Beruflich Dokumente

Kultur Dokumente

E560 Envi DB PDF

Hochgeladen von

Oleg Uskov0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

201 Ansichten8 SeitenThe telecontrol system RTU560 has been designed to meet the requirements for environmental conditions and performance of network control and process industries. The RTU560 itself and its products manufactured by ABB or others are type tested or evaluated that they fulfil the requirements specified and described. The requirements can be put in categories: V Environmental conditions (IEC 60870-2-2; Edition 1996) D temperature and humidity D Mechanical influences (iec 60870-2-1;

Originalbeschreibung:

Originaltitel

E560_ENVI_DB.pdf

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThe telecontrol system RTU560 has been designed to meet the requirements for environmental conditions and performance of network control and process industries. The RTU560 itself and its products manufactured by ABB or others are type tested or evaluated that they fulfil the requirements specified and described. The requirements can be put in categories: V Environmental conditions (IEC 60870-2-2; Edition 1996) D temperature and humidity D Mechanical influences (iec 60870-2-1;

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

201 Ansichten8 SeitenE560 Envi DB PDF

Hochgeladen von

Oleg UskovThe telecontrol system RTU560 has been designed to meet the requirements for environmental conditions and performance of network control and process industries. The RTU560 itself and its products manufactured by ABB or others are type tested or evaluated that they fulfil the requirements specified and described. The requirements can be put in categories: V Environmental conditions (IEC 60870-2-2; Edition 1996) D temperature and humidity D Mechanical influences (iec 60870-2-1;

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 8

RTU560

Remote Terminal Unit

ABB Utilities GmbH

Doc. -No.: 1KGT 150 400 V001 1 1

Data Sheet

Environmental Data

General

The RTU560 telecontrol equipment family has been

designed to meet the requirements for environmen-

tal conditions and performance of network control

and process industries.

The telecontrol system RTU560 itself and its prod-

ucts manufactured by ABB or others are type tested

or evaluated that they fulfil the requirements speci-

fied and described.

The RTU560 meets and achieves the requirements

listed in Table 1 to Table 6.

The requirements can be put in categories:

V Environmental conditions

(IEC 60870-2-2; Edition 1996)

D Temperature and humidity

D Mechanical influences

(IEC 60870-2-1; Edition 1987)

V Electrical Interfaces

(IEC 60870-2-1; Edition 1995)

D Power supply and isolation

D Electromagnetic compatibility

- Immunity tests

- Emission tests

V Performance requirements

(IEC 60870-4; Edition 1990)

D Reliability, Availability, Maintenance

D Time quality for process signals

Table 1: Power Supply and Isolation

Performance characteristic Required data / value Class Test specification

Mains voltage (Power supply):

AC voltage tolerances

1)

- 20 % ... + 15 % AC3 IEC 60870-2-1

Frequency tolerances

1)

5 % FC3 IEC 60870-2-1

DC voltage tolerances - 20 % ... + 15 % DC3 IEC 60870-2-1

Insulation withstand voltages (IEC 60664-1):

Binary signals 2.5 kV; 50 Hz; 1 minute VW3 IEC 60870-2-1

Analog input signals 2.5 kV; 50 Hz; 1 minute VW3 IEC 60870-2-1

Analog output signals 2.5 kV; 50 Hz; 1 minute VW3 IEC 60870-2-1

Power supply 2.5 kV; 50 Hz; 1 minute VW3 IEC 60870-2-1

Impulse voltage withstand test (IEC 60664-1)

Power supply 5 kV Impulse test voltage VW3 IEC 60870-2-1

Analog input signals 4 kV Impulse test voltage VW2 IEC 60870-2-1

Analog output signals 5 kV Impulse test voltage VW3 IEC 60870-2-1

Binary signals 5 kV Impulse test voltage VW3 IEC 60870-2-1

1)

Classes are valid for AC DC Mains Adapter 23VGXX.

