

V

V

VBE(on) Base-Emitter On Voltage VCE = 5.0 V, IC = 2.0

mA VCE = 5.0 V, IC =

10 mA

0.58 0.70

0.77

V

V

Symbol Parameter Test Conditions Min Max Units

17

2.4.2 PNP General Purpose Transistor

General Description:-

FEATURES :-

1. Low current (max. 100 mA).

2. Low voltage (max. 65 V).

DESCRIPTION :-

PNP transistor in a TO-92; SOT54 plastic package.

NPN complements: BC546 and BC547.

2.4.3 LM741 Operational Amplifier

General Description

The LM741 series are general purpose operational amplifiers which

feature improved performance over industry standards like the LM709.

They are direct, plug-in replacements for the 709C, LM201, MC1439 and

748 in most applications. The amplifiers offer many features which make

their application nearly foolproof: overload protection on the input and

output, no latch-up when the common mode range is exceeded, as well as

freedom from oscillations. The LM741C is identical to the

LM741/LM741A except that the LM741C has their performance

guaranteed over a 0C to+70C temperature range, instead of 55C to

+125C.

Electrical Characteristics

Note 1: Absolute Maximum Ratings indicate limits beyond which

damage to the device may occur. Operating Ratings indicate conditions

for which the device is functional, but do not guarantee specific

performance limits.

18

NOTE 2: For operation at elevated temperatures, these devices must be

derated based on thermal resistance, and Tj max. (Listed under Absolute

Maximum

Ratings). Tj = TA + (jA PD).

Note3: For supply voltages less than 15V, the absolute maximum input

Voltage is equal to the supply voltage.

Note 4: Unless otherwise specified, these specifications apply for VS =

LM741C/LM741E,

Note 5: Calculated value from: BW (MHz) = 0.35/Rise Time(s).

Connection Diagrams

Metal Can Package Dual-In-Line or S.O. Package

Thermal

Resistance

Cerdip (J) DIP (N) HO8 (H) SO-8 (M)

jA (Junction

to Ambient)

100C/W 100C/W 170C/W 195C/W

jC (Junction

to Case)

N/A N/A 25C/W N/A

19

2.4.4 LM386 Low Voltage Audio Power Amplifier

General Description

The LM386 is a power amplifier designed for use in low voltage

consumer applications. The gain is internally set to 20 to keep external

part count low, but the addition of an external resistor and capacitor

between pins 1 and 8 will increase the gain to any value from20 to 200.

The inputs are ground referenced while the output automatically biases to

one-half the supply voltage. The quiescent power drain is only 24 mill

watts when operating from a 6 volt supply, making the LM386 ideal for

battery operation.

Features

Battery operation

Minimum external parts

Wide supply voltage range: 4V12V or 5V18V

Low quiescent current drain: 4mA

Voltage gains from 20 to 200

Ground referenced input

Self-centering output quiescent voltage

Low distortion: 0.2% (AV = 20, VS = 6V, RL = 8W, PO =

125mW, f = 1kHz)

Available in 8 pin MSOP package

Applications

AM-FM radio amplifiers

Portable tape player amplifiers

Intercoms

TV sound systems

Line drivers

Ultrasonic drivers

Small servo drivers

Power converters

20

Parameter Conditions Min Typ Max Units

OperatingSupply Voltage

(VS)

LM386N1,3,LM386M1,

LM386MM

1LM386N-4

4

5

12

18

V

V

Quiescent Current (IQ) VS = 6V, VIN = 0 4 8 mA

Output Power (POUT)

LM386N-1, LM386M-1,

LM386MM-1LM386N-

3LM386N-4

VS = 6V,

RL=8 =10%

VS = 9V, RL =

THD =10%,VS =

16V, RL = 32 ,

THD = 10%

250

500

700

325

700

1000

mW

mW

mW

Voltage Gain (AV) VS = 6V, f = 1 kHz

10 F from Pin1to8

26 dB

Bandwidth (BW) VS = 6V, Pins 1 and

8 Open

300 khz

Total

HarmonicDistortion(THD)