ABB Utilities GmbH

RTU560 Data Sheet Environmental Data

Doc. -No.: 1KGT 150 400 V001 1

2

Table 2: Environmental Conditions

Performance characteristic Required data / value Class Test specification

Air temperature, humidity and atmospheric pressure:

Temperature range -10 ...+ 55

o

C C1 IEC 60870-2-2

Relative humidity 5 ... 95 % (non condensing) C1 IEC 60870-2-2

Maximum rate of change 0,5

o

C/min C1 IEC 60870-2-2

Atmospheric pressure 70 to 108 kPa C1 IEC 60870-2-2

Altitude (operation) up to 3000 m IEC 60870-2-2

Vibration and shock:

- Low frequency vibration:

Frequency range 2..150 Hz; sinus VL3 IEC 60870-2-1;

Amplitude 5 ... 9 Hz = 1.5 mm constant Edition 1987

9 ... 150 Hz = 0.5 g constant

Rate of change 1 octave / min

Test cycles 5 cycles in x, y, z direction

- - High frequency vibration:

Frequency range 10 ... 3000 Hz; sinus VH3 IEC 60870-2-1;

Amplitude 10 ... 60 Hz = 0.075 mm constant Edition 1987

60 ... 3000 Hz = 1 g constant

Rate of change 1 octave / min

Test cycles 5 cycles in x, y, z direction

- Shock (non- -operational):

Shock form half sine wave SH2 IEC 60870-2-1;

Acceleration 70 m/s

2

Edition 1987

Shock duration 50 ms

Test cycles 4 shocks each in x, y, z in positive

and negative direction

Shock form half sine wave SH4 IEC 60870-2-1;

Acceleration 250 m/s

2

Edition 1987

Shock duration 10 ms

Test cycles 4 shocks each in x and z in positive

and negative direction

The tests were made with a typical RTU560 telecon-

trol station in a standard cubicle (IP 55 / DIN40050).

The functionality was during and after tests perma-

nently verified with typical 60 % active input signals.

The shock values express the shock strains which

may occur during transportation. The results of the

vibration and shock tests are mainly influenced by

the used cubicle and mounting methods. The tests

are valid for the RTU560 standard cubicles and

mounting methods.

ABB Utilities GmbH

RTU560 Data Sheet Environmental Data

3

Doc. No.: 1KGT 150 400 V001 1

Table 3: RTU560 EMC Immunity Tests

IEC 60870-2-1 Requirements RTU560

Test results

RTU Unit / Port

Test Immunity test

(IEC 61000-4-1)

T C D A Standard Test Value Level Unit / Port

A.2.2 1,2/50 -- 8/20 s

surges

x x x IEC 61000--4--5 2 kV Differential

2 kV Common

3 C and D

A.2.3 Fast transient bursts x x x x IEC 61000--4--4 PS = 2 kV

I/O = 2 kV

3

4

T, C and D

A.2.5 Damped oscillatory

waves

x x x x IEC 61000--4--12 1 kV Differential

2,5 kV Common

3 T, C and D

A.2.7 Conducted RF distur-

bances

150 kHz to 80 MHz

IEC 61000--4--6 10 V 3 C and D

A.3.1 Electrostatic dis-

charges

x IEC 61000--4--2 8 / 15 kV 4 T, C and D

A.5.1 Radiated,

electromagnetic field

80--1000 MHz

x IEC 61000--4--3 10 V/m 3 T, C and D

RTU Unit / Port:

T = Telecommunication lines

C = Control and signal lines

D = DC Power supply

A = AC Power supply x = Requested by IEC 60870--2--1

AC power supply is not needed in the RTU 560 (only additional AC/DC Mains Adapter)

Table 4: RTU560 Emission Tests

IEC 60870--2--1 Requirements RTU560

Test results

RTU Unit / Port

Test Immunity test T C D A Standard Test Value Level

1 RF disturbance voltages

CISPR 22

x x EN 55022 0,15 to 30 MHz A and B

2 RF radiated fields

CISPR 22

x EN 55022 30 to 1000 MHz A

RTU Unit / Port:

T = Telecommunication lines

C = Control and signal lines

D = DC Power supply

A = AC Power supply

ABB Utilities GmbH

RTU560 Data Sheet Environmental Data

Doc. -No.: 1KGT 150 400 V001 1

4

The immunity and emission tests were made ac-

cording to the requested IEC standards. The list of

tests needed for the RTU560 is taken from table 9

and table 10 of the IEC 60870-2-1 standard.

RTU 560 fulfils the requested levels specified in

IEC 60870-2-1.

It has tobe regarded that these tests were made with

a RTU560 mounted in an ABBstandard cabinet. The

rules for cable routing and grounding have strictly to

be fulfilled to reach the requested levels. This has to

be taken into consideration for commissioning and

engineering.

Table 5: RTU560 Performance Classes (IEC 60870-4)

Performance characteristic Required data / value Class Test specification

Reliability MTBF 8760 h R3 IEC 60870-4

Availability A 99.95 % A3 IEC 60870-4

Maintainability MTTR 12 h M3 IEC 60870-4

Depends on maintenance strategy

Mean Repair Time MRT 1 h RT4 IEC 60870-4

Data Integrity classes IE 10

- -10

I2 IEC 60870-4

(protocols with telegram format

FT 1.2 IEC 60870-5-1)

Time separating capability 10 ms (between stations) SP2 IEC 60870-4

5 ms (within a station) SP3 IEC 60870-4

Time resolution 1 ms TR4 IEC 60870-4

Analog overall accuracy Error 0.5 % A4 IEC 60870-4

The reliability of a RTU560 telecontrol station is cal-

culated onthe basis of a typical RTU560 station. The

size is the experience of several hundred supplied

stations.

V 48 Analog measured values

V 100 Single indication messages

V 64 Double indication messages

V 8 Impulse counter

V 80 Double commands

V 1 Command supervision (1 out of n check)

V 3 Subracks with power supplies

V 1 FSK modem

The typical reliability for such a station is approx.

41600 h. The reliability is defined by a serial struc-

ture, that means a failure of one of the boards/units

is a system failure. The calculation is shown in Table

6, which also allows to calculate every other RTU560

station configuration.

The MRT of a RTU560 telecontrol stationwill betypi-

cally 1 h. The RTU560 concept has several supervi-

sion and diagnostic capabilities which assist the de-

bugging and maintenance activities when needed.

V Table Permanent online diagnostic of all I/O

boards

V LEDs on all boards indicating internal / ex-

ternal errors

V None or only few configuration settings on

board necessary

V PC- -based diagnostic tools

ABB Utilities GmbH

RTU560 Data Sheet Environmental Data

5

Doc. No.: 1KGT 150 400 V001 1

The main telecontrol transmission protocols are

based on format class FT1.2 ( IEC 60870-5.1). In

addition the transmission protocol allows for com-

mands the Select and execute command strategy

which essentially decreases the residual informa-

tion error probability in command direction.

The performance of time separating is given by the

time synchronization quality of the network control

system. The RTU560 has the capability to be syn-

chronized via communication line from the Network

Control Centre (NCC) central systemor by a DCF 77

or GPS. The scan cycle for binary input signals is

1 ms executed by the microcontroller on each input

board. The boards are synchronized by the commu-

nication unit of the RTU560, that allows a time reso-

lution within a station of 1 ms for binary signals.

The overall accuracy for analog signals is given by

the total error of the 23AE21 analog input board. For

the real overall error of the Analog Input board, see

the hardware data sheet.