VS = 6V, RL =

8W,POUT=125mW

f = 1 kHz, Pins1and 8

Open

0.2 %

Power Supply Rejection

Ratio (PSRR)

Input Resistance (RIN)

Input Bias Current

(IBIAS) VS = 6V, Pins 2

and 3 Open

VS = 6V, f = 1

kHz,CBYPASS=10

F Pins 1 and 8

Open, Referred to

Output

50

50

250

dB

kW

nA

Absolute Maximum Ratings

Note 1: All voltages are measured with respect to the ground pin, unless otherwise

specified.

Note 2: Absolute Maximum Ratings indicate limits beyond which damage to the

device may occur. OperatingRatingsindicateconditions,for which the device is

functional, but do not guarantee specific performance limits. Electrical Characteristics

state DC and AC electrical specifications under particular test conditions which

guarantee specific performance limits. This assumes that the device is within the

Operating Ratings. Specifications are not guaranteed for parameters where no limit is

given, however, the typical value is a good indication of device performance.

Note 3: For operation in ambient temperatures above 25C, the device must be

derated based on a 150C maximum junction temperature and 1) a thermal resistance

21

of 107C/W junction to ambient for the dual-in-line package and 2) a thermal

resistance of 170C/W for the small outline package

Top View

LM 386 PIN OUT

LM 386 Audio Amplifier

22

2.5 PCB manufacturing process:

2.5(a) Design Specification

It is an important process in the fabrication of electronic equipment. The design of

PCBs (Printed circuit board) depends on circuit requirements like noise immunity,

working frequency and voltage levels etc. High power PCBs requires a special design

strategy. The fortification process to the printed circuit board will determine to a large

extent the price and reliability of the equipment. A common target aimed is the

fabrication of small series of small series of highly reliable professional quality PCBs

with low investment.

The layout of a PCB has to incorporate all the information of the board before one can

go on the artwork preparation. This means that a concept which clearly defines all the

details of the circuit and partly defines the final equipment is prerequisite before the

actual layout can start.

2.5(b) Board types

The two most popular PCB types are:

1.] Single Sided Boards ~

The single sided PCBs are mostly used in entertainment electronics where

manufacturing costs have to be kept at a minimum. However in industrial electronics

cost factors cannot be neglected and single sided boards should be used wherever a

particular circuit can be accommodated on such boards.

2.] Double Sided Boards ~

Double sided PCBs can be made with or without plated through holes. The production

of boards with plated through holes is fairly expensive. Therefore plated through hole

boards are only chosen where the circuit complexities and density of components does

not leave any other choice.

23

2.6 PCB Designing:

After the accomplishment of circuit designing, next step that follows is PCB making.

Among the various discoveries and development to bring electronics to the level it has

reached until now, PCB has definitely contributed in a significant manner as a means

to inter-connect electronic components. The design of PCB can be considered as the

last step in the electronic circuit design as well as the first major step in the production

of PCBs. Intimate knowledge of all implication is required. The designing of PCB

consist of designing of layout followed by generation or preparation of artwork. The

layout therefore includes all the relevant aspects and details of the PCB design. The

various steps involved in PCB making are as follows:

a) Layout Planning

b) Component Hole

c) Graphic Layout

d) Etching

e) Drilling

f) Component Mounting

g) Soldering

2.6(a) Layout Planning

The layout of PCB must incorporate all the information that clearly defines all details

of the circuit and partly of the final equipment. A detail circuit diagram is an

important prerequisite. Layout planning takes care of component layout as well as

their interconnection. The layout should be developed in the direction of signal flow

as far as possible, so that one achieves shortest possible interconnections. Among the

components, the larger ones are placed first and the space between is filled with

smaller ones. Components requiring input/output connections come near the

connectors. In designing the interconnection, which are usually done with pencil,

actual space requirement in the artwork must be considered. The end of the layout

designing is the pencil sketched component and conductor drawing, which is called

layout sketch. Beside the component outline, component holes and interconnecting

pattern, the layout sketch should also include information on:

24

2.6(b) Component holes

Usually in a given PCB cost of the holes required is of one particular diameter and

this diameter is mentioned once in the layout sketch. Holes of different diameter are

shown with a code in the actual layout sketch. The code must explain outside the

layout area. For e.g. we have used two kinds of holes are of 0.8mm and 1.1mm.0.8

mm for all the components except jumpers and IC base. For jumpers and IC based we

drilled 1mm holes. Changing of our track from large to small and then back to large

again is known as necking. This is often required when we have to go between IC

or component pads. This allows having nice big low impedance tracks, but still has

the flexibility of route between tight spots.

In practice, the current flowing through it and the maximum temperature rise of the

track that can be tolerated will dictate track width. Every track will have a certain

amount of resistance, so the track will dissipate heat just like a resistor. The wider the

track, the lower is the resistance.

2.6(c) Graphic Layout

The Graphic layout or the Artwork is the basic circuit design that is required on the

PCB. The circuit connections and the components are together setup in a particular

design which is printed on the Circuit Board.

2.6(d) Etching (Patterning)

Copper over the entire substrate, sometimes on both sides, (creating a blank PCB)

then removing unwanted copper after applying a temporary mask (e.g. by chemical

etching), leaving only the desired copper traces. A few PCBs are made by adding

traces to the bare substrate (or a substrate with a very thin layer of copper) usually by

a complex process of multiple electroplating steps.

1.] Chemical etching

Inexpensive ingredients, and with proper use and maintenance, literally never wears

out. The real beauty of this mixture of hydrogen peroxide, sulphuric acid, copper

sulphate and organic stabilizers is that excess copper can be removed by simple

precipitation, after which, the bath is ready to consume more copper. In addition,

25

during operation, the etch ant is self agitating. The bubbles and heat evolve during

etching, so thoroughly stir up the bath the etch ant works almost as well in a simple

dip (immersion) tank as it does in a far more expensive spray etcher. Screen printing

ink is used according to the type of etch ant used. For acid etching, an acid resistive

ink is used, which is soluble in alkaline solution

2.6(e) Drilling

Drilling can be done using a CNC machine or manually.

1.] Manual Drilling ~

With the laminate stack formatted as detailed above, manual drilling is a

straightforward, if somewhat mind-numbing process. Items to consider include: When

using a conventional drill press, hole placement accuracy can be improved and drill

breakage minimized through the use of a sensitive drilling or finger chuck. Small

format, precision high-speed drill presses, ideal for PCB fabrication, is also available

from a number of sources.

If available, position a work lamp on a flexible mount as close to the work surface as

possible. Minimize burr formation, and outlast HSS bits almost 10 to 1. The carbide

drills are easier to break and must be handled carefully. Always use drill bits that have

been fitted with depth setting rings. This will allow you to set the plunge depth stop

on your drill press to a single value that will work for all bit diameters.

2.] Through-holes ~

Load the largest diameter bit to be used into the drill chuck, making sure that the

depth ring is pressed firmly against the ends of the chuck jaws when they are fully

tightened. Using a piece of scrap backing materials as a gauge, adjust the spindle

travel stop on your drill press to a depth that insures that the entire tip of the drill bit

penetrates at least half of the materials thickness. Under no circumstances allow a

PCB drill bit to drill into the table of your drill press. PCB bits are specially designed

to drill copper clad and will shatter if plunged into cast iron, steel, or aluminum.

26

Starting with largest diameter drill bit, drill all the through holes, stopping

periodically to insure that the drill bit has not snapped off and that the spindle travel

stop has not slipped.

As you drill each hole size check off that diameter on the drilling chart. This is a good

bookkeeping technique that will help you keep track of your progress and insure that

no holes size is missed.

Hold the stack up to the light for visual inspection. Ascertain that all of the holes have

been drilled through and that none are blocked by drill debris. If some debris is seen,

remove by carefully pushing a smaller diameter bit through the hole.