Communication

Subrack

Ext. Subrack

Ext. Subrack

NCC

Pict. 1 Typical RTU560 Telecontrolstation

ABB Utilities GmbH

RTU560 Data Sheet Environmental Data

Doc. -No.: 1KGT 150 400 V001 1

6

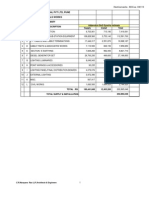

Table 6: RTU560 Reliability Values

23AA20 1126 888000 1 1126 888000 0 0 0 1 1126 888000

23AE21 383 2608000 1 383 2608000 6 2301 434667 10 3834 260800

23BA20 336 2980000 1 336 2980000 10 3356 298000 6 2013 496667

23BA22 689 1452000 1 689 1452000 1 689 1452000 2 1377 726000

23BA30 294 3402000 1 294 3402000 0 0 0 4 1176 850500

23BE21 686 1458000 1 686 1458000 15 10288 97200 50 34294 29160

23BE30 171 5846000 1 171 5846000 0 0 0 5 855 1169200

560BCU01 316 3162000 0 0 0 0 0 0 1 316 3162000

560BCU02 157 6356000 1 157 6356000 1 157 6356000 0 0 0

560BCU03 157 6356000 0 0 0 0 0 0 0 0 0

560CSR01 239 4190000 0 0 0 0 0 0 1 239 4190000

23ET23 254 3932000 0 0 0 0 0 0 0 0 0

23NG24 8772 114000 1 8772 114000 3 26316 38000 3 26316 38000

560PSU01 8772 114000 0 0 0 0 0 0 2 17544 57000

23OK22 306 3272000 0 0 0 0 0 0 0 0 0

560RTC01 425 2352000 0 0 0 0 0 0 0 0 0

23TP21 283 3534000 1 283 3534000 3 849 1178000 3 849 1178000

23WT21 217 4606000 0 0 0 0 0 0 0 0 0

23WT22 251 3984000 1 251 3984000 1 251 3984000 5 1255 796800

560SLI01 1312 762000 1 1312 762000 1 1312 762000 2 2625 381000

560SLI02 1131 884000 1 1131 884000 1 1131 884000 2 2462 442000

560ETH01 1344 744000 0 0 0 0 0 0 2 2688 372000

560ETH02 1028 973000 0 0 0 0 0 0 2 2056 48650

560ETH03 9524 1050000 0 0 0 0 0 0 2 19048 525000

13 15591 64145 42 46650 21436 103 120073 8328

MTBF-Jahre= 7,9 MTBF-Jahre= 2,5 MTBF-Jahre= 1,2

A = 99,983 % A = 99,945 % A = 99,884 %

RTU560 with Typical RTU560 Large station with

MTBF / Unit 1 Unit each station 4 satellite lines

Unit MTBF No. MTBF No. MTBF No. MTBF

[Fit] [h] [Fit] [h] [Fit] [h] [Fit] [h]

= Failure Rate (FR) [Fit] ( 1 Fit = 10-

9

failure/h )

basis = GB 40 =

Mechanical environment Ground Benign and aver-

age temperature of 40

o

C

MTBF = Mean Time Between Failure [h]

MTBF = 1 / FR [h]

A = Availability [%]

A=MTBF/ (MTBF+MTTR) [%] ( withMTTR=12 h)

Remark:

The above indicated reliability values regards the field failure rates are smaler than the forcasted rates and the

units will be inproved in future.

ABB Utilities GmbH

RTU560 Data Sheet Environmental Data

7

Doc. No.: 1KGT 150 400 V001 1

ABB Utilities GmbH

RTU560 Data Sheet Environmental Data

Doc. -No.: 1KGT 150 400 V001 1

8

ABB Utilities GmbH

68309 Mannheim (Germany)

Telephone +49 (0) 621 381-7592

Telefax +49 (0) 621 381-7622 06/2002 Subject to alteration

Das könnte Ihnen auch gefallen

- E560 23be50 DSDokument4 SeitenE560 23be50 DSSalvador FayssalNoch keine Bewertungen