2.6(f) Component Mounting

From the greatest variety of electronic components available, which runs into

thousands of different types 1, is often a perplexing task to know which is right for a

given job. There could be damage such as hairline crack on PCB. If there are, then

they can be repaired by soldering a short link of bare copper wire over the affected

part. This holds the component in position ready for soldering. Some components will

be considerably larger. So it is best to start mounting the smallest first and progressing

through the largest. Next will be probably the resistor, small signal diodes or other

similar size components. Some capacitors are also very small but it would be best to

fit it afterwards. Although transistors and integrated circuit are small items there are

good reasons for leaving the soldering of these until the last step. All the components

before mounting are rubbed with sand paper so that oxide layer is removed from the

tips. Now they are mounted according to the component layout.

2.6(g) Soldering

This is the operation of joining the components with PCB after this operation the

circuit will be ready to use to avoid any damage or fault during this operation

following care must be taken. A longer duration contact between soldering iron bit

and components lead can exceed the temperature rating of the device and cause partial

or total damage of the device. Hence, before soldering we must read the maximum

soldering temperature and soldering time for device.

27

The wattage of soldering iron should be selected as maximum as permissible for that

soldering place. To protect the device by leakage current of iron its bit should be

earthed properly.

We should select soldering wire with proper ratio of Pb and Tn to provide the suitable

melting temperature. Proper amount of good quality flux must be applied on the

soldering point to avoid dry soldering.

28

CHAPTER 3

29

3.1 RESULT

The IR Musical Transmitter & Receiver we designed is working properly. By doing

the project we got a lot of experience with the electronics components & more over

we learn the PCB designing.

30

3.2 CONCLUSION

IR ray communication is very easy to understand and simple to implement. It finds

various applications in short distance field of communications. It is one of the best

ways of building wireless gadgets.

31

3.3 FUTURE ENHANCEMENT

In future there is scope of building virtual environment using the principles of IR ray

transmission and reception. Virtual gaming which also employs IR reception

techniques is still in research process which is soon going to rule the world of gaming.

32

3.4 APPLICATIONS

1. Wireless Music Systems.

2. Mobile gadgets.

3. CC cameras.

4. Remote controls.

5. Infrared lasers are used in communications.

33

3.5 [a] ADVANTAGES

1. Highly sensitive

2. Two stage Gain control

3. Very low noise

4. Low cost and reliable circuit

5. Can transmit up to 10 meter

3.5 [b] DISADVANTAGES

1. Not for long distance

2. Work in fixed range

3. Noise if object between transmitter and receiver

34

3.6 REFERENCES

1. www.google.com

2. www.wikipedia.org

3. www.pdfmachine.com

4. www.efymag.com

5. www.electronicsforu.com

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

Das könnte Ihnen auch gefallen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Unmanned Land VehicleDokument1 SeiteUnmanned Land VehicleSuraj DuhanNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- 6 Month Industrial Training Synopsis At: Submitted in Partial Fulfillment of Requirement For Award of Degree ofDokument9 Seiten6 Month Industrial Training Synopsis At: Submitted in Partial Fulfillment of Requirement For Award of Degree ofSuraj DuhanNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- 6 Month Industrial Training Synopsis At: Submitted in Partial Fulfillment of Requirement For Award of Degree ofDokument9 Seiten6 Month Industrial Training Synopsis At: Submitted in Partial Fulfillment of Requirement For Award of Degree ofSuraj DuhanNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Human Body AsDokument22 SeitenThe Human Body AsSuraj DuhanNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- 2020 Fully-Auto Nucleic Acid Extraction Instrument Price List V1.0Dokument1 Seite2020 Fully-Auto Nucleic Acid Extraction Instrument Price List V1.0Dwomoh SarpongNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Introduction To Reactor Technology - BWR: Nuclear Regulatory CommissionDokument10 SeitenIntroduction To Reactor Technology - BWR: Nuclear Regulatory CommissionJose DenizNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- BPC Report - The - Open - Banking - Revolution - NeedsDokument14 SeitenBPC Report - The - Open - Banking - Revolution - NeedshojunxiongNoch keine Bewertungen