- 4 30Dokument6 Seiten4 30Simon PelletierNoch keine Bewertungen

- CVMk2 enDokument4 SeitenCVMk2 enSphagneNoch keine Bewertungen

- Synchro-Check Relay Guide for SPAU 140 CDokument12 SeitenSynchro-Check Relay Guide for SPAU 140 COscar Felipe C.Noch keine Bewertungen

- RISH EM 3490 SS - Digital Multifunctional Energy Meters With RS 485 CommunicationDokument6 SeitenRISH EM 3490 SS - Digital Multifunctional Energy Meters With RS 485 CommunicationAarif PatelNoch keine Bewertungen

- Specificatii Tehnice Schneider RM4TR32Dokument7 SeitenSpecificatii Tehnice Schneider RM4TR32wwcbaNoch keine Bewertungen

- 8-35-1 RSE Control PDFDokument2 Seiten8-35-1 RSE Control PDF559466Noch keine Bewertungen

- Posicionador Con ValvulaDokument20 SeitenPosicionador Con ValvulaFabian De Jesus Aragon GomezNoch keine Bewertungen

- RM4TR32 Schneider Electric Datasheet 10978291Dokument7 SeitenRM4TR32 Schneider Electric Datasheet 10978291carlosvillamar1234Noch keine Bewertungen

- Ac500 XCDokument2 SeitenAc500 XCthlsatheeshNoch keine Bewertungen

- E560 Be23 DS R1 PDFDokument4 SeitenE560 Be23 DS R1 PDFOleg UskovNoch keine Bewertungen

- Panasonic LCD (2012) TX-l55wt50 (La34)Dokument67 SeitenPanasonic LCD (2012) TX-l55wt50 (La34)Jacob EvansNoch keine Bewertungen

- ELSPEC G4420 BLACKBOX Fixed Power Quality AnalyzerDokument0 SeitenELSPEC G4420 BLACKBOX Fixed Power Quality AnalyzerEUSUZANANoch keine Bewertungen

- TM221CE40R: Product Data SheetDokument12 SeitenTM221CE40R: Product Data SheetGiles HarperNoch keine Bewertungen

- User Manual Sepam 20-1Dokument78 SeitenUser Manual Sepam 20-1Ursula JohnsonNoch keine Bewertungen

- 7UT612 Manual Part26Dokument10 Seiten7UT612 Manual Part26gppNoch keine Bewertungen

- Data Sheet PM700 Series PDFDokument11 SeitenData Sheet PM700 Series PDFHung Cuong PhamNoch keine Bewertungen

- ATV212HD45N4: Product Data SheetDokument11 SeitenATV212HD45N4: Product Data SheetArren KhanNoch keine Bewertungen

- E560 MPR01 DSDokument6 SeitenE560 MPR01 DSSalvador FayssalNoch keine Bewertungen

- Re7rm11bu PDFDokument7 SeitenRe7rm11bu PDFToth VasileNoch keine Bewertungen

- Three-Phase Overcurrent Relay Spaj 131 C: Product GuideDokument12 SeitenThree-Phase Overcurrent Relay Spaj 131 C: Product GuideSharaf Ali ZyoudNoch keine Bewertungen

- 7SG117 Argus 7: Answers For EnergyDokument10 Seiten7SG117 Argus 7: Answers For EnergygovindarulNoch keine Bewertungen

- RISHMaster 3440 - Digital Multifunctional Instrument - With 50 Electrical Parameter Measurement & RS 485 InterfaceDokument6 SeitenRISHMaster 3440 - Digital Multifunctional Instrument - With 50 Electrical Parameter Measurement & RS 485 InterfaceAarif PatelNoch keine Bewertungen

- RISONIC Ultrasonic Transit Time Module E22 210 0067751 001Dokument6 SeitenRISONIC Ultrasonic Transit Time Module E22 210 0067751 001Billy ZununNoch keine Bewertungen