- Unit III Management Information System Notes Unit 3Dokument13 SeitenUnit III Management Information System Notes Unit 3Farhad HossainNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Power System Analysis - Unit 2 - Week 1Dokument4 SeitenPower System Analysis - Unit 2 - Week 1Sayan ChatterjeeNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Technical Seminar DocumentationDokument36 SeitenTechnical Seminar DocumentationHarish KothuriNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Competitor BenchmarkingDokument12 SeitenCompetitor Benchmarkingapi-25263601Noch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- 库存管理Dokument18 Seiten库存管理kitysisterNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- KUWAITDokument3 SeitenKUWAITarvin4dNoch keine Bewertungen

- 01 Mototrbo OverviewDokument21 Seiten01 Mototrbo OverviewirwanNoch keine Bewertungen

- IS40/Triton System: Installation ManualDokument19 SeitenIS40/Triton System: Installation ManualJITHESH KNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Midea Air Cooled Chillers and Fan Coil Units 2016 CatalogueDokument37 SeitenMidea Air Cooled Chillers and Fan Coil Units 2016 CatalogueOlefile Mark MolokoNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Gridcom: E-Terra DXCDokument4 SeitenGridcom: E-Terra DXCsatyam_scribdNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Information AgeDokument4 SeitenInformation AgeJayveerose BorjaNoch keine Bewertungen

- The Unofficial Guide To Learning ONTAP 9 12OCT2017Dokument9 SeitenThe Unofficial Guide To Learning ONTAP 9 12OCT2017sbabups77Noch keine Bewertungen

- Microsoft Powerpoint Tips and TricksDokument8 SeitenMicrosoft Powerpoint Tips and TricksJayson Ismael C. SuazoNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- 516 and 520V - 8990324Dokument172 Seiten516 and 520V - 8990324Samuel Benavides100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1091)

- Research Report On Bharti Airtel Limited.Dokument15 SeitenResearch Report On Bharti Airtel Limited.bhalussNoch keine Bewertungen

- User Manual enDokument19 SeitenUser Manual enOlimpiu AlexeNoch keine Bewertungen

- Guia Aplicacion Relay DriverDokument9 SeitenGuia Aplicacion Relay DriverJulio javier Díaz GaravitoNoch keine Bewertungen

- Object Oriented Analysis and Design NotesDokument62 SeitenObject Oriented Analysis and Design Notesvraj patelNoch keine Bewertungen

- Acs BD Schematic Most CurrentDokument8 SeitenAcs BD Schematic Most CurrentgregfortkampNoch keine Bewertungen

- Risk Management TrainingDokument14 SeitenRisk Management TrainingbsjathaulNoch keine Bewertungen

- W516 E1 02+CP1L ELEM - CPU+OperManual PDFDokument854 SeitenW516 E1 02+CP1L ELEM - CPU+OperManual PDFAnonymous POne8dNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Beginners Guide To Building An Electric Go-Kart.Dokument9 SeitenA Beginners Guide To Building An Electric Go-Kart.Kabir Singh BhaiNoch keine Bewertungen

- Product Description WorksheetDokument3 SeitenProduct Description WorksheetNJ De GuzmanNoch keine Bewertungen

- PHG7-CEA7 PRO v.2.0 in 5Dokument107 SeitenPHG7-CEA7 PRO v.2.0 in 5Aleksei Podkopaev100% (15)

- Scanner For Drive Tests and I/Q Streaming: R&S®TSMW Universal Radio Network AnalyzerDokument24 SeitenScanner For Drive Tests and I/Q Streaming: R&S®TSMW Universal Radio Network AnalyzerkaminareNoch keine Bewertungen

- Digital Microwave Radio: 1. Introduction To DMRDokument14 SeitenDigital Microwave Radio: 1. Introduction To DMRgeraldstar22Noch keine Bewertungen

- PEAK Preparing For Your ConsultationDokument12 SeitenPEAK Preparing For Your ConsultationMitchTolontanNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)