- BN TACH100 Standalone Digital Tachometer Datasheet 176063Dokument9 SeitenBN TACH100 Standalone Digital Tachometer Datasheet 176063Yasmine SalehNoch keine Bewertungen

- ABB - Residual Voltage RelayDokument12 SeitenABB - Residual Voltage Relaygadgil_vikrantNoch keine Bewertungen

- 1MRK509008-BEN en Transformer and Generator Time-Overexcitation Relay and Protection Assemblies RXLK 2H RALKDokument10 Seiten1MRK509008-BEN en Transformer and Generator Time-Overexcitation Relay and Protection Assemblies RXLK 2H RALKdaniel_sa2011Noch keine Bewertungen

- DB Sherlog CRX 052013 Eng PDFDokument4 SeitenDB Sherlog CRX 052013 Eng PDFRuly FanuelNoch keine Bewertungen

- 500envi Ds enDokument8 Seiten500envi Ds enUmutNoch keine Bewertungen

- Electrical: SpecificationsDokument4 SeitenElectrical: Specificationswagner_guimarães_10% (1)

- E560 Ae23 DSDokument4 SeitenE560 Ae23 DSIrfan ÇizmecioğluNoch keine Bewertungen

- Schneider Zelio Control RM4TR32-356472Dokument8 SeitenSchneider Zelio Control RM4TR32-356472TERASAT SANoch keine Bewertungen

- S7-200 Technical SpecificationsDokument78 SeitenS7-200 Technical SpecificationsThuy Nguyen Xuan0% (1)

- RISH Energy Measures AllDokument8 SeitenRISH Energy Measures AllDevin Carlos100% (1)

- RE11RCMUDokument5 SeitenRE11RCMUbogdy0073Noch keine Bewertungen

- Trip CKT Super Vision Relay - AlstomDokument6 SeitenTrip CKT Super Vision Relay - AlstomARUMUGAMNoch keine Bewertungen

- RISHMaster 3430 Versatile Digtial Multifunctional Instrument With 37 Electrical ParametersDokument5 SeitenRISHMaster 3430 Versatile Digtial Multifunctional Instrument With 37 Electrical ParametersAarif PatelNoch keine Bewertungen

- Datasheet 8V1010002-ACOPOS 1010Dokument20 SeitenDatasheet 8V1010002-ACOPOS 1010Umut ÖnalNoch keine Bewertungen

- LM566C Voltage Controlled Oscillator: General DescriptionDokument6 SeitenLM566C Voltage Controlled Oscillator: General DescriptionNimesh NadeeshaNoch keine Bewertungen

- Electrical Works - Package 2B Addendum BoQ Synefra EstimateDokument46 SeitenElectrical Works - Package 2B Addendum BoQ Synefra Estimatemsdixit2006100% (4)

- Air Circuit Breaker: Catalogue 2012Dokument20 SeitenAir Circuit Breaker: Catalogue 2012Addin Galih PrakosoNoch keine Bewertungen

- ION8650 DatasheetDokument11 SeitenION8650 DatasheetAlthaf Axel HiroshiNoch keine Bewertungen

- LZQJXC Dab e 3.10Dokument2 SeitenLZQJXC Dab e 3.10alageshvijayNoch keine Bewertungen

- RISH EM 3490 DS - Digital Multifunctional Dual Source Energy MeterDokument8 SeitenRISH EM 3490 DS - Digital Multifunctional Dual Source Energy MeterAarif Patel100% (1)

- MedicalDokument30 SeitenMedicalEuuE2008Noch keine Bewertungen

- GFG 8219a Doc 1Dokument20 SeitenGFG 8219a Doc 1alexjx65Noch keine Bewertungen

- 30 MHz 2 Channel 4 Trace OscilloscopeDokument18 Seiten30 MHz 2 Channel 4 Trace Oscilloscopekingarpit24Noch keine Bewertungen

- Fluke Isolator Tester 1555Dokument2 SeitenFluke Isolator Tester 1555adominguezramonNoch keine Bewertungen

- Pcits2000 2Dokument3 SeitenPcits2000 2batambintanNoch keine Bewertungen

- Ds Acopos1022 1045 1090Dokument19 SeitenDs Acopos1022 1045 1090Simon DrumsNoch keine Bewertungen

- HV Divider - PaperDokument5 SeitenHV Divider - Paperrasool waniNoch keine Bewertungen

- CSCDokument12 SeitenCSCsgshekar30Noch keine Bewertungen

- Cvmk2: Three-Phase Power Analyzer, Assembly On Panel or Din RailDokument2 SeitenCvmk2: Three-Phase Power Analyzer, Assembly On Panel or Din RailRodrigo PardoNoch keine Bewertungen

- 128122-Accelerometer & VelomitorTransducerOperationDokument22 Seiten128122-Accelerometer & VelomitorTransducerOperationNorman MoralesNoch keine Bewertungen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Noch keine Bewertungen

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlVon EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlBewertung: 5 von 5 Sternen5/5 (1)

- 110 Waveform Generator Projects for the Home ConstructorVon Everand110 Waveform Generator Projects for the Home ConstructorBewertung: 4 von 5 Sternen4/5 (1)

- Instrumentation and Test Gear Circuits ManualVon EverandInstrumentation and Test Gear Circuits ManualBewertung: 5 von 5 Sternen5/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Bewertung: 2.5 von 5 Sternen2.5/5 (3)

- Abclx Driver HelpDokument56 SeitenAbclx Driver HelpOleg UskovNoch keine Bewertungen

- KEMA ABB-SIEMENS Slides R0-2 PDFDokument19 SeitenKEMA ABB-SIEMENS Slides R0-2 PDFOleg UskovNoch keine Bewertungen

- E560 CSR01 DB PDFDokument2 SeitenE560 CSR01 DB PDFOleg UskovNoch keine Bewertungen

- RTU560 Communication Unit 560CMU80 Data SheetDokument4 SeitenRTU560 Communication Unit 560CMU80 Data SheetOleg UskovNoch keine Bewertungen

- E560 Be22 DB PDFDokument4 SeitenE560 Be22 DB PDFOleg UskovNoch keine Bewertungen

- E560 Be23 DS R1 PDFDokument4 SeitenE560 Be23 DS R1 PDFOleg UskovNoch keine Bewertungen

- E560 Be30 DB PDFDokument2 SeitenE560 Be30 DB PDFOleg UskovNoch keine Bewertungen

- Rsg2300 NC DatasheetDokument10 SeitenRsg2300 NC DatasheetOleg UskovNoch keine Bewertungen

- 51235482Dokument64 Seiten51235482Oleg UskovNoch keine Bewertungen

- Netiquette & Class RulesDokument1 SeiteNetiquette & Class RulesDanny LabordoNoch keine Bewertungen

- MHP 6 (Tugas 1 Diskusi Presentasi Laudon Dan Chafey)Dokument2 SeitenMHP 6 (Tugas 1 Diskusi Presentasi Laudon Dan Chafey)Alexander William Wijaya OeiNoch keine Bewertungen

- Stranger PaperDokument3 SeitenStranger Paperellie haNoch keine Bewertungen

- Ten Frames Subtraction Lesson PlanDokument4 SeitenTen Frames Subtraction Lesson Planapi-581503405Noch keine Bewertungen

- Comparison of fibre migration in different yarn bodiesDokument5 SeitenComparison of fibre migration in different yarn bodiesJerin JosephNoch keine Bewertungen

- COT - Lesson PlanDokument4 SeitenCOT - Lesson PlanLyzeanj SuycanoNoch keine Bewertungen

- Wesleyan University-Philippines Graduate SchoolDokument6 SeitenWesleyan University-Philippines Graduate SchoolRachel Joy RosaleNoch keine Bewertungen

- STT041 and STT041.1 PDFDokument59 SeitenSTT041 and STT041.1 PDFHayrah Lawi100% (2)

- 5-Engine CharacteristicsDokument22 Seiten5-Engine CharacteristicsAli ŞENERNoch keine Bewertungen

- Cummins KTA19-G4 Genset Spec SheetDokument6 SeitenCummins KTA19-G4 Genset Spec SheetRonald BoocNoch keine Bewertungen

- Ethics by Baruch Spinoza PDFDokument2 SeitenEthics by Baruch Spinoza PDFBrianNoch keine Bewertungen

- Principles of Business Grade 10 Weeks 1-5 - Term 3Dokument49 SeitenPrinciples of Business Grade 10 Weeks 1-5 - Term 3Daniel DowdingNoch keine Bewertungen

- Cat Em58 Em58s Emc58 eDokument3 SeitenCat Em58 Em58s Emc58 eAdolfo SantoyaNoch keine Bewertungen

- MGEC61 - LEC 01 & LEC 02 International Economics: Finance Summer 2021Dokument8 SeitenMGEC61 - LEC 01 & LEC 02 International Economics: Finance Summer 2021Yutong WangNoch keine Bewertungen

- Final Exam EM 210 (COSA) : Information Technology Education ReadinessDokument2 SeitenFinal Exam EM 210 (COSA) : Information Technology Education ReadinessDonna DoradoNoch keine Bewertungen

- Advanced View of Projects Raspberry Pi List - Raspberry PI ProjectsDokument186 SeitenAdvanced View of Projects Raspberry Pi List - Raspberry PI ProjectsBilal AfzalNoch keine Bewertungen

- Brochure DRYVIEW 5700 201504 PDFDokument4 SeitenBrochure DRYVIEW 5700 201504 PDFRolando Vargas PalacioNoch keine Bewertungen

- Ultra-Deepwater Semi-Submersible: General Description Storage CapacitiesDokument2 SeitenUltra-Deepwater Semi-Submersible: General Description Storage CapacitiesFrank CloseNoch keine Bewertungen

- 2019 Orientation PresentationDokument45 Seiten2019 Orientation Presentationaee2 gm2100% (1)

- Energy Landscapes: Applications To Clusters, Biomolecules and Glasses (Cambridge Molecular Science)Dokument6 SeitenEnergy Landscapes: Applications To Clusters, Biomolecules and Glasses (Cambridge Molecular Science)darlyNoch keine Bewertungen

- Forever Living ContractDokument2 SeitenForever Living ContractRishi SehgalNoch keine Bewertungen

- Mooring AnalysisDokument17 SeitenMooring AnalysisIfediora GodsonNoch keine Bewertungen

- Milgrams Experiment On Obedience To AuthorityDokument2 SeitenMilgrams Experiment On Obedience To Authorityapi-233605868Noch keine Bewertungen

- Quarter 1 - Module 1 Nature Goals and Perspectives in Anthropology Sociology and Political ScienceDokument24 SeitenQuarter 1 - Module 1 Nature Goals and Perspectives in Anthropology Sociology and Political Science완83% (12)

- Thesis External Examiner Report SampleDokument6 SeitenThesis External Examiner Report Samplesarahgriffinbatonrouge100% (2)

- (1X Erma First Fit 400) : Technical OfferDokument23 Seiten(1X Erma First Fit 400) : Technical OfferVikas Singh100% (1)

- WTAC Study-NotesDokument9 SeitenWTAC Study-NotesBillNoch keine Bewertungen

- 004.7 - VCE150 Session 7 Cabin LiftDokument24 Seiten004.7 - VCE150 Session 7 Cabin LiftMahmoud Elpop ElsalhNoch keine Bewertungen

- Dogtooth Film ReviewDokument6 SeitenDogtooth Film ReviewAstrid JohnsonNoch keine Bewertungen

- Annotated BibliographyDokument6 SeitenAnnotated Bibliographyapi-282104538Noch keine Bewertungen